Ho hloekisa laser ke eng

Ka ho pepesetsoa matla a machane ho bokantle ba mesebetsi e silafetseng ea mosebetsi o silafetseng, ho hloekisa ha laser ho ka tlosa sepakapaka hang-hang ntle le ho senya tšebetso. Ke khetho e ntle bakeng sa moloko o mocha oa ho hloekisa mahlale a indasteri.

Theknoloji ea ho hloekisa le eona hape e bile theknoloji ea ho hloekisa indastering, ho kenyelletsa ho tlosoa ha lits'ila tsa rabara, ho tlosoa ha litšila tsa gere Filimi, le mokhoa oa ho hloekisa o phahameng oa likokoana-hloko.

Liphoso tse tloaelehileng tsa ho hloekisa

◾ ho tlosoa hoa pente

◾ Ho tlosa oli

Ho tlosoa hoa oxide

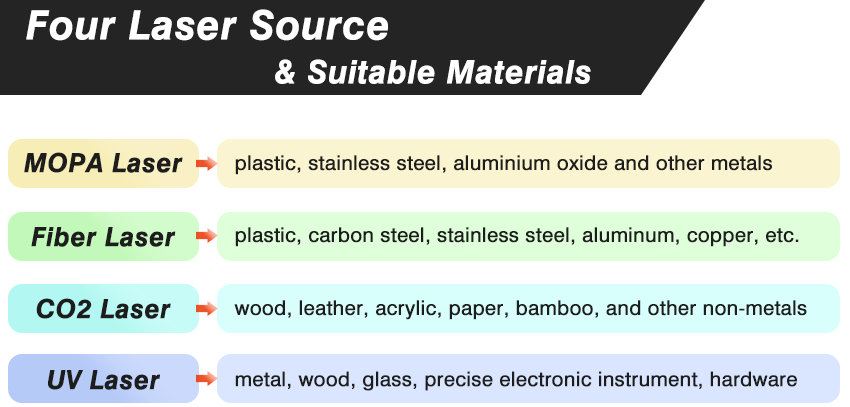

Bakeng sa theknoloji ea lar ea Laser e le laser ea ho kuta ea laser, le laser li boima ba Mohloli oa laser. Ho na le foromo bakeng sa litlhaloso tsa hau tse mabapi le mehloli ea laser le lisebelisoa tse lumellanang tse loketseng.

Mohloli o mane o mabapi le ho hloekisa laser

Ka lebaka la liphapang tsa litekanyetso tsa bohlokoa tse kang khanya ea laser, tekanyo ea thepa e fapaneng le litsie, ka hona u hloka ho khetha mochini o nepahetseng oa ho hloekisa oa Laser ho latela litlhokahalo tse silafetseng.

▶ Mopa Hulse Laser Creating

(e sebetsa mefuta eohle ea thepa)

Mopa Laser ke mofuta o sebelisoang haholo oa ho hloekisa laser. U emetse oscillator. Kaha tsamaiso ea lipalesa ea mora ea laser e ka eketsoa ka mokhoa o thata le mohloli oa pontšo ea litlokotsebe tsamaiso, li-tragwork tsa "gaveform, tse hulang metsi li ke ke tsa fetoloa. Ka hona, boholo ba phetoho ea paramente bo phahame mme bongata bo pharaletse. Bakeng sa maemo a fapaneng a kopo ea lisebelisoa tse fapaneng, ho ikamahanya le maemo.

▶ LITLHAKISO TSA FIBER LAER LAER

(Khetho e Molemohali Bakeng sa Ho Tloloa ho Tloloa ho Tloloa)

Ho hloekisa la Laser ho sebelisa semiconductor e tsoelang pele ho hlahisa khatello ea maikutlo lipakeng tsa meetlo e hlaselang, e fokolisang likhoele tse arohaneng. Ha Mohloli oa Laser o lelela lesela la matla a matla a matla a hloekileng

Ho hloekisa la laser ho kopanya laser ka laser 'me u hule mesebetsi ea laser ka nako e le' ngoe. Lebelo le phahameng, katleho e phahameng le boleng bo fetang ba ho hloekisa ka mokhoa o fapaneng, ba ka sebelisa merafong ea ho tlosa letheba.

Ka mohlala, ho hloekisoa ha lisebelisoa tse teteaneng, ho hlahisoa ha mehloli e le 'ngoe ea matla a makhulo a mafura a masela Ho hloekisoa ha laser le semicondctor laser ka potlako le ka mokhoa o atlehileng ka nepo le ka nepo Ho hloekisoa ha lisebelisoa tse bonoang haholo tse kang aluminiumhlla, laser e le 'ngoe e na le mathata a kang ho aka. Ho sebelisa ho hloekisoa ha lolse le semiconductor. Ka katleho, haholo-holo katleho ea ho tlosoa pente e eketsehe ka makhetlo a fetang a 2.

▶ CO2 LAER LAER

(Khetho e ntle bakeng sa ho hloekisa thepa e seng ea tšepe)

Carbon dioxide Laser ke laser ka khase e nang le khase e sebetsang, e nang le khase e thusang le naetrojene le linate tse nyane kapa xenon). Ho ipapisitsoe le WheveLongth e ikhethang, CO2 Laser ke khetho e ntle ka ho fetisisa ea ho hloekisa lisebelisoa tsa metllic tse kang ho tlosa sekhomaretsi, ho koahela le ho robala le enke. Mohlala, tšebeliso ea CO2 Laser ea ho tlosa pente ea pente sebakeng sa aluminium lehahang ha e senyehe botle ba filimi ea axios, ebile ha e senyehe.

▶ UV Laser hloekisa

(khetho e ntle ka ho fetisisa bakeng sa sesebelisoa sa elektroniki se ratoang

Li-Laseer tsa Ultraviolet tse sebelisitsoeng ho Laser Micbrachiching haholo li kenyelletsa li-lasers tsa mohlala le libaesekopo tsohle tse tiileng. Ultraviolet Laser Wavelebang Ka tsela ena, thepa e koaetsoeng e hlotsoe bokaholimo ka mokhoa oa khase kapa likaroloana, 'me ts'ebetso ea ho hloekisa e tla ama sebaka se tlase feela se tla ama sebaka se senyenyane feela se tla ama sebaka se senyenyane feela se tla ama sebaka se senyenyane. Ka lebaka leo, ho hloekisa UV Laser ho na le menyetla e ikhethang, e kang ho hloekisa Si, Gan le likritara tse ling, li ka sebetsa le polymerbote. ntlafatsa boleng ba tlhahiso.

UV Laser e nkoa e le leano la ho hloekisa ka ho fetisisa tšimong, bokaholimo ba eona bo botle "bo se nang sebopeho sa 'mele ha bo fetohe E sebelisoa haholo ka puisano, litso tsa mahlomoleng, sesole, lipatlisiso tsa botlokotsebe, tsa bongaka le masiba a bongaka le masimong. Mohlala, nako ea 5g e thehile tlhokahalo ea 'maraka ea ts'ebetso ea FPC. Ts'ebeliso ea mochini oa UV oaser o etsa hore ho khonehe ho nkama lifate tse batang tsa FPC le lisebelisoa tse ling.

Nako: Oct-10-2022