Liphiri tsa ho Welding ka Laser: Lokisa Mathata a Tloaelehileng Hona Joale!

Selelekela:

Tataiso e Felletseng ea ho rarolla mathata

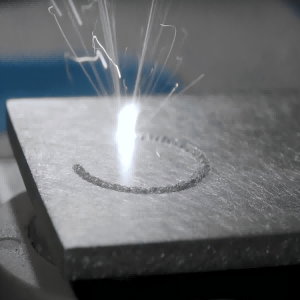

Mechini ea ho Tjhesetsa ea Laser e Tšoaroang ka Motlakase

Mochini oa ho tjheseletsa oa laser o tšoaroang ka letsoho o fumane botumo bo boholo liindastering tse fapaneng ka lebaka la ho nepahala ha oona le katleho ea oona.

Leha ho le jwalo, jwalo ka mokhoa ofe kapa ofe o mong wa ho tjheseletsa, ha o sireletsehe ho mathata le mathata a ka hlahang nakong ya tshebetso ya ho tjheseletsa.

Ena e felletsengho rarolla mathata ka ho tjheseletsa ka lasere ikemiselitse ho rarolla mathata a tloaelehileng a kopanang le mechini ea ho tjheseletsa ea laser e tšoaroang ka letsoho, mathata a amanang le ho tjheseletsa, le litaba tse amanang le boleng ba ho tjheseletsa.

Lethathamo la Dikahare:

Liphoso le Litharollo tsa Mochini oa ho Wellisa oa Laser Pele ho Qala

1. Lisebelisoa li ke ke tsa Qala (Matla)

Tharollo: Hlahloba hore na switch ea thapo ea motlakase e sebetsa.

2. Mabone a ke ke a bonesoa

Tharollo: Hlahloba boto ea pele ho mollo ka motlakase oa 220V kapa ntle le oona, hlahloba boto ea lebone; fuse ea 3A, lebone la xenon.

3. Leseli le bonesitsoe, ha ho na laser

Tharollo: Hlokomela hore karolo ea mochini oa ho tjheseletsa oa laser o tšoaroang ka letsoho oa pontšo e kantle ho khanya e tloaelehile. Taba ea pele, hlahloba hore karolo ea CNC ea konopo ea laser e koetsoe, haeba e koetsoe, ebe u bula konopo ea laser. Haeba konopo ea laser e tloaelehile, bula sebopeho sa ponts'o ea taolo ea linomoro ho bona hore na tlhophiso ea khanya e tsoelang pele, haeba ho se joalo, joale u fetole ho khanya e tsoelang pele.

Mathata le Litokiso tsa ho Welder ea Laser ea Mokhahlelo oa ho Welding

Sehokelo sa Weld se Setšo

Khase e sireletsang ha e bulehe, ha feela khase ea naetrojene e butsoe, e ka rarolloa.

Tsela eo khase e sireletsang e tsamaeang ka eona e fosahetse, tsela eo khase e sireletsang e tsamaeang ka eona e lokela ho etsoa ka tsela e fapaneng le tsela eo karolo ea mosebetsi e tsamaeang ka eona.

Khaello ea ho Kena ha Litšepe ho Welding

Ho hloka matla a laser ho ka ntlafatsa bophara ba pulse le hona joale.

Lense e shebaneng le pono ha se tekanyo e nepahetseng, ho lokisa palo e shebaneng le pono haufi le boemo ba ho shebana le pono.

Ho Fokotseha ha Lebone la Laser

Haeba metsi a pholileng a silafetse kapa a sa nkeloa sebaka ka nako e telele, a ka rarolloa ka ho nkela metsi a pholileng sebaka le ho hloekisa tube ea khalase ea UV le lebone la xenon.

Lense e shebaneng kapa diaphragm ea lense e senyehileng kapa e silafetse, e lokela ho nkeloa sebaka kapa ho hloekisoa ka nako.

Suthisa lesetara tseleng e kgolo ya optical, lokisa diaphragm ya pontsho yohle le semi-reflection tseleng e kgolo ya optical, hlahloba mme o potolohe sebaka seo ka pampiri ya setshwantsho.

Lesetara ha e ntshe lethopong la koporo le ka tlase ho hlooho e shebaneng. Lokisa diaphragm e bontshang kganya ya di-degree tse 45 e le hore lesetara e ntshe lethopong le bohareng ba lethopong la kgase.

Tharollo ea Mathata a Boleng ba ho Welding ka Laser

1. Phatsa

Kamora ho qeta ho tjheseletsa ka laser, dikarolwana tse ngata tsa tshepe di hlaha hodima thepa kapa karolo ya mosebetsi, di hoketswe hodima thepa kapa karolo ya mosebetsi.

Lebaka la ho fafatsa: bokaholimo ba thepa e sebetsitsoeng kapa karolo ea mosebetsi ha boa hloeka, ho na le oli kapa litšila, e ka boela ea bakoa ke ho fetoha ha lera la galvanized.

