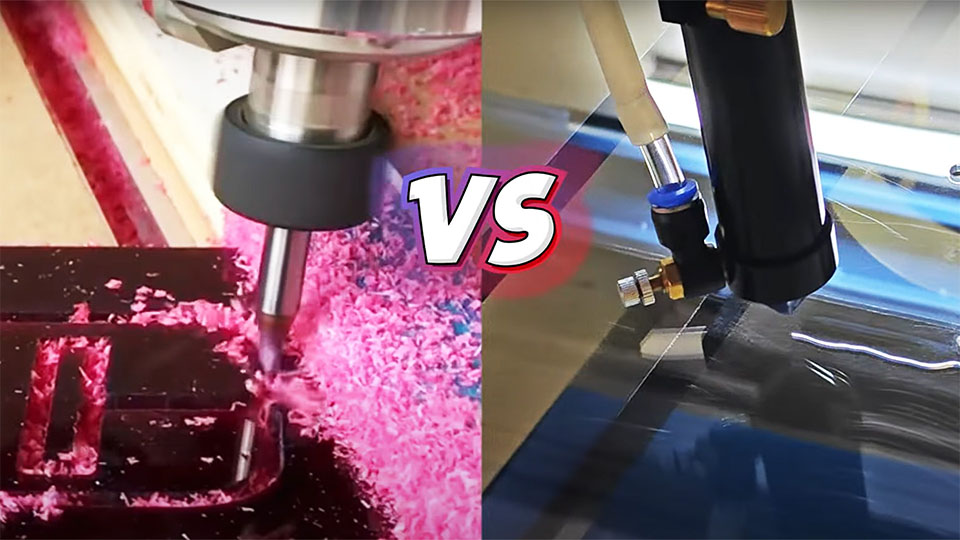

Xa kuziwa ekusikeni kwe-acrylic kunye nokukrola, iirutha ze-CNC kunye ne-lasers zihlala zithelekiswa. Yeyiphi engcono? Inyaniso kukuba, zahlukile kodwa ziyancedisana ngokudlala indima ekhethekileyo kwiinkalo ezahlukeneyo. Yintoni le yantlukwano? Kwaye kufuneka ukhethe njani? Dlula kwinqaku kwaye usixelele impendulo yakho.

Isebenza Njani? CNC Acrylic Cutting

I-router ye-CNC sisixhobo sokusika esiqhelekileyo kunye nesisetyenziswa ngokubanzi. Iintlobo ezahlukeneyo zeebhithi ziyakwazi ukusika kunye nokukrola i-acrylic kwiindawo ezinzulu kunye nezichanekileyo. Iirutha ze-CNC zinokusika amaphepha e-acrylic ukuya kuthi ga kwi-50mm ubukhulu, nto leyo ilungile kwiileta zentengiso kunye neempawu ze-3D. Nangona kunjalo, i-CNC-cut acrylic kufuneka ikhazimliswe emva koko. Njengoko enye ingcali ye-CNC yathi, 'Umzuzu omnye ukusika, imizuzu emithandathu ukupolisha.' Oku kuthatha ixesha. Ngaphezu koko, ukutshintsha amasuntswana kunye nokuseta iiparamitha ezahlukeneyo ezifana ne-RPM, i-IPM, kunye nesantya sesondlo sonyusa iindleko zokufunda nezabasebenzi. Elona candelo libi luthuli kunye nobutyobo kuyo yonke indawo, nto leyo enokuba yingozi xa irholiwe.

Ngokwahlukileyo, i-laser yokusika i-acrylic icocekile kwaye ikhuselekile.

Isebenza Njani? Laser Cutting Acrylic

Ngaphandle kwendawo ecocekileyo yokusika kunye neendawo zokusebenza ezikhuselekileyo, abasiki be-laser banikezela ukusika okuphezulu kunye nokukrola ukuchaneka kunye nomqadi oncinci njenge-0.3mm, i-CNC ayinakuhambelana. Akukho ukupolisha okanye ukutshintshwa kancinci okufunekayo, kwaye ngokucocwa okuncinci, ukusika kwe-laser kuthatha kuphela i-1/3 yexesha lokugaya i-CNC. Nangona kunjalo, ukusika kwe-laser kunemida yobukhulu. Ngokuqhelekileyo, sincoma ukusika i-acrylic ngaphakathi kwe-20mm ukufezekisa umgangatho obalaseleyo.

Ke, ngubani omele akhethe i-laser cutter? Kwaye ngubani omele akhethe i-CNC?

Ngubani omele akhethe i-CNC Router?

• IiMechanics Geek

Ukuba unamava kubunjineli boomatshini kwaye unokuphatha iiparamitha ezintsonkothileyo ezifana ne-RPM, ireyithi yokutya, iifluti, kunye neemilo zengcebiso (cue upopayi we-CNC router engqongwe ngamagama obugcisa ngenkangeleko 'eqhotsiweyo ebuchotsheni'), irutha ye-CNC lukhetho olukhulu.

