Ho tjheseletsa ka laserTheknoloji e fetotse indasteri ea tlhahiso le tlhahiso, e fana ka ho nepahala ho sa bapisoeng, lebelo le ho tenyetseha. Mokhoa ona o tsoetseng pele oa ho tjheseletsa o sebelisa mahlaseli a laser a kopaneng ho qhibilihisa le ho kopanya thepa, e leng se etsang hore e lokele mefuta e mengata ea lits'ebetso.

E 'ngoe ea melemo ea mantlha ea ho tjheseletsa ka laser ke bokhoni ba eona ba ho sebetsa ka thepa e fapaneng, e leng se nolofalletsang bahlahisi ho theha manonyeletso a matla le a tšoarellang lihlahisoa tse fapaneng.

Sehloohong sena, re tla hlahloba thepa ea bohlokoa e ka kopanngoang ka ho sebelisa mechine ea ho tjheseletsa ea laser, re totobatsa litšobotsi tsa eona tse ikhethang le lits'ebetso.

1. Tšepe tsa ho Wellisa tsa Mochini oa Laser

a. Tšepe e sa Haleng

Tšepe e sa ruseng ke e 'ngoe ea litšepe tse bōpehileng joaloka tse bōpehileng joaloka tse bōpehileng joaloka tse bōpehileng joaloka tse bōpehileng joaloka tšepe ea laser. Tšepe e sa ruseng e tsebahala ka ho hanyetsa le matla a eona a ho rusang, 'me e sebelisoa haholo liindastering tse kang ho lokisa lijo, meriana, tlhahiso ea likoloi le kaho.

Ho tjheseletsa ka laser ho fana ka di-weld tsa boleng bo hodimo, tse hlwekileng tse nang le dibaka tse fokolang tse angwang ke mocheso (HAZ), ho netefatsa hore thepa ya thepa e dula e sa senyeha. Bokgoni ba ho laola matla a laser ka nepoe dumella ho tjheseletsa dikarolo tse tshesane le tse teteaneng ka ho tshwana, e leng se etsang hore e lokele meralo e rarahaneng le dikopano tse rarahaneng.

b. Tšepe ea Khabone

Tšepe ea khabone ke tšepe e 'ngoe e ikamahanyang hantle le ho tjheseletsa ka laser. Thepa ena e atile haholo kahong le tlhahisong, moo e sebelisetsoang likarolo tsa meaho le mechini.Ho tjheseletsa ka laser ho eketsa matla le ho tšoarella ha di-weld tsa tshepe ya khabone ha ka nako e ts'oanang ho boloka qetello ya boleng bo hodimo.

Ts'ebetso ena e sebetsa hantle, e fokotsa kotsi ea ho sotha le ho sotha hoo hangata ho amanang le mekhoa ea setso ea ho tjheseletsa. Ho feta moo, lebelo la ho tjheseletsa ka laser le lumella bahlahisi ho eketsa tlhahiso ntle le ho beha boleng kotsing.

c. Aluminium le Litšepe tse kopantsoeng tsa Aluminium

Aluminium e nkoa e le ea bohlokoa ka lebaka la thepa ea eona e bobebe le e sa senyeheng ke mafome, e leng se etsang hore e be thepa e ratoang haholo indastering ea lifofane le ea likoloi. Leha ho le joalo, aluminium ea ho tjheseletsa e ka ba phephetso ka lebaka la ho khanna ha eona mocheso o phahameng le ho angoa habonolo ke mathata a amanang le mocheso.

Ho tjheseletsa ka laser ho rarolla mathata ana ka ho fana ka mohlodi o shebaneng le mocheso o fokotsang ho kenya mocheso le ho fokotsa ho sotha.Mokhoa ona o dumella ho kopanngwa ka nepo ha dikarolo tsa aluminium, ho nolofalletsa tlhahiso ya meaho e bobebe e nang le thepa e ntle ya mechini.

d. Litšepe tse kopantsoeng tsa Koporo le Koporo

Koporo e tsebahala ka ho tsamaisa motlakase hantle, e leng se etsang hore e be ea bohlokoa lits'ebetsong tsa motlakase tse kang lithapo tsa terata le liboto tsa potoloho.

Leha ho tjheseletsa koporo ho ka ba thata ka lebaka la ho tsamaisa mocheso o phahameng le bokaholimo bo bonahatsang, mechini ea ho tjheseletsa ea laser e nang le litlhophiso tse tsoetseng pele e ka fihlela liphetho tse atlehileng.

