I-laser welding ijolise ikakhulu ekuphuculeni ukusebenza kakuhle kwe-welding kunye nomgangatho wezinto ezinqabileyo zodonga kunye neengxenye ezichanekileyo. Namhlanje asizu kuthetha ngeenzuzo zokuwelda kwelaser kodwa sigxile kwindlela yokusebenzisa iigesi ezikhuselayo kwi-laser welding ngokufanelekileyo.

Kutheni usebenzisa irhasi yekhaka ukuwelda ngelaser?

Kwi-laser welding, ikhaka legesi liya kuchaphazela ukubunjwa kwe-weld, umgangatho we-weld, ubunzulu be-weld, kunye nobubanzi be-weld. Kwiimeko ezininzi, ukuvuthela igesi encedisiweyo kuya kuba nefuthe elihle kwi-weld, kodwa kunokuzisa nemiphumo emibi.

Xa uvuthela igesi yekhaka ngokuchanekileyo, kuya kukunceda:

✦Khusela ngokufanelekileyo i-weld pool ukunciphisa okanye ukuphepha i-oxidation

✦Ukunciphisa ngokufanelekileyo i-splash eveliswe kwinkqubo ye-welding

✦Ukunciphisa ngokufanelekileyo i-weld pores

✦Nceda i-weld pool isasazeke ngokulinganayo xa iqiniswa, ukuze i-weld seam ize nomphetho ococekileyo nogudileyo.

✦Impembelelo yokukhusela iplamu yomphunga wesinyithi okanye ifu yeplasma kwi-laser iyancitshiswa ngokufanelekileyo, kwaye izinga lokusetyenziswa kwe-laser liyenyuka.

Okoko nje iuhlobo lwerhasi ikhaka, izinga lokuhamba kwerhasi, kunye nokhetho lwemowudi yokuvuthelazichanekile, unokufumana isiphumo esifanelekileyo se-welding. Nangona kunjalo, ukusetyenziswa kakubi kwegesi yokukhusela kunokuchaphazela kakubi i-welding. Ukusebenzisa uhlobo olungalunganga lwegesi yekhaka kunokukhokelela kwi-creaks kwi-weld okanye ukunciphisa iimpawu zomatshini we-welding. Ukuphakama kakhulu okanye usezantsi kakhulu umyinge wokuqukuqela kwerhasi kunokukhokelela kwi-weld oxidation enzulu ngakumbi kunye nophazamiseko olumandundu lwangaphandle lwemathiriyeli yentsimbi ngaphakathi kwidama le-weld, okukhokelela ekuwohlokeni kwe-weld okanye ukwakheka kokungalingani.

Iintlobo zegesi ikhaka

Iigesi ezisetyenziswa ngokuqhelekileyo zokukhusela i-laser welding ikakhulu i-N2, i-Ar, kunye ne-He. Iimpawu zabo zomzimba kunye neekhemikhali zahlukile, ngoko ke iziphumo zazo kwi-welds nazo zahlukile.

I-nitrogen (N2)

Amandla e-ionization ye-N2 iphakathi, iphezulu kune-Ar, kwaye iphantsi kunaleyo ye-He. Ngaphantsi kwemitha yelaser, i-ionization degree ye-N2 ihlala kwi-even keel, enokunciphisa ngcono ukubunjwa kwelifu le-plasma kunye nokunyusa izinga lokusetyenziswa kwelaser. I-nitrojeni inokusabela nge-aluminium alloy kunye ne-carbon steel kwiqondo lokushisa elithile ukuvelisa i-nitrides, eya kuphucula i-weld brittleness kunye nokunciphisa ukuqina, kwaye ibe nefuthe elibi kakhulu kwiipropati ze-mechanical ze-weld joints. Ngoko ke, akukhuthazwa ukusebenzisa i-nitrogen xa udibanisa i-aluminium alloy kunye ne-carbon steel.

Nangona kunjalo, ukusabela kweekhemikhali phakathi kwe-nitrogen kunye nensimbi engenasici eveliswa yi-nitrogen inokuphucula amandla e-weld joint, eya kuba luncedo ekuphuculeni iimpawu zomatshini we-weld, ngoko ukuwelda kwensimbi engenasici kunokusebenzisa i-nitrogen njengegesi ekhuselayo.

