Uwukhetha njani oyena mxube werhasi ulungileyo kwiWelding yakho yeLaser?

Iintlobo, iiNzuzo, kunye nezicelo

Intshayelelo:

Izinto eziphambili ekufuneka uzazi ngaphambi kokungena

Ukuwelda kweLaser yindlela yokuwelda ephezulu echanekileyo esebenzisa umqadi welaser ukunyibilikisa izinto zesixhobo sokusebenza kwaye emva koko wenze i-weld emva kokupholisa. Kwi-laser welding, igesi idlala indima ebalulekileyo.

Igesi ekhuselayo ayichaphazeli kuphela ukubunjwa kwe-welding seam, umgangatho we-welding seam, ukungena kwe-welding seam, kunye nobubanzi bokungena kodwa ichaphazela ngokuthe ngqo umgangatho kunye nokusebenza kakuhle kwe-laser welding.

Zeziphi iigesi ezifunekayo kwi-laser welding?Eli nqaku liza kujonga nzuluukubaluleka kweegesi ze-laser welding, iigesi ezisetyenziswayo, nezinto ezizenzayo.

Siza kucebisa kwakhonaoyena matshini welding laserkwiimfuno zakho.

Kutheni iGesi ifuneka kwi-Laser Welding?

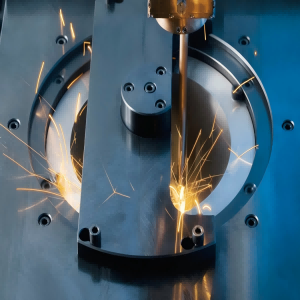

Laser Beam Welding

Ngethuba lenkqubo ye-laser welding, i-laser-high-energy-density beam ye-laser igxininise kwindawo ye-welding ye-workpiece.

Ukubangela ukunyibilika kwangoko kwezinto ezingaphezulu kwendawo yokusebenza.

Irhasi iyadingeka ngexesha welding laser ukukhusela indawo welding.

Lawula ubushushu, uphucule umgangatho we-weld, kwaye ukhusele inkqubo ye-optical system.

Ukukhetha uhlobo olufanelekileyo lwegesi kunye neeparitha zokubonelela zizinto ezibalulekileyo ekuqinisekiseni ukusebenza kakuhle.

Kwaye inkqubo yokuwelda i-laser ezinzileyo kunye nokufumana iziphumo ezikumgangatho ophezulu we-welding.

1. Ukukhuselwa kweeNdawo zeWelding

Ngethuba lenkqubo ye-laser welding, indawo ye-weld ibonakaliswe kwimeko yangaphandle kwaye ichaphazeleka lula yi-oksijini kunye nezinye iigesi emoyeni.

Ioksijini ibangela ukusabela kwe-oxidation enokuthi ikhokelele ekunciphiseni umgangatho we-weld, kunye nokudalwa kweepores kunye nokubandakanywa. I-weld inokukhuselwa ngokufanelekileyo ekungcoleni kwe-oksijini ngokunikezela ngegesi efanelekileyo, ngokuqhelekileyo igesi ye-inert efana ne-argon, kwindawo ye-welding.

2. Ukulawula Ubushushu

Ukukhethwa kwegesi kunye nokubonelela kunokunceda ukulawula ukushisa kwendawo ye-welding. Ngokulungelelanisa izinga lokuhamba kunye nohlobo lwegesi, izinga lokupholisa indawo ye-welding inokuchaphazeleka. Oku kubalulekile ukulawula indawo echaphazelekayo ukushisa (HAZ) ngexesha le-welding kunye nokunciphisa ukuphazamiseka kwe-thermal.

3. Ukuphuculwa koMgangatho weWeld

Ezinye iigesi ezincedisayo, ezifana neoksijini okanye i-nitrogen, zinokuphucula umgangatho kunye nokusebenza kwee-welds. Ngokomzekelo, ukongeza i-oksijini kunokuphucula ukungena kwe-weld kunye nokwandisa isantya se-welding, ngelixa lichaphazela imilo kunye nobunzulu be-weld.

4. Ukupholisa igesi

Kwi-laser welding, indawo ye-welding idla ngokuchaphazeleka ngamaqondo obushushu aphezulu. Ukusebenzisa inkqubo yokupholisa igesi kunokunceda ukulawula ubushushu bendawo ye-welding kunye nokukhusela ukushisa. Oku kubalulekile ukunciphisa uxinzelelo lwe-thermal kwindawo ye-welding kunye nokuphucula umgangatho we-welding.

