Litšebeliso tse tloaelehileng tsa ho tjheseletsa ka laser

Mechini ea ho tjheseletsa ka laser e ka eketsa bokhoni ba tlhahiso le ho ntlafatsa boleng ba sehlahisoa ha ho tluoa tlhahisong ea likarolo tsa tšepe. E sebelisoa haholo maemong 'ohle a bophelo:

▶ Indasteri ea Lisebelisoa tsa Bohloeki: Ho tjheseletsa lisebelisoa tsa liphaephe, lisebelisoa tsa ho fokotsa mocheso, li-tee, li-valve le lishaoara

▶ Indasteri ea liaparo tsa mahlo: Ho tjheseletsa ka nepo tšepe e sa ruseng, motsoako oa titanium, le thepa e 'ngoe bakeng sa sehokelo sa liaparo tsa mahlo le foreimi e ka ntle

▶ Indasteri ea lisebelisoa: impeller, ketlele, ho tjheseletsa handle, likarolo tse rarahaneng tsa ho hatakela, le likarolo tsa ho lahla.

▶ Indasteri ea likoloi: pad ea silindara ea enjene, ho tjheseletsa seal ea hydraulic tappet, ho tjheseletsa polaka ea spark, ho tjheseletsa filthara, jj.

▶ Indasteri ea bongaka: ho tjheseletsa lisebelisoa tsa bongaka, litiiso tsa tšepe e sa ruseng, le likarolo tsa sebopeho sa lisebelisoa tsa bongaka.

▶ Indasteri ea lisebelisoa tsa elektroniki: Ho koala le ho roba ho tjheseletsa ha li-relay tsa boemo bo tiileng, ho tjheseletsa lihokelo le lihokelo, ho tjheseletsa likhetla tsa tšepe le likarolo tsa sebopeho tse kang lifono tsa mohala le libapali tsa MP3. Li-enclosure tsa enjene le lihokelo, ho tjheseletsa lihokelo tsa lihokelo tsa fiber optic.

▶ Lisebelisoa tsa lapeng, lisebelisoa tsa kichine le ntloana, li-handle tsa mamati a tšepe e sa ruseng, likarolo tsa elektroniki, li-sensor, lioache, mechini e nepahetseng, puisano, mesebetsi ea matsoho le liindasteri tse ling, li-tappets tsa hydraulic tsa likoloi, le liindasteri tse ling tse nang le lihlahisoa tse matla haholo.

Likarolo tsa ho tjheseletsa ka laser

1. Matla a mangata a ho tsepamisa maikutlo

2. Ha ho tšilafalo

3. Sebaka se senyenyane sa ho tjheseletsa

4. Mefuta e mengata ea thepa ea ho tjheseletsa

5. Tšebeliso e matla

6. Ho tjheseletsa ka bokgoni bo phahameng le ka lebelo le phahameng

Mochini oa ho tjheseletsa oa laser ke eng?

Mochini oa ho tjheseletsa oa laser o boetse o tsejoa e le mochini oa ho tjheseletsa oa laser o nang le maikutlo a fosahetseng, mochini oa ho tjheseletsa oa laser o batang, mochini oa ho tjheseletsa oa laser oa argon, lisebelisoa tsa ho tjheseletsa tsa laser, jj.

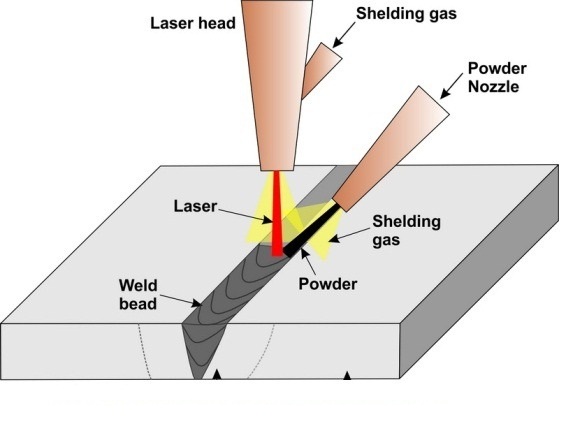

Ho tjheseletsa ka laser ho sebedisa di-pulse tsa laser tse nang le matla a mangata ho futhumatsa thepa sebakeng se senyenyane. Matla a mahlaseli a laser a hasana ka hara thepa ka ho tsamaisa mocheso, mme thepa e a qhibiliha ho etsa letamo le itseng le qhibilihisitsweng. Ke mokgwa o motjha wa ho tjheseletsa, o sebediswang haholoholo bakeng sa thepa e tshesane ya lebota le ho tjheseletsa dikarolo tse nepahetseng. E ka fihlella karolelano e phahameng ya aspect, bophara bo bonyenyane ba weld, ho tjheseletsa sebaka se senyenyane se amehileng ke mocheso, ho tjheseletsa ka morao, ho tjheseletsa ka seam, ho tjheseletsa ka tiiso, jj. Phetoho e nyane, lebelo le potlakileng la ho tjheseletsa, ho tjheseletsa ka boreledi le botle, ho se sebetse kapa ho sebetsa ka tsela e bonolo kamora ho tjheseletsa, ho tjheseletsa ka boleng bo hodimo, ho se na masoba, taolo e nepahetseng, ho tsepamisa maikutlo hanyane, ho nepahala ha maemo a hodimo, ho iketsahalla habonolo.

Ke lihlahisoa life tse loketseng ho sebelisoa mochini oa ho tjheseletsa oa laser

Lihlahisoa tse nang le litlhoko tsa ho tjheseletsa:

Lihlahisoa tse hlokang ho tjheseletsa li tjheseletsa ka lisebelisoa tsa ho tjheseletsa tsa laser, tse seng feela tse nang le bophara bo bonyenyane ba ho tjheseletsa empa hape li sa hloke ho tjheseletsa.

Lihlahisoa tse iketsang ka boiketsetso haholo:

Tabeng ena, thepa ea ho tjheseletsa ka laser e ka hlophisoa ka letsoho hore e tjheseletse 'me tsela e iketsahalla ka bo eona.

Lihlahisoa tse mochesong oa kamore kapa tlas'a maemo a khethehileng:

E ka emisa ho tjheseletsa mochesong wa kamore kapa tlasa maemo a ikgethang, mme disebediswa tsa ho tjheseletsa ka laser di bonolo ho di kenya. Mohlala, ha laser e feta tshimong ya motlakase, lehlasedi ha le sothehe. Lehlasedi le ka tjheseletsa sebakeng se se nang letho, moyeng, le dibakeng tse itseng tsa kgase, mme le ka feta ka khalaseng kapa thepa e bonaletsang lehlasedi ho emisa ho tjheseletsa.

Likarolo tse ling tse thata ho li fihlella li hloka lisebelisoa tsa ho tjheseletsa ka laser:

E ka tjheseletsa dikarolo tse thata ho fihlella, mme ya fihlella ho tjheseletsa hole ho sa amaneng, ka kutlwisiso e phahameng. Haholo-holo dilemong tsa morao tjena, tlasa boemo ba theknoloji ya laser le faeba ya YAG e se e hodile haholo, theknoloji ya ho tjheseletsa ya laser e se e kgothaleditswe le ho sebediswa haholo.

Ithute haholoanyane ka lits'ebetso tsa ho tjheseletsa ka laser le mefuta ea mechini

Nako ea poso: Phato-16-2022