Ho seha ka ho sunanake mokhoa oa ho seha o sebelisoang liindastering tse fapaneng, tse kang khatiso le tlhahiso.

E kenyelletsa ho seha lera le ka holimo la thepa, hangata lera le lesesaane la bokaholimo, ntle le ho seha lera le ka morao.

Polelwana "kako" ho seheng ka ho suna e bolela taba ea hore lehare kapa sesebelisoa sa ho seha se kopana le thepa hanyane, joalo ka ha se e "suna".

Mokhoa ona o atisa ho sebelisoa bakeng sa ho etsa li-sticker, mabitso, li-decal, kapa lipaterone tse rarahaneng moo lera le ka holimo le hlokang ho sehoa ha le ntse le siea karolo e ka morao e sa senyeha.

Ho seha ka ho suna ke mokhoa o nepahetseng o netefatsang hore thepa e sehiloe hantle ntle le ho senya substrate e ka tlase.

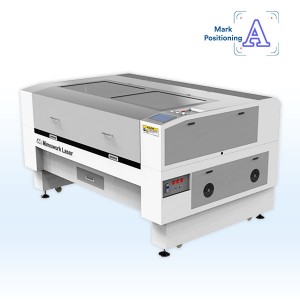

Ho seha ka laser ke mokhoa o nepahetseng le o feto-fetohang oa ho seha o sebelisang lehlaseli la laser ho seha lera le ka holimo la thepa ntle le ho seha thepa e ka morao.

Ke mofuta o fapaneng oa ho seha ka kiss, o kenyeletsang ho seha ntle le ho kenella ka har'a substrate.

Ho seheng ka laser, lehlasedi la laser le shebaneng le sebediswa ho etsa dikotwana tse nepahetseng haholo, mme hangata le sebediswa bakeng sa ho seha thepa e tshehetswang ka sekhomaretsi jwalo ka distikara, dilaebele le di-decal.

Matla a laser a laoloa ho netefatsa hore e phunyeletsa lera le ka holimo ha e ntse e siea karolo e ka morao e sa angoa.

Mokhoa ona o sebelisoa haholo liindastering moo meralo e rarahaneng kapa e etselitsoeng motho ka mong e hlokang ho sehoa ka nepo e phahameng.

Ho Seha ka Laser Kiss: Bohlokoa le Bohlokoa

1. Indasteri ea ho Paka:

Ho seha ka laser ho bohlokoa indastering ea liphutheloana bakeng sa ho etsa mabitso, li-stickers le li-decal tse ikhethileng.

Ts'ebetso e nepahetseng ea ho seha e netefatsa hore mabitso a khomarela liphutheloana hantle, e ntlafatsa tlhahiso ea lebitso le tlhaiso-leseling ea sehlahisoa.

2. Lisebelisoa tsa Bongaka:

Lisebelisoa tsa bongaka li hloka likarolo tse rarahaneng tse nang le mamello e nepahetseng.

Ho seha ka laser ho bohlokoa bakeng sa ho hlahisa likarolo tse kang masela a maqeba, likhomaretsi tsa bongaka le lisebelisoa tsa tlhahlobo.

3. Matšoao le Khatiso:

Indastering ea matšoao le khatiso, ho seha ka laser ho sebelisoa ho etsa meralo e rarahaneng bakeng sa matšoao, lifolakha le thepa ea papatso.

4. Lesela le Feshene:

Bakeng sa di-elektroniki, ho seha ka laser ho netefatsa tlhahiso e nepahetseng ya dintho tse kang ditheipi tse kgomaretsang, disireletsi tsa skrine le thepa e sireletsang mocheso.

5. Indasteri ea Elektroniki:

Lisebelisoa tsa bongaka li hloka likarolo tse rarahaneng tse nang le mamello e nepahetseng.

Ho seha ka laser ho bohlokoa bakeng sa ho hlahisa likarolo tse kang masela a maqeba, likhomaretsi tsa bongaka le lisebelisoa tsa tlhahlobo.