I-Automated Laser Beam Welding

5. Ukukhuselwa kwegesi yeeNkqubo ze-Optical

I-laser beam igxininise kwindawo ye-welding ngokusebenzisa inkqubo ye-optical system.

Ngexesha lenkqubo ye-soldering, izinto ezityhidiweyo kunye ne-aerosols ezenziweyo zinokungcolisa amacandelo optical.

Ngokuzisa iigesi kwindawo ye-welding, umngcipheko wokungcola uyancipha kwaye ubomi benkqubo ye-optical yandiswa.

Zeziphi iigesi ezisetyenziswa kwi-Laser Welding?

Kwi-laser welding, irhasi inokwahlula umoya kwipleyiti ye-welding kwaye iwuthintele ukuba ungasabeli nomoya. Ngale ndlela, i-welding surface yeplate yensimbi iya kuba mhlophe kwaye ihle kakhulu. Ukusebenzisa irhasi kukwakhusela iilensi kuthuli lwewelding. Ngokuqhelekileyo, ezi gesi zilandelayo zisetyenziswa:

1. Igesi yoKhuselo:

Iigesi ezikhuselayo, ngamanye amaxesha zibizwa ngokuba "ziigesi ze-inert," zidlala indima ebalulekileyo kwinkqubo ye-laser welding. Iinkqubo ze-laser welding zihlala zisebenzisa iigesi ezingenayo ukukhusela i-weld pool. Iigesi ezisetyenziswa ngokuqhelekileyo kwi-laser welding ziquka i-argon kunye neon. Iimpawu zabo zomzimba kunye neekhemikhali zahlukile, ngoko ke iziphumo zazo kwi-weld nazo zahlukile.

Igesi yoKhuselo:Argon

I-Argon yenye yeegesi ze-inert ezisetyenziswa ngokuqhelekileyo.

Inomgangatho ophezulu we-ionization phantsi kwesenzo se-laser, engafanelekanga ukulawula ukubunjwa kwamafu e-plasma, eya kuba nefuthe elithile ekusebenziseni ngokufanelekileyo i-lasers.

Ubume obungenasiphelo be-argon bugcina ngaphandle kwenkqubo ye-soldering, ngelixa iphinda ikhuphe ubushushu kakuhle, inceda ukulawula ubushushu kwindawo ye-soldering.

Igesi yoKhuselo:Neon

I-Neon isoloko isetyenziswa njengegesi ye-inert, efana ne-argon, kwaye isetyenziselwa ukukhusela indawo ye-welding kwi-oksijeni kunye nezinye izinto ezingcolileyo kwindawo yangaphandle.

Kubalulekile ukuba uqaphele ukuba i-neon ayifanelekanga kuzo zonke izicelo ze-laser welding.

Isetyenziswa ikakhulu kwimisebenzi ethile yokuwelda, efana nezixhobo zokuwelda ezityebileyo okanye xa kufuneka imithungo enzulu yeweld.

2. Igesi eNcedisayo:

Ngethuba lenkqubo ye-laser welding, ngaphezu kwegesi ekhuselekileyo yokukhusela, iigesi ezincedisayo zingasetyenziselwa ukuphucula ukusebenza kwe-welding kunye nomgangatho. Ezi zilandelayo zezinye iigesi ezincedisayo eziqhelekileyo ezisetyenziswa kwi-laser welding.

Igesi eNcedisayo:Ioksijini

Ioksijeni isetyenziswa ngokuqhelekileyo njengegesi yokuncedisa kwaye ingasetyenziselwa ukunyusa ubushushu kunye nobunzulu be-weld ngexesha le-welding.

Ukongeza i-oksijini kunokunyusa isantya se-welding kunye nokungena, kodwa kufuneka ilawulwe ngononophelo ukunqanda i-oxygen engaphezulu ebangela iingxaki ze-oxidation.

Igesi eNcedisayo:IHydrojeni/Umxube weHydrojeni

I-Hydrogen iphucula umgangatho we-welds kwaye inciphisa ukubunjwa kwe-porosity.

