Tataiso e Felletseng ea Lesela la Sefahla sa ho Seha ka Laser:

Mefuta, Melemo le Litšebeliso

Selelekela:

Lintho tsa Bohlokoa tseo U Lokelang ho li Tseba Pele U Itlhapela

Masela a sefe a bapala karolo ea bohlokoa liindastering tse ngata tse fapaneng, ho tloha ho sefa metsi le moea ho ea ho meriana le ts'ebetso ea lijo. Ha likhoebo li ntse li batla ho ntlafatsa bokhoni, ho nepahala le ho iketsetsa tlhahiso ea lesela la sefe, lesela la sefe le sehang ka laser le hlahile e le tharollo e ratoang. Ho fapana le mekhoa ea setso ea ho seha, lesela la sefe le sehang ka laser le fana ka tekanyo e phahameng ea ho nepahala, lebelo le tšenyo e fokolang ea thepa, e leng se etsang hore e be khetho e ntle bakeng sa ho seha masela a sefe a entsoeng ka thepa e fapaneng joalo kapoliester, naelonelemasela a sa lohiloeng.

Sehloohong sena, re tla shebisisa mefuta e fapaneng ea lesela la sefe le hore na lesela la sefe le sehang ka laser le sebetsa joang linthong tse fapaneng. U tla bona hore na ke hobane'ng ha e se e fetohiletharollo e tsebahalang haholo bakeng sa ho hlahisa boleng bo holimo, lihlahisoa tsa ho sefa tse ikhethilengRe tla boela re arolelane temohisiso e tsoang litekong tsa rona tsa morao tjena ka thepa e kang foam le polyester, re u fe mehlala ea sebele ea kamoo lesela la sefe la ho seha ka laser le ka ntlafatsang katleho le botsitso tlhahisong.

Mokhoa oa ho Seha Lesela la Sefa ka Laser | Mochini oa ho Seha ka Laser bakeng sa Indasteri ea ho Sefa

Tloong videong ho tla hlahloba mokhoa oa ho seha ka laser ka lesela la sefe. Tlhokahalo e phahameng ea ho seha ka nepo e etsa hore mochini oa ho seha ka laser o tume indastering ea ho seha.

Lihlooho tse peli tsa laser li ntlafatsa tlhahiso haholoanyane, li eketsa lebelo la ho seha ha li ntse li netefatsa boleng.

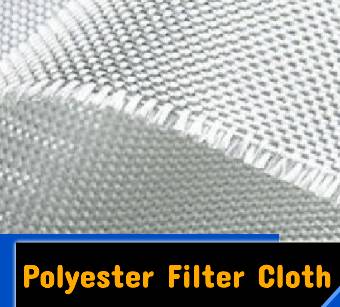

1. Lesela la Sefe ea Polyester:

• Tšebeliso:Lesela la sefe la polyester ke e 'ngoe ea thepa e sebelisoang haholo ho sefeng ka lebaka la ho tšoarella ha lona, ho hanyetsa lik'hemik'hale le bokhoni ba ho mamella mocheso o phahameng.

•Likopo:Hangata e sebelisoa lits'ebetsong tsa ho sefa moea, kalafo ea metsi le lits'ebetsong tsa ho sefa tsa indasteri.

•Melemo ea ho Seha ka Laser:Polyester e tsamaisana hantle lelesela la filtara la ho itšeha ka laserhobane e hlahisa mathoko a hloekileng le a nepahetseng. Laser e boetse e koala mathoko, e thibela ho taboha le ho ntlafatsa matla a lesela ka kakaretso.

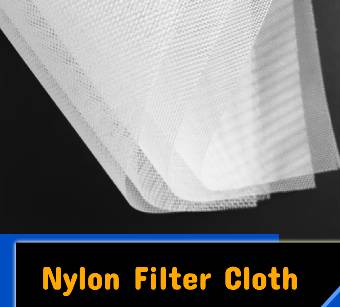

2. Lesela la Sefe ea Nylon:

• Tšebeliso:Lesela la sefe la nylon le tsebahala ka ho tenyetseha ha lona le ho tiea, le loketse ho sebelisoa ka thata ho sefa, joalo ka indastering ea lik'hemik'hale kapa lefapheng la lijo le lino.

