Ho hlokomela mochini oa hau oa ho seha ka laser ho bohlokoa, ebang u se u ntse u o sebelisa kapa u nahana ho o fumana.

Hase feela taba ea ho boloka mochini o sebetsa; ke taba ea ho finyella likarolo tse hloekileng le litšoantšo tse bohale tseo u li lakatsang, ho netefatsa hore mochini oa hau o sebetsa joaloka toro letsatsi le leng le le leng.

Ho sa tsotelehe hore na o etsa meralo e qaqileng kapa o sebetsana le merero e meholo, tlhokomelo e nepahetseng ea sehahi sa hau sa laser ke sesebelisoa sa lekunutu sa ho fumana liphetho tse ntle ka ho fetisisa.

Sehloohong sena, re tla tsepamisa maikutlo mechineng ea ho seha le ho betla ka laser ea CO2, re arolelana malebela le mekhoa e meng e thusang ea tlhokomelo.

Tafole ea likateng

Ntho ea pele pele: mochini o hloekileng ke mochini o sebetsang hantle!

Nahana ka lense le liipone tsa sehahi sa hao sa laser e le mahlo a sona. Haeba li le litšila, maqeba a hao a ke ke a ba matle hakaalo. Lerōle, lithōle le masalla a atisa ho bokellana holim'a libaka tsena, e leng se ka senyang ho nepahala ha hao ha ho seha.

Ho boloka ntho e 'ngoe le e 'ngoe e sebetsa hantle, iketsetse mokhoa oa ho hloekisa lense le liipone khafetsa. Ntšepe, mochini oa hau o tla u leboha!

Mokhoa oa ho hloekisa lense le liipone tsa hau? Mehato e meraro ke e latelang:

Qhaqha:Tlosa diipone 'me u tabole lihlooho tsa laser ho tlosa lense ka bonolo. Beha ntho e 'ngoe le e 'ngoe holim'a lesela le bonolo, le se nang lesela.

Lokisa Lisebelisoa tsa Hao:Nka Q-tip 'me u e qoelise ka har'a tharollo ea ho hloekisa lense. Bakeng sa ho hloekisa khafetsa, metsi a hloekileng a sebetsa hantle, empa haeba u sebetsana le lerōle le thata, tharollo e thehiloeng ho joala ke khetho ea hau e ntle ka ho fetisisa.

E hlakole:Sebelisa Q-tip ka hloko ho hlwekisa bokaholimo ba lense le liipone. Keletso e potlakileng feela: boloka menoana ea hau hole le bokaholimo ba lense—ama mathōko feela!

Hape hopola, haeba liipone kapa lense ea hao li senyehile kapa li senyehile,ho molemo ho li nkela sebaka ka tse nchaMochini oa hau o tšoaneloa ke tse ntle ka ho fetisisa!

Thuto ea Video: Mokhoa oa ho Hloekisa le ho Kenya Lense ea Laser?

Ha ho tluoa tabeng ea tafole ea hau ea ho seha ka laser le sebaka sa mosebetsi, ho li boloka li hloekile kamora mosebetsi o mong le o mong ho bohlokoa.

Ho tlosa lintho tse setseng le lithōle ho etsa bonnete ba hore ha ho letho le sitisang mahlaseli a laser, ho lumella ho khaoloa ho hloekileng le ho nepahetseng nako le nako.

Le se ke la lebala ka sistimi ea moea! Etsa bonnete ba hore o hloekisa li-filter le li-duct tseo ho boloka moea o phalla le mosi o le sieo.

Keletso ea ho Sesa ka Sekepe se Boreleli:Ho hlahloba kamehla ho ka ’na ha ikutloa eka ke bothata, empa ho ba le melemo e mengata. Ho hlahloba mochine oa hao kapele ho ka thusa ho rarolla mathata a manyenyane pele a fetoha mathata a maholo nakong e tlang!

2. Tlhokomelo ea Sistimi ea ho Pholisa

Jwale, ha re buisaneng ka ho boloka dintho di pholile—ka ho toba!