Theknoloji ena e nolofalletsa ho kopanya koporo le metsoako ea eona ka katleho, e netefatsa likhokahano tse matla le tse tšepahalang tse bohlokoa lits'ebetsong tsa motlakase.

e. Li-Alloys tsa Nickel le Nickel

Nickel le metsoako ea eona e kopantsoeng hangata li sebelisoa libakeng tse nang le mocheso o phahameng le tse senyang, joalo ka liindastering tsa lik'hemik'hale le oli.

Ho tjheseletsa ka laser ho fana ka tharollo e sebetsang hantle le e sebetsang bakeng sa ho kopanya thepa ena, ho netefatsa hore li-weld li boloka botsitso ba tsona tlas'a maemo a feteletseng.

Ho nepahala ha ho tjheseletsa ka laser ho molemo haholo-holo lits'ebetsong moo ts'ebetso ea lenonyello le tjheseletsoeng e leng ea bohlokoa.

2. Ho Sebelisa Plastiki ea ho Welding ea Laser

Ntle le litšepe,Ho tjheseletsa ka laser ho boetse ho sebetsa bakeng sa mefuta e fapaneng ea polasetiki, e atolosa ho sebetsa ha yona diindastering tse fapaneng.

Mochini oa ho Tjhesetsa oa Laser oa Tšepe Aluminium

a. Polypropylene (PP)

Polypropylene e sebelisoa haholo ho paka, likarolo tsa likoloi le thepa ea bareki. Ho tjheseletsa ka laser ho lumella manonyeletso a matla, a se nang sekoli a ka ntlafatsang ts'ebetso ea lihlahisoa tsa polypropylene.

Ts'ebetso ena e hloekile ebile e sebetsa hantle, e fokotsa tlhoko ea likhomaretsi tse ling kapa li-fasteners tsa mechini, tse ka bolokang nako le ho fokotsa litšenyehelo.

b. Polyethylene (PE)

Polyethylene ke polasetiki e 'ngoe e tloaelehileng e ka kopanngoang ka ho sebelisa theknoloji ea laser. E sebelisoa lits'ebetsong tse fapaneng ho tloha lijaneng ho ea lits'ebetsong tsa liphaephe. Ho kopanngoa ka laser ha polyethylene ho fana ka mokhoa o matla oa ho kopanya o ka mamellang maemo a fapaneng a tikoloho.Ho nepahala ha ts'ebetso ho netefatsa hore li-weld li matla ebile lia tšepahala, li fihlela litlhoko tsa lits'ebetso tsa bohlokoa.

c. Polycarbonate (PC)

Polycarbonate e ratoa ka lebaka la ho hanyetsa tshusumetso le ho hlaka ha mahlo, e leng se etsang hore e be khetho e ntle bakeng sa lits'ebetso tse kang likhalase tsa polokeho le lipontšo tsa elektroniki. Ho tjheseletsa ka laser ho fana ka mokhoa oa ho kopanya likarolo tsa polycarbonate ntle le ho beha botšepehi ba tsona kotsing.Bokhoni bona bo molemo haholo-holo liindastering moo ponaletso le ho tšoarella li leng bohlokoa.

d. Polyamide (Nylon)

Nylon, e tsebahalang ka matla a eona le ho tenyetseha ha eona, e sebelisoa hangata lihlahisoa tsa likoloi, masela le tsa bareki. Ho tjheseletsa ka laser ho ka sebelisoa ho kopanya likarolo tsa nylon ka katleho, ho fana ka litlamo tse matla tse ka mamellang khatello ea mechine.Bokhoni ba ho tjheseletsa nylon ka ho sebedisa di-laser bo bula menyetla e metjha moralong wa dihlahiswa le boenjiniere.

Na u batla ho reka sesebelisoa sa ho welder ka laser?

3. Lisebelisoa tse kopaneng tsa ho Welding ka Laser

Ha liindasteri li ntse li tsoela pele ho sebelisa thepa e kopaneng bakeng sa thepa ea tsona e ikhethang,Theknoloji ea ho tjheseletsa ka laser e ntse e ikamahanya le maemo ho fihlela litlhoko tsena.

a. Metswako ya Tšepe le Plastiki

Metswako ya tshepe le polasetiki e kopanya melemo ya thepa ka bobedi, e fana ka ditharollo tse bobebe empa di le matla bakeng sa ditshebediso tse fapaneng.

Ho tjheseletsa ka laser ho ka kopanya metsoako ena ka katleho, e leng se etsang hore e be mokhoa oa bohlokoa tlhahisong ea likoloi le ea elektroniki.