Imixube ye-argon kunye ne-hydrogen isetyenziswa kwizicelo ezikhethekileyo, ezifana nokuwelda intsimbi engatyiwayo. Umxholo we-hydrogen womxube uqhelekile ukusuka kwi-2 ukuya kwi-15%.

Igesi yoKhuselo:Nitrogen

I-nitrojeni isoloko isetyenziswa njengegesi encedisayo kwi-laser welding.

Amandla e-ionization ye-nitrogen aphakathi, aphezulu kune-argon kwaye aphantsi kune-hydrogen.

Isidanga se-ionization ngokuqhelekileyo siphantsi kwesenzo selaser. Inokunciphisa ngcono ukubunjwa kwamafu e-plasma, inikeze umgangatho ophezulu we-welds kunye nokubonakala, kunye nokunciphisa impembelelo ye-oksijini kwi-welds.

I-nitrojeni ingasetyenziselwa ukulawula ubushushu bendawo ye-welding kunye nokunciphisa ukubunjwa kwamaqamu kunye neepores.

Igesi yoKhuselo:IHelium

I-Helium idla ngokusetyenziselwa ukuwelda i-laser ephezulu ngenxa yokuba ine-conductivity ephantsi ye-thermal kwaye ayinayo i-ionized ngokulula, ivumela i-laser ukuba idlule ngokutyibilikayo kunye namandla e-beam ukufikelela kumphezulu womsebenzi ngaphandle kwemiqobo.

Ikhuthaza ukuwelda amandla aphezulu. I-Helium ingasetyenziselwa ukuphucula umgangatho we-weld kunye nokulawula ubushushu be-welding. Le yeyona rhasi ikhuselayo esetyenziswa kwi-laser welding, kodwa iyabiza kakhulu.

3. IGesi yokupholisa:

Irhasi yokupholisa ihlala isetyenziswa ngexesha lokuwelda kwelaser ukulawula ubushushu bendawo yokuwelda, ukuthintela ubushushu obugqithisileyo, nokugcina umgangatho wokuwelda. Ezi zilandelayo zezinye iigesi zokupholisa eziqhelekileyo ezisetyenziswayo:

Irhasi yokupholisa/Phakathi:Amanzi

Amanzi sisixhobo esiqhelekileyo sokupholisa esihlala sisetyenziselwa ukupholisa iijenereyitha zelaser kunye neenkqubo zelaser welding optical.

Iinkqubo zokupholisa amanzi zinokunceda ukugcina ubushushu obuzinzileyo bejeneretha ye-laser kunye namacandelo optical ukuqinisekisa ukuzinza kwe-laser beam kunye nokusebenza.

Irhasi yokupholisa/Phakathi:Iigesi ze-Atmospheric

Kwezinye iinkqubo ze-laser welding, iigesi ze-ambient atmospheric zingasetyenziselwa ukupholisa.

Ngokomzekelo, kwinkqubo ye-optical ye-laser generator, i-atmosphere ejikelezileyo igesi inokubonelela ngesiphumo sokupholisa.

Irhasi yokupholisa/Phakathi:Iigesi ezingasebenziyo

Iigesi ezingasebenziyo ezifana ne-argon kunye ne-nitrogen nazo zingasetyenziswa njengeegesi zokupholisa.

Zine-conductivity ephantsi ye-thermal kwaye zingasetyenziselwa ukulawula ukushisa kwendawo ye-welding kunye nokunciphisa indawo echaphazelekayo ukushisa (HAZ).

Irhasi yokupholisa/Phakathi:Ulwelo lweNitrojeni

Initrogen yolwelo sisixhobo sokupholisa sobushushu obuphantsi kakhulu esinokusetyenziselwa ukuwelda ngelaser enamandla kakhulu.

Inika umphumo wokupholisa osebenzayo kakhulu kwaye iqinisekisa ulawulo lobushushu kwindawo ye-welding.

4. IGesi exutyiweyo:

Imixube yerhasi iqhele ukusetyenziselwa ukuwelda ukukhulisa imiba eyahlukeneyo yenkqubo, njengesantya se-welding, ubunzulu bokungena, kunye nokuzinza kwe-arc. Kukho iintlobo ezimbini eziphambili zemixube yegesi: imixube yokubini kunye ne-ternary.