IArgon (Ar)

Amandla e-ionization yeArgon aphantsi, kwaye idigri yayo ye-ionization iya kuba phezulu phantsi kwesenzo selaser. Emva koko, iArgon, njengegesi ekhuselayo, ayikwazi ukulawula ngokufanelekileyo ukubunjwa kwamafu eplasma, eya kunciphisa izinga lokusetyenziswa kwe-laser welding. Umbuzo uvela: ngaba i-argon ngumviwa ongalunganga wokusetyenziswa kwe-welding njengegesi ekhuselayo? Impendulo nguNo. Ukuba yigesi engasebenziyo, iArgon inzima ukusabela ngobuninzi besinyithi, kwaye iAr itshiphu ukuyisebenzisa. Ukongeza, ingxinano ye-Ar inkulu, iya kuba luncedo ukutshona kumphezulu we-weld pool etyhidiweyo kwaye inokukhusela ngcono i-weld pool, ngoko i-Argon ingasetyenziswa njengegesi eqhelekileyo yokukhusela.

Helium (Yena)

Ngokungafaniyo neArgon, iHelium inamandla aphezulu e-ionization anokulawula ukubunjwa kwamafu eplasma ngokulula. Kwangaxeshanye, iHelium ayifuni nangayiphi na isinyithi. Ngokwenene lukhetho olulungileyo lwe-laser welding. Ingxaki kuphela kukuba iHelium iyabiza kakhulu. Kubenzi bemveliso ababonelela ngeemveliso zetsimbi ezininzi, i-helium iya kwongeza inani elikhulu kwiindleko zokuvelisa. Ngaloo ndlela i-helium isetyenziswa ngokubanzi kuphando lwezenzululwazi okanye iimveliso ezinexabiso eliphezulu kakhulu elongezelelweyo.

Indlela yokuvuthela igesi ikhaka?

Okokuqala, kufuneka kucace ukuba into ebizwa ngokuba yi "oxidation" ye-weld kuphela igama eliqhelekileyo, elibhekiselele kwi-chemical reaction phakathi kwe-weld kunye namacandelo ayingozi emoyeni, ekhokelela ekudakaleni kwe-weld. Ngokuqhelekileyo, i-weld metal isabela kunye neoksijini, i-nitrogen, kunye ne-hydrogen emoyeni kwiqondo elithile lobushushu.

Ukuthintela i-weld ekubeni "i-oxidized" ifuna ukunciphisa okanye ukuphepha ukudibanisa phakathi kwamacandelo anjalo ayingozi kunye nentsimbi ye-weld phantsi kobushushu obuphezulu, obungekho kuphela kwisinyithi esityhidiweyo sechibi kodwa lonke ixesha ukusuka kwixesha xa isinyithi esityhidiweyo sinyibilika de isinyithi esityhidiweyo siqiniswe kwaye ubushushu balo buphola phantsi kwiqondo elithile lobushushu.

Iindlela ezimbini eziphambili zokuvuthela irhasi yekhaka

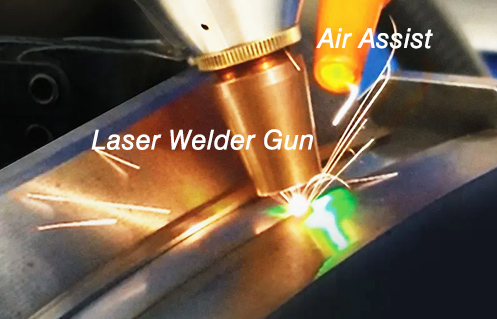

▶Enye ivuthela irhasi yekhaka kwicala elihamba macala, njengoko kubonisiwe kuMfanekiso 1.