Bokhoni ba ho theha manonyeletso a matla ntle le ho eketsa boima bo boholo ke monyetla o moholo indastering ena.

b. Dikompose tse Matlafaditsweng ka Faeba

Lisebelisoa tsena, tse kenyelletsang likhoele ka har'a resin matrix, li tsebahala ka likarolelano tsa tsona tse matla ho ea boima.

Theknoloji ea ho tjheseletsa ka laser e ka sebelisoa mefuteng e itseng ea metsoako e matlafalitsoeng ka faeba, e lumellang ho kopana ka nepo ho bolokang botšepehi ba lifaeba.

Bokhoni bona bo bohlokoa haholo lits'ebetsong tsa lifofane le likoloi, moo meaho e bobebe e leng ea bohlokoa bakeng sa ts'ebetso.

4. Lisebelisoa tse Hlahang tsa ho Weld Machine ea ho Weld ea Laser

Ho tenyetseha ha theknoloji ea ho tjheseletsa ka laser ho lebisa ho amoheloeng ha eona lits'ebetsong tse ncha le tse ncha.

Liindasteri tse kang matla a nchafatsoang li ntse li hlahloba tšebeliso ea ho tjheseletsa ka laser bakeng sa tlhahiso ea liphanele tsa letsatsi, moo bokhoni ba ho kopanya thepa e fapaneng bo leng bohlokoa.

Ho phaella moo,Tsoelo-pele theknolojing ea laser e nolofalletsa ho tjheseletsa thepa e rarahaneng haholoanyane, e leng se eketsang le ho feta sebaka sa ho tjheseletsa ka laser.

5. Qetello

Mechini ea ho tjheseletsa ea laser e khona ho kopanyamefuta e fapaneng ea thepa, ho kenyeletsoa le litšepe, polasetiki le metsoako.

Ho nepahala le katleho ea ho tjheseletsa ka laser ho etsa hore e be khetho e ntlebakeng sa liindasteri tse fapaneng, ho kenyeletsoa le likoloi, lifofane, lisebelisoa tsa elektroniki le lits'ebetso tsa bongaka.

Ha theknoloji e ntse e tsoela pele ho hatela pele, mefuta e fapaneng ea thepa e ka kopanngoang ka katleho ho sebelisoa lasers e ka 'na ea atoloha, e leng se ntlafatsang ho tenyetseha ha eona le ho sebetsa ha eona tlhahisong ea sejoale-joale.

Ho ikamahanya le maemo hona ho beha welding ea laser e le ts'ebetso ea bohlokoa ho fihlelleng lihlahisoa tsa boleng bo holimo le tse tšoarellang 'marakeng o ntseng o qothisana lehlokoa haholoanyane.

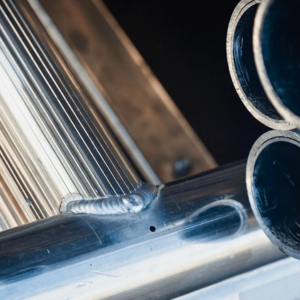

Tšepe ea ho Welder ea Laser

Batla ho Tseba Haholoanyane kaSehoelisa sa Laser?

Mochini o Amanang: Bahoebi ba Laser

Sesebelisoa sa ho welda ka laser ea faeba se tšoaroang ka letsoho se entsoe ka likarolo tse hlano: khabinete, mohloli oa laser ea faeba, sistimi e chitja ea ho pholisa metsi, sistimi ea taolo ea laser, le sethunya sa ho welda se tšoaroang ka letsoho.

Sebopeho sa mochini se bonolo empa se tsitsitse se etsa hore ho be bonolo hore mosebelisi a tsamaise mochini oa ho tjheseletsa oa laser le ho tjheseletsa tšepe ka bolokolohi.

Sesebelisoa sa ho weldera sa laser se nkehang habobebe se sebediswa hangata ho welding ya diboto tsa tshepe, ho welding ya tshepe e sa ruseng, ho welding ya dikhabinete tsa tshepe ya lakane, le ho welding ya sebopeho sa tshepe e kgolo ya lakane.

Mochini oa ho welda ka laser o na le sethunya se tenyetsehang sa ho welda ka laser se u thusang ho etsa ts'ebetso e tšoaroang ka letsoho.

Ho latela thapo ea faeba ea bolelele bo itseng, lehlaseli la laser le tsitsitseng le la boleng bo holimo le fetisetsoa ho tloha mohloling oa laser ea faeba ho ea nozzle ea ho welding ea laser.

Seo se ntlafatsa palo ea polokeho 'me se mosa ho motho ea qalang ho sebelisa sesebelisoa sa ho weldera ka laser se tšoaroang ka letsoho.

Nako ea poso: Pherekhong-06-2025