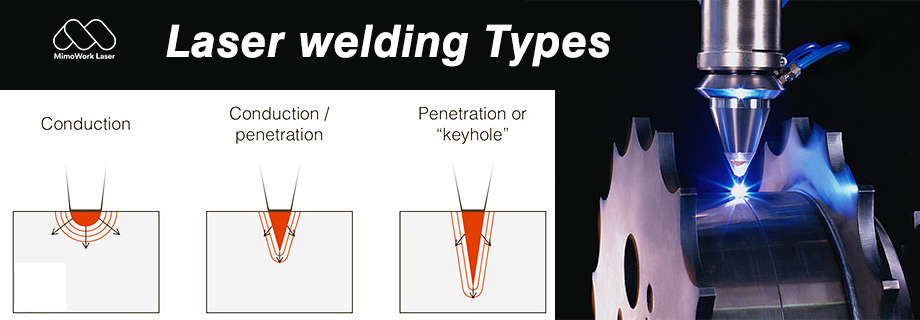

I-laser welding inokuqondwa ngokuqhubekayo okanye i-pulsed laser generator. Umgaqo we-laser welding unokwahlulwa ube yi-welding conduction yobushushu kunye ne-laser ye-fusion deep fusion welding. Ubuninzi bamandla obungaphantsi kwe-104 ~ 105 W / cm2 yi-welding conduction yokushisa, ngeli xesha, ubunzulu bokunyibilika, kunye nesantya se-welding siyacotha; Xa uxinaniso lwamandla lungaphezu kwe-105 ~ 107 W / cm2, umphezulu wesinyithi ugoba kwi "keyholes" phantsi kwesenzo sobushushu, ukwenza i-welding ye-fusion enzulu, eneempawu zesantya sokudibanisa ngokukhawuleza kunye nomlinganiselo omkhulu wobubanzi obunzulu.

Namhlanje, siza kugubungela ikakhulu ulwazi lwezinto eziphambili ezichaphazela umgangatho we-laser deep fusion welding

1. Amandla eLaser

Kwi-laser deep fusion welding, amandla e-laser alawula ubunzulu bokungena kunye nesantya se-welding. Ubunzulu be-weld bunxulumene ngokuthe ngqo noxinaniso lwamandla e-beam kwaye ngumsebenzi wesiganeko samandla we-beam kunye nendawo ekugxilwe kuyo. Ngokubanzi, kumqadi othile we-laser, ubunzulu bokungena buyanda ngokunyuka kwamandla ombane.

2. Indawo ekugxilwe kuyo

Ubungakanani bendawo yeBeam yenye yezona zinto zibalulekileyo kwi-laser welding kuba imisela ukuxinana kwamandla. Kodwa ukuyilinganisa kungumngeni kwiilaser ezinamandla aphezulu, nangona zininzi iindlela zokulinganisa ezingathanga ngqo ezikhoyo.

Ubungakanani bomda wediffraction ubukhulu bendawo yogxininiso lomqadi bungabalwa ngokwenkcazo-bungcali yokwahlukana, kodwa obona bungakanani bendawo bukhulu kunexabiso elibaliweyo ngenxa yobukho bembonakalo engalunganga. Eyona ndlela ilula yokulinganisa yindlela yeprofayili ye-iso-ubushushu, elinganisa ububanzi bendawo ekugxilwe kuyo kunye nokugqobhoza emva kokuba iphepha elishinyeneyo litshisiwe kwaye lingene ngepleyiti yepolypropylene. Le ndlela ngokuziqhelanisa nomlinganiselo, ilawula ubungakanani bamandla e-laser kunye nexesha lesenzo se-beam.

