Ukuthetha nge-CO2 laser cutter, ngokuqinisekileyo asiqhelekanga, kodwa ukuthetha ngeenzuzo zomshini wokusika i-CO2 laser, sinokuthi bangaphi? Namhlanje, ndiza kukwazisa iingenelo eziphambili zokusika i-CO2 laser kuwe.

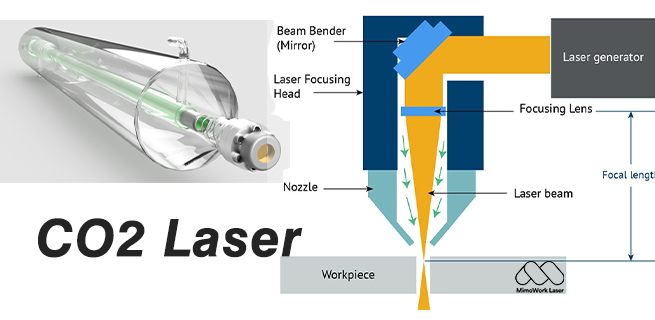

Yintoni i-co2 laser cut

Itekhnoloji yokusika i-Laser iphuhliswe ngokukhawuleza kwiminyaka yakutshanje ngenxa yobukhulu bayo obuchanekileyo bokusika, ukusika ngaphandle kwe-burr, ukusika umthungo ngaphandle kokuguqulwa, isantya esiphezulu sokusika, kwaye akukho zithintelo zokusika, umatshini wokusika we-laser uye wasetyenziswa ngakumbi nangakumbi kwintsimi yokulungiswa komatshini.

Umatshini wokusika we-CO2 we-laser usebenzisa i-lens egxile ekugxininiseni umqadi we-CO2 we-laser kumphezulu wezinto ezinyibilikayo, kwaye kwangaxeshanye usebenzisa i-coaxial yegesi ecinezelweyo ngomqadi we-laser ukuvuthela imathiriyeli enyibilikisiweyo, kwaye wenze umqadi welaser kunye nezinto ezihambelanayo zihambelane kunye ecaleni kwendlela ethile, ngaloo ndlela yenze imilo ethile ye-slit.

Ziziphi iingenelo zokusika i-co2 laser

✦ Ukuchaneka okuphezulu

Ukubeka ukuchaneka kwe-0.05mm, phinda ukuchaneka kokubeka 0.02mm

✦ Isantya esikhawulezayo

Ukusika isantya ukuya kwi-10m / min, isantya esiphezulu sokumisa ukuya kwi-70m / min

✦ Ukugcinwa kwezinto

Ngokwamkela isoftware yokuzalela, iimilo ezahlukeneyo zeemveliso zinokuzinziswa kuyilo olunye, ukwandisa ukusetyenziswa kwemathiriyeli.

✦ Umphezulu wokusika ogudileyo

Akukho burr kwindawo yokusika, uburhabaxa bendawo yokusikeka bulawulwa ngokubanzi ngaphakathi kweRa12.5

✦ Akukho monakalo kuMsebenzi

Intloko yokusika i-laser ayiyi kuqhagamshelana nomphezulu wezinto eziphathekayo, ukuqinisekisa ukuba i-workpiece ayikhatywanga

✦ Ukusika iMilo eguquguqukayo

I-laser processing bhetyebhetye ilungile, inokuqhuba imizobo engafunekiyo, inokusika umbhobho kunye nezinye iiprofayili.

✦ Umgangatho olungileyo wokusika

Akukho kusikwa koqhagamshelwano, umda wokusika uchaphazeleka kancinci bubushushu, ngokusisiseko akukho deformation yobushushu bokusebenza, kunqande ngokupheleleyo ukudilika kwezinto xa ucheba, i-slit ayifuni ukusetyenzwa kabini.

✦ Nabuphi na Ukuqina kweMpahla

I-Laser inokucutshungulwa kwi-acrylic, iplanga, i-fiberglass elaminethiweyo, kunye nezinye izinto eziqinileyo, zonke ezi zinto zingeyontsimbi zinokusikwa ngaphandle koguquko.

✦ Akukho mfuneko yoMngundo

Laser processing ayifuni ukungunda, akukho ukusetyenziswa ngundo, akukho mfuneko yokulungisa ukungunda, kwaye konga ixesha lokubuyisela umngundo, ngaloo ndlela ukonga iindleko processing, ukunciphisa iindleko imveliso, kwaye ingakumbi ilungele ukusetyenzwa kweemveliso ezinkulu.

✦ I-Slit yokusika emxinwa

I-laser beam igxile kwindawo encinci kakhulu yokukhanya ukuze indawo ekugxilwe kuyo ifikelele kumandla aphezulu kakhulu, izinto eziphathekayo zifudunyezwa ngokukhawuleza kwinqanaba le-gasification, kwaye i-evaporation yenza imingxuma. Njengoko umqadi uhamba ngokuthe ngqo kunye nezinto eziphathekayo, imingxuma ngokuqhubekayo yenza i-slit emxinwa kakhulu. Ububanzi bokusika ngokuqhelekileyo yi-0.10 ~ 0.20mm

Ngentla sisishwankathelo seenzuzo zomatshini wokusika we-CO2 laser

Okokugqibela sicebisa kakhulu iMimoWork Laser Machine kuwe!

Funda ngakumbi malunga neentlobo ze-CO2 laser cutter kunye namaxabiso

Ixesha lokuposa: Sep-23-2022