Imixube yegesi yeBhinary:Argon + Ioksijini

Ukongeza inani elincinci le-oksijini kwi-argon kuphucula ukuzinza kwe-arc, icoca i-weld pool, kunye nokwandisa isantya se-welding. Lo mxube uqhele ukusetyenziselwa ukuwelda i-carbon steel, i-low-alloy steel, kunye nentsimbi engenasici.

Imixube yegesi yeBhinary:Argon + Carbon Dioxide

Ukongezwa kwe-CO₂ kwi-argon kwandisa amandla e-welding kunye nokumelana nokubola ngelixa kunciphisa i-spatter. Lo mxube udla ngokusetyenziselwa ukuwelda intsimbi yekhabhoni kunye nentsimbi engatyiwayo.

Imixube yegesi yeBhinary:Argon + Hydrogen

IHydrojeni yonyusa ubushushu be-arc, iphucula isantya se-welding, kwaye inciphisa iziphene zokuwelda. Iluncedo ngakumbi kwi-welding-based alloys esekelwe kwi-nickel kunye nentsimbi engatyiwa.

Imixube yerhasi yaseTernary:IArgon + iOxygen + Carbon Dioxide

Lo mxube udibanisa iingenelo zombini i-argon-oxygen kunye ne-argon-CO₂ imixube. Inciphisa ispatter, iphucula ukumanzi kwe-weld pool, kwaye iphucula umgangatho we-weld. Isetyenziswa ngokubanzi ukuwelda ubungqingqwa obahlukeneyo bentsimbi yekhabhoni, intsimbi ephantsi, kunye nentsimbi engatyiwayo.

Imixube yerhasi yaseTernary:Argon + Helium + Carbon Dioxide

Lo mxube unceda ukuphucula uzinzo lwe-arc, ukwandisa ubushushu be-weld pool, kunye nokwandisa isantya se-welding. Isetyenziswa kwi-welding ye-arc ye-short-circuit kunye ne-welding enzima yezicelo, inika ulawulo olungcono kwi-oxidation.

Ukukhetha igesi kwizicelo ezahlukeneyo

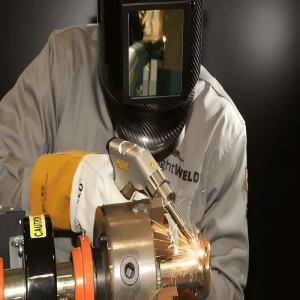

Ukuwelda kweLaser ngesandla

Kwizicelo ezahlukeneyo ze-laser welding, ukukhetha irhasi efanelekileyo kubalulekile, kuba indibaniselwano eyahlukeneyo yegesi inokuvelisa umgangatho wokuwelda owahlukileyo, isantya kunye nokusebenza kakuhle. Nazi ezinye izikhokelo zokukunceda ukhethe irhasi efanelekileyo kwisicelo sakho esithile:

Uhlobo lweMathiriyeli yeWelding:

Yenziwe ngentsimbi eshayinayongokuqhelekileyo isebenzisaArgon okanye Argon / Hydrogen Umxube.

I-Aluminiyam kunye ne-Aluminiyam i-alloyssebenzisa rhoqoIArgon ecocekileyo.

I-Titanium Alloyssebenzisa rhoqoNitrogen.

Iintsimbi zeCarbon eziPhezulusebenzisa rhoqoIoksijini njengeGesi eNcedisayo.

Isantya seWelding kunye nokungena:

Ukuba isantya esiphezulu se-welding okanye ukungena kwe-welding enzulu kuyadingeka, ukudibanisa kwegesi kunokulungiswa. Ukongeza i-oksijini kaninzi kuphucula isantya kunye nokungena, kodwa kufuneka ilawulwe ngononophelo ukuphepha iingxaki ze-oxidation.

Ulawulo loMmandla oChaphazeleke bubushushu (HAZ):

Ngokuxhomekeke kwizinto ezihlanjululwayo, inkunkuma enobungozi efuna iinkqubo zokuphatha ezikhethekileyo zinokuveliswa ngexesha lokucoca. Oku kunokongeza kwiindleko ezipheleleyo zenkqubo yokucoca i-laser.

Umgangatho weWeld:

Ezinye iindibaniso zegesi zinokuphucula umgangatho kunye nokubonakala kwee-welds. Ngokomzekelo, i-nitrogen inokubonelela ngenkangeleko engcono kunye nomgangatho ophezulu.

