Iphepha lokusika iLaser:

UkuKhanya ubuDala obungenamda kunye nokuChaneka

▶ Intshayelelo:

Ukusika kweLaser kwephepha kuthatha ubuchule kunye nokuchaneka kwiindawo eziphakamileyo. Ngetekhnoloji yelaser, uyilo oluntsonkothileyo, iipateni ezintsonkothileyo, kunye neemilo ezithambileyo zinokusikwa ngaphandle komzamo ngokuchaneka okungenakuthelekiswa nanto. Nokuba yeyobugcisa, izimemo, ukupakishwa, okanye ukuhombisa, ukusika i-laser kuvula amathuba angapheliyo. Yithi ndlela-ntle kumsebenzi onzima wokusika ngesandla kwaye wamkele imiphetho ecocekileyo, ecocekileyo ephunyezwe ngokusikwa kwelaser. Amava okuguquguquka kunye nokusebenza kakuhle kobu buchule bokusika, ukuzisa iiprojekthi zakho zephepha ebomini ngokuchaneka okumangalisayo kunye neenkcukacha ezintsonkothileyo. Phakamisa ubugcisa bakho bephepha ngokuchaneka kokusikwa kwelaser.

Imigaqo ephambili kunye nezinto eziluncedo zeLaser Cutting Paper:

▶ Ukusika iPhepha leLaser:

Xa kuthelekiswa neendlela zezandla zemveli, ukusika kwe-laser kunika isantya esikhulu, ukunciphisa iindleko zabasebenzi, kuphelisa imfuno yokudala i-mold yesibini, kwaye ibonelela ngamathuba oyilo angenamkhawulo ngaphandle kwezithintelo kwiimilo. Ukusika i-Laser kunika ukucwangciswa kwepateni echanekileyo kunye neyinkimbinkimbi, iyenza isisombululo esisodwa ngaphandle kwesidingo sokulungiswa kwesibini.

Ukusika iphepha leLaser kusebenzisa imiqadi yelaser yoxinaniso lwamandla aphezulu ukusika ngokucocekileyo kunye nokwenza iipateni ezintsonkothileyo ezingenanto ephepheni. Ngokudlulisela imizobo efunekayo kwikhompyuter, ukufikelela kwisiphumo esifunekayo kuba lula. I-Laser yokusika kunye noomatshini bokukrola, kunye noyilo lwabo olulodwa kunye nokucwangciswa kokusebenza okuphezulu, kuphucula kakhulu ukusebenza kakuhle, kubenza babe izixhobo ezibalulekileyo kumashishini emveliso yephepha.

Umboniso weVidiyo | indlela yokusika i-laser kunye nokukrola iphepha

onokukufunda kule vidiyo:

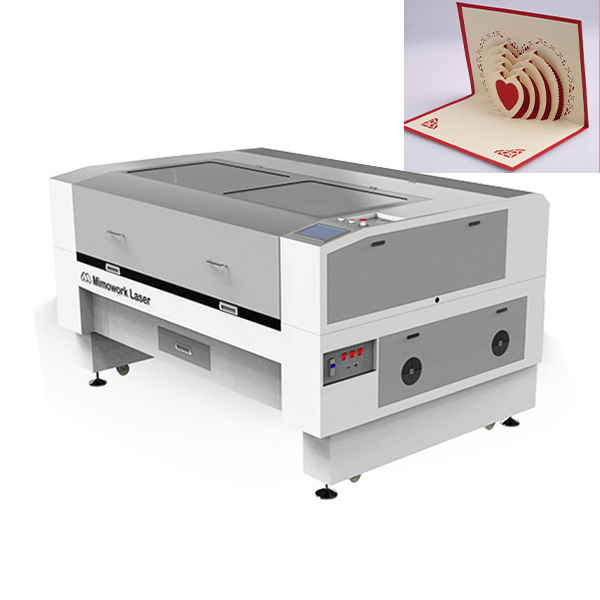

Kule vidiyo, uya kuphonononga ukuseta i-CO2 laser engraving kunye ne-laser cut of paperboard, utyhila iimpawu zayo ezimangalisayo kunye nobuchule. Eyaziwayo ngesantya esiphezulu kunye nokuchaneka kwayo, lo matshini wokumakisha we-laser uhambisa iziphumo ezigqwesileyo ze-laser ezikrolwe ngebhodi yephepha kwaye unikezela ukuguquguquka ekusikeni iphepha leemilo ezahlukeneyo. Ukusebenza kwayo okusebenziseka lula kwenza ukuba ifikeleleke nakubaqalayo, ngelixa i-laser ezenzekelayo yokusika kunye nemisebenzi yokukrola yenza yonke inkqubo ibe lula kwaye isebenziseka lula.

