Mokhoa oa ho Khetha Metsoako e Molemohali ea Khase bakeng sa ho Welding ha Hao ka Laser?

Mefuta, Melemo le Litšebeliso

Selelekela:

Lintho tsa Bohlokoa tseo U Lokelang ho li Tseba Pele U Itlhapela

Ho tjheseletsa ka laser ke mokhoa o nepahetseng haholo oa ho tjheseletsa o sebelisang lehlaseli la laser ho qhibilihisa thepa ea mosebetsi ebe o etsa weld ka mor'a ho pholisa. Ho tjheseletsa ka laser, khase e bapala karolo ea bohlokoa.

Khase e sireletsang ha e ame feela sebopeho sa moalo oa ho welding, boleng ba moalo oa ho welding, ho kenella ha moalo oa ho welding, le bophara ba ho kenella empa hape e ama ka kotloloho boleng le katleho ea ho welding ka laser.

Ke likhase life tse hlokahalang bakeng sa ho tjheseletsa ka laser?Sehlooho sena se tla sheba ka boteboBohlokoa ba likhase tsa ho tjheseletsa ka laser, likhase tse sebelisoang, le seo li se etsang.

Re tla boela re khothaletsemochini o motle ka ho fetisisa oa ho tjheseletsa oa laserbakeng sa litlhoko tsa hau.

Ke Hobane'ng ha Khase e Hlokahala Bakeng sa ho Welding ka Laser?

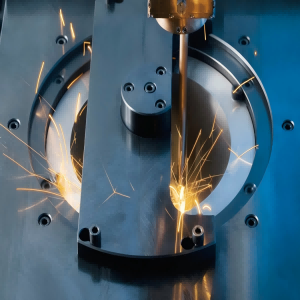

Ho tjheseletsa ka Laser Beam

Nakong ea ts'ebetso ea ho tjheseletsa ka laser, lehlaseli la laser le nang le matla a mangata le shebane le sebaka sa ho tjheseletsa sa mosebetsi.

Ho baka ho qhibiliha hang-hang ha thepa ea bokaholimo ba mosebetsi.

Khase ea hlokahala nakong ea ho tjheseletsa ka laser ho sireletsa sebaka sa ho tjheseletsa.

Laola mocheso, ntlafatsa boleng ba weld, 'me u sireletse sistimi ea optical.

Ho khetha mofuta o nepahetseng oa khase le liparamente tsa phepelo ke lintlha tsa bohlokoa ho netefatseng hore e sebetsa hantle.

Le ts'ebetso e tsitsitseng ea ho tjheseletsa ka laser le ho fumana liphetho tsa boleng bo holimo tsa ho tjheseletsa.

1. Tšireletso ea Libaka tsa ho Chesetsa

Nakong ea ts'ebetso ea ho tjheseletsa ka laser, sebaka sa ho tjheseletsa se pepesehela tikoloho ea kantle 'me se angoa habonolo ke oksijene le likhase tse ling moeeng.

Oksijene e baka diphetoho tsa oxidation tse ka lebisang ho fokotseng boleng ba weld, le ho thehwa ha masoba le di-inclusions. Weld e ka sireletsoa ka katleho ho tshwaetso ya oksijene ka ho fana ka kgase e loketseng, hangata kgase e sa sebetseng jwalo ka argon, sebakeng sa weld.

2. Taolo ea Mocheso

Khetho le phepelo ea khase li ka thusa ho laola mocheso oa sebaka sa ho tjheseletsa. Ka ho fetola sekhahla sa phallo le mofuta oa khase, sekhahla sa ho pholisa sa sebaka sa ho tjheseletsa se ka angoa. Sena se bohlokoa ho laola sebaka se amehileng ke mocheso (HAZ) nakong ea ho tjheseletsa le ho fokotsa ho sotha ha mocheso.

3. Boleng bo Ntlafalitsoeng ba ho Weld

Dikhase tse ding tse thusang, tse kang oksijene kapa naetrojene, di ka ntlafatsa boleng le tshebetso ya di-weld. Mohlala, ho eketsa oksijene ho ka ntlafatsa ho kenella ha weld le ho eketsa lebelo la ho tjheseletsa, ha ka nako e ts'oanang ho ama sebopeho le botebo ba weld.

4. Ho Pholisa Khase

Ha ho tjhesetsoa ka laser, sebaka sa ho tjheseletsa hangata se angoa ke mocheso o phahameng. Ho sebedisa sistimi ya ho phodisa kgase ho ka thusa ho laola mocheso wa sebaka sa ho tjheseletsa le ho thibela ho chesa haholo. Sena se bohlokwa ho fokotsa kgatello ya mocheso sebakeng sa ho tjheseletsa le ho ntlafatsa boleng ba ho tjheseletsa.