Sesebelisoa sa ho futhumatsa metsi se bohlokoa bakeng sa ho boloka tube ea hau ea laser mochesong o nepahetseng.

Ho hlahloba boemo ba metsi le boleng ba metsi khafetsa ke habohlokoa.

Kamehla khetha metsi a hloekisitsoeng ho qoba ho bokellana ha diminerale tse kotsi, 'me u se ke ua lebala ho fetola metsi nako le nako ho thibela bolele hore bo se ke ba kena ka hare.

Ka kakaretso, ke mohopolo o motle ho fetola metsi ka har'a sehatsetsing likhoeli tse ling le tse ling tse 3 ho isa ho tse 6.

Leha ho le jwalo, nako ena e ka fetoha ho latela boleng ba metsi a hao le hore na o sebedisa mochini wa hao hangata hakae. Haeba metsi a qala ho shebahala a le ditshila kapa a le maru, tswela pele mme o a ntshe kapele!

Ho tšoenyeha ha Mariha? Eseng ka Malebela Ana!

Ha mocheso o theoha, kotsi ea hore sesebelisoa sa hau sa ho futhumatsa metsi se hoame le eona ea theoha.Ho eketsa antifreeze ho chiller ho ka e sireletsa nakong eo ea likhoeli tse batang.Etsa bonnete ba hore o sebelisa mofuta o nepahetseng oa antifreeze 'me u latele litaelo tsa moetsi bakeng sa karolelano e nepahetseng.

Haeba o batla ho tseba ka mokhoa oa ho eketsa antifreeze ka har'a sehatsetsing sa metsi ho sireletsa mochini oa hau hore o se ke oa hoamisoa. Sheba tataiso:Malebela a 3 a ho sireletsa mochini oa hau oa ho futhumatsa metsi le oa laser

'Me u se ke ua lebala: phallo e tsitsitseng ea metsi ea hlokahala. Etsa bonnete ba hore pompo e sebetsa hantle le hore ha ho na lithibelo. Phaephe ea laser e chesang haholo e ka lebisa litokisong tse turang, kahoo tlhokomelo e nyane mona e thusa haholo.

3. Tlhokomelo ea Tube ea Laser

Chubu ea hao ea laser ke pelo ea mochini oa hao oa ho seha oa laser.

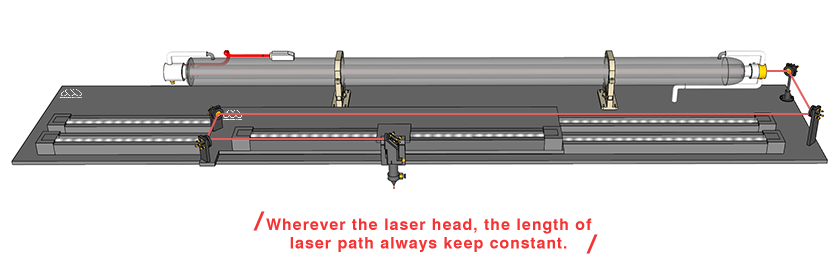

Ho boloka ho otloloha le ho sebetsa hantle ha eona ho bohlokoa bakeng sa ho netefatsa matla a ho seha le ho nepahala.

Itloaetse ho hlahloba ho tsitsa ha libolo khafetsa.

Haeba o bona matšoao afe kapa afe a ho se tsamaisane hantle—joalo ka ho se kgaohe ho sa tsitsang kapa matla a fokolang a mahlaseli—etsa bonnete ba hore o lokisa phaephe ho latela tataiso ea moetsi.

Ho boloka ntho e 'ngoe le e 'ngoe e le moleng ho tla boloka likotoana tsa hau li le bohale!

Keletso ea Botsebi: U se ke ua sutumelletsa mochini oa hau ho fihlela moo o fellang teng!

Ho sebedisa laser ka matla a maholo ka nako e telele ho ka kgutsufatsa nako ya bophelo ba tube ya hao. Ho ena le hoo, fetola di-setting tsa motlakase ho ya ka thepa eo o e sehang.

