Yintoni i-laser welding? Ukuwelda kweLaser kucacisiwe! Konke okufuneka ukwazi malunga ne-Laser Welding, kubandakanywa umgaqo obalulekileyo kunye neeparitha zenkqubo ephambili!

Abathengi abaninzi abayiqondi imigaqo esisiseko yokusebenza yomatshini wokuwelda we-laser, singasathethi ke ngokukhetha umatshini wokuwelda we-laser, nangona kunjalo iMimowork Laser ilapha ukukunceda wenze isigqibo esifanelekileyo kunye nokubonelela ngenkxaso eyongezelelweyo ukukunceda ekuqondeni ukuwelda kwe-laser.

Yintoni iLaser Welding?

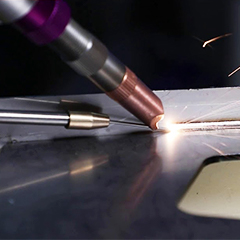

Ukuwelda kweLaser luhlobo lokunyibilikisa ukuwelda, kusetyenziswa umqadi we-laser njengomthombo wobushushu wokuwelda, umgaqo wokuwelda kukuba indlela ethile yokuvuselela i-medium esebenzayo, ukwenza i-oscillation ye-resonant cavity, kwaye emva koko iguqule ibe ngumqadi ovuselelweyo wemitha, xa umqadi kunye neqhekeza lomsebenzi zinxibelelana, amandla afunxwa sisiqwengana somsebenzi, xa iqondo lobushushu lifikelela kwindawo yokunyibilika.

Ngokwendlela ephambili ye-welding pool, i-laser welding ineendlela ezimbini ezisisiseko ze-welding: i-welding conduction yelding kunye nokungena nzulu (i-keyhole) welding. Ubushushu obuveliswa yi-welding conduction yobushushu busasazwa kwiqhekeza lomsebenzi ngokugqithisela ubushushu, ukuze umphezulu we-weld unyibilike, akukho mphunga omele ukwenzeka, odla ngokusetyenziswa ekudibaneni kwamacandelo amancinci ngesantya esincinci. I-welding enzulu ye-fusion ikhupha izinto kwaye yenza isixa esikhulu seplasma. Ngenxa yobushushu obuphezulu, kuya kubakho imingxuma phambi kwedama elinyibilikisiweyo. I-welding yokungena enzulu yeyona ndlela isetyenziswa kakhulu ye-laser welding, inokuwelda icwecwe ngokucokisekileyo, kwaye igalelo lamandla likhulu, likhokelela kwisantya sokuwelda ngokukhawuleza.

Iiparamitha zeNkqubo kwi-Laser Welding

Zininzi iiparameters zenkqubo ezichaphazela umgangatho we-laser welding, ezifana nokuxinana kwamandla, i-laser pulse waveform, defocusing, isantya se-welding kunye nokukhethwa kwegesi encedisayo yokukhusela.

Laser Power Density

Uxinaniso lwamandla yenye yezona parameters zibalulekileyo kwi-laser processing. Ngoxinaniso lwamandla oluphezulu, umaleko womphezulu unokufudunyezwa kwindawo yokubila ngaphakathi kwe-microsecond, okukhokelela kwixabiso elikhulu lokufunxa. Ke ngoko, ukuxinana kwamandla aphezulu kunenzuzo kwiinkqubo zokususa izinto ezifana nokubhola, ukusika kunye nokukrola. Ukuxinana kwamandla aphantsi, kuthatha i-millisecond ezininzi ukuze ubushushu bomphezulu bufike kwindawo yokubila, kwaye ngaphambi kokuba umphezulu ube ngumphunga, umzantsi ufikelela kwindawo yokunyibilika, ekulula ukwenza i-weld yokunyibilika elungileyo. Ngoko ke, ngendlela yokushisa ukushisa kwe-laser welding, uluhlu lwamandla obuninzi luyi-104-106W / cm2.

Laser Pulse Waveform

I-Laser pulse waveform ayisiyiyo iparameter ebalulekileyo kuphela yokwahlula ukususwa kwezinto ezibonakalayo ekunyibilikeni kwezinto, kodwa kunye nepharamitha ephambili yokumisela umthamo kunye neendleko zezixhobo zokusebenza. Xa umqa we-laser ophezulu udutyulwa kumphezulu wezinto eziphathekayo, umphezulu wezinto eziphathekayo uya kuba ne-60 ~ 90% yamandla e-laser abonakaliswe kwaye athathelwe ingqalelo njengelahleko, ngakumbi igolide, isilivere, ubhedu, i-aluminiyam, i-titanium kunye nezinye izinto ezinomfanekiso oqinileyo kunye nokudluliselwa kobushushu okukhawulezayo. Ukubonakaliswa kwentsimbi kuyahluka kunye nexesha ngexesha le-laser pulse. Xa ubushushu bomphezulu bezinto buphakama kwindawo yokunyibilika, ukubonakaliswa kuncipha ngokukhawuleza, kwaye xa ubuso bukwimeko yokunyibilika, umboniso uzinzisa kwixabiso elithile.

