Inkqubo ye-laser welding esisiseko ibandakanya ukugxila kwi-laser beam kwindawo edibeneyo phakathi kwezinto ezimbini usebenzisa inkqubo yokuhanjiswa kwe-optical. Xa i-boam idibanisa nezinto eziphathekayo, idlulisela amandla ayo, ifudumeza ngokukhawuleza kwaye inyibilike indawo encinci.

Itheyibhile yomxholo

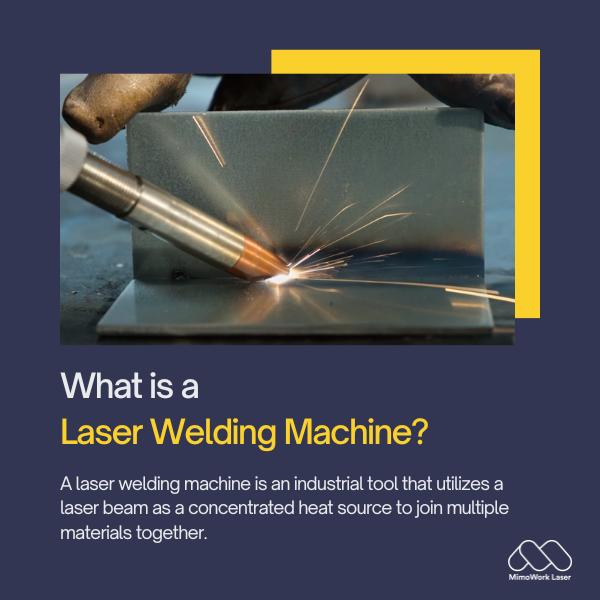

1. Yintoni iLaser Welding Machine?

Umatshini we-laser welding sisixhobo soshishino esisebenzisa i-laser beam njengomthombo wokushisa ogxininisiweyo ukujoyina izinto ezininzi kunye.

Ezinye iimpawu eziphambili koomatshini bokuwelda ngelaser ziquka:

1. Umthombo weLaser:Uninzi lwabashicileli belaser bale mihla basebenzisa i-solid-state laser diode evelisa umqadi welaser onamandla aphezulu kwi-infrared spectrum. Imithombo ye-laser eqhelekileyo ibandakanya i-CO2, i-fiber, kunye ne-diode lasers.

2. Amehlo:I-laser beam ihamba ngoluhlu lwamacandelo e-optical njengezibuko, iilensi, kunye nemibhobho egxininisa kwaye iqondise i-beam kwindawo ye-weld ngokuchanekileyo. Iingalo zetelescoping okanye iigantries zibeka umqadi.

3. Ukuzenzekela:Uninzi lwee-laser welders lubandakanya ulawulo lwamanani ekhompyuter (CNC) kunye nerobhothi ukwenza iipateni ezintsonkothileyo zokuwelda kunye neenkqubo. Iindlela ezicwangcisiweyo kunye nezinzwa zempendulo ziqinisekisa ukuchaneka.

4. Ukubeka iliso kwinkqubo:Iikhamera ezidityanisiweyo, ii-spectrometers, kunye nezinye izinzwa esweni inkqubo yokuwelda ngexesha lokwenyani. Nayiphi na imiba ngolungelelwaniso lomqadi, ukungena, okanye umgangatho unokufunyanwa ngokukhawuleza kwaye uqwalaselwe.

5. Ukhuseleko lonxibelelwano:Izindlu ezikhuselayo, iingcango, kunye namaqhosha e-e-stop akhusela abasebenzi kumqadi welaser one-powered ephezulu. Ii-Interlocks zivala i-laser ukuba iiprothokholi zokhuseleko zophulwe.

Ke ngoko, isishwankathelo, umatshini we-laser welding sisixhobo esilawulwa yikhompyuter, esichanekileyo kwimizi-mveliso esebenzisa umqadi ogxininisiweyo welaser ozenzekelayo, uphinda-phinda izicelo zokuwelda.

