Ho Welding ka Laser khahlanong le ho Welding ka TIG: Se Fetohileng ka 2024

Ho Welding ka Laser e Tšoaroang ka Letsoho ke Eng?

Ho Wellisa ka Laser e Tšoarellang ka Mochini

Ho tjheseletsa ka laser e tšoaroang ka letsohoe sebelisa sesebelisoa sa laser se nkehang habobebe ho kopanya thepa, hangata litšepe.

Ho tjheseletsa ka laser e tšoaroang ka letsoho ho lumellae kholoanyaneho kgona ho tsamaisa le ho nepahala,

'Me e hlahisa weld ea boleng bo holimo, e hloekileng e nang lebonyaneho kenya mocheso,

Ho fokotsaho sotha le tlhoko ea ts'ebetso e kholo ea kamora ho chesetsoa.

Basebetsi ba ka fetola matla le lebelo la laser habonolo,

Ho nolofalletsalitlhophiso tse etselitsoeng uenabakeng sa thepa le botenya bo fapaneng.

Lethathamo la Dikahare:

Ho Hloekisa ka ho Weld ka Laser ke Eng?

Bohlokoa ba Bohloeki ho Welding

Ho Hloekisa Pele ho Weld bakeng sa ho Weldela TIG

Ha ho tluoa tabeng ea ho tjheseletsa,

Bohloeki bo bapala karolo ea bohlokoa ho fihlellengboleng bo phahamengliphetho.

Molao-motheo ona o sebetsa ho ho tjheseletsa ha TIG le ho tjheseletsa ka laser ka letsoho,

Empa mekhoa ea ho lokisa thepa e fapana haholo.

Bakeng sa ts'ebetso efe kapa efe ea ho tjheseletsa,

Boteng ba lintho tse silafatsang tse kang mafome, pente le mafura

Nkaho sekisetsa ka matlabotšepehi ba weld.

Litšila tsena li ka lebisa manonyeletsong a fokolang, masoba le likoli tse ling

Seo se fokolisa matla a sehlahisoa sa ho qetela.

Ena ke tsela eo uLOKELA HO LOKELASebetsana le Litšila tsena:Ho Hloekisa ho Weld ka Laser.

Ho Welding ka Laser vs ho Welding ka TIG: Ho Hloekisa ho Welding ka Laser

Libaka tse Hloekisitsoeng li Hlahisa Li-Weld tsa Boleng bo Holimo

Ho Hloekisa ka ho Weld ka Laser bakeng sa ho Hloekisa ka Laser ka Matsoho

Leha ho tjheseletsa ha TIG ho itshetlehile hodimabuka ea litaelomekhoa ea ho hloekisa joalo ka ho sila ka sekhutlo le ho hlakola acetone,

Ho tjheseletsa ka laser e tšoaroang ka letsoho ho fana ka ho eketsehilengbonolomokhoa o mong o nang le bokgoni ba wona bo kopaneng ba ho hlwekisa.

Tlhahiso ena ha e ntlafatse bokgoni feela

Empa hape e netefatsa hore ts'ebetso ea ho tjheseletsa e sebetsa hantle kamoo ho ka khonehang,

Qetellong ho lebisa liphellong tse betere.

Litokisetso tsa ho tjheseletsa tsa TIG:

Ka TIG (Khase e se nang thuso ea Tungsten) ho tjheseletsa, ho lokisa ka hloko hoa hlokahala.

Pele o qala ts'ebetso ea ho tjheseletsa,

Ho tloaelehile ho sebelisali-grinder tsa angleho tlosa mafome kapa masela a koahelang holim'a thepa.

Ho hlwekisa hona ka mechine ho thusa ho netefatsa hore bokaholimo ha bo na litšila.

Ka mor'a sena, hlakola ka botlalo kaasetonehangata e etsoa.

Acetone ke tharollo e matla e etsang horee tlosa ka katlehomafura afe kapa afe a setseng kapa lintho tse silafatsang,

Ho siea sebaka se hloekileng bakeng sa ho tjheseletsa.