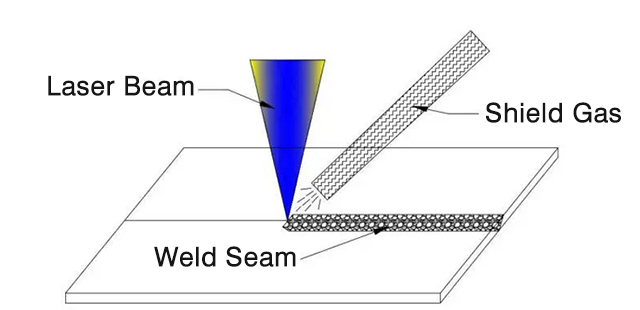

▶Enye yindlela yokuvuthela i-coaxial, njengoko kubonisiwe kuMfanekiso 2.

Umfanekiso woku-1.

Umfanekiso wesi-2.

Ukhetho oluthile lweendlela ezimbini zokuvuthela luqwalaselo olubanzi lwemiba emininzi. Ngokuqhelekileyo, kucetyiswa ukuba kuthathwe indlela yegesi ekhuselayo esecaleni.

Eminye imizekelo ye-laser welding

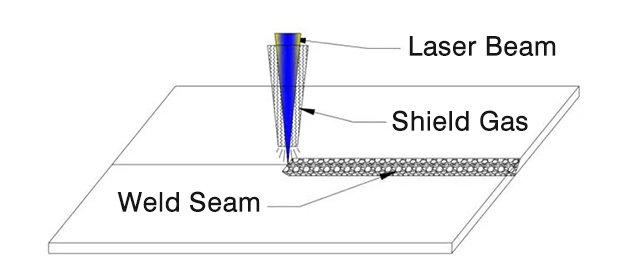

1. Ibead ethe ngqo/intambo yokuwelda

Njengoko kubonisiwe kuMfanekiso 3, imilo ye-weld yemveliso inomgca, kwaye ifom edibeneyo inokuba yinto edibeneyo ye-butt, i-lap joint, i-joint yekona engafanelekanga, okanye i-welding joint joint. Ngolu hlobo lwemveliso, kungcono ukwamkela i-side-axis evuthela igesi yokukhusela njengoko kubonisiwe kuMfanekiso 1.

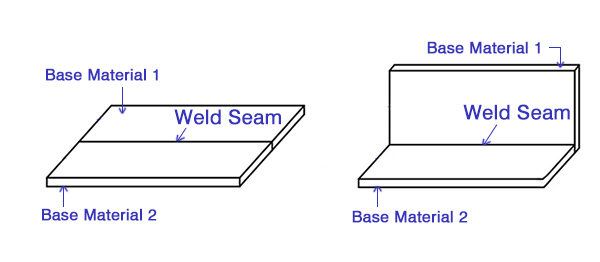

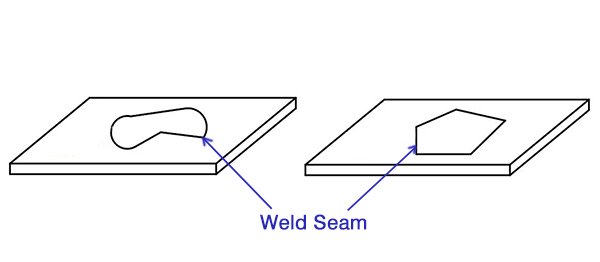

2. Vala umzobo okanye i-welding yendawo

Njengoko kubonisiwe kwi-Figure 4, i-weld shape yemveliso yipatheni evaliweyo efana ne-plane circumference, i-plane shape multilateral shape, i-plane multi-segment linear shape, njl njl.

Ukukhethwa kwegesi ekhuselayo kuchaphazela ngokuthe ngqo umgangatho we-welding, ukusebenza kakuhle, kunye neendleko zemveliso, kodwa ngenxa yokwahluka kwezinto zokuwelda, kwinkqubo ye-welding yokwenene, ukukhethwa kwegesi ye-welding inzima kakhulu kwaye idinga ukuqwalaselwa okubanzi kwezinto ze-welding, indlela ye-welding, indawo ye-welding, kunye neemfuno ze-welding effect. Ngokusebenzisa iimvavanyo ze-welding, unokukhetha i-gas ye-welding efanelekileyo ngakumbi ukufezekisa iziphumo ezingcono.

Unomdla kwi-laser welding kwaye uzimisele ukufunda indlela yokukhetha igesi yekhaka

Unxulumano oluNxulumeneyo:

Ixesha lokuposa: Oct-10-2022