Mokhoa oa ho Weld ka Laser Litšepe tse kopantsoeng tsa Aluminium

Ho Welding Aluminium e ka ba Thata

Li-alloy tsa aluminium li arotsoe ka lihlopha ho latela likarolo tsa tsona tsa mantlha tsa ho kopanya.

Letoto ka leng le na le litšobotsi tse ikhethang tse amang ho tjheseletsa ha lona, haholo-holo ha ho sebelisoa ho tjheseletsa ka laser ka letsoho.

Ka tlase ke kakaretso ea letoto la li-alloy tsa aluminium tse tloaelehileng, litšobotsi tsa tsona, likhase tse sireletsang tse loketseng, lithapo tse loketseng tsa ho tlatsa, le malebela a ho fihlela li-weld tsa boleng bo holimo.

Lethathamo la Dikahare:

1. Litšepe tse Tloaelehileng tsa Aluminium bakeng sa ho Welding ka Laser

Mohato oa Pele oa ho Finyella ho Tšela ho Lokile: Kutloisiso

Li-Aluminium tse kopantsoeng tsa letoto la 1000

Sebopeho:E na le aluminium ea 99.00% kapa ho feta.

Thepa:E bobebe ebile e bonolo ho e sebelisa, e leng se etsang hore ho be bonolo ho sebetsa ka eona.

Khase e Sireletsang:Argon ea 100% e khothaletsoa ho thibela oxidation.

Terata ea ho Tlatsa:Sebelisa terata ea ho tlatsa ea 4047 kapa 4045 bakeng sa ho tsamaisana hamolemo.

Malebela a ho tjheseletsa:Netefatsa hore bokaholimo bo hloekile ebile ha bo na li-oxide. Hangata ha ho hlokahale ho futhumatsa ka lebaka la ho ba bonolo ho hoholo.

Li-Aluminium tse kopantsoeng tsa letoto la 2000

Sebopeho:E kopantsoe haholo-holo ka koporo (2-10%).

Thepa:Matla a phahameng empa a sa sebetse hantle; a ka petsoha habonolo nakong ea ho tjheseletsa.

Khase e Sireletsang:Argon e nang le peresente e nyane ea Helium e ka thusa ho ntlafatsa ho kenella ha metsi.

Terata ea ho Tlatsa:Sebelisa terata ea ho tlatsa ea 4047 kapa 2319, e etselitsoeng li-alloy tse nang le koporo e ngata.

Malebela a ho tjheseletsa:Chesa thepa ho fokotsa kotsi ea ho petsoha. Laola mocheso ka hloko ho qoba khatello e feteletseng ea mocheso.

Li-Aluminium tse kopantsoeng tsa letoto la 3000

Sebopeho:E kopantsoe le manganese.

Thepa:E hanela mafome hantle ebile e na le matla; e boloka matla mochesong o phahameng.

Khase e Sireletsang:100% Argon e sebetsa hantle.

Terata ea ho Tlatsa:Terata ea ho tlatsa ea 4045 kapa 4047 e loketse.

Malebela a ho tjheseletsa:Hloekisa bokaholimo hantle ho tlosa litšila life kapa life. Boloka lebelo le tsitsitseng la ho tsamaea ho netefatsa hore mocheso o ajoa ka ho lekana.

Litšepe tse kopantsoeng tsa Aluminium tsa Letoto la 4000

Sebopeho:E na le silicon, e fokotsang ntlha ea ho qhibiliha.

Thepa:Ho ductility e eketsehileng le e ntle haholo bakeng saho lahla ka ho tjhesa; e sa phekoleheng mochesong.

Khase e Sireletsang:Argon e khethoa.

Terata ea ho Tlatsa:Sebelisa terata ea ho tlatsa ea 4047 bakeng sa liphetho tse ntle ka ho fetisisa.

Malebela a ho tjheseletsa:Ho futhumatsa ho ka thusa ka ho kenella. Ela hloko mocheso o kenang haufi-ufi ho qoba ho sotha.

Li-Aluminium tse kopantsoeng tsa letoto la 5000

Sebopeho:E kopantsoe le magnesium.

Thepa:Matla a phahameng le ho hanyetsa mafome hantle; e loketse maqephe le lipoleiti.

Khase e Sireletsang:Argon ea 100% e khothaletsoa.

Terata ea ho Tlatsa:Sebelisa terata ea ho tlatsa ea 5356 bakeng sa ho tsamaisana hamolemo.

Malebela a ho tjheseletsa:Ho futhumatsa ho molemo bakeng sa likarolo tse teteaneng. Sebelisa mokhoa oa ho sututsa ho ntlafatsa ts'ebetso ea ho hloekisa le ho fokotsa tšilafalo.

Litšepe tse kopantsoeng tsa Aluminium tsa Letoto la 6000

Sebopeho:E na le magnesium le silicon ka bobeli.

Thepa:E bonolo ho e sebedisa mme e ka phekolwa ka mocheso; e loketse di-extrusion.

Khase e Sireletsang:Argon kapa motsoako oa Argon le Helium.

