LAER WADing? Ho hlalosoa WAS Weld! Sohle seo u hlokang ho se tseba ka laser sahloa, ho kenyelletsa molao-motheo oa Bokreste le liparathara tsa mantlha!

Bareki ba bangata ha ba utloisise melao-motheo ea mantlha ea mochini oa laser oa lereng, leha ho le molemo oa Mimowork laser ho u thusa ho utloisisa laser.

LAER WADing?

WAser Welding ke mofuta oa ho qhibiliha, o sebelisa Mohloli oa Laser, o sebelisa Osctrinant ea Laser, ebe o sebetsana le borashe ba radiation, ha motho ea hlasimollang 'Me karolo ea mosebetsi e kopana, matla a kenella ke karolo ea mosebetsi, ha thempereichara e fihla sehlohlolong sa boitsebiso bo ka felisoa.

Ho latela mochini o ka sehloohong oa letsopa la Welding oa letamo la Welding Leqhubu la mocheso le hlahisitsoeng ke mocheso ka mocheso o khelohileng ka sengoathoana sa mocheso se ka qhibiliha, ho se koaetsoe ka lebaka la likarolo tse lebelo le boima ba methapo ea kutlo. Fune Fusion e tebileng ea likhomo tsa mafura ebile e etsa plasma e ngata. Ka lebaka la mocheso o phahameng, ho tla ba le masoba ka pele ho lebokose le chesang. Ho boloka lintho tse tebileng tsa weldration ke mokhoa o sebelisoang haholo oa laser o sebelisoang ka ho fetisisa, o ka jara mosebetsi ka botlalo, 'me matla a kenyellelitsoeng a etsa hore lebelo le boima le le leng.

Ts'ebetso ea Ts'ebetso ho Laser Welding

Ho na le litekanyetso tse ngata tsa tšebetso tse amang boleng ba lehola tsa laser, joalo ka botebo ba matla, li-pulse tsa laser suyfor, li fokotseha ha peō e thusang e thusang.

Bohahlauli ba Laser

Bokhopo ba matla ke e 'ngoe ea liparame tsa bohlokoahali tsa ts'ebetso ea laser. Bongata bo phahameng ba matla a phahamisitsoeng, bokaholimo bo ka holim'a ho belisa ho bokella ntlha ka har'a microsecond, e fella ka vaporization e kholo. Ka hona, tekanyetso e phahameng ea matla a phahameng e na le molemo bakeng sa lits'ebetso tsa ho tlosoa lintho tse bonahalang tse kang ho cheka, ho itšeha le ho ngola. Bakeng sa botekathong ba matla a tlase, ho nka li-millisecond tse 'maloa bakeng sa mocheso o pharaletseng,' me tlase o fihla sehlohlolong se qhibilihang. Ka hona, ka mokhoa oa ho palama o futhumetseng oa mocheso, matla a matla a matla ke a 104-106w / cm2.

Laser House Waveforman

Leqhubu la laser Hyse ha e khetholle feela ho tlosoa lintho tse bonahalang ho lintho tse qhibilihang, empa hape ho sunamente ea bohlokoa ho khetholla molumo le litšenyehelo tsa lisebelisoa tsa ts'ebetso. Ha leqhubu le phahameng la laser le thunthuni pontsho e matla le phetisetso e potlakileng ea mocheso. Ho nahanisisa ka mehele e mengata e nang le nako nakong ea halle ea laser. Ha mocheso o metlatsi oa thepa o kotsing ea ho utloisisa kapele, ponahatello e boetse e le teng naheng e makatsang, e tiisa katleho e kholo ka boleng bo itseng.

Bophara ba laser

Bophara ba hulse ke paramente ea bohlokoa ea la laser. Bophara bo hulang bo ne bo khethoa ke botebo ba ho kenella le mocheso o amehang sebaka. Ha bophara ba nako e telele ke hore na karolo e kholo ea mocheso e ne e le eona, 'me botebo ba ho ithuta ho eketseha ka bophara ba hulseth. Leha ho le joalo, keketseho ea bophara ba hutan e tla fokotsa matla a tebileng, ka hona keketseho ea mocheso o pharaletseng, o tšoaneloang haholo bakeng sa ho phunya liqhomane tse tšesaane le tse boima. Leha ho le joalo, matla a tlase a tlhoro a fella ka tlhahiso e feteletseng, 'me karolo e' ngoe le e 'ngoe e na le bophara e lekaneng e hohelang botebo ba ho kenella ha metsi.

