1. Ukusika isantya

Abathengi abaninzi ekuboniseni umatshini wokusika i-laser baya kubuza ukuba umatshini we-laser unokusika ngokukhawuleza kangakanani. Enyanisweni, umatshini wokusika i-laser sisixhobo esisebenza kakuhle kakhulu, kwaye isantya sokusika ngokwemvelo sigxininise kubathengi. Kodwa isantya esikhawulezayo sokusika asichazi umgangatho wokusika i-laser.

Ngokukhawuleza kakhulu tyena usika isantya

a. Ayikwazi ukunqumla imathiriyeli

b. Umphezulu wokusika ubonisa i-oblique grain, kwaye isiqingatha esisezantsi somsebenzi sivelisa amabala anyibilikayo

c. I-rough cutting edge

Ukucotha kakhulu isantya sokusika

a. Ngaphezulu kwemeko yokunyibilika kunye nomphezulu wokusika

b. I-gap yokusika ebanzi kunye nekona ebukhali iyancibilika kwiikona ezijikelezileyo

Ukwenza izixhobo zomatshini wokusika i-laser zidlale ngcono umsebenzi wawo wokusika, musa ukubuza nje ukuba umatshini we-laser unokusika kangakanani, impendulo ihlala ingachanekanga. Ngokuchasene noko, nikezela ngeMimoWork ngengcaciso yemathiriyeli yakho, kwaye siya kukunika impendulo enoxanduva ngakumbi.

2. Indawo ekugxilwe kuyo

Ngenxa yokuba ubuninzi bamandla we-laser bunempembelelo enkulu kwisantya sokusika, ukukhethwa kobude be-lens kugxininiso olubalulekileyo. Ubungakanani bendawo yelaser emva kokugxila kwelaser bulingana nobude bojoliso belensi. Emva kokuba i-laser beam igxininiswe yi-lens kunye nobude obufutshane obugxilwe, ubungakanani bendawo ye-laser buncinci kakhulu kwaye ubuninzi bamandla kwindawo ekugxilwe kuyo buphezulu kakhulu, enenzuzo ekusikeni izinto eziphathekayo. Kodwa ukungonakali kwayo kukuba ngobunzulu obufutshane obugxilwe, kuphela isibonelelo esincinci sohlengahlengiso lobunzima bezinto eziphathekayo. Ngokubanzi, i-lens egxininisekile enobude obufutshane obugxininiswe bufaneleka ngakumbi kwi-high-speed cut cut material ebhityileyo. Kwaye i-lens ekugxilwe kuyo enobude bojoliso obude inobunzulu bojoliso olubanzi, okoko nje inamandla okwaneleyo oxinaniso, ifaneleka ngakumbi ukusika izinto zokusebenza ezishinyeneyo ezinje ngogwebu, i-acrylic, kunye nomthi.

Emva kokugqiba ukuba yeyiphi i-lens yobude be-focal enokusetyenziswa, indawo ehambelanayo yendawo ekugxilwe kuyo kwindawo yokusebenza ibaluleke kakhulu ukuqinisekisa umgangatho wokusika. Ngenxa yobuninzi bamandla obuphezulu kwindawo ekugxilwe kuyo, kwiimeko ezininzi, indawo ekugxilwe kuyo ingaphantsi okanye kancinane kumphezulu wesixhobo sokusebenza xa usikwa. Kuyo yonke inkqubo yokusika, yimeko ebalulekileyo yokuqinisekisa ukuba indawo ehambelanayo yokugxila kunye ne-workpiece ihlala rhoqo ukufumana umgangatho wokusika ozinzile.

3. Inkqubo yokuVuthela umoya kunye neGesi eNcedisayo

Ngokuqhelekileyo, ukusika kwe-laser yezinto kufuna ukusetyenziswa kwegesi encedisayo, ngokukodwa ehambelana nohlobo kunye noxinzelelo lwegesi encedisayo. Ngokuqhelekileyo, igesi encedisayo ikhutshwe i-coaxially kunye ne-laser beam ukukhusela i-lens ekungcoleni kunye nokuvuthela i-slag ezantsi kwendawo yokusika. Kwizinto ezingezizo zetsimbi kunye nezinye izinto zetsimbi, umoya oxinyiweyo okanye igesi ye-inert isetyenziselwa ukususa izinto ezincibilikisiweyo kunye ne-evaporated, ngelixa zivimbela ukutshisa okugqithiseleyo kwindawo yokusika.

Ngaphantsi kwesiseko sokuqinisekisa igesi encedisayo, uxinzelelo lwegesi luyinto ebaluleke kakhulu. Xa usika izinto ezincinci ngesantya esiphezulu, uxinzelelo lwegesi oluphezulu luyafuneka ukukhusela i-slag ukuba ibambelele ngasemva kwe-cut (i-slag eshushu iya kulimaza i-cut cut xa ibetha i-workpiece). Xa ubukhulu bezinto eziphathekayo bukhula okanye isantya sokusika sicotha, uxinzelelo lwegesi kufuneka luncitshiswe ngokufanelekileyo.