Chupu ea hau e tla e ananela, 'me u tla thabela mochini o nkang nako e telele!

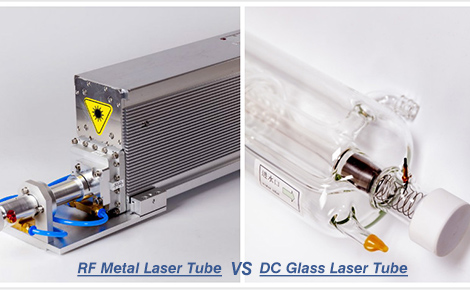

Ho na le mefuta e 'meli ea liphaephe tsa laser tsa CO2: liphaephe tsa laser tsa RF le liphaephe tsa laser tsa khalase.

Liphaephe tsa Laser tsa RF:

>> Diyuniti tse koetsoeng tse hlokang tlhokomelo e nyane.

>> Hangata e nka lihora tse pakeng tsa 20,000 le 50,000 tsa ts'ebetso.

>> Mefuta e meholo e kenyelletsa Coherent le Synrad.

Liphaephe tsa Laser tsa Khalase:

>> E sebelisoa hangata le ho tšoaroa e le thepa e ka jeoang.

>> Ka kakaretso e hloka ho nkeloa sebaka lilemo tse ling le tse ling tse peli.

>> Bophelo ba tšebeletso bo tloaelehileng ke lihora tse ka bang 3,000, empa lipeipi tse tlaase li ka nka lihora tse 1,000 ho isa ho tse 2,000 feela.

>> Mefuta e tšepahalang e kenyelletsa RECI, Yongli Laser, le SPT Laser.

Ha o kgetha mochini o sehang ka laser, buisana le ditsebi tsa bona ho utlwisisa mefuta ya diphaephe tsa laser tseo ba fanang ka tsona!

Haeba o sa tsebe hantle hore na o ka kgetha diphaephe tsa laser jwang bakeng sa mochini wa hao, hobaneng o sa tsebe?bua le setsebi sa rona sa laserho ba le puisano e tebileng?

Buisana le Sehlopha sa Rona

Laser ea MimoWork

(Moetsi oa Mochini oa Laser oa Setsebi)

4. Malebela a Tlhokomelo ea Mariha

Mariha a ka ba thata mochining oa hau, empa ka mehato e 'maloa e eketsehileng, u ka o boloka o sebetsa hantle.

Haeba seha sa hao sa laser se le sebakeng se sa futhumatsoang, nahana ka ho se fetisetsa tikolohong e futhumetseng.Mocheso o batang o ka ama tshebetso ya dikarolo tsa elektroniki mme wa lebisa ho kolobisong ka hare ho mochini.Mocheso o loketseng mochini oa laser ke ofe?Sheba leqephe ho fumana ho eketsehileng.

Qalo e Mofuthu:Pele o seha, dumella mochini wa hao ho futhumala. Sena se thibela ho koloba ha lense le diipone, e leng se ka sitisang lebone la laser.

Kamora hore mochini o futhumale, o hlahlobe bakeng sa matšoao afe kapa afe a ho koloba. Haeba o bona leha e le efe, e fe nako ea ho monya pele o e sebelisa. Re tšepe, ho qoba ho koloba ke senotlolo sa ho thibela ho senyeha ha motlakase le tšenyo e 'ngoe.

5. Ho tlotsa ha Likarolo tse Tsamaeang

Boloka lintho li tsamaea hantle ka ho tlotsa li-linear rails le li-bearing khafetsa. Likarolo tsena li bohlokoa bakeng sa ho lumella hlooho ea laser ho thella habonolo holim'a thepa.

Mona ke seo o lokelang ho se etsa:

1. Kenya setlolo se bobebe:Sebelisa oli e bobebe ea mochini kapa setlolo ho thibela mafome le ho netefatsa hore mokelikeli o tsamaea.

2. Hlakola ho Feta Tekanyo:Kamora ho tlotsa, etsa bonnete ba hore o hlakola setlolo sefe kapa sefe se feteletseng. Sena se thusa ho thibela lerōle le lithōle ho bokellana.