6. Ho Etsa Hore Lintho li Ikhethe le ho li Etsa Hore li Ikhethele:

Bokhoni ba ho iketsetsa le ho etsa hore lihlahisoa li be tsa botho ka ho li seha ka laser bo fana ka monyetla oa tlholisano liindastering tse fapaneng, bo lumellang likhoebo ho fihlela likhetho tsa motho ka mong le ho etsa meralo e ikhethang.

Ka Bohlokwa:

Ho seha ka laser ke mokhoa o feto-fetohang le o nepahetseng o nang le tšusumetso e kholo indastering e mengata.

Bokhoni ba eona ba ho sebetsana le mefuta e mengata ea thepa, ho tloha lihlahisoa tse tšehelitsoeng ka sekhomaretsi ho ea ho masela le likarolo tsa elektroniki, bo etsa hore e be ts'ebetso ea bohlokoa bakeng sa likhoebo tse shebaneng le ho fana ka litharollo tsa boleng bo holimo, tse ikhethileng le tse tšoarellang.

Melemo e Mengata: CO2 Laser Kiss Cutting

1. Mokhoa oa ho Seha ka nepo le ho se Kopane

Mekhoa ea laser ea CO2 e fana ka ho nepahala le ho nepahala ho hoholo, e nolofalletsang ho seha thepa e fapaneng ka mokhoa o rarahaneng le o qaqileng.

Sena se etsa hore li be ntle bakeng sa lits'ebetso tse hlokang mamello e nepahetseng le lintlha tse nyane.

Mokhoa oa ho seha o sa amaneng le ho kopana o felisa kotsi ea tšenyo ea thepa e bonolo kapa e bonolo.

Sena se bohlokoa haholo ha ho sehoa thepa e kang lifilimi tse khomaretsang, masela, kapa foam.

2. Litšila tse fokolang tsa thepa le ho feto-fetoha ha lintho

Lehlasedi la laser le shebaneng le fokotsa litšila tsa thepa hobane le seha ka ho nepahala ho feteletseng.

Sena se bohlokoa bakeng sa liindasteri tse batlang ho fokotsa litšenyehelo tsa tlhahiso le ho ntlafatsa tšebeliso ea thepa.

Li-laser tsa CO2 li ka seha mefuta e mengata ea thepa, ho tloha ho thepa ea sekhomaretsi ho ea ho masela, foam le polasetiki.

Ho feto-fetoha hona ho etsa hore li lokele lits'ebetso tse fapaneng ho pholletsa le liindasteri.

3. Lebelo le Phahameng le Meeli e Hloekileng

Li-laser tsa CO2 li ka sebetsa ka lebelo le phahameng, li tlatsetsa tlhahisong e eketsehileng.

Lebelo la tsona le molemo haholo bakeng sa tlhahiso e ngata.

Mocheso o hlahisoang ke laser nakong ea ho seha o koala mathōko a thepa, o thibela ho taboha kapa ho qhaqhoa.

Sena se molemo haholo ha o sebetsa ka masela le masela.

4. Litšenyehelo tse Fokolitsoeng tsa Lisebelisoa le ho Etsa Li-Prototype ka Potlako

Ho fapana le mekhoa ea setso ea ho seha ka die-cut kapa ea ho seha ka mechine, ho seha ka laser ea CO2 ho felisa tlhoko ea lisebelisoa tse turang kapa hlobo, ho boloka litšenyehelo tsa ho seta le linako tsa ho etella pele.

Ho seha ka laser ea CO2 ke khetho e ntle haholo bakeng sa ho etsa li-prototype ka potlako, e lumellang liphetoho tse potlakileng le liphetoho tsa moralo ntle le tlhoko ea liphetoho tsa lisebelisoa.

