• Ukulawulwa komgangatho kwi-Laser Welling?

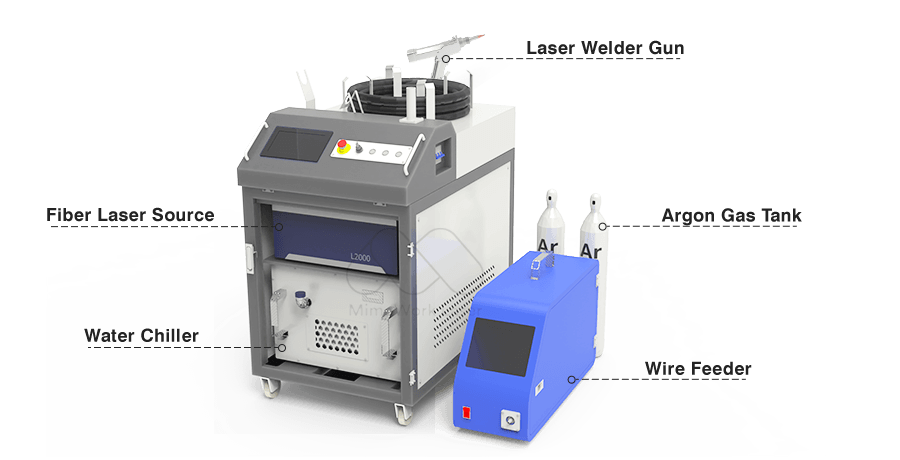

Ngokuchaneka okuphezulu, ukuchaneka okuphezulu, ukudityaniswa okukhulu kwe-welding, ukudityaniswa okulula okulula, kunye nezinye izibonelelo, i-welling isetyenziswe ngokubanzi kwimizi-mveliso ye-Welding kunye nemveliso, kubandakanya emkhosini, kwi-Aerospace, 3C Iinxalenye ezizenzekelayo, i-PHICHY SPICHE SPICH, ENTSHA ENTSHA, izixhobo zenkanuko yococeko, kunye namanye amashishini.

Nangona kunjalo, nayiphi na indlela ye-welding ukuba ayiziwa umgaqo wayo kunye netekhnoloji, iya kuvelisa isiphene okanye iimveliso ezinesiphene, i-welling ye-ler ayifani.

• Ndingenza ntoni ukusombulula ezo ziphene?

Kuphela kukuqonda okuhle kwezi ziphene, kwaye ufunde indlela yokuphepha ezi ziphene, ukuze udlale ixabiso le-werling welding, ukulungisa imbonakalo entle, kunye neemveliso ezintle.

Iinjineli zokuqokelelwa kwamava okwexesha elide, zishwankathe iziphene zesiphumo esiqhelekileyo sesisombululo, kwireferensi yoRhwebo lweShishini!

Zithini iziphene eziqhelekileyo zelding?

>> rocks

>> I-Poures kwi-weld

>> I-SPlash

>> I-ARTCY

>> Ukuwa kwephuli ye-molten

Ukuba ungathanda ukwazi ngakumbi malunga ne-Handercheld Lesers Weldrs, ungajonga iphepha lethu ukufumana ulwazi oluthe kratyangokusebenzisa ikhonkco phantsi!

◼ Imibuliso xa i-sell yelding

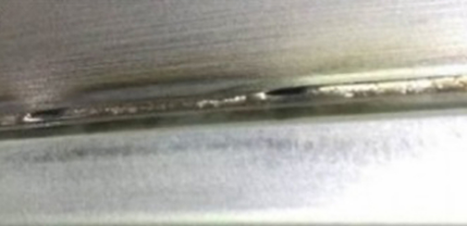

Imingxunya efakwe kwi-Irser eqhubekayo i-ilding ishushu ikakhulu ishushu, njengokutyibilika kwe-crycks, i-rocks etyhutywe, njl.

Esona sizathu kukuba i-Weld ivelisa amandla amakhulu e-shrinkige ngaphambi kokuqiniseka ngokupheleleyo.

Usebenzisa i-wire feer ukugcwalisa iingcingo okanye ukutshintsha isiqwenga sesinyithi kunokunciphisa okanye ukuphelisa imingxunya eboniswe ngexesha le-laser.