Ts'ebetso ena ea ho hloekisa ea mehato e 'meli e ka nka nako e telele,

Empa ke habohlokoa bakeng sa ho fumana weld e matla le e tšoarellang.

Ho Lokisetsa ho Wellisa ka Laser e Tšoaretsoeng ka Motlakase

Ka lehlakoreng le leng, ho tjheseletsa ka laser ka letsoho ho fana ka dihlahiswa

Tse ling hapemokhoa o nolofalitsoengho lokisa bokaholimo.

Ka3-ho-1Ka ho welder ka laser, ts'ebetso e ba bonolo haholo.

Mechini ena e tsoetseng pele hangata e tla e na leli-nozzle tse fapanyetsanoang

Seo se dumella ho hlwekiswa ha bokaholimo pele ho hokellwa.

Ho fapana le mekhoa ea setso, moo ho hlokahalang lisebelisoa tse arohaneng le lintho tse hloekisang,

Ba tjheseletsang ka laser ba ka hlwekisa bokaholimo ntle le mathata ka lehlasedi la laser le tsepamisitsoeng.

Sena ha se boloke nako feela empa se boetse se fokotsapalo ea lisebelisoae hlokahalang sebakeng seo.

Ho Welding ka Laser khahlanong le ho Welding ka TIG ho Fetohile ka 2024

Ikopanye le Rona bakeng sa Tse ling tse eketsehileng mabapi le Sistimi ea ho Welding ea Laser e Tšoaretsoeng ka Letsoho

Hobaneng ho Sebedisa Khase e Sireletsang ho Welding?

Khetho ea Khase e Sireletsang e Phetha Karolo ea Bohlokoa

Khase e Sireletsang bakeng sa ho Welding ea TIG: Argon

Ha ho tluoa tabeng ea ho tjheseletsa,

Khetho ea khase e sireletsang ke ea bohlokoa bakeng sa ho netefatsa liphetho tsa boleng bo holimo.

Haholo-holo, ho welding ha TIG le ho welding ha laser ka letsoho ho na le litlhoko le likhetho tse fapaneng.

Ha ho tluoa tabeng ea ho sireletsa likhase, ho ama ts'ebetso le litšenyehelo.

Ho Sireletsa Khase hoHo tjheseletsa TIG

Ka TIG (Tungsten Inert Gas) tjheseletsa,

Khase e sireletsang e sebelisoang haholo kebohloeki bo phahamengargon.

Khase ena e ntle e khethiloe ka lebaka la bokhoni ba eona bo botle ba hosireletsa letamo la ho cheseletsa

Ho tsoa tšilafatsong ea sepakapaka, haholo-holo oxidation.

Ho ntša oksijene ho ka lebisa holiphosoka har'a weld, joalo ka masoba le manonyeletso a fokolang,

E lenglitumellanobotšepehi bohle ba tšepe.

Ka lebaka la katleho ea eona,

Ho tjheseletsa TIG hangata ho hlokae tsoelang pelephepelo ea argon nakong eohle ea ts'ebetso ea ho tjheseletsa.

Leha ho le jwalo, argon e ka ba theko e boima haholo, e leng se lebisang ditjeong tse hodimo tsa tshebetso,

Haholo-holo mererong e hlokang ho tjheseletsa ka bongata.

Ho Sireletsa Khase hoHo tjheseletsa ka Laser e Tshwarwang ka Motlakase

Khase e Sireletsang e 'Ngoe bakeng sa ho Welding ka Laser: Naetrojene

Ka lehlakoreng le leng, ho tjheseletsa ka laser ka letsoho hangata ho sebedisa naetrojene e le kgase e sireletsang.

Naetrojene ha se feelae sebetsa hantleho thibela oxidation

Empa hape e bohlokoa le ho fetae bolokang tjheleteho feta argon.

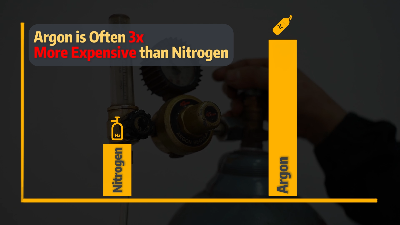

Phapang ea theko e ka ba kholo haholo;

Naetrojene e ka ba hoo e ka bangmakhetlo a mararoe theko e tlase ho feta argon e hloekileng haholo.