Ho tjheseletsa ka Laser Beam ka Othomathiki

5. Tšireletso ea Khase ea Mekhoa ea Optical

Lehlasedi la laser le shebane le sebaka sa ho tjheseletsa ka sistimi ya optical.

Nakong ea ts'ebetso ea ho kopanya, thepa e qhibilihisitsoeng le li-aerosol tse hlahisoang li ka silafatsa likarolo tsa mahlo.

Ka ho kenya likhase sebakeng sa ho tjheseletsa, kotsi ea tšilafalo ea fokotseha 'me bophelo ba sistimi ea optical boa atolosoa.

Ke Likhase Life Tse Sebelisoang ho Welding ka Laser?

Ho tjheseletsa ka laser, khase e ka arola moya ho tloha poleiting ya ho tjheseletsa mme ya o thibela ho arabela le moya. Ka tsela ena, bokaholimo ba ho tjheseletsa ba poleiti ya tshepe bo tla ba bosweu le ho ba botle le ho feta. Ho sebedisa kgase ho boetse ho sireletsa dilense leroleng la ho tjheseletsa. Hangata, dikhase tse latelang di a sebediswa:

1. Khase e Sireletsang:

Likhase tse sireletsang, tseo ka linako tse ling li bitsoang "likhase tse sa sebetseng," li bapala karolo ea bohlokoa ts'ebetsong ea ho tjheseletsa ka laser. Mekhoa ea ho tjheseletsa ka laser hangata e sebelisa likhase tse sa sebetseng ho sireletsa letamo la ho tjheseletsa. Likhase tse sireletsang tse sebelisoang hangata ho tjheseletsa ka laser li kenyelletsa haholo-holo argon le neon. Thepa ea tsona ea 'mele le ea lik'hemik'hale lia fapana, kahoo litlamorao tsa tsona ho tjheseletsa le tsona lia fapana.

Khase e Sireletsang:Argon

Argon ke e 'ngoe ea likhase tse sa sebetseng tse sebelisoang haholo.

E na le tekanyo e phahameng ea ionization tlas'a ts'ebetso ea laser, e leng se sa lumelleng ho laola ho thehoa ha maru a plasma, e leng se tla ba le tšusumetso e itseng tšebelisong e atlehang ea laser.

Tlhaho e sa sebetseng ea argon e e thibela ho kenella ts'ebetsong ea ho kopanya, ha e ntse e boetse e qhala mocheso hantle, e thusa ho laola mocheso sebakeng sa ho kopanya.

Khase e Sireletsang:Neon

Neon hangata e sebelisoa e le khase e sa sebetseng, e tšoanang le argon, 'me e sebelisoa haholo-holo ho sireletsa sebaka sa ho tjheseletsa ho tloha oksijene le litšila tse ling tikolohong e kantle.

Ho bohlokoa ho hlokomela hore neon ha e loketse lits'ebetso tsohle tsa ho tjheseletsa ka laser.

E sebelisoa haholo bakeng sa mesebetsi e meng e khethehileng ea ho tjheseletsa, joalo ka ho tjheseletsa thepa e teteaneng kapa ha ho hlokahala li-seam tse tebileng tsa ho tjheseletsa.

2. Khase e Thusang:

Nakong ea ts'ebetso ea ho tjheseletsa ka laser, ntle le khase e sireletsang ea mantlha, likhase tse thusang li ka boela tsa sebelisoa ho ntlafatsa ts'ebetso le boleng ba ho tjheseletsa. Tse latelang ke tse ling tsa likhase tse thusang tse tloaelehileng tse sebelisoang ho tjheseletsa ka laser.

Khase e Thusang:Oksijene

Oksijene e sebediswa hangata e le kgase e thusang mme e ka sebediswa ho eketsa mocheso le botebo ba ho tjheseletsa nakong ya ho tjheseletsa.

Ho eketsa oksijene ho ka eketsa lebelo la ho tjheseletsa le ho kenella ha yona, empa ho hloka ho laolwa ka hloko ho qoba oksijene e ngata e bakang mathata a ho kenngwa ha oksijene.

Khase e Thusang:Motsoako oa Haedrojene/ Haedrojene

Haedrojene e ntlafatsa boleng ba di-weld mme e fokotsa ho thehwa ha masoba.