Palo ea Defocus

Hangata re sotlehileng hangata se hloka tekanyo e itseng ea setsi sa sebaka lebopong la laser e phahame haholo, e leng ho fetolela ho bapala ka masoba matlong. Ho tsamaisoa ha botebo ba matla a matla ho tšoana hantle ka sefofaneng se seng le se seng hole le laser.

Ho na le mekhoa e 'meli ea Doucus:

Litšila tse ntle le tse fosahetseng. Haeba sefofane se boholo se ka holim'a mosebetsi oa mosebetsi, ke Doucus e ntle; Ho seng joalo, ke litšila tse mpe. Ho ea ka khopolo ea li-geometric: Ha sebaka se pakeng tsa lifofane tse ntle le tse mpe tsa ho tlosa litšila le sefofaneng sa matla se ka bang sefora se fumanehang habonolo se fapane. Tabeng ea Doucus e fosahetseng, ho kenella ho hoholo ho ka fumanoa, tse amanang le mokhoa oa ho fafatsa letamo.

Lebelo la welding

Lebelo la Welding le nka qeto ea boleng ba 'mele oa bophahamo, botebo ba ho kenella, mocheso o amehang sebaka sa tikoloho joalo-joalo. Lebelo la Welding le tla ama mocheso oa mocheso ka nako ea unit. Haeba lebelo la ho palama le na le butle haholo, ho kenya maikutlo a mocheso haholo, ho felletseng ka lebaka la ho buloa ha mosebetsi o ntse o tuka. Haeba lebelo le wel le le lebelo le le boima haholo, ho fana ka mocheso ho honyenyane ho le seng hanyane, ho fela ho ea boima ba ho palama le ho sa fetohe le ho se hlakisoe. Ho fokotsa lebelo la ho fokola hangata ho sebelisoa ho ntlafatsa ho kenella.

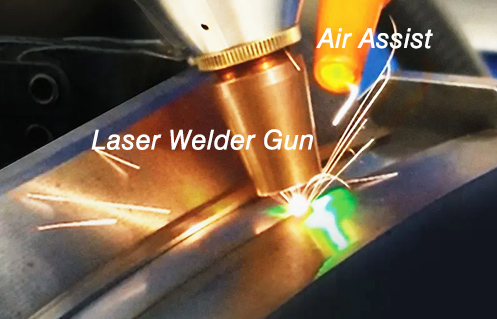

Phetoho e thusang ea Ts'ireletso

Ho ba le matla a sirelehang a tšireletso ke mokhoa oa bohlokoa ka lebelo le phahameng la Laser. Ka lehlakoreng le leng, ho thibela lisebelisoa tsa tšepe ho tsoa ho kokobela le ho silafatsa seipone se tsepamisitsoeng. Ka lehlakoreng le leng, ke ho thibela plasma ho hlahisoa tšebetsong ea ho bonya ho tloha ho tsepamisa maikutlo ho feta le ho thibela laser ho fihla holimo ho fihla holimo ho fihla holimo ho hlobola holimo. Mohato oa Laser Welding, Helium, Argon, Netrojene le likhase tse ling li sebelisoa ho sireletsa lebokose le nang le moea ho tsoa ho boenjiniere bo tsoang boenjiniering. Lintho tse kang mofuta oa khase e sirelelitsoeng, boholo ba phallo ea moea le mekhoa e fapaneng le tsona li tla ba le tšusumetso e itseng boleng ba ho bopa.

Tsela eo re e khothalelitsoeng ea letsoho la WEDER:

Laser Welder - Tikoloho ea ho sebetsa

◾ Lipalo tsa mocheso tsa tikoloho e sebetsang: 15 ~ 35 ℃

◾ Humidity ea tikoloho ea ho sebetsa: <70% ha e na thuso

Ho futhumatsa: Li-chiller ea metsi lia hlokahala ka lebaka la ts'ebetso ea mocheso o tlosa likarolo tsa mocheso oa laser, ho netefatsa la laser a mathela hantle.

(Ts'ebetso e qaqileng le Tataiso mabapi le metsi a metsi, o ka hlahloba:Mehato ea ho paka)

O batla ho tseba ho eketsehileng ka lehola le lehola la laser?

Nako ea poso: Dec-22- 22022