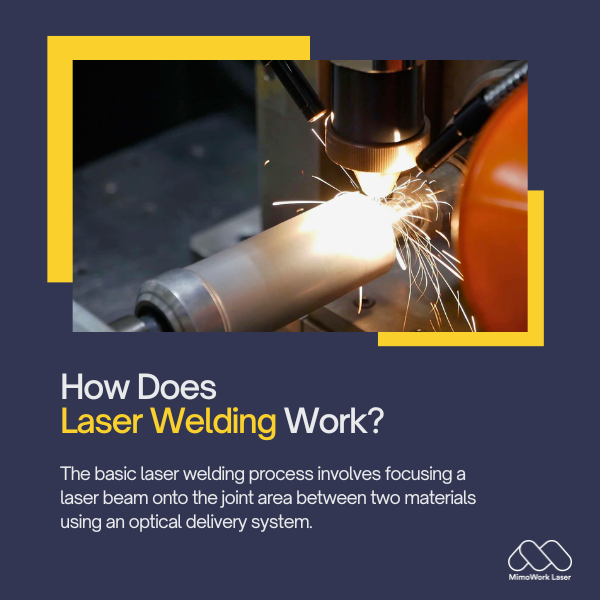

2. Isebenza njani iLaser Welding?

Ezinye izigaba eziphambili kwinkqubo ye-laser welding ziquka:

1. ILaser Beam Generation:I-solid-state laser diode okanye omnye umthombo uvelisa i-infrared beam.

2. Ukuhanjiswa kweBeam: Izibuko, iilensi, kunye nombhobho zigxininisa ngokuchanekileyo umqadi kwindawo eqinileyo kwindawo yokusebenza.

3. Ukufudumala kweMathiriyeli:Umqadi utshisa ngokukhawuleza izinto eziphathekayo, kunye noxinzelelo olusondela kwi-106 W / cm2.

4. Ukunyibilika kunye nokudibanisa:Idama elincinci lokunyibilika libumba apho imathiriyeli ixubana khona. Njengoko i-pool iqina, i-weld joint yenziwa.

5. Ukupholisa kunye nokuqinisa kwakhona: Indawo ye-weld ipholisa kumazinga aphezulu ngaphezu kwe-104 ° C / yesibini, idala i-microstructure ecocekileyo, eqinile.

6. Ukuqhubela phambili:Umqadi uyashukuma okanye iinxalenye zibekwe ngokutsha kwaye inkqubo iphinda igqibezele i-weld seam. Irhasi yokukhusela engasebenziyo nayo ingasetyenziswa.

Ke ngoko isishwankathelo, i-laser welding isebenzisa umqadi welaser ogxininise kakhulu kunye nokulawulwa kwebhayisekile eshushu ukuvelisa umgangatho ophantsi, welds ezichatshazelwe bubushushu obuphantsi.

Sibonelele ngolwazi oluluncedo koomatshini bokuwelda beLaser

Kanye kunye nezisombululo ezenzelwe wena kwiShishini lakho

3. Ngaba i-Laser Welding ingcono kune-MIG?

Xa kuthelekiswa nenkqubo yokuwelda igesi yentsimbi yemveli (MIG)...

I-laser welding ineenzuzo ezininzi:

1. Ukuchaneka: Imiqadi yeLaser inokujoliswa kwindawo encinci ye-0.1-1mm, ivumela ukuchaneka okuchanekileyo, ukuphinda kuphindwe kwakhona. Oku kukulungele kwiindawo ezincinci, ezinokunyamezela okuphezulu.

2. Isantya:Amaxabiso e-welding ye-laser akhawuleza kakhulu kune-MIG, ngakumbi kwiigeyiji ezincinci. Oku kuphucula imveliso kwaye kunciphisa amaxesha omjikelezo.