Sena se etsa hore naetrojene e be khetho e hohelang bakeng sa likhoebo tse batlang ho fokotsa litšenyehelontle le ho itelaboleng.

Ho Welding ha TIG khahlanong le Laser: Likhetho tsa Khase ea ho Sireletsa

Finyella Poloko Ha U ntse U Boloka Boleng

Papiso ea Theko Pakeng tsa Argon le Naetrojene

Ho fetohela ho naetrojene ho tjheseletsa ka laser ka letsoho ho fana ka dihlahiswatse 'maloamelemo

Lipholoso tsa Litšenyehelo:

Kaea bohlokoaphapang ea theko pakeng tsa argon le naetrojene,

Ho sebelisa naetrojene ho ka lebisa polokong e kholo ha nako e ntse e ea.

Sena kee na le thuso haholo-holobakeng sa merero kapa likhoebo tse kholo

Ba etsang mesebetsi ea ho tjheseletsa khafetsa.

Tšireletso e Sebetsang:

Naetrojene e fana katšireletso e lekanengkhahlanong le oxidation,

Ho netefatsa hore weld e lula e le tenge hloekile ebile e matla.

Leha argon e tsebahala ka tšireletso ea eona e phahameng,

Naetrojene e ntse e le tengkhetho e sebetsange finyellang litlhoko tsa lits'ebetso tse ngata tsa ho tjheseletsa ka katleho.

Bapisa Mokhoa oa ho Welding: Ho Welding ka Laser vs TIG

Ho Ela Hloko Mokhoa oa Theknoloji ho Finyella Liphetho tse Molemohali

Sekhutlo se Nepahetseng bakeng sa ho Welding ka Laser: Dikereiti tse 45

Hang ha khase e sireletsang e phalla hantle,

Ke nako ea ho tsepamisa maikutlo ts'ebetsong ea 'nete ea ho tjheseletsa.

Ho tjheseletsa TIG (Tungsten Inert Gas) le ho tjheseletsa ka laser ka letsoho ka bobedi.

Hlokamekhoa e nepahetsengho fihlela liphetho tsa boleng bo holimo,

Leha ho le jwalo, di fapana ka ditlhoko le mekgwa ya tsona e ikgethang.

Ho tjheseletsa TIGMokhoa

Sepheo sa ho boloka electrode e le maemong asebaka le lebelo le nepahetsengho theha le ho etella pele letamo la ho tjheseletsa.

Sebaka sena se ka fapana ho latela thepa le botenya bo tjheselletswang.

Ho boloka sekhutlo se nepahetseng, hangata ho potolohamocheso oa likhato tse 15 ho isa ho tse 20,

E thusa ho fihlella weld e tsitsitseng le e hloekileng.

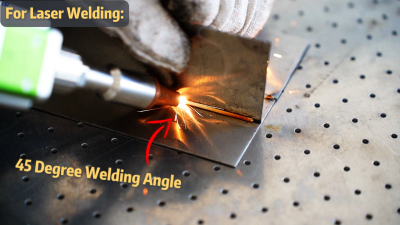

Ho tjheseletsa ka Laser e Tshwarwang ka MotlakaseMokhoa

E 'ngoe ea melemo ea ho tjheseletsa ka laser ke bokhoni ba ho beha sekhutlo se tsitsitseng

Hangata ho potolohaDi-degree tse 45, e leng se nolofalletsang tsamaiso ea ts'ebetso ea ho tjheseletsa.

Hang ha sekhutlo se se se behiloe, hlokomelalebelo le tsitsitsengke senotlolo.

Ho tjheseletsa ka laser e tšoaroang ka letsoho hangata ho hlahisamocheso o fokolangha ho bapisoa le ho tjheseletsa ha TIG.

Sena se bolela hore ho na lekotsi e fokolang ea ho sotha kapa ho sotha,

Ho e etsa hore e be ntle bakeng sa mosebetsi o nepahetseng holim'a thepa e tšesaane.