• Ngokusikwa kweMathiriyeli eThiyekileyo

Ilungele ukusika i-acrylic engqindilili, ngaphezulu kwe-20mm, iyenza igqibelele ngoonobumba be-3D okanye iiphaneli ezishinyeneyo ze-aquarium.

• NgeMizobo eNzulu

I-router ye-CNC iyagqwesa kwimisebenzi yokukrola enzulu, efana nokukrolwa kwesitampu, ngenxa yokugaya okuqinileyo koomatshini.

Ngubani omele akhethe i-Laser Router?

• NgeMisebenzi echanekileyo

Ilungele imisebenzi efuna ukuchaneka okuphezulu. Kwiibhodi zokufa ze-acrylic, iinxalenye zonyango, iideshibhodi zemoto kunye nenqwelomoya, kunye ne-LGP, i-laser cutter inokufezekisa ukuchaneka kwe-0.3mm.

• Kufuneka ekuhleni okuPhezulu

Kwiiprojekthi ezicacileyo ze-acrylic ezifana neebhokisi zokukhanya, iipaneli zokubonisa i-LED, kunye needeshibhodi, iilaser ziqinisekisa ukucaca okungenakulinganiswa kunye nokungafihli.

• Ukuqala eqala

Kumashishini agxile kwizinto ezincinci, ezinexabiso eliphezulu ezifana nobucwebe, iziqwenga zobugcisa, okanye iindebe, i-laser cutter inikezela ngokulula kunye nokuguquguquka kokwenziwa ngokwezifiso, ukwenza iinkcukacha ezityebileyo nezilungileyo.

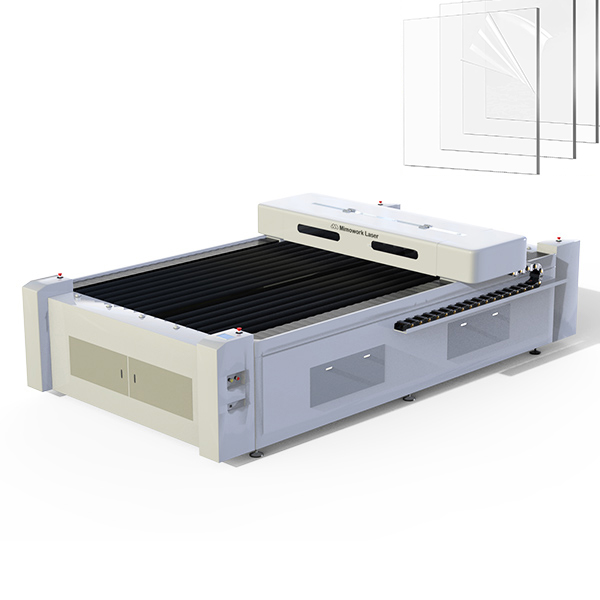

Kukho oomatshini ababini bokusika i-laser esemgangathweni kuwe: abakroli be-laser encinci ye-acrylic (yokusika kunye nokukrola) kunye nefomathi enkulu ye-acrylic sheet laser cutting machines (enokusika i-acrylic engqindilili ukuya kwi-20mm).

1. I-Acrylic Laser Cutter encinci kunye ne-Engaraver

• Indawo yokusebenzela (W * L): 1300mm * 900mm (51.2” * 35.4 ”)

• Amandla eLaser: 100W/150W/300W

• Umthombo weLaser: CO2 Glass Laser Tube okanye CO2 RF Metal Laser Tube

• Isantya esiphezulu sokusika: 400mm/s

• Ubukhulu besantya sokukrola: 2000mm/s

Iumsiki we-laser flatbed 130ilungile kwizinto ezincinci zokusika kunye nokukrola, njenge-keychain, imihombiso. Kulula ukuyisebenzisa kwaye igqibelele kuyilo oluntsonkothileyo.

2. I-Acrylic Sheet enkulu yeLaser Cutter

• Indawo yokusebenzela (W * L): 1300mm * 2500mm (51” * 98.4”)

• Amandla eLaser: 150W/300W/450W

• Umthombo weLaser: CO2 Glass Laser Tube okanye CO2 RF Metal Laser Tube

• Isantya esiphezulu sokusika: 600mm/s

• Ukuchaneka kwendawo: ≤±0.05mm

Iflatbed laser cutter 130Lilungele ifomathi enkulu ye-acrylic sheet okanye i-acrylic engqingqwa. Ulungile ekuphatheni imiqondiso yentengiso, umboniso. Ubungakanani obukhulu bokusebenza, kodwa ukusika okucocekileyo kunye nokuchanekileyo.

Ukuba uneemfuno ezikhethekileyo ezinje ngokukrola kwizinto zecylindrical, ukusika i-sprues, okanye iindawo ezikhethekileyo zeemoto,thetha nathiiingcebiso zobungcali laser. Silapha ukukunceda!