▶Uncedo olwahlukileyo lwePhepha lokuSika iLaser xa lithelekiswa noShicilelo lwe-Inki okanye ukuSika iDie:

1.Imeko yokusebenza eguquguqukayo ilungele iiofisi, iivenkile, okanye iivenkile zokuprinta.

2. Itekhnoloji ecocekileyo nekhuselekileyo efuna ukucocwa kwelensi kuphela.

3. Uqoqosho kunye neendleko zokugcinwa okuphantsi, akukho zixhobo, kwaye akukho mfuneko yokubumba.

4. Ukulungiswa okuchanekileyo koyilo oluntsonkothileyo.

5. Ukusebenza okuninzi:ukumakishwa komphezulu, ukugqobhozwa kwemicro, ukusika, amanqaku, iipateni, umbhalo, iilogo, kunye nokunye kwinkqubo enye.

6.Ubungane bendalo obungenazo izongezo zekhemikhali.

Imveliso ye-7.Flexible yeesampuli enye okanye i-batch processing encinci.

8. Iplagi kwaye udlale ngaphandle kokuqhubekela phambili okufunekayo.

▶Usetyenziso olufanelekileyo:

Amakhadi oshishino omntu, amakhadi okubulisa, ii-scrapbooks, imiboniso yentengiso, ukupakishwa, imisebenzi yezandla, iikhava kunye neejenali, iibhukhimakhi, kunye neemveliso zephepha ezahlukeneyo, ukuphucula umgangatho wemveliso.

Oomatshini bokusika i-Laser banokukhawuleza ukusika iintlobo ezahlukeneyo zephepha ngaphandle kwemiphumo emibi ngokusekelwe kubukhulu bephepha, kuquka ukusika iphepha, iibhokisi zephepha, kunye neemveliso zephepha ezahlukeneyo. Iphepha lokusika i-Laser libambe amandla amakhulu ngenxa yendalo yalo yokungabundi, livumela nasiphi na isimbo sokusika, ngaloo ndlela libonelela ngokuguquguquka okuphezulu. Ngaphezu koko, oomatshini bokusika iphepha le-laser babonelela ngokuchaneka okukhethekileyo, enye yeenzuzo zabo ezibalulekileyo, kungekho mandla angaphandle acinezelayo okanye abangela ukuguqulwa ngexesha lokusika.

Ukujonga ividiyo | ukusika iphepha

Iimpawu eziphambili zoMatshini wokusika weLaser othembekileyo:

1. Indawo yokusika egudileyo engenazo iibhula.

2. I-Thin cut seams, ngokuqhelekileyo ukusuka kwi-0.01 ukuya kwi-0.20 centimeters.

3. Ilungele ukusetyenzwa kweemveliso zobungakanani obukhulu, ukuphepha iindleko eziphezulu zokwenziwa komngundo.

4. I-deformation encinci ye-thermal ngenxa yamandla agxininisiweyo kunye nemvelo ye-high-speed ye-laser cutting.

5. Efanelekileyo kwiprototyping ngokukhawuleza, ukunciphisa umjikelo wophuhliso lwemveliso.

6. Izakhono zokulondoloza izinto eziphathekayo ngokusebenzisa inkqubo yekhompyutha, ukwandisa ukusetyenziswa kwezinto eziphathekayo.

▶ Iingcebiso zokusika iPhepha leLaser:

-Sebenzisa ilensi enobude obufutshane bojoliso kwindawo ecolekileyo yelaser kunye nokuchaneka okwandisiweyo.

- Ukuthintela ukushisa kwephepha, sebenzisa ubuncinane i-50% yesantya esiphezulu se-laser.

- Imiqadi ye-laser ebonakalisayo ebetha itafile yesinyithi ngexesha lokusika inokushiya amanqaku ngasemva kwephepha, ngoko kuyacetyiswa ukuba usebenzise i-Honeycomb Laser Bed okanye i-Knife Strip Table.