4. Inqanaba lokuJonga

Ubude belaser ye-CO2 yi-10.6 μm elungele ukuba izinto ezingezizo ezentsimbi zifunxe. Kodwa i-laser ye-CO2 ayifanelekanga ukusika isinyithi, ngakumbi izinto zetsimbi ezinokubonakala okuphezulu njengegolide, isilivere, ubhedu kunye nentsimbi ye-aluminium, njl.

Isantya sokufakwa kwezinto kwi-beam sidlala indima ebalulekileyo kwinqanaba lokuqala lokufudumeza, kodwa emva kokuba umngxuma wokusika uqulunqwe ngaphakathi kwendawo yokusebenza, umphumo womzimba omnyama womngxuma wenza izinga lokufunxa izinto kwi-boam kufuphi ne-100%.

Ubume bezinto eziphathekayo buchaphazela ngokuthe ngqo ukufunxwa kwe-beam, ngokukodwa uburhabaxa bomphezulu, kunye nomgangatho we-oxide ongaphezulu uya kubangela utshintsho olucacileyo kwisantya sokufunxa. Kwinkqubo yokusika i-laser, ngamanye amaxesha ukusika kwezinto eziphathekayo kunokuphuculwa ngempembelelo yemeko yendawo yezinto eziphathekayo kwizinga lokungena kwe-beam.

5. Laser Head Nozzle

Ukuba umlomo wombhobho awukhethwanga ngokufanelekileyo okanye ugcinwe kakuhle, kulula ukubangela ungcoliseko okanye umonakalo, okanye ngenxa yokujikeleza okubi komlomo we-nozzle okanye ukuvaleka kwendawo okubangelwa ukutshiza kwentsimbi eshushu, imisinga ye-eddy iya kwenziwa kwi-nozzle, ekhokelela ekusebenzeni okubi kakhulu kokusika. Ngamanye amaxesha, umlomo we-nozzle awuhambelani nomqadi ogxininisekileyo, okwenza umqadi ukucheba umphetho we-nozzle, oya kuchaphazela umgangatho wokusika umgca, ukwandisa ububanzi bokuqhawula kwaye wenze ukunqunyulwa kobukhulu bokusika.

Kwimibhobho, imiba emibini kufuneka ihlawulwe ingqalelo ekhethekileyo

a. Impembelelo yobubanzi bombhobho.

b. Impembelelo yomgama phakathi kombhobho kunye nomphezulu womsebenzi.

6. Indlela yokubona

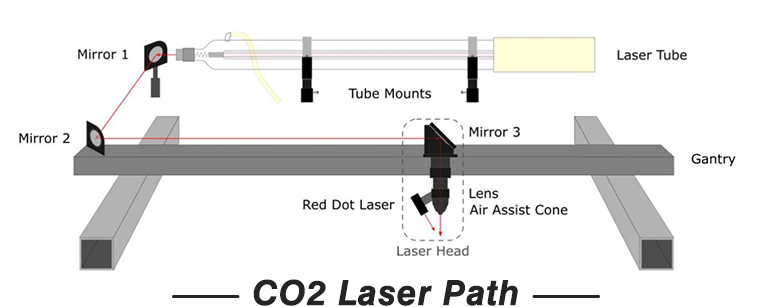

Umqadi wokuqala okhutshwe yi-laser usasazwa (kubandakanya ukubonakalisa kunye nokuhanjiswa) ngenkqubo yangaphandle ye-optical path system, kwaye ikhanyise ngokuchanekileyo umphezulu we-workpiece kunye nokuxinana kwamandla aphezulu kakhulu.

Izinto ezibonakalayo zenkqubo yangaphandle ye-optical path kufuneka zihlolwe rhoqo kwaye zilungelelaniswe ngexesha lokuqinisekisa ukuba xa itotshi yokusika isebenza ngaphezu kwendawo yokusebenza, i-beam yokukhanya idluliselwe ngokuchanekileyo kumbindi we-lens kwaye igxininise kwindawo encinci ukusika i-workpiece enomgangatho ophezulu. Emva kokuba isikhundla se-optical element sitshintshile okanye singcolisekile, umgangatho wokusika uya kuchaphazeleka, kwaye ukusika akunakwenziwa.

I-lens yangaphandle yendlela ye-optical ingcoliswa yizinto ezingcolileyo kwi-airflow kwaye iboshwe ngokutshiza iincinci kwindawo yokusika, okanye i-lens ayipholi ngokwaneleyo, eya kubangela ukuba i-lens igqithise kwaye ichaphazele ukuhanjiswa kwamandla e-beam. Ibangela ukungqubana kwendlela yokubona ukukhukuliseka kwaye ikhokelela kwiziphumo ezibi. I-lens overheating nayo iya kuvelisa ukugqwetheka okugxile kwaye ibeke emngciphekweni lens ngokwayo.

Funda ngakumbi malunga neentlobo ze-co2 laser cutter kunye namaxabiso

Ixesha lokuposa: Sep-20-2022