Ho sebelisa mochini oa tjheseletsa oa Laser ke mokhoa o sebelisoang haholo oa tlhahiso o kenyelletsang ho sebelisa lebone la laser le nang le matla a phahameng ho kopanya thepa hammoho. Theknoloji ena e fumane ts'ebeliso ea eona liindastering tse fapaneng, ho tloha ho likoloi le lifofane ho ea ho tsa bongaka le tsa elektronike. Sehloohong sena, re tla hlahloba lits'ebetso tse fapaneng tsa ho sebelisa laser welder, re totobatsa melemo ea eona tšimong ka 'ngoe.

Lisebelisoa tsa Laser Welding?

Indasteri ea Likoloi

Indasteri ea likoloi ke e 'ngoe ea basebelisi ba kholo ka ho fetisisa ba theknoloji ea laser welding. Sena se bakoa ke ho nepahala le ho potlaka ha laser welding, e lumellang bahlahisi ho hlahisa likarolo tsa koloi tsa boleng bo holimo ka bongata. Sesebelisoa sa Laser se sebelisetsoa ho cheselletsa likarolo tsa 'mele, likarolo tsa chassis, lisebelisoa tsa ho ntša metsi le likarolo tse ling tsa bohlokoa ka koloing. Laser welding e fana ka boleng bo phahameng ba welding, bo tiisang matla le ho tšoarella ha sehlahisoa sa ho qetela.

Indasteri ea Sepakapaka

Indasteri ea sepakapaka e hloka welding ea boleng bo holimo ho hlahisa likarolo tse tšepahalang le tse bolokehileng. Laser welding e fumane ts'ebeliso ea eona indastering ea sepakapaka ka lebaka la bokhoni ba eona ba ho tjheseletsa li-alloys tse matla haholo le lisebelisoa tse bobebe. Ho nepahala le lebelo la ho cheselletsa ka laser ho etsa hore e be mokhoa o loketseng oa ho tjheseletsa thepa e tšesaane e sebelisoang ha ho etsoa likarolo tsa sefofane, tse kang sebaka sa taolo, mapheo le litanka tsa mafura.

Indasteri ea Bongaka

Indasteri ea bongaka e fumane likopo tse 'maloa tsa welding ea laser. Mochini oa welding oa Laser o sebelisetsoa ho etsa li-implants tsa bongaka, lisebelisoa le lisebelisoa tse hlokang ho nepahala le ho nepahala ho phahameng. Taolo e phahameng ea laser beam e lumella hore ho be le tjheseletso e nepahetseng ea likaroloana tse nyane le tse rarahaneng, e leng ntho ea bohlokoa tlhahisong ea lisebelisoa tsa bongaka.

Indasteri ea Elektronike

Indasteri ea lisebelisoa tsa elektroniki le eona e fumane lits'ebetso tse fapaneng tsa ho sebelisa mochini oa laser welder o tšoaroang ka letsoho. Laser welding e sebelisetsoa ho tjheseletsa likarolo tsa elektroniki joalo ka lisensara, likhokahano le libeteri. Boemo bo phahameng ba ho nepahala le taolo ea welding ea laser e etsa hore ho thehoe lisebelisoa tsa boleng bo phahameng tse netefatsang botšepehi le ts'ebetso ea sehlahisoa sa ho qetela.

Indasteri ea Mabenyane

Ponahalo ea mochini oa ho tjheseletsa laser o kentsoeng ka letsoho o fetotse indasteri ea mabenyane ka ho fana ka ts'ebetso e nepahetseng haholoanyane, e nepahetseng le e sebetsang hantle. Baetsi ba mabenyane ba sebelisa lisebelisoa tsa laser ho lokisa le ho kopanya likaroloana tse nyenyane, tse kang li-clasps, li-prong le li-setting. Ho tjheseletsa ho nepahetseng ho dumella moetsi ho etsa meralo e rarahaneng le ho ntlafatsa boleng ba sehlahiswa sa ho qetela.

Re khothalelitse Handheld Laser Welder:

Laser Welder - Tikoloho ea Mosebetsi

◾ Mofuta oa mocheso oa tikoloho ea ho sebetsa: 15 ~ 35 ℃

◾ Mofuta oa mongobo oa tikoloho ea mosebetsi: <70%Ha ho condensation

◾ Pholiso: chiller ea metsi ea hlokahala ka lebaka la ts'ebetso ea ho tlosa mocheso bakeng sa likarolo tsa laser tse tlosang mocheso, ho netefatsa hore laser welder e sebetsa hantle.

(Tšebeliso e felletseng le tataiso mabapi le chiller ea metsi, o ka sheba:Mehato ea ho thibela leqhoa bakeng sa CO2 Laser System)

Melemo ea ho Welding Laser?

• Ho nepahala ho phahameng le ho nepahala ha ho cheselletsa

• Mokhoa o potlakileng le o sebetsang hantle

• Li-welds tsa boleng bo holimo tse se nang ho sotha

• Bokhoni ba ho tjheseletsa lisebelisoa tse tšesaane le tse bonojoana

• Sebaka se fokolang se amehileng ke mocheso

• Ha ho hlokahale ho qeta ho qeta ho tjheseletsa ka morao

• Ts'ebetso ea welding e sa kopane

Go tlhoka mesola ea Laser Welding?

• Litsenyehelo tse phahameng tsa matsete a pele

• Litšenyehelo tsa tlhokomelo le nako ea ho phomola

• Lintlha tsa polokeho ka lebaka la matla a phahameng a lebone la laser

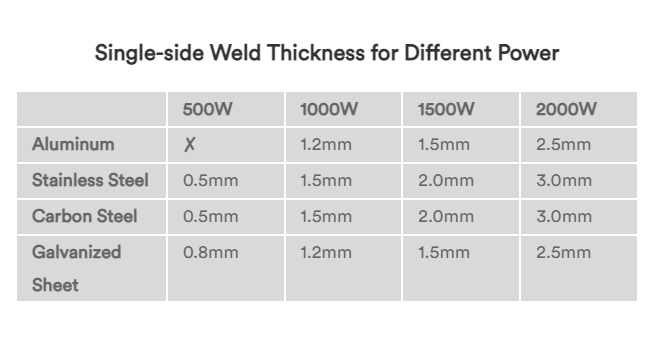

• Botenya bo fokolang ba thepa e ka chesetsoang

• Botebo bo fokolang ba ho kenella

Qetellong, laser welding e fumane ts'ebeliso ea eona liindastering tse fapaneng ka lebaka la ho nepahala, lebelo le ho nepahala ha eona. Melemo ea ho sebelisa mochini oa welding oa laser o kenyelletsa li-welds tsa boleng bo holimo, ts'ebetso e sebetsang hantle, le ho qeta ho fokolang ho hlokahalang. Leha ho le joalo, litšenyehelo tsa pele tsa matsete le tlhokomelo, hammoho le lintlha tsa polokeho, li lokela ho nkoa. Ka kakaretso, laser welding ke theknoloji ea bohlokoa bakeng sa ho theha lihlahisoa tsa boleng bo holimo le tse tšepahalang liindastering tse ngata.

U batla ho tseba haholoanyane ka Laser Welders?

Nako ea poso: Feb-23-2023