1) Ela hloko ho hlwekisa thepa kapa karolo ea mosebetsi pele o tjheseletsa ka laser;

2) Ho fafatsa ho amana ka ho toba le bongata ba matla. Phokotso e loketseng ea matla a ho tjheseletsa e ka fokotsa ho fafatsa.

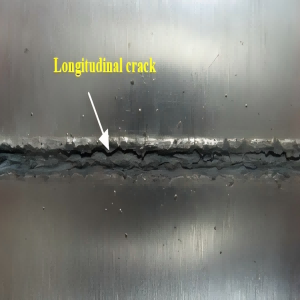

2. Mapetso

Haeba lebelo la ho phodisa la sesebediswa sa ho sebetsa le potlakile haholo, mocheso wa metsi a phodisang o lokela ho lokiswa hodima sesebediswa ho eketsa mocheso wa metsi.

Ha sekgeo sa ho lekana ha mosebetsi se le seholo haholo kapa ho na le burr, ho nepahala ha ho sebetsa ha mosebetsi ho lokela ho ntlafatswa.

Mosebetsi ha o so hlwekiswe. Tabeng ena, mosebetsi o hloka ho hlwekiswa hape.

Sekhahla sa phallo ea khase e sireletsang se seholo haholo, e leng se ka rarolloang ka ho fokotsa sekhahla sa phallo ea khase e sireletsang.

3. Masoba a holim'a Weld

Mabaka a ho hlahisa porosity:

1) Letangoana le qhibilihisitsoeng la ho welding ka laser le tebile ebile le lesesaane, 'me sekhahla sa ho pholisa se potlakile haholo. Khase e hlahisoang letamong le qhibilihisitsoeng e liehile haholo hore e ka tlala, e leng se ka lebisang habonolo ho thehoeng ha masoba.

2) Bokaholimo ba weld ha bo hloekisoe, kapa mouoane oa zinki oa lakane e entsoeng ka galvanized oa fetoha mouoane.

Hloekisa bokaholimo ba mosebetsi le bokaholimo ba weld pele o tjheseletsa ho ntlafatsa ho fetoha ha zinki ha e futhumatsoa.

4. Ho kheloha ha ho tjheseletsa

Tšepe e welded e ke ke ea tiea bohareng ba sebopeho sa manonyeletso.

Lebaka la ho kheloha: Sebaka se sa nepahalang nakong ea ho tjheseletsa, kapa nako e sa nepahalang ea ho tlatsa le ho hokahanya terata.

Tharollo: Fetola boemo ba ho tjheseletsa, kapa nako ea ho tlatsa le boemo ba terata, hammoho le boemo ba lebone, terata le ho tjheseletsa.

5. Ho Kena ha Letlalo la ho Sila ka Holimo, le Hlahang Haholo-holo Pakeng tsa Mealo

Ho koalloa ha slag holim'a metsi ho baka:

1) Ha ho tjheseletsa ka diphaseje tse ngata tse nang le mekhahlelo e mengata, lera le pakeng tsa mekhahlelo ha le hlweke; kapa bokaholimo ba tjheseletsa ya pele ha bo bataletse kapa bokaholimo ba tjheseletsa ha bo fihlelle ditlhoko.

2) Mekhoa e sa nepahalang ea ts'ebetso ea ho tjheseletsa, joalo ka matla a tlase a ho kenya ho tjheseletsa, lebelo la ho tjheseletsa le potlakile haholo.

Tharollo: Khetha motlakase o loketseng oa ho tjheseletsa le lebelo la ho tjheseletsa, 'me seaparo sa interlayer se lokela ho hloekisoa ha ho tjheseletsa multilayer ka multilayer. Sila 'me u tlose weld ka slag holim'a metsi, 'me u etse weld haeba ho hlokahala.

Lisebelisoa tse ling - Sesepa sa Laser se Tšoaroang ka Letsoho Mathata le Litharollo tse Tloaelehileng

1. Ho hloleha ha Sesebelisoa sa Tšireletso ea Polokeho

Disebediswa tsa tshireletso ya polokeho ya mochini wa ho tjheseletsa ka laser, tse kang lemati la kamore ya ho tjheseletsa, sensor ya phallo ya kgase, le sensor ya mocheso, di bohlokwa bakeng sa tshebetso ya wona e nepahetseng. Ho hloleha ha disebediswa tsena ho ke ke ha sitisa tshebetso e tlwaelehileng ya disebediswa feela empa hape ho ka baka kotsi ya kotsi ho mosebedisi.

Haeba ho ka ba le phoso ka disebediswa tsa tshireletso ya polokeho, ho bohlokwa ho emisa tshebetso hanghang mme o ikopanye le ditsebi bakeng sa ho di lokisa le ho di nkela sebaka.