3. IGesi yoKhuselo

Inkqubo ye-laser welding ihlala isebenzisa iigesi ezikhuselayo (i-helium, i-argon, i-nitrogen) ukukhusela i-pool etyhidiweyo, ukukhusela i-workpiece kwi-oxidation kwinkqubo ye-welding. Isizathu sesibini sokusebenzisa igesi ekhuselayo kukukhusela i-lens egxininisekileyo ekungcolisweni ngumphunga wesinyithi kunye nokutshiza ngamaconsi angamanzi. Ngokukodwa kwi-high-power laser welding, i-ejecta iba namandla kakhulu, kuyimfuneko ukukhusela i-lens. Isiphumo sesithathu segesi ekhuselayo kukuba sisebenza kakhulu ekusasazeni i-plasma shielding eveliswa yi-high-power laser welding. Umphunga wesinyithi ufunxa i-laser beam kwaye i-ionize kwi-plasma cloud. Irhasi ekhuselayo ejikeleze umphunga wesinyithi nayo i-ionize ngenxa yobushushu. Ukuba kukho iplasma eninzi kakhulu, umqadi welaser ngandlel’ ithile utyiwa yiplasma. Njengamandla esibini, iplasma ikhona kumphezulu osebenzayo, nto leyo eyenza ubunzulu beweld bungabi nzulu kwaye umphezulu we weld pool ube banzi.

Indlela yokukhetha igesi efanelekileyo yokukhusela?

4. Inqanaba lokufunxa

Ukufunxwa kwe-laser yezinto kuxhomekeke kwezinye iipropathi ezibalulekileyo zemathiriyeli, ezinje ngesantya sokufunxa, ukubonakaliswa kwe-reflection, i-thermal conductivity, ubushushu obunyibilikayo, kunye nobushushu bokuphuma komphunga. Phakathi kwazo zonke izinto, eyona nto ibalulekileyo lizinga lokufunxa.

Izinto ezimbini ezichaphazela izinga lokufunxa izinto kwi-laser beam. Eyokuqala yi-coefficient yokumelana nezinto. Kufunyaniswa ukuba izinga lokufunxa izinto lilingana nengcambu yesikwele somqobo wokumelana, kwaye i-coefficient yokumelana iyahluka kunye nobushushu. Okwesibini, umgangatho ophezulu (okanye ukugqiba) wezinto eziphathekayo unempembelelo ebalulekileyo kwizinga lokufunxa kwe-boam, enefuthe elibalulekileyo kwi-welding effect.

5. Isantya seWelding

Isantya se-welding sinempembelelo enkulu kubunzulu bokungena. Ukwandisa isantya kuya kwenza ubunzulu bokungena bube nzulu, kodwa buphantsi kakhulu kuya kukhokelela ekunyibilikeni okugqithisileyo kwemathiriyeli kunye ne-workpiece welding ngokusebenzisa. Ke ngoko, kukho uluhlu olufanelekileyo lwesantya se-welding kwizinto ezithile ezinamandla athile e-laser kunye nobukhulu obuthile, kunye nobunzulu bokungena obuphezulu bunokufunyanwa kwixabiso lesantya esihambelanayo.

6. Ubude obuGxinileyo beLensi yokuGqalisela

I-lens yokugxila ivame ukufakwa kwintloko ye-welding gun, ngokuqhelekileyo, i-63 ~ 254mm (i-diameter 2.5 "~ 10") ubude obugxininise bukhethiwe. Ubungakanani bendawo egqalileyo bulingana nobude bojoliso, okukhona mfutshane ubude benkangeleko, kokukhona ibala elincinci. Nangona kunjalo, ubude bogxininiso lobude buchaphazela ubunzulu bogxininiso, oko kukuthi, ubunzulu bogxininiso bunyuka ngokuhambelana nobude obugxininisekile, ngoko ubude obufutshane obugxininisekile bunokuphucula ukuxinana kwamandla, kodwa ngenxa yokuba ubunzulu bogxininiso buncinci, umgama phakathi kwelensi kunye nomsebenzi kufuneka ugcinwe ngokuchanekileyo, kwaye ubunzulu bokungena abukho bukhulu. Ngenxa yempembelelo ye-splashes kunye nemodi ye-laser ngexesha le-welding, ubunzulu obufutshane be-focal esetyenziswa kwi-welding yangempela ubukhulu becala yi-126mm (ububanzi be-5 "). Kule meko, i-laser ephezulu yokuphuma kwamandla (ubuninzi bamandla) iyafuneka ukuze kuphunyezwe isiphumo somngxuma onzulu.

Imibuzo engakumbi malunga ephathwayo laser welding ixabiso umatshini kunye noqwalaselo

Ixesha lokuposa: Sep-27-2022