Laser Welding Machine Welding Parameters Inkcazo eneenkcukacha

I-laser welding yindlela echanekileyo nesebenzayo yokudibanisa izixhobo, ngakumbi iintsimbi.

Ukuqonda iiparamitha ze-welding kubalulekile ekufezekiseni iziphumo ezilungileyo.

Eli nqaku lichaza imigaqo ebalulekileyo kunye neeparameters ezichaphazela ukusebenza kwe-laser welding, kubandakanywa nobukhulu bezinto eziphathekayo, i-wire diameter, iisetingi zamandla, kunye nokunye.

Imigaqo ephambili ye-Laser Welding

1. Ukutyeba kweMathiriyeli kunye neDayimitha yocingo:

o Xa welding imathiriyeli engqindilili, kubalulekile ukusebenzisa ucingo olushinyeneyo kunye nesetingi yamandla ephezulu.

Ngokwahlukileyo, kwizinto ezincinci, i-wire welding wire kunye namandla angaphantsi afanelekile.

o Umzekelo, ukuba ubukhulu bezinto buyanda, i-diameter yocingo kufuneka inyuke ngokulinganayo, kwaye amandla kufuneka ahlengahlengiswe abe phezulu ngelixa kuncitshiswa isantya sokutya kocingo.

Oku kuqinisekisa ukuba amandla aneleyo angena kwizinto eziphathekayo kwi-weld eqinile.

2. Iisetingi zaMandla kunye neNkangeleko yeWeld:

o Ulungiselelo lwamandla luchaphazela ngokuthe ngqo inkangeleko ye-weld.

Amandla asezantsi athanda ukuvelisa umphezulu we-weld omhlophe, ngelixa amandla aphezulu ekhokelela kumthungo we-weld omnyama, onemibala engaphezulu.

Njengoko amandla esanda, i-weld inokutshintsha ukusuka kwimbonakalo enemibala emininzi ukuya kumbala omnyama kakhulu, okubonisa ukuba i-weld yenziwa kwicala elinye.

o Olu phawu lubalulekile ekuhloleni umgangatho we-weld kunye nokuqinisekisa ukuba iyahambelana nemigangatho efunekayo.

3. UKhetho lweDayimitha yocingo:

o Ukukhetha idiameter yocingo efanelekileyo kubalulekile.

Ububanzi bocingo lwe-welding akufuneki bugqithise ubukhulu bezinto eziphathekayo, kwaye kufuneka ngokufanelekileyo buthambekele ekubeni bunzima kunesiseko sesiseko.

Olu khetho luchaphazela kakhulu ukuzala kwe-weld bead.

o Ucingo olungqindilili lunokuba negalelo ekubeni luqine ngakumbi, ngelixa ucingo olubhityileyo lunokubangela ukudityaniswa okunganelanga kunye nelungu elibuthathaka.

4. I-Welding Wire Diameter kunye nobubanzi bokuskena:

o Ububanzi bocingo lwe-welding bukwachaphazela ububanzi bokuskena be-laser beam.

Ucingo olucokisekileyo luya kufuna ububanzi obuncinci bokuskena, obunokuba luncedo kwizicelo ezichanekileyo ze-welding apho iinkcukacha ezifunekayo zifunekayo.

o Olu dlelwane luvumela ukulawulwa okungcono kwegalelo lokushisa kunye nokuqinisekisa ukuba i-weld igxininise kwindawo efunwayo, ukunciphisa umonakalo onokwenzeka kwizinto ezijikelezayo.

Ufuna ukwazi Iinkcukacha ezingakumbi

Malunga neLaser Welding?

Izinto zangaphandle ezichaphazela i-Welding Parameters

Kubalulekile ukuba uqaphele ukuba izinto ezahlukeneyo zangaphandle, ezifana nokukhusela igesi kunye neemeko zokusingqongileyo, zinokuchaphazela kakhulu inkqubo ye-welding.

Ngoko ke, kuyacetyiswa ukuba ulungelelanise i-welding parameters ngokusekelwe kwiimeko zexesha langempela.