3. Umgangatho:Umthombo wobushushu obugxininisiweyo uvelisa ukugqwetheka okuncinci kunye neendawo ezincinci ezichaphazelekayo kubushushu. Oku kubangela iiwelds ezinamandla, ezikumgangatho ophezulu.

4. Ukuzenzekela:Ukuwelda kweLaser kulula ngokuzenzekelayo kusetyenziswa iirobhothi kunye neCNC. Oku kwenza iipateni ezintsonkothileyo kunye nokuphuculwa kokuqina vs manual MIG welding.

5. Izinto:I-Lasers inokujoyina indibaniselwano yezinto ezininzi, kubandakanya izinto ezininzi kunye neentsimbi zentsimbi ezingafaniyo.

Nangona kunjalo, i-MIG welding inayoezinye iingenelophezu kwe-laser kwezinye izicelo:

1. Iindleko:Izixhobo ze-MIG zinexabiso eliphantsi lotyalo-mali lokuqala kuneenkqubo zelaser.

2. Imathiriyeli engqindilili:I-MIG ifanelekele ngakumbi ukuwelda amacandelo entsimbi atyebileyo ngaphezulu kwe-3mm, apho ukufunxwa kwelaser kunokuba yingxaki.

3. Irhasi yokukhusela:I-MIG isebenzisa ikhaka legesi engasebenziyo ukukhusela indawo ye-weld, ngelixa i-laser ihlala isebenzisa indlela evaliweyo.

Ke ngoko isishwankathelo, i-laser welding ikhethwa ngokubanziukuchaneka, ukuzenzekelayo, kunye nomgangatho we-welding.

Kodwa i-MIG ihlala ikhuphisana kwimveliso yeiigeyiji ezityebileyo kuhlahlo lwabiwo-mali.

Inkqubo echanekileyo ixhomekeke kwisicelo esithile se-welding kunye neemfuno zenxalenye.

4. Ngaba i-Laser Welding ingcono kune-TIG Welding?

I-tungsten inert gas (TIG) welding yinkqubo yezandla, enobugcisa obunokuvelisa iziphumo ezigqwesileyo kwizinto ezibhityileyo.

Nangona kunjalo, i-laser welding ineengenelo ezithile ngaphezulu kwe-TIG:

1. Isantya:I-laser welding ikhawuleza kakhulu kune-TIG kwizicelo zemveliso ngenxa yokuchaneka kwayo okuzenzekelayo. Oku kuphucula ukwenziwa komsebenzi.

2. Ukuchaneka:I-laser beam egxininisiweyo ivumela ukuchaneka kwendawo ukuya kwikhulu le-millimeter. Oku akunakuthelekiswa sisandla somntu esine-TIG.

3. Ulawulo:Izinto eziguquguqukayo zenkqubo ezinje ngegalelo lobushushu kunye nejometri yeweld zilawulwa ngokuqinileyo ngelaser, ziqinisekisa ukuba iziphumo zebhetshi phezu kwebhetshi engaguqukiyo.

4. Izinto:I-TIG yeyona nto ingcono kwizixhobo zokuqhuba ezibhityileyo, ngelixa i-laser welding ivula uluhlu olubanzi lokudityaniswa kwezinto ezininzi.

5. Ukuzenzekela: Iinkqubo zerobhothi zelaser zivumela ukuwelda ngokupheleleyo ngaphandle kokudinwa, ngelixa i-TIG ngokubanzi ifuna ingqalelo epheleleyo kunye nobuchule bomsebenzi.

Nangona kunjalo, i-TIG welding igcina inzuzoumsebenzi ochanekileyo wegauge okanye i-alloy weldingapho igalelo lobushushu kufuneka lilungiswe ngononophelo. Kwezi zicelo igcisa elinobuchule libalulekile.

