Uyila njani owona mgangatho uphezulu wokusika i-laser?

▶ Injongo Yakho:

Injongo yakho kukufezekisa imveliso ekumgangatho ophezulu ngokusebenzisa ngokupheleleyo amandla e-laser ephezulu echanekileyo kunye nezixhobo. Oku kuthetha ukuqonda amandla e-laser kunye nezinto ezisetyenziswayo kunye nokuqinisekisa ukuba azityhalelwa ngaphaya kwemida yazo.

I-laser ephezulu echanekileyo sisixhobo esinamandla esonyusa kakhulu inkqubo yokuvelisa. Ukuchaneka kwayo nokuchaneka kwayo kwenza kube lula ukuyila imizobo entsonkothileyo neneenkcukacha. Ngokusebenzisa ngokupheleleyo i-laser, abavelisi banokuqinisekisa ukuba yonke inkalo yemveliso yenziwe ngokuchanekileyo, okukhokelela kwisiphumo esiphezulu.

Yintoni ekufuneka uyazi?

▶ Ubuncinci bobungakanani bophawu:

Xa ujongana neempawu ezincinci kuno-0.040 intshi okanye i-1 millimeter, kubalulekile ukuqaphela ukuba zinobuthathaka okanye zibuthathaka. Le milinganiso encinci yenza amacandelo okanye iinkcukacha zithinteke ekuphukelweni okanye kumonakalo, ngakumbi ngexesha lokuphatha okanye ukusetyenziswa.

Ukuqinisekisa ukuba usebenza ngaphakathi kwemida yesakhono semathiriyeli nganye, kuyacetyiswa ukuba ubhekisele kwimilinganiselo yobungakanani obuncinci obunikwe kwiphepha lemathiriyeli kwikhathalogu yezinto. Le milinganiso isebenza njengezikhokelo zokumisela eyona milinganiselo mincinci inokuthi imphathe ngokuthembekileyo ngaphandle kokubeka esichengeni isidima sayo sesakhiwo.

Ngokujonga ubuncinci bemilinganiselo yobungakanani, unokugqiba ukuba uyilo olucetyiweyo okanye iinkcukacha ziwela phakathi kwemida yezinto. Oku kuya kukunceda uphephe imiba enokubakho njengokuqhekeka okungalindelekanga, ukugqwetheka, okanye ezinye iindlela zokusilela ezinokuvela ngokutyhala izinto ezingaphaya kwamandla ayo.

Ukuthathela ingqalelo ubuthathaka beempawu ezingaphantsi kwe-intshi ze-0.040 (1mm) kwaye ubhekisa kubungakanani obuncinci bemilinganiselo yekhathalogu, unokwenza izigqibo ezinolwazi kunye nohlengahlengiso ukuqinisekisa ukwenziwa ngempumelelo kunye nokusebenza kwezinto ozifunayo.

▶Ubungakanani beNdawo ephantsi:

Xa usebenza ngebhedi ye-laser, kubalulekile ukuba uqaphele ukulinganiselwa kobungakanani beendawo ezisetyenziswayo. Amalungu amancinci kune-intshi ye-0.236 okanye i-6mm ububanzi anokuthi awele kwibhedi ye-laser kwaye ilahleke. Oku kuthetha ukuba ukuba inxalenye incinci kakhulu, ayinakubanjwa ngokukhuselekileyo ngexesha lokusikwa kwelaser okanye inkqubo yokukrola, kwaye inokutyibilika kwizikhewu ebhedini.

ToQinisekisa ukuba iindawo zakho zikulungele ukusika okanye ukukrolwa ngelaser, kubalulekile ukujonga ubuncinci bemilinganiselo yenxalenye yesixhobo ngasinye. Le milinganiselo inokufumaneka kwiphepha lezinto eziphathekayo kwikhathalogu yezinto. Ngokubhekiselele kwezi nkcukacha, unokumisela ubuncinci beemfuno zobungakanani bamalungu akho kwaye unqande nayiphi na ilahleko enokubakho okanye umonakalo ngexesha lokusika kwelaser okanye inkqubo yokukrola.

▶Eyona ndawo iphantsi yoMzobo:

Xa kufikwa kwindawo yokukrola i-raster, ukucaca kokubhaliweyo kunye neendawo ezincinci ezingaphantsi kwe-0.040 intshi (1mm) azibukhali kakhulu. Oku kunqongophala kokucaca kuya kubonakala ngakumbi njengoko ubungakanani bombhalo buncipha. Nangona kunjalo, kukho indlela yokuphucula umgangatho wokukrola kwaye wenze isicatshulwa sakho okanye iimilo zibonakale ngakumbi.

Enye indlela esebenzayo yokufezekisa oku kukudibanisa indawo kunye neendlela zokukrola umgca. Ngokubandakanya zombini iindlela, unokwenza umzobo obukekayo onomtsalane kunye nokuma okumile. Ukukrolwa kwendawo kubandakanya ukususa izinto ezivela kumphezulu ngendlela eqhubekayo, okubangela ukubonakala okugudileyo kunye nokuhambelana. Kwelinye icala, ukukrolwa komgca kubandakanya ukuhombisa imigca ecolekileyo kumphezulu, eyongeza ubunzulu kunye nenkcazo kuyilo.

Ukujonga ividiyo | Sika kwaye ukrole i-Acrylic Tutorial

Ukujonga ividiyo | ukusika iphepha

Ukwahluka koKutyeba kwezinto:

Igama elithi "ukunyamezela ukutyeba" libhekisa kuluhlu olwamkelekileyo lokwahluka kobunzima besixhobo. Yinkcazo ebalulekileyo enceda ukuqinisekisa umgangatho kunye nokuhambelana kwezinto eziphathekayo. Lo mlinganiso unikezelwa kwiimathiriyeli ezahlukeneyo kwaye unokufumaneka kwiphepha lemathiriyeli efanelekileyo kwikhathalogu yemathiriyeli.