•Likopo:E sebediswa hangata bakeng sa ho sefa ka dikhemikhale, kalafo ya metsi, le ho sefa ka dihlahiswa tsa dijo.

•Melemo ea ho Seha ka Laser:Matla a Nylon le ho hanyetsa ho aparoa ha eona li etsa hore e be khetho e ntle bakeng salesela la filtara la ho itšeha ka laserLaser e netefatsa mathoko a boreleli, a koetsoeng a bolokang botsitso ba thepa le thepa ea ho sefa.

3. Lesela la Sefe ea Polypropylene:

• Tšebeliso:Polypropylene e tsebahala ka ho hanyetsa lik'hemik'hale hantle haholo, e leng se etsang hore e be ntle bakeng sa ho sefa lik'hemik'hale tse mabifi kapa lintho tse chesang haholo.

•Likopo:E sebelisoa ho sefa meriana, ho sefa liindastering, le ho sefa metsi.

•Melemo ea ho Seha ka Laser: Lesela la filtara la ho itšeha ka laserjoalo ka polypropylene e lumella ho seha ka nepo le meralo e rarahaneng ntle le ho senya thepa. Meeli e koetsoeng e fana ka botsitso bo betere ba sebopeho, e leng se etsang hore e lokele lits'ebetso tsa bohlokoa.

4. Lesela la Sefe e sa Lohiloeng:

• Tšebeliso:Lesela la sefe le sa lohiloeng le bobebe, le tenyetseha ebile le theko e tlase. Le sebelisoa lits'ebetsong moo bonolo ba tšebeliso le khatello e tlase li leng bohlokoa.

•Likopo:E sebelisoa ho sefeng likoloi, moea le lerōle, hammoho le lihlahisoa tsa sefe tse lahloang.

•Melemo ea ho Seha ka Laser:Masela a sa lohiloeng a ka baho seha ka laserka potlako le ka bokgabane.Lesela la filtara la ho itšeha ka lasere na le mekhoa e mengata haholo bakeng sa litlhoko tse fapaneng tsa ho sefa, e lumellang ho phunyeha ha mapetso le ho seha ha sebaka se seholo.

Lesela la sefe se sehang ka laser le sebedisa lehlasedi la laser le tsepamisitsweng, le nang le matla a hodimo le qhibilihisang kapa le fetolang lesela mouoane hona moo le kopanang teng. Ka tataiso ya sistimi ya CNC (Computer Numerical Control), laser e tsamaya ka ho nepahala ho makatsang, e etsang hore ho kgonehe ho seha kapa ho betla mefuta e fapaneng ya lesela la sefe ka ho nepahala ho ikgethang.

Ehlile, ha se thepa eohle ea lesela la sefe e tšoanang. E 'ngoe le e 'ngoe e hloka litlhophiso tse lokisitsoeng hantle ho fihlela liphetho tse ntle ka ho fetisisa tsa ho seha. A re hlahlobisiseng hore na lesela la sefe la ho seha ka laser le sebetsa joang ho tse ling tsa thepa e sebelisoang haholo.

Polyester e khaotsoeng ka laser:

Lesela la sefe la polyester le tiile ebile le hanela ho otlolla, e leng se ka etsang hore ho be thata ho seha ka disebediswa tsa setso. Ho seha ka laser ho fana ka monyetla o hlakileng mona, kaha ho fana ka mathoko a boreleli, a kwalehileng a thibelang ho taboha ha lesela le ntse le boloka matla a lona. Ho nepahala hona ho bohlokwa haholo diindastering tse kang kalafo ya metsi kapa tshebetso ya dijo, moo tshebetso e tsitsitseng ya sefe e hlokahalang.