5. Ho iketsetsa le ho ntlafatsa bokgoni ba ho sebetsa

Ho tenyetseha ha li-laser tsa CO2 ho nolofalletsa ho fetoha habonolo pakeng tsa mekhoa e fapaneng ea ho seha, e leng se etsang hore ho be bonolo ho amohela meralo e ikhethileng le litlhoko tse fapaneng tsa tlhahiso.

Likarolo tsa othomathike tse kang li-feeder tse iketsang le litlhophiso tsa lihlooho tse ngata li ntlafatsa katleho ea lits'ebetso tsa tlhahiso ea bongata.

6. Tlhokomelo e Fokolitsoeng le ho Kgolofala

Litsamaiso tsa laser tsa CO2 li tsebahala ka ho tšoarella ha tsona le litlhoko tse tlase tsa tlhokomelo, e leng se fellang ka ho fokotseha ha nako ea ho sebetsa le litšenyehelo tsa ts'ebetso.

Li-cutter tsa laser tsa CO2 li loketse mesebetsi e menyenyane le lits'ebetsong tse kholo tsa indasteri, li fana ka bokhoni ba ho hola ho lekana le litlhoko tsa tlhahiso.

Lisebelisoa tse Loketseng ho Seha ka Laser Kiss

Litheipi le lifilimi tse khomarelang

Maqephe a khomaretsang a mahlakore a mabeli

Likhomaretsi tse utloang khatello (PSA)

Lifilimi le lifoile tse sireletsang

Masela a liaparo

Lisebelisoa tsa upholstery

Letlalo

Masela a maiketsetso

Kanavase

Lebokose

Letlapa la pampiri

Likarete tsa litumeliso

Lileibole tsa pampiri le li-sticker

Lisebelisoa tsa bubble

Rabara ea seponche

Neoprene

Rabara ea silicone

Thepa ea gasket (pampiri, rabara, kork)

Lisebelisoa tsa tiiso

Lisebelisoa tsa ho kenya mocheso

Maqephe a polasetiki a masesaane

Li-polyester

Polypropylene

Polyethylene

Filimi ea poliester

Mylar

Lifoile tse tšesaane tsa tšepe (aluminium, koporo)

Filimi ea Kapton

Maqephe a vinyl

Lifilimi tsa vinyl

Lisebelisoa tse koahetsoeng ka vinyl

Lisebelisoa tse kopantsoeng tse nang le likarolo tse khomaretsang

Li-laminate tse nang le mekhahlelo e mengata

Lisebelisoa tse nang le bokaholimo bo nang le masela, joalo ka pampiri e betliloeng kapa polasetiki e nang le masela

Lifilimi tse sireletsang tse sebelisoang liindastering tse fapaneng

Likarolo tse khomarelang tsa lisebelisoa tsa elektroniki

Lifilimi tse sireletsang bakeng sa li-skrini le lipontšo

Litheipi tsa bongaka

Liaparo tsa maqeba

Likarolo tse khomarelang bakeng sa lisebelisoa tsa bongaka

Li-label tse nang le khatello e phahameng

Li-label le li-decal tsa mekhabiso

Masela a sa lohiloeng

Vinyl ea Phetiso ea Mocheso ea Laser Engraving

> Ke tlhahisoleseding efe eo o lokelang ho e fana?

> Tlhahisoleseding ea rona ea ho ikopanya

Lipotso Tse Tloaelehileng Mabapi le ho Itšeha ka Laser Kiss

▶ Na ho seha ka laser ea CO2 ho loketse bakeng sa ho etsa mohlala le ho etsa tlhahiso e khutšoanyane?

▶ Na ho na le lintho tseo u lokelang ho nahana ka tsona mabapi le polokeho ha u sebelisa mechini ea ho seha ea laser ea CO2?

▶ Melemo ea ho sebelisa CO2 laser kiss cutting ho feta mekhoa e meng ea ho seha ke efe?

Laboratori ea Mochini oa Laser oa MimoWork

U se ke ua khotsofalla ntho leha e le efe e ka tlase ho e ikhethang

Tsetela ho tse Molemohali

Nako ea poso: Pulungoana-07-2023