Laser Pulse Ububanzi

Ububanzi be-Pulse yiparameter ebalulekileyo ye-pulsed laser welding. Ububanzi be-pulse bunqunywe bunzulu bokungena kunye nobushushu obuchaphazelekayo kwindawo. Ubude obude be-pulse ububanzi, ubukhulu bendawo echaphazelekayo yokushisa yayinkulu, kwaye ubunzulu bokungena bunyuka kunye ne-1/2 amandla obubanzi be-pulse. Nangona kunjalo, ukwanda kobubanzi be-pulse kuya kunciphisa amandla encopho, ngoko ke ukwanda kobubanzi be-pulse ngokuqhelekileyo kusetyenziselwa ukuwelda ubushushu, okukhokelela kubungakanani obubanzi kunye nobunzulu be-weld, obufanelekileyo ngokukodwa kwi-lap welding yeepleyiti ezibhityileyo nezityebileyo. Nangona kunjalo, amandla asezantsi encopho akhokelela kwigalelo lobushushu obugqithileyo, kwaye imathiriyeli nganye inobubanzi be-pulse obufanelekileyo okwandisa ubunzulu bokungena.

Defocus Ubuninzi

I-laser welding idla ngokufuna umyinge othile wokungagxininisi, kuba amandla oxinaniso lwendawo ekugxilwe kuyo ngelaser luphezulu kakhulu, ekulula ukukhupha izinto zokuwelda zibe yimingxunya. Ukusasazwa koxinaniso lwamandla kufana noko kwinqwelomoya nganye kude nogxininiso lwelaser.

Kukho iindlela ezimbini ze-defocus:

Ukungajongi kakuhle nokubi. Ukuba inqwelomoya ekugxilwe kuyo ibekwe ngaphezulu kwendawo yokusebenza, i-defocus entle; ngenye indlela, yi-negative defocus. Ngokutsho kwethiyori yejiyometri ye-optics, xa umgama phakathi kweenqwelomoya ezilungileyo nezingalunganga zokungagxininisi kunye nenqwelomoya yokuwelda ilingana, ukuxinana kwamandla kwinqwelomoya ehambelanayo kuphantse kufane, kodwa eneneni, ukumila kwechibi elityhidiweyo elifunyenweyo kwahlukile. Kwimeko ye-defocus embi, ukungena okukhulu kunokufumaneka, okuhambelana nenkqubo yokuqulunqa i-pool etyhidiweyo.

Isantya seWelding

Isantya se-welding simisela umgangatho we-welding, ubunzulu bokungena, indawo echaphazelekayo yokushisa njalo njalo. Isantya se-welding siyakuchaphazela igalelo lobushushu ngexesha leyunithi. Ukuba isantya se-welding sicotha kakhulu, igalelo lobushushu liphezulu kakhulu, okukhokelela ekubeni i-workpiece ivutha. Ukuba isantya se-welding sikhawuleza kakhulu, igalelo lobushushu lincinci kakhulu, okubangela ukuba i-workpiece idibanise ngokuyinxenye kwaye ingagqitywanga. Ukunciphisa isantya se-welding ngokuqhelekileyo kusetyenziselwa ukuphucula ukungena.

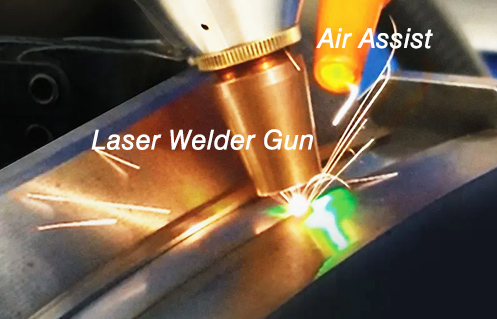

IGesi yoKhuseleko lweBlow eNcedisayo

Igesi encedisayo yokukhusela igesi yinkqubo ebalulekileyo kumandla aphezulu we-laser welding. Ngakolunye uhlangothi, ukuthintela izinto zetsimbi ukuba zitshise kwaye zingcolise isibuko sokugxila; Ngakolunye uhlangothi, kukuthintela i-plasma eveliswa kwinkqubo ye-welding ekugxininiseni kakhulu kwaye ithintele i-laser ekufikeleleni kumphezulu wezinto eziphathekayo. Kwinkqubo ye-laser welding, i-helium, i-argon, i-nitrogen kunye nezinye iigesi zihlala zisetyenziselwa ukukhusela i-pool etyhidiweyo, ukuze kuthintelwe i-workpiece kwi-oxidation kwi-welding engineering. Izinto ezifana nohlobo lwegesi yokukhusela, ubungakanani bokuhamba komoya kunye ne-Angle yokuvuthela kunempembelelo enkulu kwiziphumo ze-welding, kunye neendlela ezahlukeneyo zokuvuthela ziya kuba nefuthe elithile kumgangatho we-welding.

Isityebi seLaser esicetyiswayo esixhaswe ngesandla:

I-Laser Welder-iNdawo yokuSebenza

◾ Uluhlu lobushushu lwendawo yokusebenza: 15 ~ 35 ℃

◾ Uluhlu lokufuma lwemeko-bume yokusebenza: < 70% Akukho ukujiya

◾ Ukupholisa: i-chiller yamanzi iyimfuneko ngenxa yomsebenzi wokususa ubushushu kwi-laser-dissipating components, ukuqinisekisa ukuba i-laser welder isebenza kakuhle.

(Usetyenziso oluneenkcukacha kunye nesikhokelo malunga ne-chiller yamanzi, ungajonga:Amanyathelo okungqina umkhenkce kwiNkqubo yeLaser yeCO2)

Ngaba ufuna ukwazi ngakumbi malunga neLaser Welders?

Ixesha lokuposa: Dec-22-2022