5. Yintoni i-Didvantage ye-Laser Welding?

Njengayo nayiphi na inkqubo yemizi-mveliso, ukuwelda ngelaser kunakho ukuthoba okunokuthi kuqwalaselwe:

1. Iindleko: Ngelixa zifikeleleka ngakumbi, iinkqubo zelaser ezinamandla amakhulu zifuna utyalo-mali olukhulu xa kuthelekiswa nezinye iindlela zokuwelda.

2. Izinto ezisetyenziswayo:Imilomo yerhasi kunye ne-optics ithotywa ngokuhamba kwexesha kwaye kufuneka itshintshwe, yongeza kwiindleko zobunini.

3. Ukhuseleko:Iiprothokholi ezingqongqo kunye nezindlu ezivaliweyo zokhuseleko ziyafuneka ukuze kuthintelwe ukuvezwa kwi-high-intensity laser beam.

4. Uqeqesho:Abaqhubi bafuna uqeqesho ukuze basebenze ngokukhuselekileyo kwaye bagcine ngokufanelekileyo izixhobo zokuwelda ngelaser.

5. Umgca wembonakalo:Umqa welaser uhamba ngemigca ethe tye, ngoko ke iijiyometri ezintsonkothileyo zinokufuna imiqadi emininzi okanye ukubekwa ngokutsha kwezinto zokusebenza.

6. Ukufunxa:Izinto ezithile ezifana nentsimbi eshinyeneyo okanye i-aluminiyam kunokuba nzima ukuwelda ukuba azilufunxa kakuhle ubude bobude belaser.

Ngokhuseleko olufanelekileyo, uqeqesho, kunye nokuphuculwa kwenkqubo, nangona kunjalo, i-laser welding ihambisa imveliso, ukuchaneka, kunye nomgangatho oluncedo kwizicelo ezininzi zamashishini.

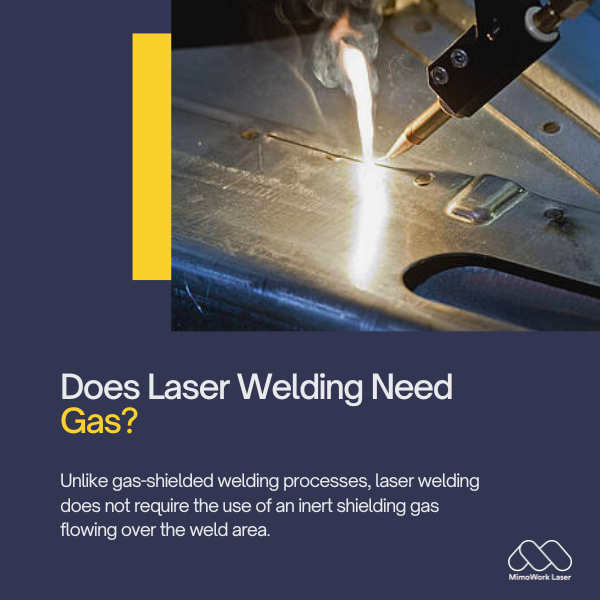

6. Ngaba i-Laser Welding ifuna iGesi?

Ngokungafaniyo neenkqubo ze-welding ezikhuselwe ngegesi, i-laser welding ayifuni ukusetyenziswa kwe-inert shielding gas ehamba phezu kwendawo ye-weld. Oku kungenxa yokuba:

1. I-laser beam egxininisiweyo ihamba emoyeni ukuze yenze i-weld pool encinci, ene-energy high-energy enyibilikayo kwaye idibanise izixhobo.