3. Tlhokomelo e tloaelehilenge tla boloka mochini oa hau o sebetsa hantle le ho lelefatsa nako ea ona ea bophelo!

Mabanta a ho Kganna, Le 'Ona!Mabanta a kgannang a phetha karolo ya bohlokwa ho netefatseng hore hlooho ya laser e tsamaya ka nepo. A hlahlobe kgafetsa bakeng sa matshwao a ho tsofala kapa ho tetebela, mme o a tiise kapa o a nkele sebaka ha ho hlokahala.

Likhokahano tsa motlakase mochining oa hau li tšoana le tsamaiso ea methapo ea kutlo.

1. Liteko tse Tloaelehileng

>> Hlahloba ho Tshabala: Sheba matšoao afe kapa afe a ho tsofala, ho bola, kapa likhokahano tse hlephileng.

>> Tiisa le ho Nkela Sebaka: Tiisa likhokahano life kapa life tse hlephileng 'me u nke lithapo tse senyehileng sebaka ho boloka ntho e 'ngoe le e 'ngoe e sebetsa hantle.

2. Lula U Ntlafalitsoe!

Se lebale ho boloka software le firmware ea mochini oa hau li le nakong. Lintlafatso tse tloaelehileng hangata li kenyelletsa:

>> Lintlafatso tsa Tshebetso: Lintlafatso tsa bokgoni.

>> Litokiso tsa Liphoso: Litharollo tsa mathata a teng.

>> Likarolo tse Ncha: Lisebelisoa tse ka nolofatsang mokhoa oa hau oa tšebetso.

Ho lula o le nakong ho netefatsa hore o tsamaisana hantle le thepa le meralo e mecha, e leng se etsang hore mochini oa hau o sebetse hantle le ho feta!

Sa ho qetela empa e se sa bohlokoa, ho lekanya kamehla ke senotlolo sa ho boloka ho nepahala ha ho seha.

1. Nako ea ho Lekanya Bocha

>> Lisebelisoa tse Ncha: Nako le nako ha o fetohela ho thepa e fapaneng.

>> Ho Fokotseha ha Boleng: Haeba o hlokomela ho fokotseha ha boleng ba ho seha, ke nako ea ho fetola liparamente tsa ho seha tsa mochini oa hau—joalo ka lebelo, matla le ho tsepamisa maikutlo.

2. Lokisa Hantle Bakeng sa Katleho

>> Fetola Lense ea Focus: Ho lokisa lense ea focus khafetsa ho netefatsa hore mahlaseli a laser a bohale 'me a tsepamisitse maikutlo hantle holim'a thepa.

>> Fumana Bolelele ba Focal: Fumana bolelele bo nepahetseng ba focal mme o lekanye sebaka ho tloha ho focal ho ya bokaholimo ba thepa. Sebaka se nepahetseng se bohlokwa bakeng sa boleng bo botle ba ho seha le ho betla.

Haeba o sa kholiseha ka ho tsepamisa maikutlo ka laser kapa mokhoa oa ho fumana bolelele bo nepahetseng ba focal, etsa bonnete ba hore o shebella video e ka tlase!

Thuto ea Video: Mokhoa oa ho Fumana Bolelele bo Nepahetseng ba Focal?

Bakeng sa mehato e qaqileng ea ts'ebetso, ka kopo sheba leqephe ho fumana ho eketsehileng:Tataiso ea Lense ea Laser ea CO2

Qetello: Mochini oa Hao o Tšoaneloa ke Tse Molemohali

Ka ho latela malebela ana a tlhokomelo, ha o lelefatse bophelo ba mochini oa hau oa ho seha oa laser oa CO2 feela—o boetse o netefatsa hore projeke e 'ngoe le e 'ngoe e fihlela maemo a holimo ka ho fetisisa a boleng.

Tlhokomelo e nepahetseng e fokotsa nako ea ho se sebetse, e fokotsa litšenyehelo tsa tokiso, 'me e eketsa tlhahiso. 'Me hopola, mariha a hloka tlhokomelo e khethehileng, joalo kaho eketsa antifreeze ho metsi a hao a pholilengle ho futhumatsa mochini oa hau pele o sebelisoa.