Metswako ya argon le haeterojene e sebediswa ditshebedisong tse ding tse ikgethang, tse kang ho tjheseletsa tshepe e sa ruseng. Haeterojene e ka hara motswako hangata e tloha ho 2% ho isa ho 15%.

Khase e Sireletsang:Naetrojene

Naetrojene e boetse e atisa ho sebelisoa e le khase e thusang ho tjheseletsa ka laser.

Matla a ionization a naetrojene a itekanetse, a phahame ho feta argon mme a tlase ho feta haeterojene.

Tekanyo ea ionization hangata e tlas'a ts'ebetso ea laser. E ka fokotsa ho thehoa ha maru a plasma hamolemo, ea fana ka li-weld tsa boleng bo holimo le ponahalo, 'me ea fokotsa tšusumetso ea oksijene ho li-weld.

Naetrojene e ka boela ea sebelisoa ho laola mocheso oa sebaka sa ho tjheseletsa le ho fokotsa ho thehoa ha lipululana le masoba.

Khase e Sireletsang:Heliamo

Hangata Helium e sebediswa bakeng sa ho tjheseletsa ka laser e nang le matla a maholo hobane e na le motlakase o tlase mme ha e fetolwe habonolo, e leng se dumellang laser ho feta hantle le matla a mahlaseli ho fihla hodima sebaka sa mosebetsi ntle le ditshitiso.

E thusa ho tjheseletsa ka matla a hodimo. Helium e ka boela ya sebediswa ho ntlafatsa boleng ba tjheseletsa le ho laola mocheso wa tjheseletsa. Ena ke kgase e sireletsang e sebetsang ka ho fetisisa e sebediswang ho tjheseletsa ka laser, empa e theko e boima haholo.

3. Khase e Pholisang:

Khase e phodisang hangata e sebediswa nakong ya ho tjheseletsa ka laser ho laola mocheso wa sebaka sa ho tjheseletsa, ho thibela ho chesa haholo, le ho boloka boleng ba ho tjheseletsa. Tse latelang ke tse ding tsa dikgase tse phodisang tse sebediswang hangata:

Khase e Pholisang/ E Mahareng:Metsi

Metsi ke sesebelisoa se tloaelehileng sa ho pholisa se atisang ho sebelisoa ho pholisa lijenereithara tsa laser le litsamaiso tsa mahlo tsa ho tjheseletsa ka laser.

Mekhoa ea ho pholisa metsi e ka thusa ho boloka mocheso o tsitsitseng oa jenereithara ea laser le likarolo tsa optical ho netefatsa botsitso le ts'ebetso ea mahlaseli a laser.

Khase e Pholisang/ E Mahareng:Likhase tsa sepakapaka

Mekhoa e meng ea ho tjheseletsa ka laser, likhase tse potolohileng sepakapaka li ka sebelisoa bakeng sa ho pholisa.

Mohlala, tsamaisong ea optical ea jenereithara ea laser, khase e potolohileng sepakapaka e ka fana ka phello ea ho pholisa.

Khase e Pholisang/ E Mahareng:Likhase tse se nang thuso

Likhase tse se nang thuso tse kang argon le naetrojene le tsona li ka sebelisoa e le likhase tse pholisang.

Li na le conductivity e tlase ea mocheso 'me li ka sebelisoa ho laola mocheso oa sebaka sa ho tjheseletsa le ho fokotsa sebaka se amehileng ke mocheso (HAZ).

Khase e Pholisang/ E Mahareng:Naetrojene e Metsi

Naetrojene e metsi ke sesebelisoa sa ho pholisa mocheso o tlase haholo se ka sebelisoang bakeng sa ho tjheseletsa ka laser ka matla a maholo haholo.

E fana ka phello e sebetsang hantle ea ho pholisa 'me e netefatsa taolo ea mocheso sebakeng sa ho tjheseletsa.

4. Khase e tsoakiloeng:

Metswako ya kgase e sebediswa hangata ho tjheseletsa ho ntlafatsa dikarolo tse fapaneng tsa tshebetso, tse kang lebelo la ho tjheseletsa, botebo ba ho kenella, le botsitso ba arc. Ho na le mefuta e mmedi e meholo ya metswako ya kgase: metswako ya binary le ya ternary.

Metswako ea Khase ea Binary:Argon + Oksijene

Ho eketsa oksijene e nyane ho argon ho ntlafatsa botsitso ba arc, ho ntlafatsa letamo la ho weld, le ho eketsa lebelo la ho weld. Motsoako ona o sebediswa hangata bakeng sa ho weld tšepe ya carbon, tshepe e nang le motswako o tlase, le tshepe e sa ruseng.