Ulawulo lwePore kunye neBubble:

Kwizicelo ezifuna i-welds ephezulu kakhulu, ingqwalasela ekhethekileyo kufuneka ihlawulwe ekubunjweni kweepores kunye namaqamza. Ukukhethwa kwegesi ngokufanelekileyo kunokunciphisa umngcipheko wezi ziphene.

Izixhobo kunye nokuqwalaselwa kweendleko:

Ukukhethwa kwegesi kukwaphenjelelwa luhlobo lwezixhobo kunye neendleko. Ezinye iigesi zinokufuna iinkqubo zokubonelela ezikhethekileyo okanye iindleko eziphezulu.

Kwizicelo ezithile, kuyacetyiswa ukuba usebenze kunye nenjineli ye-welding okanye umenzi wezixhobo zokuwelda i-laser ukufumana iingcebiso zobungcali kunye nokwandisa inkqubo yokuwelda.

Olunye ulingo kunye nokwenza ngcono kuyafuneka ngaphambi kokuba kukhethwe indibaniselwano yokugqibela yerhasi.

Ngokuxhomekeke kwisicelo esithile, udibaniso lwegesi oluhlukeneyo kunye neeparitha zinokuzanywa ukufumana iimeko ezifanelekileyo ze-welding.

Izinto ekufuneka uzazi malunga: Handheld Laser Welding

Kucetyiswa umatshini wokuwelda weLaser

Ukwandisa imisebenzi yakho yesinyithi kunye nokulungiswa kwezinto, ukukhetha izixhobo ezifanelekileyo kubalulekile. I-MimoWork Laser icebisa ukubaUmatshini wokuWelding weLaser ophathwa ngesandlaukudibanisa intsimbi echanekileyo kunye nesebenzayo.

Umthamo oPhezulu kunye nokuWattage kwizicelo ezahlukeneyo zeWelding

Umatshini wokuwelda we-laser we-2000W ubonakaliswe ngobungakanani bomatshini omncinci kodwa umgangatho we-welding omenyezelayo.

Umthombo we-fiber laser ozinzileyo kunye nentambo yefayibha edibeneyo inika ukuhanjiswa kwe-laser beam ekhuselekileyo kwaye ezinzileyo.

Ngamandla aphezulu, i-laser welding keyhole igqibelele kwaye yenza ukuba i-welding joint firmer iqine nakwintsimbi eshinyeneyo.

Ngokubonakala komatshini odibeneyo kunye nomncinci, umatshini we-laser welder ophathwayo uxhotyiswe ngompu we-laser welder oshukumayo olula kwaye ulungele ukusetyenziswa kwe-laser welding kwi-angle kunye nomphezulu.

Ukuzikhethela iintlobo ezahlukeneyo zemilomo ye-laser welder kunye neenkqubo zokutyisa ucingo oluzenzekelayo zenza umsebenzi we-laser welding lula kwaye inobubele kubaqalayo.

Isantya esiphezulu se-laser welding yonyusa kakhulu ukusebenza kwakho kwemveliso kunye nemveliso ngelixa uvumela isiphumo esihle kakhulu selaser.

Shwankathela

Ngamafutshane, i-laser welding kufuneka isebenzise igesi ukukhusela iindawo zokuwelda, ukulawula ubushushu, ukuphucula umgangatho we-weld, kunye nokukhusela iinkqubo zamehlo. Ukukhetha iintlobo zegesi ezifanelekileyo kunye neeparitha zokubonelela yinto ebalulekileyo ekuqinisekiseni inkqubo ye-laser ye-welding esebenzayo kunye nezinzileyo kunye nokufumana iziphumo eziphezulu ze-welding. Izixhobo ezahlukeneyo kunye nokusetyenziswa kunokufuna iintlobo ezahlukeneyo kunye nemilinganiselo edibeneyo ukuhlangabezana neemfuno ezithile ze-welding.

Finyelela kuthi namhlanjeukufunda ngakumbi malunga nabasiki bethu be-laser kunye nendlela abanokuphucula ngayo inkqubo yakho yokuvelisa.

Unxulumano oluNxulumeneyo

Naziphi na iimbono malunga noomatshini bokuwelda beLaser?

Ixesha lokuposa: Jan-13-2025