Sehahi sa Laser sa ho Sefa Lesela:

Ho Fetola Indasteri ea ho Sefa

Selelekela:

Lintho tsa Bohlokoa tseo U Lokelang ho li Tseba Pele U Itlhapela

Lefatšeng le fetohang la ho sefa, moo boleng le bokgoni di leng bohlokwa ka ho fetisisa, mekgwa e sebediswang ho seha masela a ho sefa e bapala karolo ya bohlokwa ho fumaneng katleho ka kakaretso ya dihlahiswa tsa ho sefa.

Mekhoa ea setso ea ho seha e 'nile ea thatafalloa ho fihlela litlhoko tse nepahetseng tsa indasteri ena, e leng se ileng sa lebisa ho amoheloeng ha mahlale a tsoetseng pele joalo ka ho seha ka laser, haholo-holo litsamaiso tsa laser tsa CO₂.

Likopo tsa Lesela la ho Sefa

Sengoloa sena se hlahloba melemo ea theknoloji ea ho seha laser ea CO₂ ea eurolaser indastering ea ho sefa.

Ho totobatsa ho nepahala ha eona, mathoko a hloekileng, le ho tenyetseha ha thepa.

E boetse e buisana ka lits'ebetso ho pholletsa le makala a fapaneng.

Ho bontša kamoo ho seha ka laser ho ntlafatsang tlhahiso le ho ntlafatsa boleng ba lihlahisoa tsa ho sefa.

Sengoloa sena se hlahloba melemo e felletseng ea ho sebelisa li-cutter tsa laser bakeng sa masela a ho sefa, se totobatsa melemo e fanoang ke li-cutter tsa laser tsa CO₂.

Tafole ea likateng

1. Ho nepahala le ho nepahala:

Theknoloji ea ho seha ka laser e tsebahala ka ho nepahala ha eona ho ikhethang, e lumellang bahlahisi ho fihlela likheo tse fihlelang litlhaloso tse thata.

Boemo bona ba ho nepahala bo bohlokoa haholo indastering ea ho sefa, moo esita le ho kheloha ho honyenyane ho ka sitisang ts'ebetso ea sefa.

Li-laser tsa CO₂ li sebetsa ka lehlaseli le shebaneng le ka sehang thepa e fapaneng ka mamello e fokolang, ho netefatsa hore lesela le leng le le leng la ho sefa le etselitsoe litekanyo tse nepahetseng.

2. Meeli e Hloekileng le ho Tšoarella ho Ntlafatsang:

E 'ngoe ea melemo ea bohlokoa ka ho fetisisa ea ho seha ka laser ke tlhahiso ea mathoko a hloekileng, a koetsoeng.

Mocheso o phahameng o hlahisoang ke laser ha o sehe feela thepa empa o boetse o qhibilihisa le ho kopanya mathoko, o thibela ho taboha.

Tšobotsi ena e bohlokoa bakeng sa masela a sefang, kaha mathoko a hloekileng a ntlafatsa ho tšoarella le bophelo ba lihlahisoa ka kakaretso.

Ho phaella moo, qetello e ntle e tlatsetsa ho khahleheng ha botle, e leng se ka bang bohlokoa bakeng sa lits'ebetso tse shebaneng le bareki.

3. Ho Feto-fetoha ha Lintho Tse Boleloang:

Li-cutter tsa laser li na le mekhoa e mengata haholo 'me li ka sebetsana le mefuta e mengata ea thepa, ho kenyeletsoa masela a maiketsetso le likhoele tsa tlhaho.

Ho ikamahanya le maemo hona ho molemo haholo indastering ea ho sefa, moo hangata bahlahisi ba hlokang ho fetola pakeng tsa thepa e fapaneng ho latela ts'ebeliso.

Bokhoni ba ho seha masela a sa lohiloeng, foam, le thepa e kopaneng ntle le ho hlophisoa bocha ho hoholo ho lumella ho tenyetseha le karabelo e kholoanyane litlhokong tsa 'maraka.

4. Litšila tse Fokolitsoeng tsa Thepa:

Bokgoni ba thepa ke taba ea bohlokoa tlhahisong.

Ho seha ka laser ho fokotsa litšila ka ho hlahisa likoto tse nepahetseng tse eketsang tšebeliso ea thepa e tala.

Bokhoni ba ho seha dikotwana haufi-ufi hodima lakane ya thepa bo fokotsa dikotwana tse sa sebetseng, e leng se dumellang bahlahisi ho ntlafatsa mehlodi ya bona.

Phokotso ena ea litšila ha e fokotse litšenyehelo tsa tlhahiso feela empa hape e fokotsa tšusumetso ea tikoloho, e lumellanang le lipheo tsa botsitso tse ntseng li eketseha bohlokoa 'marakeng oa kajeno.

5. Lebelo le Bokgoni:

Bokhoni ba ho seha ka potlako ba theknoloji ea laser bo eketsa sekhahla sa tlhahiso haholo.

