Kutheni le nto uziphande xa sikwenzele wena?

Ngaba ucinga ngokutyala imali kwi-laser welder ephathwayo?

Ezi zixhobo ziguquguqukayo ziguqula indlela yokwenza i-welding, inikezela ngokuchanekileyo kunye nokusebenza kakuhle kwiiprojekthi ezahlukeneyo.

Nangona kunjalo, ngaphambi kokuthenga, kubalulekile ukuqonda iinkalo ezininzi eziphambili.

Kweli nqaku, siza kugubungela yonke into ekufuneka uyazi,

kuquka indlela yokukhetha umthombo we-laser ochanekileyo ngokusekelwe kwiimfuno zakho ezithile,

iinketho ezikhoyo zokwenza ulungelelwaniso lwewelder kwiiprojekthi zakho,

kunye nezinye izinto ezibalulekileyo ekufuneka ziqwalaselwe.

Nokuba ungumntu othanda izinto zokuzonwabisa okanye unobuchule,

esi sikhokelo siya kukuxhobisa ngolwazi ukuze wenze isigqibo esinolwazi

kwaye ufumane i-laser welder efanelekileyo ephathwayo kwiimfuno zakho.

Usetyenziso lweLaser Welding Machine

Oomatshini bokuwelda i-laser ephathwayo baye bathandwa kakhulu ngenxa yokuguquguquka kwabo kunye nokusebenziseka ngokulula.

Nazi ezinye izicelo ezithile apho aba matshini bagqwesileyo:

Iintsimbi ze-laser eziphathwa ngesandla zilungele iiprojekthi zokwenziwa kwentsimbi ezincinci.

Banokudibanisa ngokulula iintsimbi ezahlukeneyo, njengentsimbi engatyiwa, ialuminiyam kunye nobhedu.

Esi sixhobo siluncedo ngakumbi ekudaleni iinxalenye zentsimbi yesiko, iiprototypes, okanye uyilo oluntsonkothileyo olufuna ukuchaneka.

Kushishino lweemoto, oomatshini bokuwelda belaser ngesandla basetyenziselwa ukulungisa umsebenzi womzimba kunye namalungu esakhiwo.

Ukukwazi kwabo ukuwelda ngokuchanekileyo izixhobo ezibhityileyo ngaphandle kokungqubana okanye ukonakalisa iindawo ezingqongileyo kubenza balungele ukulungisa iipaneli zeemoto, iinkqubo zokukhupha, kunye nezinye iindawo zentsimbi.

Abachwephesha bezacholo baxhamla kakhulu kwiiwelder zelaser eziphathwa ngesandla.

Aba matshini bavumela ukuwelda okuneenkcukacha kunye nokuchanekileyo kweentsimbi ezixabisekileyo, okwenza amatye anqabileyo ukuba enze uyilo oluntsonkothileyo kunye nokulungiswa kwamaqhekeza athambileyo ngaphandle kokulahla ingqibelelo yabo.

Ukugcina nokulungiswa kwemisebenzi kumashishini ahlukeneyo, oomatshini be-laser welding welding banika isisombululo esiphathwayo.

Amagcisa anokwenza ulungiso kwisiza, njengezinto zokuwelda, izibiyeli, kunye nezinye izinto zentsimbi, ngaphandle kokufuna ukuzithutha ukuya kwindawo yokusebenzela.

Amagcisa kunye nabakroli baya beguqukela ngakumbi kwi-laser welding ephathwayo ukwenza imifanekiso eqingqiweyo yesinyithi.

Ikhono lokusebenzisa kunye nokudibanisa izinto ngokuchaneka livumela ukubonakaliswa kobugcisa obutsha kunye nezakhiwo ezinzima.

Kwi-HVAC kunye nokusetyenziswa kwemibhobho, i-laser welders ephathwayo isetyenziselwa ukujoyina imibhobho kunye nokufakelwa.

Ukukwazi ukudibanisa ngaphandle kwezinto zokuzalisa ezongezelelweyo ziqinisekisa amajoyina aqinileyo kwaye kunciphisa umngcipheko wokuvuza kwiinkqubo ezibalulekileyo.

Iivenkile ezincinci zokwenziwa kwesiko zixhamla kububhetyebhetye koomatshini bokuwelda belaser ngesandla.

Banokukhawuleza ukuziqhelanisa neeprojekthi ezahlukeneyo, bevelisa yonke into ukusuka kwifanitshala yesiko ukuya kwizixhobo ezikhethekileyo ezichanekileyo.

Ukuthelekisa phakathi kweendlela ezahlukeneyo zeWelding

Oomatshini bokuwelda ngesandla be-laser babonelela ngesisombululo sale mihla semisebenzi yokuwelda,

inika iingenelo ezahlukileyo kwiindlela zemveli ezifana ne-TIG, i-MIG, kunye ne-Stick welding.

