Usetyenziso oluqhelekileyo lwe-laser welding

Oomatshini bokuwelda beLaser banokunyusa umthamo wemveliso kunye nokuphucula umgangatho wemveliso xa kufikwa kwimveliso yentsimbi. Isetyenziswa kakhulu kuzo zonke iinkalo zobomi:

▶ Umzi-mveliso weZinto zoGutyulo: Ukuwelda kwezifakelo zemibhobho, izixhobo zokunciphisa, iithiyi, iivalvu, neeshawari

▶ Umzi-mveliso wempahla yamehlo: Ukuwelda okuchanekileyo kwentsimbi engatyiwa, i-titanium alloy, kunye nezinye izinto zentsimbi yamehlo kunye nefreyimu yangaphandle.

▶ Umzi-mveliso we-Hardware: i-impeller, iketile, imiqheba yokuwelda, iindawo ezintsonkothileyo zokutywina, kunye neendawo zokuphosa.

▶ Umzi-mveliso weemoto: i-injini yesilinda, i-hydraulic tappet seal welding, i-spark plug welding, i-welding filter, njl.

▶ Umzi-mveliso wezonyango: ukuwelda izixhobo zonyango, intsimbi yetywina, kunye nezakhiwo zezixhobo zonyango.

▶ Umzi-mveliso wezobuchwephesha: Ukutywina kunye nokwaphula i-welding ye-slid state relays, ukuwelda iziqhagamshelo neziqhagamshelo, ukuwelda amaqokobhe esinyithi kunye nezinto eziyilwe njengeeselfowuni kunye nezidlali zeMP3. Iindawo ezivaliweyo zeemoto kunye nezihlanganisi, i-fiber optic connector joints welding.

▶ Izinto zendlu, ikhitshi, igumbi lokuhlambela, imiqheba yamacango entsimbi, izinto ze-elektroniki, izixhobo zoluvo, iiwotshi, oomatshini abacokisekileyo, unxibelelwano, ubugcisa neminye imizi-mveliso, iitapethi zeemoto ezisebenza ngehydraulic, neminye imizi-mveliso enemveliso yodidi oluphezulu.

Iimpawu ze-laser welding

1. Ugxininiso lwamandla aphezulu

2. Akukho lungcoliso

3. Indawo encinci ye-welding

4. Uluhlu olubanzi lwezinto ze-welding

5. Ukusebenza okuqinileyo

6. Ukusebenza okuphezulu kunye ne-welding high-speed

Yintoni umatshini welding laser?

Umatshini wokuwelda we-laser uyaziwa ngokuba ngumatshini wokuwelda we-laser ongalunganga, umatshini wokuwelda obandayo we-laser, umatshini wokuwelda we-laser argon, izixhobo zokuwelda i-laser, njl.

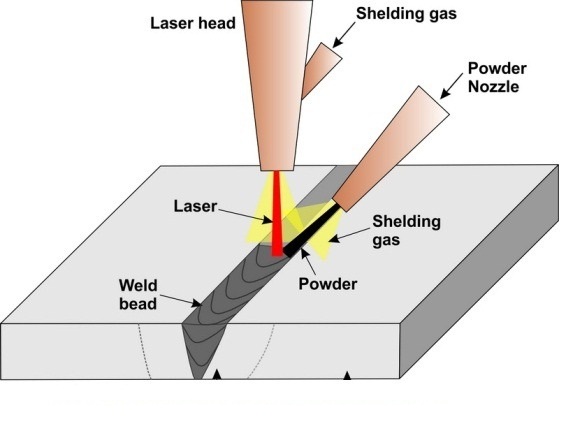

Ukuwelda kweLaser kusebenzisa i-laser pulses ephezulu yamandla ukufudumeza kwalapha indawo imathiriyeli kwindawo encinci. Amandla emitha yelaser asasazeke kwizinto ngokuqhuba ubushushu, kwaye izinto ziyanyibilika ukwenza ichibi elithile elityhidiweyo. Yindlela entsha ye-welding, esetyenziswa ikakhulu kwizinto ezincinci zodonga kunye neendawo ezichanekileyo zokuwelda. Iyakwazi ukufikelela kumlinganiselo ophezulu we-weld, ububanzi obuncinane be-weld, ubushushu obuncinci obuchaphazelekayo kwindawo ye-welding, i-butt welding, i-welding ye-seam, i-welding ye-seal, njalo njalo. I-deformation encinci, isantya se-welding ekhawulezayo, i-weld egudileyo kunye nenhle, akukho kulungiswa okanye ukusetyenzwa okulula emva kwe-welding, i-weld ekumgangatho ophezulu, akukho pores, ulawulo oluchanekileyo, ukugxila okuncinci, ukuchaneka kokuma okuphezulu, kulula ukuyiqonda i-automation.

Zeziphi iimveliso ezifanelekileyo ukusetyenziswa umatshini welding laser

Iimveliso ezineemfuno ze-welding:

Iimveliso ezifuna i-welds zifakwe kwi-welding ye-laser, ezingenayo kuphela i-welds encinci ububanzi kodwa ayifuni i-solder.

Iimveliso ezizenzekelayo kakhulu:

Kule meko, izixhobo ze-laser welding zinokucwangciswa ngesandla ukuba zidibanise kwaye indlela iyazenzekela.

Iimveliso kubushushu begumbi okanye phantsi kweemeko ezizodwa:

Iyakwazi ukumisa i-welding kwindawo yokushisa okanye phantsi kweemeko ezikhethekileyo, kunye nezixhobo ze-laser welding kulula ukuzifaka. Umzekelo, xa i-laser idlula kwindawo ye-electromagnetic, umqadi awujiki. I-laser inokuwelda kwi-vacuum, umoya, kunye neemeko ezithile zegesi, kwaye inokudlula kwiglasi okanye izinto ezibonakalayo elubala kwi-beam ukumisa ukuwelda.

Ezinye iindawo ezinzima ukufikelela kuzo zifuna izixhobo zokuwelda ngelaser:

Iyakwazi ukuwelda iindawo ekunzima ukufikelela kuzo, kwaye ifezekise i-welding ekude, enovakalelo oluphezulu. Ngokukodwa kwiminyaka yakutshanje, phantsi kwemeko ye-YAG laser kunye ne-fiber laser technology ikhulile kakhulu, iteknoloji ye-laser welding iye yakhuthazwa ngokubanzi kwaye yasetyenziswa.

Funda ngakumbi malunga nezicelo ze-laser welding kunye neentlobo zoomatshini

Ixesha lokuposa: Aug-16-2022