Laser Weld Cleaning

Ukucoca i-Laser Weld yiNdlela esetyenziselwa ukukhupha izinto ezingcolileyo, ii-Oxides, kunye nezinye izinto ezingafunekiyo kwi-Surface ye-Weld.Ngaphambi mvaInkqubo yeWelding igqityiwe. Oku kuCoca linyathelo eliBalulekileyo kwiZicelo ezininzi zoShishino kunye nezeMveliso ukuyaQinisekisa Imfezeko kunye nenkangelekoyoMdibaniso oDidiyelweyo.

Laser Ukucoca for Metal

Ngexesha lenkqubo ye-welding, ukungcola okwahlukeneyo kunye neeproducts zinokufakwa kwindawo ye-weld, njengei-slag, i-spatter, kunye nokuguqulwa kwebala.

Xa zishiywe zingacocekanga, ezi zinakoIfuthe elibi kumandla e-weld, ukuxhathisa ukubola, kunye nobuhle obubonakalayo.

Ukucocwa kwe-laser weld kusebenzisa umqadi welaser one-eneji ephezulu ukukhetha umphunga kwaye ususe ezi diphozithi zinganqwenelekiyo.ngaphandle kokonakalisaintsimbi engaphantsi.

Izinto eziluncedo Laser Weld Cleaning

1. Ukuchaneka- I-laser inokujoliswa ngokuchanekileyo ukucoca kuphela indawo ye-weld ngaphandle kokuchaphazela izinto ezijikelezileyo.

2. Isantya- Ukucocwa kweLaser yinkqubo ekhawulezayo, ezenzekelayo enokucoca i-welds ngokukhawuleza kunobuchule bezandla.

3. Ukungqinelana- Ukucocwa kweLaser kuvelisa iyunifomu, umphumo ophindaphindiweyo, ukuqinisekisa ukuba zonke ii-welds zicocwa kumgangatho ophezulu ofanayo.

4. Akukho Izinto ezisetyenziswayo- Ukucocwa kweLaser kufuna akukho abrasives okanye iikhemikhali, ukunciphisa iindleko zokusebenza kunye nenkunkuma.

izicelo: Laser Weld Cleaning

I-High-Strength Low-Alloy Low (HSLA) iipleyiti zensimbi zeLaser Weld Cleaning

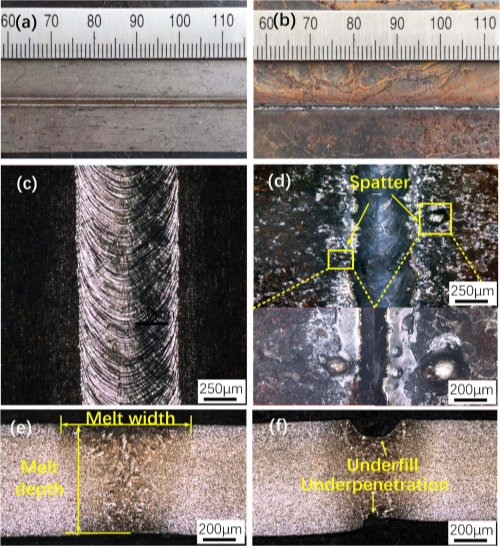

Imbonakalo yeWeld yokuNyangwa ngokuCoca iLaser (a, c, e) kunye nokungaphathwa ngokuCoca iLaser (b, d, f)

Iiparamitha zenkqubo yokucoca i-laser efanelekileyo inakosusaukurusa kunye negrisi ukusuka kumphezulu womsebenzi.

Ukungena okuphezuluibonwe kwimizekelo eyacocwayo xa ithelekiswa naleyo ingacocwanga.

I-laser yokucoca unyango lwangaphambili lunceda ngokufanelekileyoziphepheukwenzeka kweepores kunye neentanda kwi-weld kunyeiyaphucukaumgangatho wokwenziwa kweweld.

Ukucoca i-Laser Weld Ukucoca kwangaphambili unyango kunciphisa iziphene ezininzi ezinje ngeepores kunye nokuqhekeka ngaphakathi kweweld, ngaloo ndlela.ukuphuculaiimpawu zokuqina kwe weld.

Umyinge wamandla we-tensile yesampuli kunye nokucoca i-laser yonyango lwangaphambili yi-510 MPa, eyiyo30% ngaphezulukunokuba ngaphandle kwe-laser yokucoca kwangaphambili unyango.

Ubude be-laser-clean weld joint yi-36% leyoAmaxesha ama-3eye weld joint engahlambulukanga (12%).