Nalu uthelekiso oluthe ngqo lwezi ndlela zokuwelda:

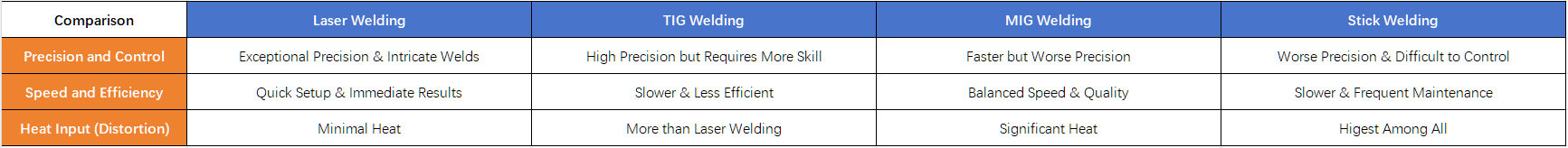

Itshathi ebonisa uthelekiso phakathi kweendlela ezahlukeneyo zokuwelda

Ngaba uyafuna ukwazi ngakumbi malunga noomatshini bokuwelda beLaser?

Qala ukuncokola nathi namhlanje!

Ukwenziwa ngokwezifiso kunye noKhetho

Sinikezela ngoluhlu olubanzi lweenketho zokwenza ngokwezifiso kubathengi bethu.

Unokukhetha yonke into esuka kumthombo we-laser kunye nemodyuli yokucoca kwimodyuli ye-laser kunye ne-chiller yamanzi.

Kwaye, ukuba uodola ngobuninzi (iiyunithi ezili-10 okanye ngaphezulu), unokukhetha umbala owuthandayo!

Ukukhethwa koMthombo weLaser

I-JPT ngumenzi obalaseleyo owaziwayo ngemithombo yayo ye-laser ekumgangatho ophezulu, ngakumbi kwintsimi ye-fiber laser technology.

Banikezela ngoluhlu lweemveliso ezifanelekileyo kwizicelo ezahlukeneyo, kubandakanya ukuwelda, ukusika, kunye nokumakishwa.

I-laser ye-JPT ibonwa ngokuthembeka kunye nokusebenza, ukubonelela ngeziphumo ezizinzileyo kunye nokusetyenziswa kwamandla ngokufanelekileyo.

Inkampani igxile ekwenzeni izinto ezintsha, ngokuqhubekayo iphucula iimveliso zayo ukuhlangabezana neemfuno zeshishini.

Inkxaso yabo yabathengi kunye nenkonzo ngokubanzi zijongwa kakuhle, zibenza ukhetho oludumileyo phakathi kwabasebenzisi.

I-RAYCUS ngomnye umvelisi okhokelayo wemithombo yefiber laser, enobukho obunamandla kwiimarike zasekhaya nezamazwe ngamazwe.

Basebenza ngokukhethekileyo ekuphuhliseni nasekuveliseni iinkqubo zelaser ezibonelela uluhlu olubanzi lwezicelo zamashishini, ezinje ngokusika, ukukrola, kunye nokuwelda.

I-RAYCUS lasers ziyaziwa ngamaxabiso azo okukhuphisana kunye nokusebenza okuqinileyo, okunomtsalane kuluhlu olubanzi lwabathengi.

Inkampani igxininisa uphando kunye nophuhliso, izama ukwandisa ukusebenza kakuhle kunye nokubanako kwemithombo yelaser ngelixa igcina imigangatho yolawulo elungileyo.

I-MAX luphawu oluhlonelwayo kumzi-mveliso we-laser, ngakumbi olwamkelwa ubuchwephesha bayo belaser yefiber ephezulu.

Banikezela ngemithombo eyahlukeneyo yelaser eyenzelwe izicelo ezifana nokumakisha, ukukrola, kunye nokusika.

Ii-laser ze-MAX ziphawulwa ngokuchaneka kwazo okuphezulu kunye nomgangatho obalaseleyo we-beam, ezinegalelo kwiziphumo eziphezulu kwimisebenzi eyahlukeneyo.

Inkampani iphinda igxininise kakhulu kwinkonzo yabathengi kunye nenkxaso, iqinisekisa ukuba abasebenzisi bafumana uncedo xa lufuneka.

I-MAX ihlala inconywa ngendlela yayo entsha kunye nokuzinikela ekunikezeni izisombululo ezithembekileyo nezisebenzayo zelaser.

Ngaba ufuna enye into?

Yichaze!

Siza kuyenza yenzeke!

(Ukuba kuyenzeka.)