• IGesi yokuKhusela: Uhlobo kunye nesantya sokuhamba kwerhasi ekhuselayo inokuchaphazela umgangatho weweld kunye nenkangeleko.

Ukugubungela igesi ngokufanelekileyo kunokuthintela i-oxidation kunye nokuphucula ukugqitywa okupheleleyo.

• IiMeko zokusiNgqongileyo: Izinto ezifana nobushushu, ukufuma, kunye nokuhamba komoya kunokuphembelela ukusebenza komatshini we-laser welding kunye neempawu ze-weld.

Naluphi na olunye ulwazi malunga neLaser Welder?

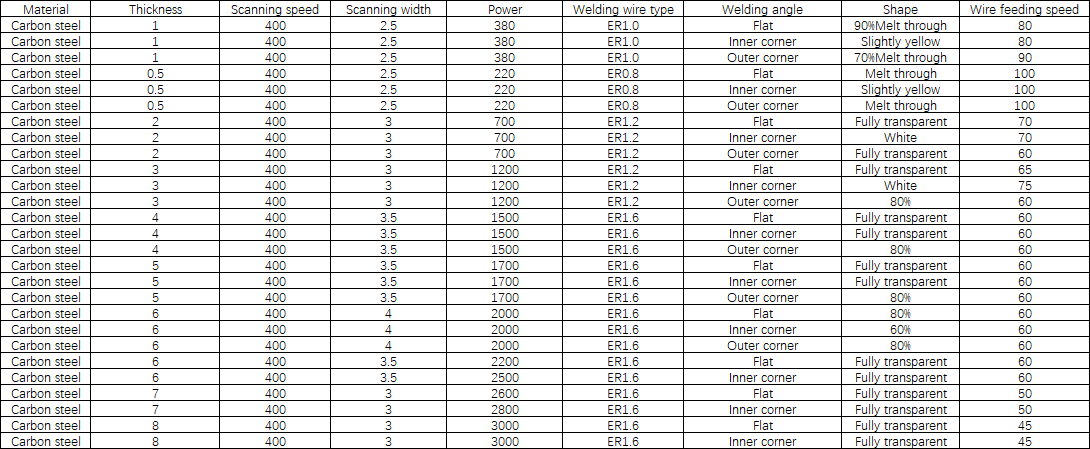

Laser Welding Carbon Steel

Qaphela: Ngenxa yempembelelo ye-zinc layer ye-galvanized sheet, amandla e-galvanized sheet anokwehliswa ngokufanelekileyo.

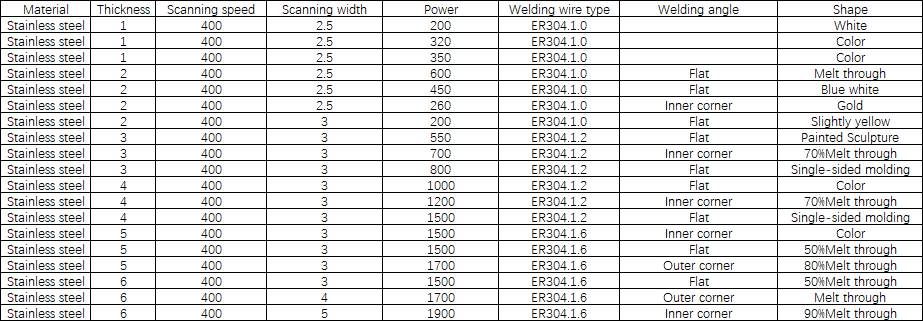

Handheld Laser Welding Steel Stainless

Amanqaku: I-3000W yensimbi engenasici yamandla yereferensi ye-carbon steel

Andazi ukuba ungawukhetha njani umatshini weLaser?

Sinako Ukunceda!

Ukusuka kwiividiyo ezibandakanyayo ukuya kumaNqaku anengcaciso

Indlela yokusebenzisa i-Handheld Laser Welder | Imfundiso yabaQalayo

Ixesha lokuposa: Jan-06-2025