Na u se u loketse ho fumana tse ling hape?

Haeba o batla disehi le di-engraver tsa laser tse hloahloa, re na le seo o ka se shebang.

Mimowork e fana ka mefuta e fapaneng ea mechini e etselitsoeng lits'ebetso tse fapaneng:

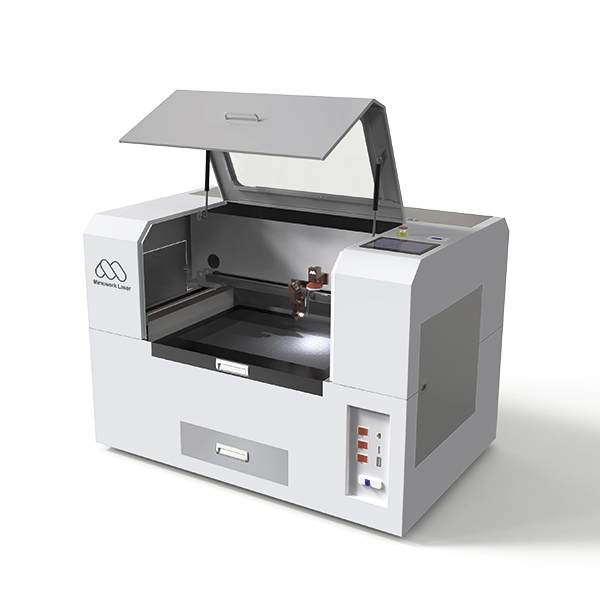

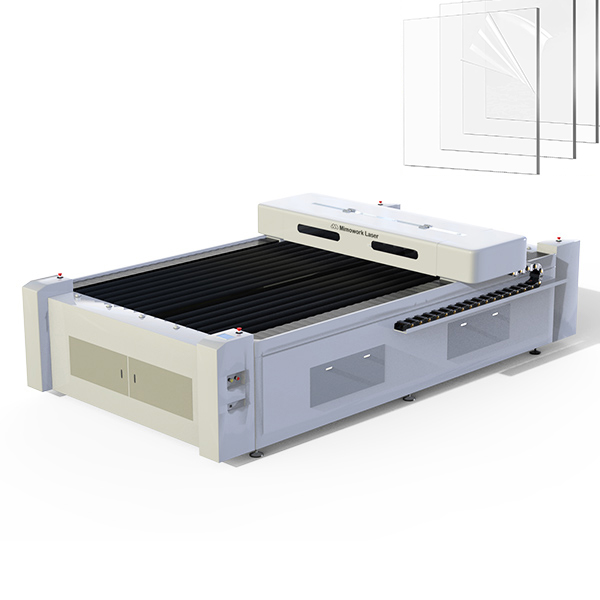

• Seha le Sefaha sa Laser bakeng sa Acrylic le Patsi:

E loketse meralo e rarahaneng ea ho betla le ho khaola ka nepo thepa ka bobeli.

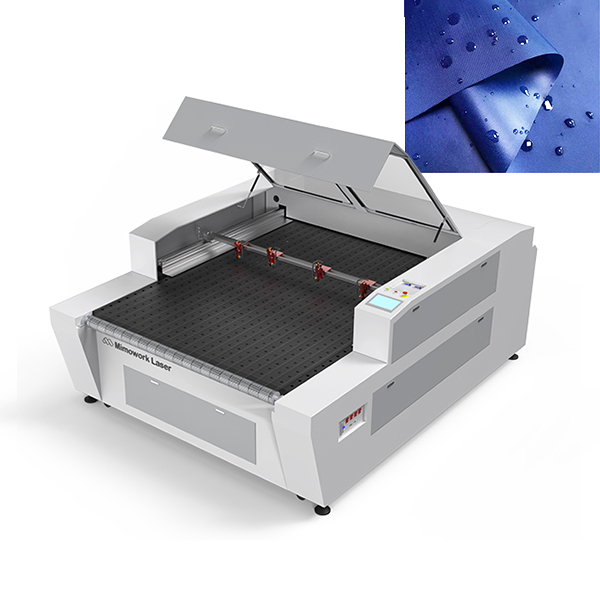

• Mochini oa ho Seha ka Laser bakeng sa Lesela le Letlalo:

Othomathike e phahameng, e loketse ba sebetsang ka masela, e netefatsa ho seha ho boreleli le ho hloekileng nako le nako.