Iinketho zokwenza ngokwezifiso

1. Imodyuli ye-Single Axis Swing

2. Imodyuli ye-Axis Swing ephindwe kabini

3. SuperCharged Module

Ukutya okuSebenzayo kweFiller ngocingo ngexesha lokuSebenza kwe-Welding.

1. Inguqulelo ezimeleyo

2. Integrated Verson

Iyafumaneka kwiBule Ukuthenga ngaphezulu kwe-10

Awuqinisekanga ukuba ungakhetha ntoni? Akukho maxhala!

Sazise nje ukuba zeziphi izixhobo oza kusebenza ngazo, ubukhulu bazo, kunye nesantya osifunayo sokuwelda.

Silapha ukukunceda wenze ukuseta okugqibeleleyo kwiimfuno zakho!

Izixhobo zeLaser Welder

Kwizinto ezincedisayo, sinikezela ngeelensi ezongezelelweyo zokukhusela kunye neentlobo ezahlukeneyo zemilomo eyenzelwe usetyenziso lwewelding ezahlukeneyo.

Ukuba ufuna ulwazi oluneenkcukacha okanye ufuna ukuthenga izixhobo ezongezelelweyo, zive ukhululekile ukuncokola nathi!

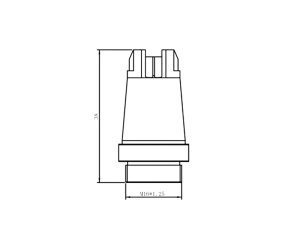

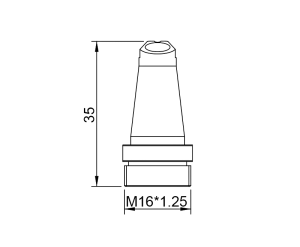

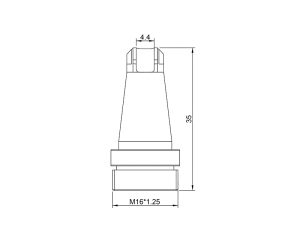

UKhetho lweMibhobho eyahlukeneyo yokuCoca iLaser/umatshini wokuwelda

Ulwazi olongezelelweyo malunga neLaser Welder

Ngokungafaniyo neendlela zokuwelda, aba matshini basebenzisa imiqadi yelaser egxininisiweyo ukwenza iiwelds ezomeleleyo, ezicocekileyo ezinokuphazamiseka okuncinci kobushushu.

| Ukhetho lwamandla | 500W- 3000W |

| Imo yokusebenza | Iyaqhubekeka/ Lungiselela |

| Ukuhlelwa kweLaser | I-Optical Fiber Laser |

| Indlela yokupholisa | I-Industrial Water Chiller |

| Uphawu lokuthengisa | MimoWork Laser |

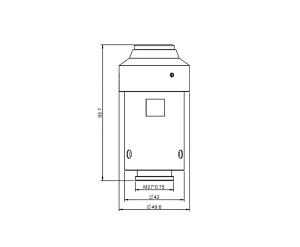

Ngokubonakala komatshini odibeneyo kunye nomncinci, uxhotyiswe ngompu oshukumayo we-welder elula kwaye ulungele ukusetyenziswa kwe-laser ye-welding eninzi kuyo nayiphi na i-angle kunye nomhlaba.

| Ukhetho lwamandla | 1000W - 1500W |

| Imo yokusebenza | Iyaqhubekeka/ Lungiselela |

| Isantya seWelding | 0~120 mm/s |

| Iimfuno ze-Weld Seam | <0.2mm |

| Uphawu lokuthengisa | MimoWork Laser |

Iividiyo malunga neLaser Welding

Oomatshini bokuwelda bezandla belaser zizixhobo ezintsha ezenzelwe ukuwelda kwesinyithi ngokuchanekileyo nangokufanelekileyo.

Ziyaphatheka kwaye zisebenziseka lula, zizenza zilungele usetyenziso oluhlukeneyo, ukusuka ekulungisweni kweemoto ukuya ekwenzeni ubucwebe.

Ngokukwazi ukuwelda izixhobo ezibhityileyo kunye noyilo oluntsonkothileyo, iiwelda ze-laser eziphathwayo zilungele iiprojekthi ezincinci ezifuna ukuchaneka.

Ukuguquguquka kwabo kuvumela abasebenzisi ukuba basebenze kwisiza, ukunciphisa imfuno yokuseta okubanzi okanye oomatshini abanzima.

Ngenxa yoko, ziya zithandwa kakhulu phakathi kweengcali kunye nabadlali bokuzonwabisa abafuna izisombululo ezithembekileyo nezisebenzayo.

Ixesha lokuposa: Nov-06-2024