Terata ea ho Tlatsa:Terata ea ho tlatsa ea 4045 kapa 5356 e loketse.

Malebela a ho tjheseletsa:Netefatsa hore bokaholimo bo hlwekisitsoe hantle. Sebelisa lebelo le phahameng la ho tsamaea ho thibela ho chesa haholo.

Li-Aluminium tse kopantsoeng tsa letoto la 7000

Sebopeho:Haholo-holo e kopantsoe le zinki.

Thepa:Matla a phahameng empa ka kakaretso ha a lokele ho kopanngoa ha tjheseletso ka lebaka la mathata a ho petsoha.

Khase e Sireletsang:Argon e nang le Helium e ka ba molemo.

Terata ea ho Tlatsa:Sebelisa terata ea ho tlatsa ea 7072 kapa 7005.

Malebela a ho tjheseletsa:Ho futhumatsa ke habohlokoa ho fokotsa kotsi ea ho petsoha. Sebelisa mocheso o laoloang 'me u qobe lebelo le feteletseng la ho tsamaea.

Ka Tsoelo-pele ea Theknoloji ea Kajeno

Theko ea Mochini oa ho Welding oa Laser ha e so ka e ba Theko e Tlase Hakaale!

2. Malebela a Tloaelehileng bakeng sa Aluminium ea ho Welding ka Laser

Bakeng sa ho Finyella Liphetho tse Ntle tsa ho Welding, Lintlha tse ling tsa Bohlokoa ke tsena:

Tokisetso ea Bokaholimo

Kamehla hlwekisa bokaholimo ba aluminium ho tlosa di-oxide le ditshila.

Taolo ea Mocheso

Lekola mocheso ka hloko ho qoba ho sotha le ho sotha, haholo-holo linthong tse tšesaane.

Lebelo la ho Tsamaea

Fetola lebelo la ho tsamaea ho latela botenya ba thepa ho leka-lekanya ho kenella le ho kenya mocheso.

Phetoho ea Lintlha tse ka Sehloohong

Tsepamisa lebone hanyane ka tlase ho bokaholimo bakeng sa ho kenella hamolemo le ho fokotsa ho reflectivity.

Ho Khetha Pakeng tsa Mefuta e Fapaneng ea Mochini oa ho Welding oa Laser?

Re ka Thusa ho Etsa Qeto e Nepahetseng ho latela Likopo

3. Mokhoa oa ho Finyella ho Weld ho Molemo ka Litšepe tse kopantsoeng tsa Aluminium

Ho utloisisa Boitsebiso ba Hao ho Halofo

Ho utloisisa letoto la alloy ea aluminium e tloaelehileng ho bohlokoa bakeng sa ho fihlela weld e ntle ka welder ea laser e tšoaroang ka letsoho ka mabaka a 'maloa:

Thepa ea Thepa

Letoto le leng le le leng la alloy ea aluminium le na le thepa e ikhethang, ho kenyeletsoa matla, ho ductility, le ntlha ea ho qhibiliha.

Ho tseba litšobotsi tsena ho thusa ho khetheng liparamente tse loketseng tsa ho tjheseletsa, tse kang litlhophiso tsa motlakase le lebelo la ho tsamaea, ho netefatsa ho tjheseletsa ho matla le ho sebetsang hantle.

Liphephetso tsa ho tjheseletsa

Letoto le fapaneng la alloy le hlahisa liphephetso tse itseng nakong ea ho tjheseletsa.

Mohlala, di-alloy tsa letoto la 2000 di sekametse ho petsoha, ha di-alloy tsa letoto la 4000 di ka phalla habonolo haholo.

Ho utloisisa liphephetso tsena ho nolofalletsa ba tjheseletsang ho sebelisa mekhoa ea ho fokotsa mathata, joalo ka ho futhumatsa pele kapa ho lokisa thepa ea ho tlatsa.

Ho lumellana ha thepa ea ho tlatsa

Li-alloy tse fapaneng tsa aluminium li hloka thepa e lumellanang ea ho tlatsa ho netefatsa tlamo e matla.

Mohlala, ho sebelisa terata e nepahetseng ea ho tlatsa ho ka thibela mathata a kang masoba kapa ho se kopane hantle.

Tsebo ea letoto la li-alloy e thusa ho khetheng terata e nepahetseng ea ho tlatsa ho ntlafatsa boleng ba weld.

Khetho ea Khase e Sireletsang

Khetho ea khase e sireletsang e ka ama boleng ba weld haholo.

Letoto le leng le le leng la motsoako le ka hloka likhase tse itseng tse sireletsang ho thibela oxidation le ho ntlafatsa ho kenella ha tsona.

Ho utloisisa sebopeho sa motsoako ho thusa ba tjheseletsang ho kgetha kgase e sireletsang e ntle ka ho fetisisa bakeng sa diphetho tse ntle ka ho fetisisa.

Taolo ea Mocheso

Mefuta e fapaneng ea litšepe e arabela ka tsela e fapaneng mochesong.