2. Ho Jamming ha Sesebelisoa sa ho Fepa ka Terata

Haeba ho na le jeme ea sesebelisoa sa ho fepa ka terata boemong bona, ntho ea pele eo re hlokang ho e etsa ke ho hlahloba hore na nozzle ea sethunya e koetsoe, mohato oa bobeli ke ho hlahloba hore na sesebelisoa sa ho fepa ka terata se koetsoe 'me ho na le ho potoloha ha diski ea silika ho tloaelehile.

Akaretsa

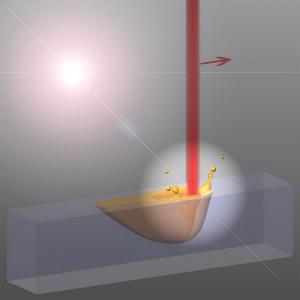

Ka ho nepahala ho sa bapisoeng, lebelo le ho tenyetseha, ho tjheseletsa ka laser ke theknoloji ea bohlokoa liindastering tse kang tsa likoloi, tsa lifofane le tsa elektroniki.

Leha ho le jwalo, diphoso tse fapaneng di ka hlaha nakong ya tshebetso ya ho tjheseletsa, ho kenyeletswa le masoba, ho petsoha, ho fafatsa, sefaha se sa tlwaelehang, ho tjha, ho fetoha ha sebopeho le ho qhibilihisa.

Sekoli se seng le se seng se na le sesosa se itseng, joalo ka Litlhophiso tse sa lokelang tsa laser, litšila tsa thepa, likhase tse sa lekaneng tsa tšireletso, kapa manonyeletso a sa tsamaellaneng hantle.

Ka ho utloisisa mefokolo ena le lisosa tsa eona tsa motheo, bahlahisi ba ka kenya tšebetsong litharollo tse reriloeng, tse kang ho ntlafatsa liparamente tsa laser, ho netefatsa hore manonyeletso aa lekana hantle, ho sebelisa likhase tse sireletsang tsa boleng bo holimo, le ho sebelisa mekhoa ea pele le ea kamora ho tjheseletsa.

Koetliso e nepahetseng ea mosebelisi, tlhokomelo ea lisebelisoa tsa letsatsi le letsatsi le tlhokomelo ea ts'ebetso ka nako ea sebele li ntlafatsa boleng ba ho tjheseletsa le ho fokotsa liphoso.

Ka mokhoa o akaretsang oa thibelo ea liphoso le ntlafatso ea ts'ebetso, ho tjheseletsa ka laser ho fana ka li-weld tse matla, tse tšepahalang le tsa boleng bo holimo tse fihlelang maemo a thata a indasteri.

Ha o tsebe hore na o khetha mofuta ofe oa mochini oa ho tjheseletsa oa laser?

U hloka ho tseba: Mokhoa oa ho khetha mochini oa laser o tšoaroang ka letsoho

Bokgoni bo Phahameng le Matla a ho Tjhesa bakeng sa Ditshebediso tse Fapaneng tsa ho Tjhesa

Mochini oa ho tjheseletsa oa laser oa 2000W o tšoauoa ka boholo bo bonyenyane ba mochini empa boleng ba ho tjheseletsa bo benyang.

Mohloli o tsitsitseng oa laser ea fiber le thapo ea fiber e hokahaneng li fana ka phano e sireletsehileng le e tsitsitseng ea laser.

Ka matla a phahameng, lesoba la ho welding la laser le phethahetse mme le nolofalletsa ho tiisa lenonyeletso esita le bakeng sa tšepe e teteaneng.

Ho Kgona ho Fetoha ha Maemo

Ka ponahalo ea mochini o monyane le o monyenyane, mochini oa ho welder oa laser o nkehang habobebe o na le sethunya sa ho welder sa laser se ka tsamaisoang ka letsoho se bobebe ebile se loketse lits'ebetso tsa ho welder tsa laser tse ngata ka lehlakoreng lefe kapa lefe le bokaholimo bofe kapa bofe.

Mefuta e fapaneng ea boikhethelo ea li-nozzle tsa ho welder ka laser le litsamaiso tsa ho fepa ka terata ka boiketsetso li etsa hore ts'ebetso ea ho welder ka laser e be bonolo 'me e be bonolo bakeng sa ba qalang.

Ho tjheseletsa ka laser ka lebelo le phahameng ho eketsa haholo bokgoni ba tlhahiso le tlhahiso ya hao ha ka nako e ts'oanang ho nolofalletsa phello e ntle ya ho tjheseletsa ka laser.

Lintho tseo u lokelang ho li tseba ka: Ho tjheseletsa ka laser ka letsoho

Haeba u thabetse video ena, ke hobane'ng ha u sa nahane ka eonaU ingolisa ho Channel ea rona ea Youtube?

Likopo tse Amanang tseo U ka li Thahasellisang:

Theko e 'Ngoe le e 'Ngoe e Lokela ho Tsebisoa Hantle

Re ka Thusa ka Tlhahisoleseling e Batsi le Keletso!

Nako ea poso: Pherekhong-16-2025