Metswako ea Khase ea Binary:Argon + Carbon Dioxide

Ho eketsoa ha CO₂ ho argon ho eketsa matla a ho tjheseletsa le ho hanyetsa mafome ha ka nako e ts'oanang ho fokotsa ho fafatsa. Motswako ona o atisa ho sebediswa bakeng sa ho tjheseletsa tshepe ya carbon le tshepe e sa ruseng.

Metswako ea Khase ea Binary:Argon + Haedrojene

Haeterojene e eketsa mocheso oa arc, e ntlafatsa lebelo la ho tjheseletsa, 'me e fokotsa liphoso tsa ho tjheseletsa. E bohlokoa haholo bakeng sa ho tjheseletsa li-alloy tse thehiloeng ho nickel le tšepe e sa hloekang.

Metswako ea Khase ea Ternary:Argon + Oksijene + Carbon Dioxide

Motsoako ona o kopanya melemo ea metsoako ea argon-oksijene le argon-CO₂. O fokotsa ho fafatsa, o ntlafatsa ho phalla ha letamo la ho tjheseletsa, 'me o ntlafatsa boleng ba ho tjheseletsa. O sebelisoa haholo bakeng sa ho tjheseletsa botenya bo fapaneng ba tšepe ea carbon, tšepe e nang le motsoako o tlase le tšepe e sa hloekang.

Metswako ea Khase ea Ternary:Argon + Helium + Carbon Dioxide

Motsoako ona o thusa ho ntlafatsa botsitso ba arc, o eketsa mocheso oa letamo la ho cheseletsa, le ho eketsa lebelo la ho cheseletsa. O sebelisoa ho tjheseletsa arc ea potoloho e khuts'oane le lits'ebetsong tse boima tsa ho cheseletsa, o fana ka taolo e betere holim'a oxidation.

Khetho ea Khase Litšebelisong Tse Fapaneng

Ho tjheseletsa ka Laser e Tshwarwang ka Motlakase

Litšebelisong tse fapaneng tsa ho tjheseletsa ka laser, ho khetha khase e loketseng ho bohlokoa, hobane metsoako e fapaneng ea khase e ka hlahisa boleng bo fapaneng ba ho tjheseletsa, lebelo le katleho. Mona ke litataiso tse ling tse tla u thusa ho khetha khase e nepahetseng bakeng sa ts'ebeliso ea hau e ikhethileng:

Mofuta oa Thepa ea ho Welding:

Ts'epe e sa beng le mabalihangata e sebelisaMotsoako oa Argon kapa Argon/Hydrogen.

Aluminium le Litšepe tse kopantsoeng tsa Aluminiumhangata e sebelisaArgon e Hloekileng.

Li-alloy tsa Titaniumhangata e sebelisaNaetrojene.

Litšepe tse nang le khabone e ngatahangata e sebelisaOksijene e le Khase e Thusang.

Lebelo la ho tjheseletsa le ho Petla:

Haeba ho hlokahala lebelo le phahameng la ho tjheseletsa kapa ho kenella ka botebo ha ho tjheseletsa, motswako wa kgase o ka fetolwa. Ho eketsa oksijene hangata ho ntlafatsa lebelo le ho kenella, empa ho hloka ho laolwa ka hloko ho qoba mathata a oxidation.

Taolo ea Sebaka se Amehileng ke Mocheso (HAZ):

Ho latela thepa e hloekisoang, litšila tse kotsi tse hlokang mekhoa e khethehileng ea ho sebetsana le tsona li ka hlahisoa nakong ea ts'ebetso ea ho hloekisa. Sena se ka eketsa litšenyehelo tsa kakaretso tsa ts'ebetso ea ho hloekisa ka laser.

Boleng ba ho Welded:

Metswako e meng ea khase e ka ntlafatsa boleng le ponahalo ea li-weld. Mohlala, naetrojene e ka fana ka ponahalo e ntle le boleng ba bokaholimo.

Taolo ea Meno le Lipululana:

Bakeng sa lits'ebetso tse hlokang li-weld tsa boleng bo holimo haholo, tlhokomelo e khethehileng e hloka ho lefshoa ho thehoeng ha masoba le lipululana. Khetho e nepahetseng ea khase e ka fokotsa kotsi ea liphoso tsena.

Lintho Tse Lokelang ho Nahaneloa ka Thepa le Litšenyehelo:

Khetho ea khase le eona e susumetsoa ke mofuta oa lisebelisoa le litšenyehelo. Likhase tse ling li ka hloka litsamaiso tse khethehileng tsa phepelo kapa litšenyehelo tse phahameng.