Tse ling li ka 'na tsa hloka phekolo ea ho futhumatsa pele kapa ea ka mor'a ho chesetsoa ho imolla khatello ea maikutlo.

Ho utloisisa letoto la litšepe tsa alloy ho lumella ba tjheseletsang ho laola mocheso ka katleho, ho fokotsa kotsi ea ho sotha kapa ho petsoha.

Ho Tšoaneleha ha Kopo

Li-alloy tse itseng tsa aluminium li loketse haholoanyane lits'ebetsong tse itseng, tse kang tsa lifofane kapa tsa likoloi.

Ho tseba litšobotsi tsa letoto ka leng ho thusa ho khetha motsoako o nepahetseng bakeng sa mosebetsi, ho netefatsa hore sehlahisoa sa ho qetela se fihlela maemo a ts'ebetso le polokeho.

Ho Bokgoni ba Litšenyehelo

Ho sebelisa liparamente tse loketseng tsa motsoako le ho tjheseletsa ho ka lebisa lits'ebetsong tse sebetsang hantle tsa ho tjheseletsa, ho fokotsa litšila tsa thepa le ho e lokisa bocha.

Ho utloisisa litšobotsi tsa motsoako ho tlatsetsa ho rala le ho phethahatsa hamolemo, qetellong ho boloka nako le litšenyehelo.

Netefaletso ea boleng

Ho tseba letoto le fapaneng la aluminium ho thusa ho theha mehato ea taolo ea boleng.

Bahoehla ba ka sebelisa mekhoa le maemo a itseng ho latela mofuta oa motsoako, e leng se lebisang ho hoehla ho tsitsitseng le ho boleng bo holimo.

Ho Welsha Aluminium ho Thatafalloa ka ho Welsha ka Setso

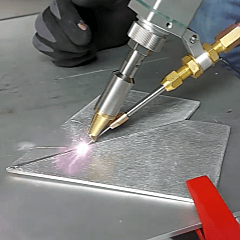

Ho Welding ka Laser Nolofatsa Ts'ebetso ena

Na U Batla ho Tseba Haholoanyane ka Aluminium ea ho Welding ka Laser?

Ho Welding Aluminium ho Bobebe ho Feta ho Welding Lisebelisoa tse Ling.

Ka hona re ngotse Sengoloa se buang ka Mokhoa oa ho Finyella Li-Weld tse Ntle ka Aluminium.

Ho tloha ho Litlhophiso ho ea ho Mokhoa oa ho.

Ka Livideo le Tlhahisoleseling e 'Ngoe.

Na u na le thahasello ho Welding ea Laser?

Na u batla ho qala ho tjheseletsa ka laser ka potlako?

Na u batla ho ntlafatsa tsebo ea hau ea ho tjheseletsa ka laser?

Tataiso ena e Felletseng ea Litšupiso e Entsoe Bakeng sa Hao Feela!

Bokgoni bo Phahameng le Matla a ho Tjhesa bakeng sa Ditshebediso tse Fapaneng tsa ho Tjhesa

Mochini oa ho tjheseletsa oa laser oa 2000W o tšoauoa ka boholo bo bonyenyane ba mochini empa boleng ba ho tjheseletsa bo benyang.

Mohloli o tsitsitseng oa laser ea fiber le thapo ea fiber e hokahaneng li fana ka phano e sireletsehileng le e tsitsitseng ea laser.

Ka matla a phahameng, lesoba la ho welding la laser le phethahetse mme le nolofalletsa ho tiisa lenonyeletso esita le bakeng sa tšepe e teteaneng.

Ho Kgona ho Fetoha ha Maemo

Ka ponahalo ea mochini o monyane le o monyenyane, mochini oa ho welder oa laser o nkehang habobebe o na le sethunya sa ho welder sa laser se ka tsamaisoang ka letsoho se bobebe ebile se loketse lits'ebetso tsa ho welder tsa laser tse ngata ka lehlakoreng lefe kapa lefe le bokaholimo bofe kapa bofe.

Mefuta e fapaneng ea boikhethelo ea li-nozzle tsa ho welder ka laser le litsamaiso tsa ho fepa ka terata ka boiketsetso li etsa hore ts'ebetso ea ho welder ka laser e be bonolo 'me e be bonolo bakeng sa ba qalang.

Ho tjheseletsa ka laser ka lebelo le phahameng ho eketsa haholo bokgoni ba tlhahiso le tlhahiso ya hao ha ka nako e ts'oanang ho nolofalletsa phello e ntle ya ho tjheseletsa ka laser.

Lintho tseo U LOKELANG HO LI Tseba ka: Ho Welding ka Laser e Tšoareloang ka Letsoho

Haeba u thabetse video ena, ke hobane'ng ha u sa nahane ka eonaU ingolisa ho Channel ea rona ea Youtube?

Likopo tse Amanang tseo U ka li Thahasellisang:

Theko e 'Ngoe le e 'Ngoe e Lokela ho Tsebisoa Hantle

Re ka Thusa ka Tlhahisoleseling e Batsi le Keletso!

Nako ea poso: Tshitwe-20-2024