Yintoni i-sell yelding? I-Laser Welling vs Arc yelding? Ngaba ungayifumana i-weld yelluminum (kunye nentsimbi engenasitayile)? Ngaba ujonge i-laser ye-laser ye-lelder yentengiso elungele wena? Eli nqaku liza kukuxelela ukuba kutheni umlenze wesandla se-laser selder ungcono kwizicelo ezahlukeneyo kunye nebhonasi eyongeziweyo yeshishini lakho, kunye noluhlu oluneenkcukacha zoluhlu lwezinto ezenziweyo.

Intsha kwihlabathi le-laser okanye umsebenzisi otyunjiweyo womatshini wase-lamer, unamathandabuzo ngokuthenga kwakho okulandelayo okanye uphuculo? Ukuxhalaba akusekho kuba i-mimopyork lar ifumene umva wakho, eneminyaka engama-20 + ye-20 + yamava e-laser, silapha kwimibuzo yakho kwaye silungele imibuzo yakho.

Yintoni i-sell yelding?

I-Fiber Laser Welr ye-Welder Surheld isebenza kwizinto ngendlela yokuphola. Ngokuphathelele ubushushu obukhulu kwaye bububushushu obukhulu kwi-laser ye-laser, intsimbi ebonakalayo inyibilikisiwe okanye ivaliwe, udibanise enye isinyithi emva kokupholisa isinyithi kunye nokuqina ukwenza i-gelbing dibanise.

Ubusazi?

I-Laser ye-Laser yaseThembe ilunge ngakumbi kune-Arc ye-Arc Welc kwaye nantsi ukuba kutheni.

Xa kuthelekiswa ne-Arc ye-Arc Welder, i-laser ye-laser ibonelela:

•IsezantsiUkusetyenziswa kwamandla

•UbuncinciIndawo echaphazelekayo

•Okanye okanye hayiUkusebenza kwezinto ezibonakalayo

•Iguqukile kwaye ihambe kakuhleIndawo ye-Welding

•IcocekileI-Welding Edhayi ngakumbiukuqhubekeka

•MfutshaneIxesha le-welding -I-2 ukuya kwi-10amaxesha ngokukhawuleza

• Ukukhupha ukukhanya kwe-Ir-radiariance ngeAkukho monakalo

• Kusingqongileyoubuhlobo

Iimpawu eziphambili zoMatshini we-Laser Weld Weller Wolder:

Khuselekile

Iigesi ezikhuselweyo ezisetyenziswayo ze-laser ye-laser ikakhulu ziyi-N2, Ar, kwaye yena. Iipropathi zabo zomzimba kunye neekhemikhali zahlukile, ke iziphumo zabo kwi-welds zahlukile.

Ukufikelela

Inkqubo ye-Wesfuld ye-Welding ixhotywe nge-compact ye-compact ye-compact, ekuboneleleni ngokulula kunye nokuguquguquka ngaphandle kokubethwa, i-weld ingenziwa ngokulula kunye nokusebenza kwe-welding kungaphezulu komgca.

Isebenza kakuhle emalini

Ngokweemvavanyo ezenziwa ngabasebenzi basentsimini, ixabiso lomthi omnye wezandla ye-Laser welding ilingana namaxesha amabini iindleko zomsebenzi womatshini weWolding weMveli.

Ukuziqhelanisa

I-Laser Welsheld ilula ukuba isebenza, inokusebenza ngokulula i-Wel ye-Stainess Stainess Staines, i-Iron Sheet kunye nezinye izinto zensimbi.

Ukuqhubela phambili

Ukuzalwa kwe-Handutld Laser Welder yindawo enkulu yokuphucula ubuchwephesha, kwaye luphawu oluphawuli lwesiko le-wels ye-welc lelc welc welc welc welc wels, i-welling welding kunye neyodwa kwaye ukuze kuthathelwe indawo zizisombululo.

Izixhobo eziqhele ukusetyenziswa kwi-ser yelding-iimpawu kunye neengcebiso:

Olu luhlu lwezixhobo eziqhelekileyo ezisetyenziselwa i-laser ye-welling, kwezinye izinto ezongezelelekileyo kunye neempawu zezixhobo ngokweenkcukacha kunye nezinye iingcebiso zakho ukuze ufezekise iziphumo ezingcono zeldding.

Yenziwe ngentsimbi eshayinayo

Ukulandelwa kwe-thermal ukusebenza kwensimbi engenasimo kuphakama isiqwenga somsebenzi we-ildi engaphezulu xa kukho i-welting yezisombululo, indawo echaphazelekayo iphambili kunezixhobo ezinzima ukuze zikhokele kwiingxaki ezinzima. Nangona kunjalo, ngokusebenzisa umatshini we-selfar we-welding welsuting kusombulula iingxaki ezininzi ze-welding ubushushu obuphantsi, zidibene nento yokuba intsimbi engenasimo iphantsi, inyibilike kwaye inyibilike kwaye inyibilike kwaye inyibilike inyathelo ngokuphumelelayo. I-SORD entle, i-sheld egudileyo inokufumaneka emva kwe-welding ngokukhululekileyo.