Bakeng sa lits'ebetso tse ikhethileng, ho kgothaletswa ho sebetsa le moenjiniere oa ho tjheseletsa kapa moetsi oa lisebelisoa tsa ho tjheseletsa tsa laser ea litsebi ho fumana likeletso tsa litsebi le ho ntlafatsa ts'ebetso ea ho tjheseletsa.

Hangata ho hlokahala liteko le ntlafatso e itseng pele ho khethoa motsoako oa ho qetela oa khase.

Ho latela ts'ebeliso e itseng, ho ka lekoa metsoako le liparamente tse fapaneng tsa khase ho fumana maemo a nepahetseng a ho tjheseletsa.

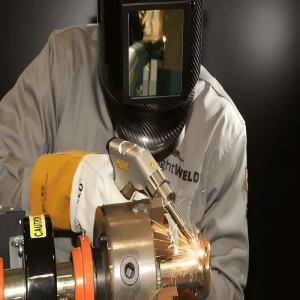

Lintho Tseo U Lokelang ho li Tseba ka: Ho Welding ka Laser e Tšoareloang ka Letsoho

Mochini o Khothaletsoang oa ho Tjhesetsa oa Laser

Ho ntlafatsa mesebetsi ea hau ea ts'ebetso ea tšepe le ea ho sebetsana le thepa, ho khetha lisebelisoa tse nepahetseng hoa hlokahala. MimoWork Laser e khothaletsaMochini oa ho tjheseletsa oa Laser o tšoaroang ka letsohobakeng sa ho kopanya tšepe ka nepo le ka katleho.

Bokgoni bo Phahameng le Matla a ho Tjhesa bakeng sa Ditshebediso tse Fapaneng tsa ho Tjhesa

Mochini oa ho tjheseletsa oa laser oa 2000W o tšoauoa ka boholo bo bonyenyane ba mochini empa boleng ba ho tjheseletsa bo benyang.

Mohloli o tsitsitseng oa laser ea fiber le thapo ea fiber e hokahaneng li fana ka phano e sireletsehileng le e tsitsitseng ea laser.

Ka matla a phahameng, lesoba la ho welding la laser le phethahetse mme le nolofalletsa ho tiisa lenonyeletso esita le bakeng sa tšepe e teteaneng.

Ho Kgona ho Fetoha ha Maemo

Ka ponahalo ea mochini o monyane le o monyenyane, mochini oa ho welder oa laser o nkehang habobebe o na le sethunya sa ho welder sa laser se ka tsamaisoang ka letsoho se bobebe ebile se loketse lits'ebetso tsa ho welder tsa laser tse ngata ka lehlakoreng lefe kapa lefe le bokaholimo bofe kapa bofe.

Mefuta e fapaneng ea boikhethelo ea li-nozzle tsa ho welder ka laser le litsamaiso tsa ho fepa ka terata ka boiketsetso li etsa hore ts'ebetso ea ho welder ka laser e be bonolo 'me e be bonolo bakeng sa ba qalang.

Ho tjheseletsa ka laser ka lebelo le phahameng ho eketsa haholo bokgoni ba tlhahiso le tlhahiso ya hao ha ka nako e ts'oanang ho nolofalletsa phello e ntle ya ho tjheseletsa ka laser.

Akaretsa

Ka bokhutšoanyane, ho tjheseletsa ka laser ho hloka ho sebedisa kgase ho sireletsa dibaka tsa ho tjheseletsa, ho laola mocheso, ho ntlafatsa boleng ba ho tjheseletsa, le ho sireletsa ditsamaiso tsa mahlo. Ho kgetha mefuta e loketseng ya kgase le diparamente tsa phepelo ke ntlha ya bohlokwa ho netefatseng tshebetso e sebetsang hantle le e tsitsitseng ya ho tjheseletsa ka laser le ho fumana diphetho tsa boleng bo hodimo tsa ho tjheseletsa. Disebediswa le ditshebediso tse fapaneng di ka hloka mefuta e fapaneng le dikarolwana tse fapaneng ho fihlela ditlhoko tse itseng tsa ho tjheseletsa.

Ikopanye le rona kajenoho ithuta haholoanyane ka li-cutter tsa rona tsa laser le kamoo li ka ntlafatsang ts'ebetso ea hau ea tlhahiso ea ho seha.

Lihokelo tse Amanang

Na ho na le Mehopolo efe kapa efe ka Mechini ea ho Welding ea Laser?

Nako ea poso: Pherekhong-13-2025