I-Aluminiyam yoRhwebo i-5A06 yokucoca i-Laser Weld

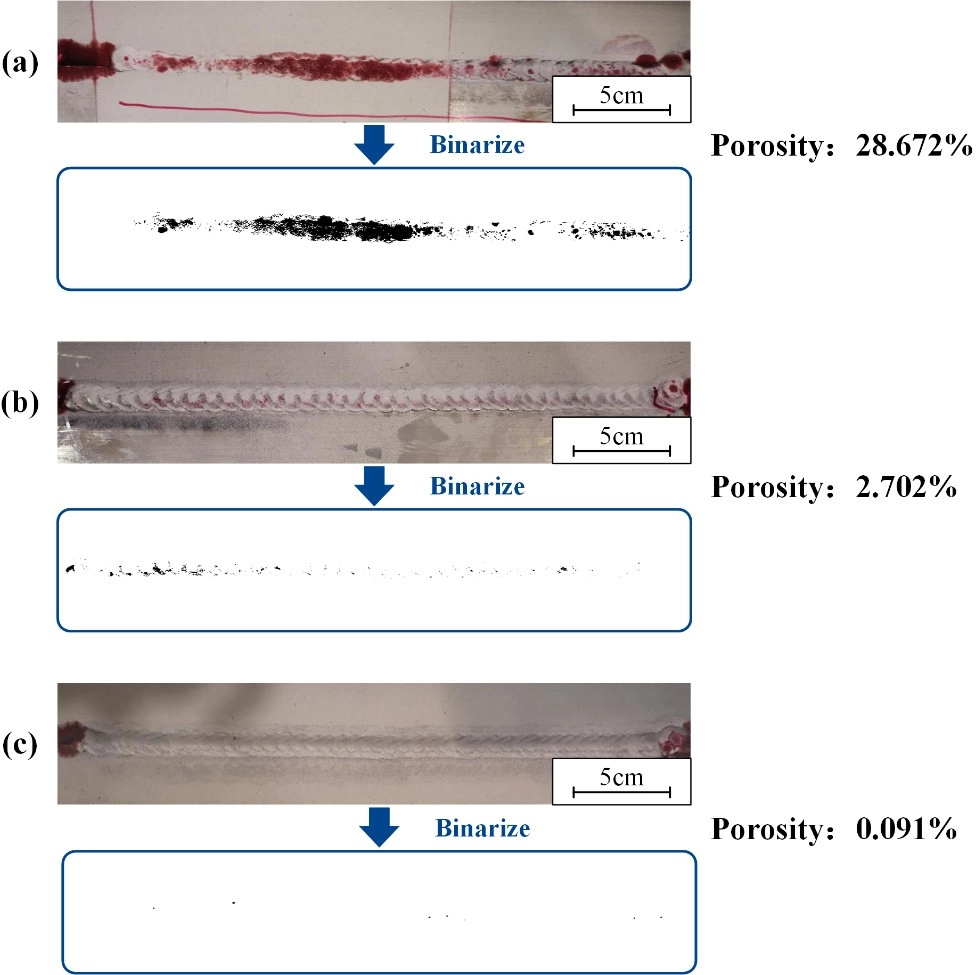

Isiphumo soVavanyo lwePermeation kunye nePorosity kwiSampuli ene: (a) I-oyile; (b) Amanzi; (c)Ukucocwa kweLaser.

Ubukhulu be-aluminium alloy 5A06 oxide layer yi-1-2 lm, kwaye ukucocwa kwelaser kubonisaisiphumo esithembisayoekukhutshweni kwe-oxide ye-TIG welding.

I-Porosity yafunyanwakwindawo yokudibanisa ye-TIG weldsemva komhlaba oqhelekileyo, kunye nokufakwa kunye ne-morphology ebukhali kwavavanywa ngokunjalo.

Emva kokucoca nge-laser,akukho porosity yayikhonakwindawo yokudibanisa.

Ngaphezu koko, kukho i-oxygenyehle kakhulu, evumelana neziphumo zangaphambili.

Ukongeza, umaleko omncinci wokunyibilika kwe-thermal kwenzeka ngexesha lokucoca nge-laser, okubangelei-microstructure ecocekileyokwindawo yokudibanisa.

Jonga iPhepha loPhando lokuqala kwiSango loPhando Apha.

Okanye Jonga eli Nqaku eSipapashe ngalo:IAluminiyam yokucoca iLaser (Indlela abaphandi abayenze ngayo)

Ngaba uyafuna ukwazi malunga nokuCoca i-Laser weld?

Sinako Ukunceda!

Ndingasebenzisa ntoni ukucoca iiWelds zam?