Imifuno eLaser Welling

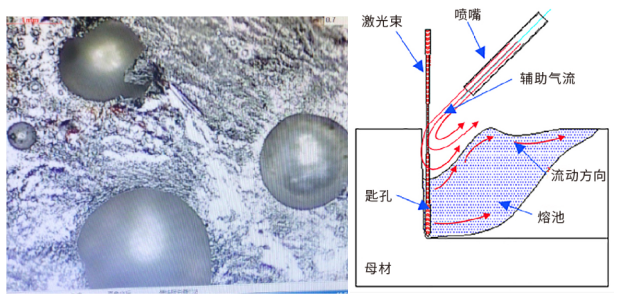

◼ pores kwi-weld

I-pores kwi-weld

Ngokwesiqhelo, i-lel yelding echibini inzulu kwaye imxinwa, kwaye i-metasi iqhele ukwenza ubushushu kakuhle kwaye uqhubeke kakhulu. Igesi eveliswe kwiphuli ye-molten ayinaxesha elaneleyo lokubaleka ngaphambi kokuba i-welding yensimbi ipholile. Ityala elinjalo kulula ukuba likhokelele ekuqulunweni kweepores.

Kodwa nangenxa yokuba i-Wels yelding Indawo incinci, isinyithi sinokuphola ngokukhawuleza, kwaye isibakala esibonisiweyo kwi-Laser Welling sincinci kune-upholdion yemveli.

Ukucoca umphezulu we-Worpiece ngaphambi kokuba i-welding inokunciphisa umkhwa we-pores, kwaye indlela yokubetha iya kuchaphazela ukwenziwa kweepores.

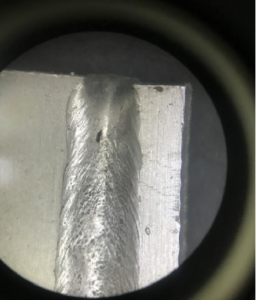

◼ I-splash

◼ Ukuwa kwephuli ye-molten

I-splash eveliswe nguLaser Welding ichaphazela umgangatho we-weld bow kwaye unokungcolisa kwaye wonakalise ilensi.

I-Spatter inxulumene ngqo nengxinano yamandla kwaye inokuncitshiswa ngokunciphisa ngokufanelekileyo amandla omzimba.

Ukuba ukungena awonelanga, isantya se-welding sinokuncitshiswa.

I-splash eLaser Welling

Ukuba isantya se-welding sicothise, iphuli enyikima inkulu kwaye ibanzi, inani lentsimbi enyibilikayo liyanda, imbiza yomphezulu kunzima ukugcina isinyithi esinzima, iziko le-weld liza kuthwala, liphule kunye nemingxunya.

Ngeli xesha, kuyimfuneko ukunciphisa uxinzelelo lwamandla ngokufanelekileyo ukunqanda ukuwa kwephuli yecoln.

Ukuwa kwephuli ye-molten

◼ I-Undercut kwi-laser yelling

Ukuba uluphakamisa umsebenzi wesinyithi wokukhawuleza, intsimbi yolwelo emva komngxunya osalathisi kwiziko le-shld alikho ixesha lokusasazeka.

Ukuqina kumacala omabini e-weld kuya kuba kukuluma. Xa umsantsa phakathi kwamaqhekeza amabini omsebenzi omkhulu kakhulu, kuya kubakho intsimbi engonelanga ifumanekayo ukuze ifumaneke, apho imeko ye-welding ye-welding iya kwenzeka.

Kwinqanaba lokuphela kwe-laser, ukuba amandla ehla ngokukhawuleza, umngxunya kulula ukuwa kwaye kukhokelela kwiziphene zedleleni ezifanayo. Ixabiso elingcono lomlinganiso kunye nesantya sokuhamba se-Laser Welsersing useto unokusombulula isizukulwana sokuqaqamba.

I-pulfut kwi-laser yelling

I-Handheld Leser Wesers ye-Welds yakho ukhetha

Ngaba ufuna ukwazi ngakumbi malunga ne-lared?

Nasiphi na isiphithiphithi kunye nemibuzo yamatshini ophathwayo we-laser welding?

IXESHA LOKUQALA: UJan-30 ukuya kwi-2023