Matla a ho Weld a Laser khahlanong le TIG: Ho Hlalosa Litšōmo

Khopolo e Fosahetseng e Tloaelehileng Mabapi le ho Welding ka Laser

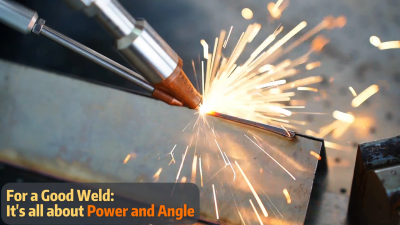

Bakeng sa ho Wellisa ka Laser e Tšoaretsoeng ka Motlakase e Molemo: Matla le Angle

E 'ngoe ea melemo ea bohlokoa ea ho tjheseletsa ka laser ka letsoho ke bokhoni ba eona ba ho fana ka matla a kopanenghantlemoo ho hlokahalang.

Kalitlhophiso tsa matla a nepahetsenglesekhutlo se nepahetseng

Hangata ho potolohaDi-degree tse 45, ho tjheseletsa ka laser ho ka fihlella ho kenella le matla a babatsehang.

Tlhahiso e Nepahetseng ea Matla

Ho beha matla a sesebelisoa sa ho welder ka laser ho bohlokoa.

Matla a fokolang haholo a ka fella kaho kenella ho sa lekaneng, e leng se lebisang ho li-weld tse fokolang.

Ka lehlakoreng le leng, boemo bo loketseng ba matla bo dumella laser ho qhibilihisa thepa ka katleho, e leng se etsang hore ho be le manonyeletso a matla.

Ho sebelisa lisebelisoa tse sa sebetseng hantle ho ke ke ha fana ka litholoana tse lakatsehang.

Ho Welding ka Laser ea TIG le ea Handheld ka bobeli lia sebetsa hantle

Na u batla ho ithuta ho eketsehileng ka ho tjheseletsa ka laser e tšoaroang ka letsoho?

Ho Welsha ka Laser e Tšoaroang ka Letsoho: Mokhoa oa ho Hlokomela Lisebelisoa

Tlhokomelo e Loketseng le Tlhokomelo e Ncha li tla netefatsa Tlhahiso le Botšepehi

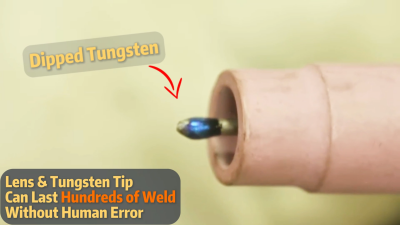

Na u ne u tseba hore ho tjheseletsa TIG (Tungsten Inert Gas) le ho tjheseletsa ka laser ka letsoho li arotsoe ka lihlopha tse peli:

Mekhoa ea ho tjheseletsa e sa sebelisoeng?

Sena se bolela hore, tlas'a maemo a matle le ka tlhokomelo e nepahetseng,

Likarolo tsa bohlokoa tse sebelisoang lits'ebetsong tsena li ka nka nako e telele

Ntle le ho hloka phetolo khafetsa.

Likarolo tse sa Sebedisweng

Phoso ea Tungsten e qoelitsoeng bakeng sa ho tjheseletsa TIG

Electrode ea tungsten ke karolo ea bohlokoa ho tjheseletsa ea TIG.

Ho fapana le li-electrode tse ka sebelisoang tse sebelisoang mekhoeng e meng ea ho tjheseletsa,

tse kang ho tjheseletsa ha MIG, elektrode ea tungstenha e qhibilihenakong ea ts'ebetso ea ho tjheseletsa.

Ho e-na le hoo, e boloka botšepehi ba eona, e lumella tšebeliso ea nako e telele.

Leha ho le jwalo, electrode e ka silafala kapa ya "inwetswa" haeba e ka tshwarwa.haufi haholo le letamo la ho tjheseletsa le qhibilihisitsoeng.

Maemong a joalo, e tlameha ho rengoa le ho silwa ho tsosolosa ntlha ea eona e bohale le ts'ebetso e sebetsang hantle.