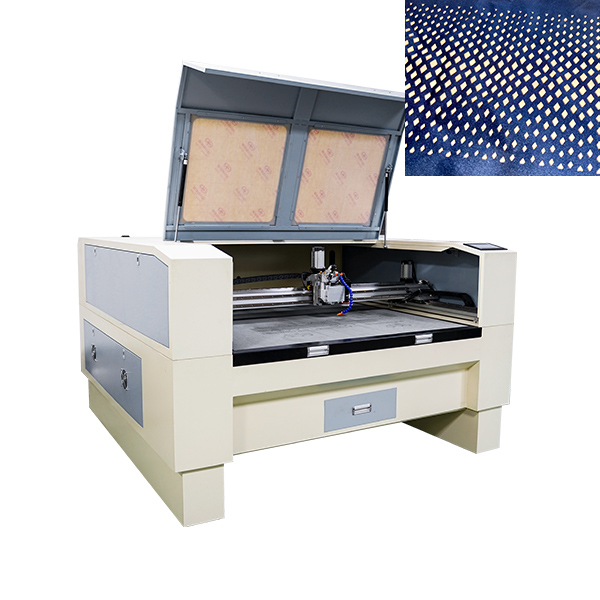

• Mochini oa ho Tšoaea oa Galvo Laser bakeng sa Pampiri, Denim, Letlalo:

E potlakile, e sebetsa hantle, 'me e phethahetse bakeng sa tlhahiso ea bongata bo phahameng ka lintlha tse ikhethileng tsa ho betla le matšoao.

Ithute Haholoanyane ka Mochini oa ho Seha oa Laser, Mochini oa ho Ngola oa Laser

Sheba Pokello ea Mechini ea Rona

Re Bo-mang?

Mimowork ke moetsi oa laser ea shebaneng le liphetho, ea thehiloeng Shanghai le Dongguan, Chaena. Ka boiphihlelo bo tebileng ba lilemo tse fetang 20 ba ts'ebetso, re ikhethile ho hlahiseng litsamaiso tsa laser le ho fana ka litharollo tse felletseng tsa ts'ebetso le tlhahiso ho likhoebo tse nyane le tse mahareng (SMEs) ho pholletsa le mefuta e mengata ea liindasteri.

Phihlelo ea rona e pharaletseng litharollong tsa laser bakeng sa ts'ebetso ea thepa ea tšepe le e seng ea tšepe e re entse molekane ea tšepahalang lefatšeng ka bophara, haholo-holo masimong a lipapatso, likoloi le lifofane, lisebelisoa tsa tšepe, lits'ebetso tsa sublimation ea dae, indasteri ea masela le masela.

Ho fapana le ba bang ba bangata, re laola karolo e 'ngoe le e 'ngoe ea ketane ea tlhahiso, re netefatsa hore lihlahisoa tsa rona li fana ka ts'ebetso e ntle ka linako tsohle. Hobaneng u ka khotsofalla ntho e fokolang ha u ka itšetleha ka tharollo e entsoeng ke litsebi tse utloisisang litlhoko tsa hau?

U ka 'na ua ba le thahasello

Mehopolo e meng ea Video >>

Mokhoa oa ho Boloka le ho Kenya Laser Tube?

Mokhoa oa ho Khetha Tafole ea ho Seha ea Laser?

Sehahi sa Laser se Sebetsa Joang?

Re moetsi oa mochini oa ho itšeha oa laser ea litsebi,

Ke Matšoenyeho a Hao, Rea U Tsotella!

Nako ea poso: Phato-30-2024