Litsamaiso tsa laser li ka sebetsa ka ho tsoelang pele le ka lebelo le phahameng, li nolofalletsa bahlahisi ho fihlela linako tse behiloeng ntle le ho lahla boleng.

Bokgoni bona bo molemo haholo-holo diindastering moo nako ya ho reka e leng bohlokwa, kaha bokgoni ba ho hlahisa masela a boleng bo hodimo a ho sefa ka potlako bo ka fana ka monyetla wa tlholisano.

6. Ho iketsetsa le ho iketsetsa lintho ka boiketsetso:

Theknoloji ea sejoale-joale ea ho seha ka laser e kenyelletsa likarolo tse kang ho fepa ka ho nepahala ha khatello le litsamaiso tsa ho hlopha ka boiketsetso, tse nolofalletsang ho kopanngoa ho se nang sekoli meleng ea tlhahiso e iketsang.

Othomathiki ena e fokotsa tlhoko ea ho kenella ka letsoho, e fokotsa litšenyehelo tsa basebetsi le monyetla oa liphoso tsa batho.

Ho feta moo, libaka tsa mosebetsi li ka fetoloa ho latela litlhoko tse itseng tsa tlhahiso, ho ntlafatsa ho tenyetseha ha ts'ebetso.

Videong ena, re bonts'a ts'ebetso ea lesela la sefe la ho seha ka laser, re totobatsa bohlokoa ba ho khetha thepa e nepahetseng le litlhophiso tsa laser bakeng sa ts'ebetso e ntle ka ho fetisisa.

Shebella ha re ntse re lokisa moralo oa rona le ho seta sesebelisoa sa laser, re netefatsa hore re khaola ka nepo bakeng sa ho sefa ka katleho.

Qetellong, re bonts'a likarolo tse felileng 'me re buisana ka lits'ebeliso tsa tsona tse fapaneng mesebetsing ea matsoho le ea indasteri!

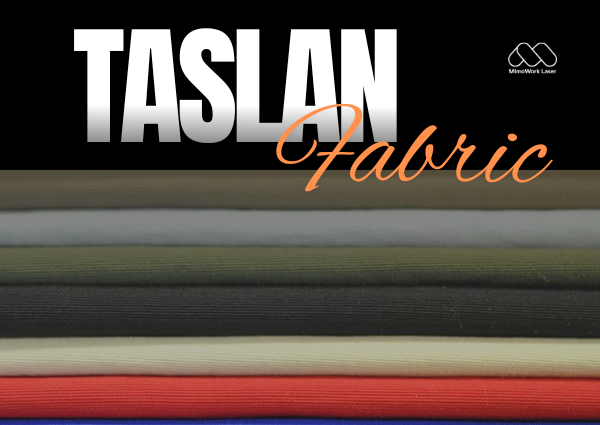

Lisebelisoa tse 'maloa li sebelisoa haholo indastering ea ho sefa 'me li loketse hantle ho seha ka laser:

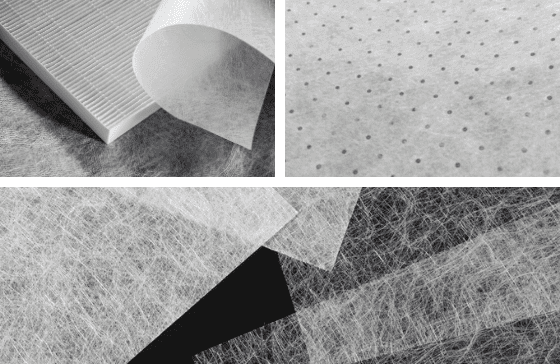

Masela a sa Lohiloeng

Tsena li loketse ho sefa moea le metsi ka lebaka la thepa ea tsona e ntle ea ho sefa le botsitso ba sebopeho.

Liphoofolo

Ha e sebelisoa haholo bakeng sa ho sefa molumo le moea, foam e ka sehoa ka nepo ho fihlela litlhoko tse itseng tsa moralo.

Lisebelisoa tse kopantsoeng

Ka ho fana ka ho tšoarella le matla a ntlafalitsoeng, thepa ena ea bohlokoa bakeng sa mesebetsi e boima ea ho sefa e hlokang litharollo tse matla.

Ho lumellana ha thepa e tsoetseng pele

Li-cutter tsa CO₂ laser li etselitsoe ka ho khetheha ho sebetsana le mefuta e mengata ea masela a tekheniki a sebelisoang tlhahisong ea sefe.

Boenjiniere ba bona bo dumella ts'ebetso e atlehang ea thepa e kang masela a sa lohiloeng, foam le thepa e kopaneng, tse atisang ho sebelisoa lits'ebetsong tse fapaneng tsa ho sefa.

Ho tsamaellana hona ho tswetseng pele ho netefatsa hore bahlahisi ba ka fihlella diphetho tse ntle ka ho fetisisa mefuteng e fapaneng ya dihlahiswa.