Tlhokomelo e tloaelehilengea electrode ea tungsten ke ea bohlokoa bakeng sa ho fihlela li-weld tse hloekileng le tsa boleng bo holimo.

Ho Lokisetsa ho Wellisa ka Laser e Tšoaretsoeng ka Motlakase

Lense ea Laser bakeng sa Tlhokomelo ea ho Welding ea Laser e Tšoareloang ka Letsoho

Ha ho tjheselletsoa ka laser ka letsoho, lense ea laser e sebetsa e le ntlha ea bohlokoa bakeng sa lehlaseli la laser.

Lense e behiloeng hantle e ka nka nako e telele, e fana ka ts'ebetso e tsitsitseng.

Leha ho le jwalo, haeba lense e petsoha ka lebaka la ho beha sebaka se sa lokelang kapa ho pepesehela mocheso o feteletseng

E tla hloka ho nkeloa sebaka.

Ho boloka lense e le boemong bo botle ke habohlokoa,

Kaha esita le tshenyo e nyane e ka ama ho nepahala le katleho ya laser, e leng se lebisang ho di-weld tse sa lokelang.

Na u batla Tataiso e Felletseng ea Litšupiso bakeng sa ho Welding ka Laser e Tšoaretsoeng ka Letsoho?

Ho tjheseletsa ka laser e tšoaroang ka letsoho ho fana ka melemo e mengata,

Empa hape ho hloka tlhokomelo e hlokolosi melaong ea polokeho.

Sengoloa sena se tla hlahloba lintlha tsa bohlokoa tsa polokeho bakeng sa ho tjheseletsa ka laser ka letsoho.

Hape ho fana ka dikgothaletso mabapi le kgetho ya kgase e sireletsang le dikgetho tsa terata ya ho tlatsa bakeng sa mefuta e tlwaelehileng ya tshepe.

Na ho Welda ka Laser ho Matla joalo ka ho Welda ka TIG?

Ho tjheseletsa ka laserle ho welding ha TIG (Tungsten Inert Gas) ka bobedi di tsebahala ka ho nepahala ha tsona le boleng ba tsona ba ho kopanya tshepe.

Empa li kopana joang mabapi le matla?

Videong ena, re tla teba ka ho teba liphapang tsa bohlokoa hotshebetso ya ho tjheseletsa,ho lumellana ha lintho tse bonahalangleho tšoarella ka kakaretsopakeng tsa ho tjheseletsa ka laser le TIG.

Ho Wellisa ka Laser ea Faeba e Tšoaretsoeng ka Letsoho (Ho Wellisa ka Laser e Tšoaretsoeng ka Letsoho)

Keketso ea Bohlokoa Sebakeng sa ho Weld sa Laser se Tšoaroang ka Letsoho

Sehokelo sa ho Welda sa Laser se Senyenyane se Etsa Hore ho Welda ho be le Theko e Tlase le e Bolokehileng

Ka ponahalo e nyane le e nyane ea mochini.

Mochini o nkehang habobebe oa ho welda ka laser o na le sethunya sa ho welda ka laser se ka tsamaisoang ka letsoho see bobebe.

E loketse lits'ebetso tsa ho tjheseletsa ka laser e ngata hosekhutlo sefe kapa sefelebokaholimo.

Mefuta e fapaneng ea li-nozzle tsa laser tse ka khethoang.

Sistimi ea ho fepa ka terata e iketsang e ikhethelang e etsa hore ts'ebetso ea ho tjheseletsa ka laser e be bonolo 'me e be bonolo bakeng sa ba qalang.

Lintho tse 5 ka ho Welding ka Laser (Tseo U li Fositseng)

Haeba u thabetse video ena, ke hobane'ng ha u sa nahane ka eonaU ingolisa ho Channel ea rona ea Youtube?

Likopo tse Amanang tseo U ka li Thahasellisang:

Ho Weld ka Laser e Tšoaroang ka Motlakase ke Khetho e Molemohali bakeng sa Mesebetsi ea ho Weld ka Matsoho

'Me Bokamoso bo Qala ka Uena!

Nako ea poso: Loetse 14-2024