- Ukusika iLaser kuvelisa umsi kunye nothuli olunokuthi luhlale kwaye lungcolise iphepha, ngoko kuyacetyiswa ukuba usebenzise isixhobo sokukhupha umsi.

IsiKhokelo seVidiyo | Vavanya phambi kokuba Ugawulwe ngeLaser Multilayer

onokukufunda kule vidiyo:

Ividiyo ithatha i-multilayer laser cutting paper umzekelo, umngeni umda we-CO2 umatshini wokusika we-laser kunye nokubonisa umgangatho obalaseleyo wokusika xa i-galvo laser ikrola iphepha. zingaphi iileya ezinokuthi ilaser isike isiqwenga sephepha? Njengoko uvavanyo lubonisiwe, kunokwenzeka ukusuka kwi-laser ukusika i-2 yephepha ukuya kwi-laser ukusika i-10 yamaphepha ephepha, kodwa i-10 ibeka umngcipheko wokuba iphepha livutha. Kuthekani ngelaser ukusika ilaphu le-2? Kuthekani ngelaphu yokusika isangweji edibeneyo yelaphu? Sivavanya i-laser yokusika i-Velcro, iileya ezi-2 zelaphu kunye ne-laser yokusika i-3 yelaphu.

Ngaba uyafuna ukuqala ngentloko?

Kuthekani Ngezi Zikhetho Zikhulu?

Ngaba uyafuna ukuqalisa ngeLaser Cutter kunye nomzobi kwangoko?

Qhagamshelana nathi ukuze uBuzise ukuze uqalise kwangoko!

▶ Malunga Nathi-MimoWork Laser

Asizinzanga ngeziphumo eziPhakathi

I-Mimowork yimveliso yelaser ejolise kwiziphumo, ese-Shanghai nase-Dongguan China, izisa iminyaka engama-20 yobuchwephesha bokusebenza obunzulu ukuvelisa iinkqubo ze-laser kunye nokubonelela ngezisombululo ezibanzi zokusetyenzwa kunye nemveliso kwii-SME (amashishini amancinci naphakathi) kuluhlu olubanzi lwamashishini.

Amava ethu atyebileyo ezisombululo ze-laser zokwenziwa kwesinyithi kunye nezingezizo ezentsimbi zimiliselwe ngokunzulu kwintengiso yehlabathi jikelele, iimoto kunye nenqwelomoya, i-metalware, ukusetyenziswa kwedayi sublimation, ilaphu kunye neshishini lelaphu.

Kunokuba unikeze isisombululo esingaqinisekanga esifuna ukuthengwa kubavelisi abangafanelanga, iMimoWork ilawula yonke inxalenye yekhonkco lemveliso ukuqinisekisa ukuba iimveliso zethu zisebenza kakuhle rhoqo.

IMimoWork izibophelele ekudaleni nasekuphuculeni imveliso yelaser kwaye yaphuhlisa intaphane yetekhnoloji yelaser ephucukileyo ukuqhubela phambili nokuphucula umthamo wemveliso wabathengi kunye nokusebenza kakuhle okukhulu. Ukufumana amalungelo awodwa omenzi we-laser technology, sihlala sigxile kumgangatho kunye nokhuseleko lweenkqubo zoomatshini belaser ukuze siqinisekise imveliso ehambelanayo nethembekileyo. Umgangatho womatshini we-laser uqinisekiswe yi-CE kunye ne-FDA.

I-MimoWork Laser System inokusika i-laser ye-Acrylic kunye ne-laser engrave Acrylic, ekuvumela ukuba uqalise iimveliso ezintsha kwiindidi ezahlukeneyo zamashishini. Ngokungafaniyo nabasiki bokugaya, ukukrola njengento yokuhombisa kunokufezekiswa kwimizuzwana ngokusebenzisa umkroli welaser. Ikwakunika ithuba lokuthatha iiodolo ezincinci njengeyunithi enye elungiselelwe imveliso, kwaye inkulu ngamawaka emveliso ekhawulezayo kwiibhetshi, zonke ngaphakathi kwamaxabiso otyalo-mali afikelelekayo.

Fumana iMibono eyongezelelekileyo kwisitishi sethu sikaYouTube

Ixesha lokuposa: Jul-18-2023