Masela a sa Lohiloeng a Laser:

Masela a sa lohiloeng a bobebe ebile a bonolo, e leng se etsang hore a tšoane hantle le ho seha ka laser. Ka theknoloji ena, thepa e ka sebetsoa kapele ntle le ho beha sebopeho sa eona kotsing, e leng se fellang ka ho seha ho hloekileng le ho nepahetseng ho bohlokoa bakeng sa ho bopa li-filter. Mokhoa ona o bohlokoa haholo ha ho sebetsoa ka masela a sa lohiloeng ho sefa sa bongaka kapa sa likoloi, moo ho nepahala le botsitso e leng tsa bohlokoa.

Nylon e Sehiloeng ka Laser:

Masela a nylon a tsebahala ka ho tenyetseha le ho tiea ha 'ona, empa a ka ba thata ho a sebetsana le 'ona ka mekhoa ea ho seha ka mechine. Ho sebetsana le laser ho rarolla phephetso ena ka ho hlahisa likotoana tse bohale le tse nepahetseng ntle le ho baka ho sotha. Sephetho ke li-filter tse bolokang sebopeho sa tsona le ho fana ka ts'ebetso e tšepahalang, e leng ea bohlokoa libakeng tse thata tse kang ts'ebeliso ea lik'hemik'hale kapa meriana.

Foam e Sehiloeng ka Laser:

Foam ke thepa e bonolo le e nang le masoba e ka tabohang kapa ea senyeha habonolo ha e sehoa ka mahare. Theknoloji ea laser e fana ka tharollo e hloekileng le e tšepahalang haholoanyane, kaha e seha foam hantle ntle le ho pshatla lisele kapa ho beha sebopeho sa eona kotsing. Sena se netefatsa hore li-filter tse entsoeng ka foam li boloka masoba le ts'ebetso ea tsona, e leng se etsang hore li be molemo haholo lits'ebetsong tse kang tlhoekiso ea moea le ho kenya mocheso oa acoustic.

Hobaneng o lokela ho kgetha ho seha ka laser bakeng sa lesela la sefa?

Lesela la filtara la ho itšeha ka laserE fana ka melemo e mengata ho feta mekhoa ea setso ea ho seha, haholo-holo bakeng sa thepa ea lesela la sefe. Mona ke tse ling tsa melemo ea bohlokoa:

1. Ho nepahala le ho Hloekisa Edge

Lesela la filtara la ho itšeha ka lasere netefatsa ho seha ho nepahetseng ka mathoko a hlwekileng, a koetsoeng, e leng sa bohlokwa bakeng sa ho boloka botsitso ba sebopeho sa lesela la sefe. Sena se bohlokwa haholo ditsamaisong tsa sefe moo thepa e lokelang ho boloka bokgoni ba yona ba ho sefe ka katleho.

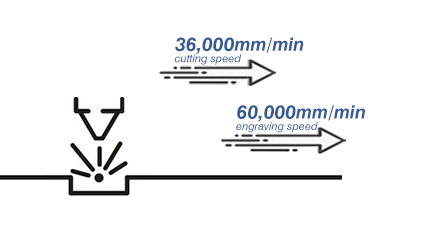

2. Lebelo le Potlakileng le Bokgoni bo Phahameng

Lesela la filtara la ho itšeha ka lasere potlakile ebile e sebetsa hantle ho feta mekhoa ea ho seha ka mechine kapa ea ho seha ka tšepe, haholo-holo bakeng sa meralo e rarahaneng kapa e ikhethileng.filtara lesela sistimi ea ho itšeha ka lasere ka boela ea etsoa ka boiketsetso, e leng se fokotsang tlhoko ea ho kenella ka letsoho le ho potlakisa linako tsa tlhahiso.

3. Litšila tse fokolang tsa thepa

Mekhoa ea setso ea ho seha hangata e baka litšila tse ngata tsa thepa, haholo-holo ha ho sehoa libopeho tse rarahaneng.Lesela la filtara la ho itšeha ka lasere fana ka ho nepahala ho hoholo le tshenyo e fokolang ya thepa, e leng se etsang hore e be kgetho e theko e tlase bakeng sa tlhahiso e nyane le e kgolo.