Ukucoca iiWelds UkubonelelaIibhondi ezomeleleyokwayeUkuthintela ukuMdla

Nazi ezinyeIindlela zesiNtuUkucoca iiWelds:

Inkcazo:Sebenzisa ibrashi yocingo okanye ivili ukususa i-slag, i-spatter, kunye nee-oxides.

IiPros:Ayibizi kwaye iyasebenza ekucoceni umphezulu.

Ububi:Inokusebenza nzima kwaye isenokungafikeleli kwiindawo ezixineneyo.

Inkcazo:Sebenzisa i-grinder ukuze ugudise i-welds kwaye ususe ukungafezeki.

IiPros:Isebenza ngokucocwa kakhulu kunye nokubunjwa.

Ububi:Ingayitshintsha iprofayile yeweld kwaye inokwazisa ubushushu.

Inkcazo:Sebenzisa izisombululo ezisekelwe kwi-asidi okanye izinyibilikisi ukunyibilikisa ungcoliseko.

IiPros:Isebenza kwiintsalela ezinzima kwaye ingasetyenziswa kwizicelo ezahlukeneyo.

Ububi:Ifuna amanyathelo okhuseleko kunye nokulahlwa okufanelekileyo.

Inkcazo:I-propel impahla ye-abrasive ngesantya esiphezulu ukususa ukungcola.

IiPros:Ngokukhawuleza kwaye kusebenza kwiindawo ezinkulu.

Ububi:Inokubangela ukhukuliseko lomhlaba ukuba alulawulwa.

Inkcazo:Sebenzisa amaza omsindo we-high-frequency kwisisombululo sokucoca ukususa i-debris.

IiPros:Ifikelela kwimilo entsonkothileyo kwaye isusa ungcoliseko ngocoselelo.

Ububi:Isixhobo sinokubiza kwaye ubungakanani bokucoca bunokulinganiselwa.

KubaUkukhutshwa kweLaser & Ukulungiswa komphezulu weLaser:

Ukukhutshwa kweLaser

Inkcazo:Sebenzisa imiqadi yelaser ene-eneji ephezulu ukwenza umphunga ungcoliseke ngaphandle kokuchaphazela izinto ezisisiseko.

IiPros:Ichanekile, ihambelana nokusingqongileyo, kwaye iyasebenza kwizicelo ezibuthathaka.

Ububi:Izixhobo zinokubiza, kwaye zifuna ukusebenza ngobuchule.

Ukulungiswa komphezulu weLaser

Inkcazo:Sebenzisa i-laser ukulungisa umphezulu ngokususa i-oksidi kunye nezinto ezingcolisayo ngaphambi kokuba udibanise.

IiPros:Ukwandisa umgangatho we-weld kwaye kunciphisa iziphene.

Ububi:Izixhobo nazo zinokubiza, kwaye zifuna ukusebenza ngobuchule.

Indlela yokuCoca iMetal ngeLaser?

Ukucocwa kweLaser yindlela esebenzayo yokususa izinto ezingcolisayo

Nxiba iPPE efanelekileyo, kuquka izibuko zokhuseleko, iiglavu, nempahla yokukhusela.

Khusela isiqwenga sesinyithi kwindawo ezinzileyo ukukhusela ukunyakaza ngexesha lokucoca. Lungisa intloko yelaser kumgama ocetyiswayo ukusuka kumphezulu, ngokuqhelekileyo phakathi10-30 mm.

Qhubeka ubeke iliso kwinkqubo yokucoca. Jonga utshintsho kumphezulu, njengokususwa kwezinto ezingcolileyo okanye nawuphi na umonakalo kwintsimbi.

Emva kokucoca, hlola indawo ye-weld yokucoceka kunye naluphi na ukungcola okuseleyo. Ngokuxhomekeke kwisicelo, qwalaselaukufaka isambatho sokukhuselaukuthintela umhlwa kwixesha elizayo.

Sesiphi esona sixhobo silungileyo sokuCoca iiWelds?

Ukucocwa kweLaser kugqame njengenye yezona zixhobo zibalaseleyo ezifumanekayo

Kuba nabani na obandakanyekayo ekwenziweni kwesinyithi okanye ekugcinweni kwayo, ukucocwa kwelaserisixhobo esixabisekileyo sokucoca i-welds.

Ukuchaneka kwayo, ukusebenza kakuhle, kunye neenzuzo zokusingqongileyo kuyenza ibe lolona khetho lufanelekileyoukufumana iziphumo ezikumgangatho ophezulungelixa unciphisa imingcipheko kunye nexesha lokunciphisa.

Ukuba ujonge ukomeleza iinkqubo zakho zokucoca, cinga ngokutyala imali kwitekhnoloji yokucoca i-laser.