2. Umoya ojikelezayo awunayo i-ionized njenge-gas plasma arc kwaye ayiphazamisi i-boam okanye i-weld formation.

3. I-weld iqina ngokukhawuleza kubushushu obugxininisiweyo kangangokuba yenze ngaphambi kokuba iioksidi zenze umphezulu.

Nangona kunjalo, usetyenziso oluthile lwe-laser welding ekhethekileyo lusenokuzuza ekusebenziseni igesi yoncedo:

1. Kwisinyithi esisebenzayo njenge-aluminiyam, igesi ikhusela iphuli ye-weld eshushu kwioksijini esemoyeni.

2. Kwimisebenzi yelaser enamandla kakhulu, irhasi izinzisa iplamu yeplasma eyenzeka ngexesha lokungena ngokunzulu.

3. Iijethi zerhasi zisusa umsi kunye nobutyobo ukuze kuhanjiswe ngcono imiqadi kwindawo emdaka okanye epeyintiweyo.

Ke ngoko isishwankathelo, ngelixa kungeyomfuneko ngokungqongqo, irhasi ye-inert inokubonelela ngezibonelelo kucelomngeni oluthile lwezicelo ze-laser welding okanye izixhobo. Kodwa inkqubo inokuthi iqhube kakuhle ngaphandle kwayo.

▶ Zeziphi izinto ezinokwenziwa ngeLaser welded?

Phantse zonke isinyithi zinokudityaniswa nge-laser kubandakanyaintsimbi, i-aluminiyam, i-titanium, i-nickel alloys, kunye nokunye.

Nokudibanisa isinyithi esingafaniyo kunokwenzeka. Undoqo ngaboKufuneka ifunxe i-laser wavelength ngokufanelekileyo.

▶ Zinokudityaniswa njani izinto ezishinyeneyo?

Amashiti abhityileyo njenge0.1mm kwaye ubukhulu be-25mminokuthi ifakwe i-laser welded, ngokuxhomekeke kwisicelo esithile kunye namandla e-laser.

Amacandelo atyebileyo anokufuna i-welding ye-multi-pass okanye i-optics ekhethekileyo.

▶ Ngaba i-Laser Welding ifanelekile kwiMveliso yeVolumu ephezulu?

Ngokuqinisekileyo. Iiseli ze-laser welding yerobhothi ziqhele ukusetyenziswa kwiindawo ezinesantya esiphezulu, ezizisebenzelayo zemveliso kwizicelo ezinje ngokwenziwa kweemoto.

Amazinga okufikelela kwiimitha ezininzi ngomzuzu ayafikeleleka.

▶ Ngawaphi amashishini asebenzisa iLaser Welding?

Ukusetyenziswa kwe-laser welding eqhelekileyo inokufumaneka kwiiimoto, i-electronics, izixhobo zonyango, i-aerospace, isixhobo/ukufa, kunye nokwenziwa kwenxalenye echanekileyo encinci.

Itekhnoloji ingokuqhubekayo ukwanda kumacandelo amatsha.

▶ Ndingayikhetha njani inkqubo yelaser welding?

Izinto ekufuneka ziqwalaselwe zibandakanya izixhobo zokusebenza, ubungakanani / ukutyeba, iimfuno zokuphuma, uhlahlo lwabiwo-mali, kunye nomgangatho weweld ofunekayo.

Ababoneleli abathembekileyo banokunceda ukucacisa uhlobo oluchanekileyo lwelaser, amandla, i-optics, kunye ne-automation yesicelo sakho esithile.

▶ Zeziphi Iintlobo zeeWeld ezinokwenziwa?

Ubuchwephesha bokuwelda belaser bubandakanya i-butt, i-lap, fillet, ukugqobhoza, kunye ne-cladding welds.

Ezinye iindlela ezintsha ezinje ngelaser additive production ziyavela ukuze zilungiswe kunye neprototyping applications.

▶ Ngaba i-Laser Welding iwufanele umsebenzi wokulungisa?

Ewe, i-laser welding ifaneleke kakuhle ukulungiswa ngokuchanekileyo kwamacandelo exabiso eliphezulu.

Igalelo lokushisa eligxininisiweyo linciphisa umonakalo owongezelelweyo kwizinto ezisisiseko ngexesha lokulungiswa.

Ngaba uyafuna ukuqalisa ngoMatshini weLaser Welder?

Kutheni ungacingeli Thina?

Ixesha lokuposa: Feb-12-2024