I-carbon yensimbi

I-sercheld ye-Laser Welder inokusetyenziswa ngokuthe ngqo kwi-carbon yekharbhoni eqhelekileyo, isiphumo sinokuthelekiswa nentsimbi engenasitali, ngelixa ubushushu obuchaphazelekayo bensimbi, kodwa ngexesha le-welding, iqondo eliyintsalela liphezulu, kunjalo Kusafuneka ukuba uthathe isiqwenga somsebenzi ngaphambi kokuba i-welding ihamba kunye nokugcinwa kobushushu emva kokuphelisa uxinzelelo ukuphepha ukugcoba.

I-Aluminium kunye ne-Aluminium

I-Aluminium kunye ne-Aluminium ye-Aluminium zizinto ezinokubonakalisa kakhulu, kwaye zinokubakho iingxaki zepuzzle kwindawo ye-welding okanye ingcambu yento yomsebenzi. Xa kuthelekiswa nezinto ezidlulileyo zentsimbi, ialuminiyam kunye ne-Aluminium Alloty ziya kuba neemfuno eziphezulu zemigangatho yeparamitha, kodwa lo gama nje iiparamitha ezikhethiweyo zilungile, unokufumana i-wels kunye neempawu zensimbi yeSiseko sensimbi.

Ubhedu kunye nobhedu

Ngokwesiqhelo, xa usebenzisa isisombululo seWolding yeWolding, izinto zobhedu ziya kuphoselwa kwinkqubo ye-welding yokuncedisa ngenxa yokuqhubela phambili kwe-sulmung ephezulu ye-sulmal ye-willing, inxenye ingekaphelelanga kunye nezinye iziphumo ezingafunekiyo ngexesha le-welding. Ngokuchasene noko, i-laser egcinwe ngesandla i-laserder inokusetyenziswa ngokuthe ngqo kwi-welding kunye ne-walvers ye-wored ngaphandle kokuzibophelela ngenxa yobuchule obugqithisileyo obugqithisileyo kunye nesantya seWelding selder.

Kufa intsimbi

Umatshini ophethe ngesandla u-Laser Welling unokusetyenziselwa ukuvelisa iintlobo ezahlukeneyo zensimbi yensimbi, kunye nesiphumo se-welding bahlala bedibana.

I-Saser yethu ekhuthazwayo

I-Laser Welder-Indawo yokusebenzela

◾ Uluhlu lobushushu lwendawo yokusebenza: 15 ~ 35 ℃

I-themidity yenqanaba lendawo yokusebenza: <70% akukho uqinisekiso

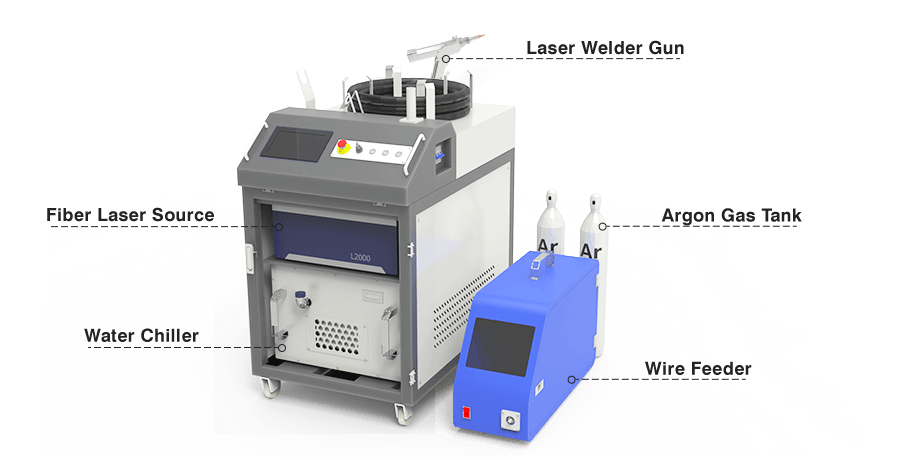

Ukupholisa: I-chiller yamanzi iyimfuneko ngenxa yomsebenzi wokushenxiswa kobushushu obushenxisa ubushushu base-laser, qinisekisa ukuba i-laser ye-laser ibaleka kakuhle.

(Ukusetyenziswa ngokuchanekileyo kunye nesikhokelo malunga ne-chiller yamanzi, ungajonga:Amanyathelo anokuqinisekisa ubungqina benkqubo ye-CO2 ye-CO2)

Ngaba uyafuna ukwazi ngakumbi nge-laser?

I-POSTAL: I-Dec-09-2022