Ukunyamezela kobunzima bubonakaliswa njengoluhlu, olubonisa ubuninzi kunye nobukhulu obuncinci obuvumelekileyo kwizinto ezithile. Umzekelo, ukuba ukunyamezela ukutyeba kwiphepha lesinyithi±0.1mm, kuthetha ukuba ubukhulu bephepha bunokwahluka phakathi kolu luhlu. Umda ongaphezulu iyakuba bubukhulu begama kunye ne-0.1mm, ngelixa umda osezantsi iyakuba bubungqingqwa begama thabatha 0.1mm.

Kubalulekile ukuba abathengi bathathele ingqalelo ukunyamezelwa kobuninzi xa bekhetha izixhobo kwiimfuno zabo ezithile. Ukuba iprojekthi idinga imilinganiselo echanekileyo, kuyacetyiswa ukuba ukhethe izinto ezinokunyamezela ukuqina kokuqina ukuqinisekisa iziphumo ezichanekileyo. Kwelinye icala, ukuba iprojekthi ivumela ukuguquguquka okuthile kobunzima, izixhobo ezinokunyamezelana okuxekethileyo zinokubiza kakhulu.

Ngaba uyafuna ukuqala ngentloko?

Kuthekani Ngezi Zikhetho Zikhulu?

Ngaba uyafuna ukuqalisa ngeLaser Cutter kunye nomzobi kwangoko?

Qhagamshelana nathi ukuze uBuzise ukuze uqalise kwangoko!

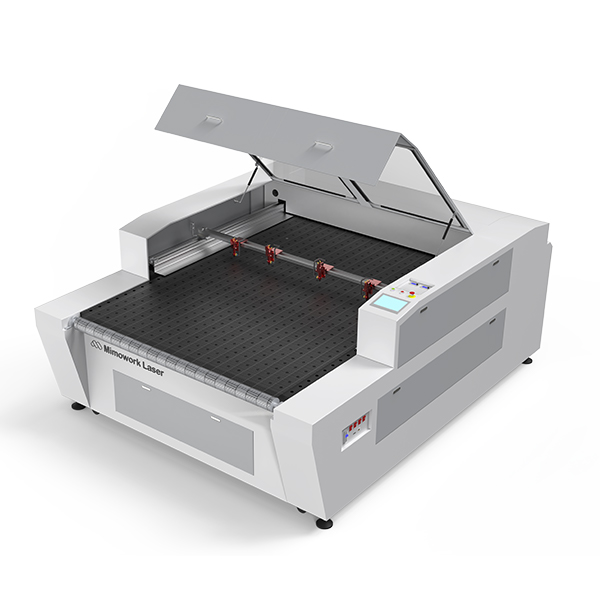

▶ Malunga Nathi-MimoWork Laser

Asizinzanga ngeziphumo eziPhakathi

I-Mimowork yimveliso yelaser ejolise kwiziphumo, ese-Shanghai nase-Dongguan China, izisa iminyaka engama-20 yobuchwephesha bokusebenza obunzulu ukuvelisa iinkqubo ze-laser kunye nokubonelela ngezisombululo ezibanzi zokusetyenzwa kunye nemveliso kwii-SME (amashishini amancinci naphakathi) kuluhlu olubanzi lwamashishini.

Amava ethu atyebileyo ezisombululo ze-laser zokwenziwa kwesinyithi kunye nezingezizo ezentsimbi zimiliselwe ngokunzulu kwintengiso yehlabathi jikelele, iimoto kunye nenqwelomoya, i-metalware, ukusetyenziswa kwedayi sublimation, ilaphu kunye neshishini lelaphu.

Kunokuba unikeze isisombululo esingaqinisekanga esifuna ukuthengwa kubavelisi abangafanelanga, iMimoWork ilawula yonke inxalenye yekhonkco lemveliso ukuqinisekisa ukuba iimveliso zethu zisebenza kakuhle rhoqo.

IMimoWork izibophelele ekudaleni nasekuphuculeni imveliso yelaser kwaye yaphuhlisa intaphane yetekhnoloji yelaser ephucukileyo ukuqhubela phambili nokuphucula umthamo wemveliso wabathengi kunye nokusebenza kakuhle okukhulu. Ukufumana amalungelo awodwa omenzi we-laser technology, sihlala sigxile kumgangatho kunye nokhuseleko lweenkqubo zoomatshini belaser ukuze siqinisekise imveliso ehambelanayo nethembekileyo. Umgangatho womatshini we-laser uqinisekiswe yi-CE kunye ne-FDA.

I-MimoWork Laser System inokusika i-laser ye-Acrylic kunye ne-laser engrave Acrylic, ekuvumela ukuba uqalise iimveliso ezintsha kwiindidi ezahlukeneyo zamashishini. Ngokungafaniyo nabasiki bokugaya, ukukrola njengento yokuhombisa kunokufezekiswa kwimizuzwana ngokusebenzisa umkroli welaser. Ikwakunika ithuba lokuthatha iiodolo ezincinci njengeyunithi enye elungiselelwe imveliso, kwaye inkulu ngamawaka emveliso ekhawulezayo kwiibhetshi, zonke ngaphakathi kwamaxabiso otyalo-mali afikelelekayo.

Fumana iMibono eyongezelelekileyo kwisitishi sethu sikaYouTube

Ixesha lokuposa: Jul-14-2023