4. Ho iketsetsa le ho tenyetseha

Lesela la filtara la ho itšeha ka lasere lumella ho etsa masela a sefe ka mokhoa o phethahetseng. Hore na o hloka masoba a manyane, dibopeho tse itseng, kapa meralo e qaqileng,lesela la filtara la ho itšeha ka lasere ka u thusa habonolo litlhoko tsa hau, e u fa monyetla oa ho hlahisa mefuta e mengata ea lihlahisoa tsa lesela la sefe.

5. Ha ho na ho roaloa ha lisebelisoa

Ho fapana le ho seha ka die-cutting kapa ho seha ka mechine,lesela la filtara la ho itšeha ka laserha e ame ho kopana le thepa ka 'mele, ho bolelang hore ha ho na ho tsofala ha mahare kapa lisebelisoa. Sena se fokotsa litšenyehelo tsa tlhokomelo le nako ea ho se sebetse, e leng se etsang hore e be tharollo e tšepahalang haholoanyane ea nako e telele.

Mechini e Khothaletsoang ea ho Seha Lesela la Laser ea Filter

Ho fumana diphetho tse ntle ka ho fetisisa ha o seha lesela la sefe, o kgetha se nepahetsengmochini oa ho itšeha ka laser oa lesela la filtharaho bohlokoa. MimoWork Laser e fana ka mefuta e fapaneng ea mechini e loketsenglesela la filtara la ho itšeha ka laser, ho kenyeletsoa:

• Sebaka sa Mosebetsi (Bophara ba hodimo): 1000mm * 600mm

• Matla a Laser: 60W/80W/100W

• Sebaka sa Mosebetsi (Bophara ba * Bophara): 1300mm * 900mm

• Matla a Laser: 100W/150W/300W

• Sebaka sa Mosebetsi (Bophara ba hodimo): 1800mm * 1000mm

• Matla a Laser: 100W/150W/300W

Ha re phethela

Lesela la filtara la ho itšeha ka lasere ipakile e le mokhoa o motle oa ho seha masela a sefe, e fana ka melemo e mengata e kang ho nepahala, lebelo le ho se be le litšila tse ngata. Hore na u seha polyester, foam, nylon, kapa masela a sa lohiloeng, lesela la sefe la ho seha la laser le netefatsa liphetho tsa boleng bo holimo ka mathoko a koetsoeng le meralo e ikhethileng. Mefuta e fapaneng ea litsamaiso tsa ho seha tsa laser tsa lesela la sefe la MimoWork Laser e fana ka tharollo e phethahetseng bakeng sa likhoebo tsa boholo bohle tse batlang ho ntlafatsa ts'ebetso ea tsona ea tlhahiso ea masela a sefe.

Ikopanye le rona kajeno ho ithuta haholoanyane ka mokhoa oa rona oa homechine ea ho itšeha ka laser ea lesela la filtharae ka ntlafatsa ts'ebetso ea hau ea ho seha masela a sefe le ho ntlafatsa boleng ba lihlahisoa tsa hau.

Ha ho tluoa tabeng ea ho khethamochini oa ho itšeha ka laser oa lesela la filthara, nahana ka tse latelang:

Mefuta ea Mechini:

Li-cutter tsa laser tsa CO2 hangata li khothaletsoa bakeng sa ho seha lesela la sefe hobane laser e ka seha libopeho le boholo bo fapaneng. U hloka ho khetha boholo le matla a mochini oa laser o loketseng ho latela mefuta le likarolo tsa thepa ea hau. Buisana le setsebi sa laser bakeng sa likeletso tsa setsebi tsa laser.

Teko ke ea Pele:

Pele o tsetela mochining oa ho seha ka laser, mokhoa o motle ke ho etsa teko ea thepa u sebelisa laser. U ka sebelisa lesela la sefe 'me ua leka matla le lebelo le fapaneng la laser ho hlahloba phello ea ho seha.

Mehopolo efe kapa efe mabapi le Lesela la Sefahla sa ho Seha ka Laser, Rea u amohela ho buisana le rona!

Na ho na le Lipotso mabapi le Mochini oa ho Seha oa Laser bakeng sa Lesela la Sefa?

Ntlafatso ea ho Qetela: Loetse 9, 2025

Nako ea poso: Pulungoana-14-2024