Mehlala ea Ts'ebeliso

Ho tenyetseha ha litsamaiso ho bonahala ts'ebelisong ea tsona makaleng a mangata, ho kenyeletsoa:

Li-filter tsa likoloi:

Masela a ho sefa a khaotsoeng ka nepo a bohlokoa bakeng sa litsamaiso tsa ho sefa moea le oli tsa koloi, e leng se netefatsang ts'ebetso e ntle le nako e telele.

Mekhoa ea ho Hloekisa Moea:

Lifiltara tsa boleng bo holimo tse entsoeng ka masela a khaotsoeng ka hloko li bohlokoa bakeng sa ho boloka boleng ba moea libakeng tsa bolulo le tsa indasteri.

Lisebelisoa tsa Bongaka:

Tlhokomelong ea bophelo bo botle, ho sefa ka katleho ho bohlokoa lisebelisoa tse kang limaske tsa opereishene le li-ventilator, moo maemo a holimo a bohloeki le botšepehi li hlokahalang.

Mekhoa e Khothaletsoang ea ho Seha Lesela la Laser ea Filter

Ho fumana diphetho tse ntle ka ho fetisisa ha o seha lesela la sefe, o kgetha se nepahetsengmochini oa ho itšeha ka laser oa lesela la filtharaho bohlokoa. MimoWork Laser e fana ka mefuta e fapaneng ea mechini e loketsenglesela la filtara la ho itšeha ka laser, ho kenyeletsoa:

• Sebaka sa Mosebetsi (Bophara ba hodimo): 1000mm * 600mm

• Matla a Laser: 60W/80W/100W

• Sebaka sa Mosebetsi (Bophara ba * Bophara): 1300mm * 900mm

• Matla a Laser: 100W/150W/300W

• Sebaka sa Mosebetsi (Bophara ba hodimo): 1800mm * 1000mm

• Matla a Laser: 100W/150W/300W

Ha re phethela

Ho kopanngoa ha theknoloji ea ho seha ka laser, haholo-holo ka litsamaiso tse tsoetseng pele joalo ka li-cutter tsa laser tsa CO₂, ho fetotse tlhahiso ea masela a ho sefa.

Ka melemo e tlohang ho nepahala le lebelo ho isa ho ho tenyetseha ha thepa, theknoloji ena e ntlafatsa tlhahiso mme e kenya letsoho boleng le katlehong ya dihlahiswa tsa ho sefa ka kakaretso.

Ha indasteri e ntse e tsoela pele ho fetoha, ho seha ka laser ntle ho pelaelo ho tla dula ho le ka pele ho boqapi lefapheng la ho sefa, ho bula tsela bakeng sa ditharollo tse ntlafetseng tsa ho sefa tse fihlelang ditlhoko tse ntseng di hola tsa bareki le diindasteri ka ho tshwana.

P: Na ho na le Mehopolo ea Polokeho ha ho sebelisoa Laser Cutter?

K: E, polokeho e bohlokwa ha o sebedisa seha ka laser. Dintlha tsa bohlokwa di kenyeletsa:

• Ho apara thepa e loketseng ea tšireletso ea botho (PPE)

• Ho netefatsa hore moea o kena hantle ho qoba mosi o kotsi

• Ho latela litataiso tsa moetsi bakeng sa ts'ebetso le tlhokomelo

P: Ke Eng Seo ke Lokelang ho se Nahana Ha ke Khetha Sehahi sa Laser bakeng sa Masela a Sefang?

K: Nahana ka lintlha tse latelang:

• Ho seha boholo ba sebaka: Netefatsa hore se fihlela litlhoko tsa hau tsa tlhahiso.

• Matla a laser: Matla a mangata a lumella ho seha thepa e teteaneng.

• Ho lumellana ha software: E lokela ho sebetsa hantle le software ea hau ea moralo.

• Tšehetso le koetliso: Batla bahlahisi ba fanang ka tšehetso le koetliso e felletseng.

P: Tlhokomelo e Tloaelehileng e Hlokahalang bakeng sa Sehahi sa Laser ke Eng?

K: Tlhokomelo e tloaelehileng e ka kenyeletsa:

• Ho hlwekisa lense le diipone

• Ho hlahloba le ho nkela tube ea laser sebaka ha ho hlokahala

• Ho netefatsa hore sistimi ea ho pholisa e sebetsa hantle

• Ho lekanya le ho hlahloba kamehla bakeng sa ho nepahala

P: Na Li-cutter tsa Laser li ka sebetsana le bongata bo boholo ba tlhahiso?

K: E, disekere tsa laser tsa sejwalejwale di etseditswe ho hlahisa dintho tse ngata mme di ka sebetsana le tlhahiso e kgolo ka katleho, e leng se etsang hore di lokele ditshebediso tsa indasteri.

Mehopolo efe kapa efe mabapi le Sehahi sa Laser sa Filtration,

Tloo ho tla re bolella!

Na ho na le Lipotso mabapi le Mochini oa ho Seha oa Lesela la Filter Laser?

Nako ea poso: Pherekhong-08-2025