Uzenza njani iiWelds zibukeke zicocekile?

Ukucocwa kweLaser kuNcedisa ukuPhumelela iiWelds ezicocekileyo neziJongayo

Ukulungiswa koMphezulu

Ukucoca kokuqala:Ngaphambi kwe-welding, qinisekisa ukuba isiseko sesinyithi asinazo izinto ezingcolileyo ezifana nomhlwa, ioli kunye nokungcola. Eli nyathelo likubalulekile ukufezekisa i-weld ecocekileyo.

Ukucoca ngeLaser:Sebenzisa inkqubo yokucoca i-laser ukususa ngokufanelekileyo nakuphi na ukungcola okungaphezulu. Indlela ekujoliswe kuyo iqinisekisa ukuba kuphela ukungcola okususiweyongaphandle kokonakalisa isinyithi.

Ukucoca emva kweWeld

Ukucoca emva kweWeld:Emva kwe-welding, ngokukhawuleza ucoce indawo ye-weld nge-laser ukususa i-slag, i-spatter, kunye ne-oxidation enokuphazamisa ukubonakala kwe-weld.

Ukungqinelana:Inkqubo yokucoca i-laser ibonelela ngeziphumo ezifanayo, iqinisekisa ukuba zonke ii-welds zinesiphelo esingaguqukiyo, esicocekileyo.

Imiboniso yevidiyo: Ukucocwa kweLaser kwiMetal

Yintoni ukucocwa kweLaser kwaye isebenza njani?

Enye yeenzuzo ezinkulu zokucoca ngelaser kukuba kunjaloinkqubo eyomileyo.

Okuthetha ukuba akukho mfuneko yokucocwa kobutyobo emva kokucoca.

Yalathisa ngokulula umqa we-laser kumphezulu ofuna ukuwucocangaphandle kokuchaphazela izinto ezisisiseko.

Izicoci zeLaser nazocompact kwaye iyaphatheka, ukuvumelaukucoca ngokufanelekileyo kwindawo.

Ngokuqhelekileyo kufunakuphela izixhobo ezisisiseko zokuzikhusela, njengeeglasi zokhuseleko kunye nezixhobo zokuphefumla.

Ukukhutshwa kweLaser kuNgcono kuCoca umhlwa

Ukuqhunyiswa kwesanti kunokudalauthuli oluninzi kwaye ifuna ukucocwa okukhulu.

Ukucoca umkhenkce owomileyoezinokuba yindleko kwaye aziyifanelekeli imisebenzi emikhulu.

Ukucoca ngamachiza kungenzekazibandakanya izinto ezinobungozi kunye nemiba yokulahlwa.

Okuchasene,ukucocwa kwe-laser kuvela njengendlela yokuma.

Isebenza ngeendlela ezininzi ngokumangalisayo, iphatha uluhlu lwezinto ezingcolisayo ngokuchanekileyo

Inkqubo ineendleko-esebenzayo kwixesha elide ngenxanoukusetyenziswa kwezinto eziphathekayo kunye neemfuno zokugcinwa okuphantsi.

Umatshini wokuCoca iLaser ophathwa ngesandla: Ukucoca i-Laser Weld

IPulsed Laser Cleaner(100W, 200W, 300W, 400W)

Izicoci ze-laser fiber pulsed zikulungele ngokukodwa ukucocwaethe-ethe,onovakalelo, okanyesengozini yobushushuumphezulu, apho ubume obuchanekileyo kunye nokulawulwa kwe-laser ye-pulsed ibalulekile ekucoceni okusebenzayo kunye nomonakalo.

Amandla eLaser:100-500W

UkuModareyitha koBude bePulse:10-350ns

Ubude beCable Cable:3-10m

Ubude bamaza:1064nm

Umthombo weLaser:I-Pulsed Fiber Laser

Umatshini wokususa umhlwa weLaser(Ngaphambi & nokuPosa i-Laser weld yokuCoca)

Ukucoca i-laser weld isetyenziswa kakhulu kumashishini afanai-aerospace,iimoto,ukwakhiwa kweenqanawa, kwayeukwenziwa kwezinto zombaneaphoezikumgangatho ophezulu, iiweldi ezingenasiphakozibalulekile kukhuseleko, ukusebenza, kunye nenkangeleko.

Amandla eLaser:100-3000W

I-Laser Pulse Frequency ehlengahlengiswayo:Ukuya kuthi ga kwi-1000KHz

Ubude beCable Cable:3-20m

Ubude bamaza:1064nm, 1070nm

InkxasoEzahlukeneyoIilwimi