Inkcazo yevidiyo: I-CNC Router VS Laser Cutter

Isishwankathelo, ii-router ze-CNC zinokuphatha i-acrylic engqindilili, ukuya kuthi ga kwi-50mm, kwaye zinikeze izinto ezininzi ezahlukeneyo ngamasuntswana ahlukeneyo kodwa zifuna ukupolisha emva kokusikwa kwaye zivelise uthuli. Abasiki beLaser babonelela ngesicoci, ukusikwa okuchane ngakumbi, akukho mfuneko yokutshintshwa kwesixhobo, kwaye akukho kunxitywa kwesixhobo. Kodwa, ukuba ufuna ukusika i-acrylic etyebileyo kune-25mm, iilaser aziyi kunceda.

Ke, i-CNC VS. I-Laser, yeyiphi engcono kwimveliso yakho ye-acrylic? Yabelana nathi ngezimvo zakho!

1. Uthini umahluko phakathi kwe-CNC acrylic kunye ne-laser cutting?

Iirutha ze-CNC zisebenzisa isixhobo sokusika esijikelezayo ukuze zisuse izinto ezibonakalayo, ezifanelekileyo kwi-acrylic engqindilili (ukuya kuthi ga kwi-50mm) kodwa zihlala zifuna ukupolisha. Abasiki beLaser basebenzisa i-laser beam ukuze banyibilike okanye bafake umphunga kwizinto eziphathekayo, banikezela ngokuchaneka okuphezulu kunye nemiphetho ecocekileyo ngaphandle kwemfuneko yokupolisha, eyona nto ingcono kwi-acrylic encinci (ukuya kwi-20-25mm).

2. Ngaba ukusika i-laser kungcono kune-CNC?

Abasiki beLaser kunye ne-CNC routers bagqwesa kwiindawo ezahlukeneyo. Abasiki beLaser banikezela ngokuchaneka okuphezulu kunye nokusikeka okucociweyo, okufanelekileyo kuyilo oluntsonkothileyo kunye neenkcukacha ezintle. Iirutha ze-CNC ziyakwazi ukuphatha imathiriyeli engqindilili kwaye zingcono kumzobo onzulu kunye neeprojekthi ze-3D. Ukukhetha kwakho kuxhomekeke kwiimfuno zakho ezithile.

3. Ithetha ukuthini i-CNC kwi-laser cutting?

Kwi-laser cutting, i-CNC imele "uLawulo lweenombolo zeKhompyutha." Ibhekisa kulawulo oluzenzekelayo lwe-laser cutter usebenzisa ikhompyuter, eyalathisa ngokuchanekileyo intshukumo kunye nokusebenza komqadi welaser ukusika okanye ukukrola izinto.

4. Ukukhawuleza kangakanani i-CNC xa kuthelekiswa nelaser?

Iirutha ze-CNC ziqhele ukusika imathiriyeli engqindilili ngokukhawuleza kune-laser cutters. Nangona kunjalo, abasiki belaser bayakhawuleza kuyilo oluneenkcukacha kunye noluntsokothileyo kwizixhobo ezibhityileyo, njengoko abafuni tshintsho lwesixhobo kwaye babonelele ngokusikeka okucociweyo ngokucocwa kancinci emva kokulungiswa.

5. Kutheni i-diode laser ayikwazi ukusika i-acrylic?

Iilaser zeDiode zinokuzabalaza kunye ne-acrylic ngenxa yemicimbi ye-wavelength, ngakumbi ngezinto ezicacileyo okanye ezinombala okhanyayo ezingabambi kakuhle ukukhanya kwelaser. Ukuba uzama ukusika okanye ukukrola i-acrylic nge-laser diode, kungcono ukuvavanya kuqala kwaye ulungele ukusilela okunokwenzeka, njengoko ukufumana useto oluchanekileyo kunokuba lucelomngeni. Ukukrola, unokuzama ukutshiza umaleko wepeyinti okanye usebenzise ifilimu kwindawo ye-acrylic, kodwa ngokubanzi, ndincoma ukusebenzisa i-CO2 laser ngeziphumo ezilungileyo.

Ngaphezu koko, iilaser zediode zinokusika i-acrylic emnyama, e-opaque. Nangona kunjalo, abanakusika okanye bakrole i-acrylic ecacileyo ngenxa yokuba izinto eziphathekayo aziwubambi kakuhle umqa we-laser. Ngokukodwa, i-laser ye-diode eluhlaza okwesibhakabhaka ayinakusika okanye ikrole i-acrylic eluhlaza ngesizathu esifanayo: umbala ohambelanayo uthintela ukufunxa ngokufanelekileyo.

6. Yiyiphi i-laser efanelekileyo yokusika i-acrylic?

I-laser engcono kakhulu yokusika i-acrylic yi-CO2 laser. Ibonelela ngokucocekileyo, ukusikwa okuchanekileyo kwaye iyakwazi ukusika ubukhulu obuhlukeneyo be-acrylic ngokufanelekileyo. Iilaser ze-CO2 zisebenza kakuhle kwaye zifanelekile kuzo zombini i-acrylic ecacileyo kunye nenemibala, ezenza zibe lolona khetho lukhethwayo kubuchwephesha kunye nomgangatho ophezulu wokusika i-acrylic kunye nokukrola.

Khetha umatshini ofanelekileyo kwimveliso yakho ye-acrylic! Nawuphi na umbuzo, dibana nathi!

Ixesha lokuposa: Jul-27-2024