I-Laser Welding Secrets: Lungisa imiba eqhelekileyo ngoku!

Intshayelelo:

IsiKhokelo esiGqibeleleyo sokuJonga ingxaki

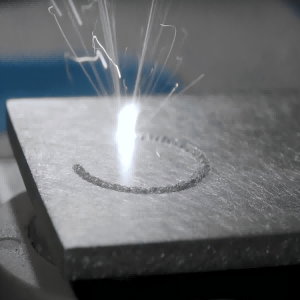

Oomatshini bokuWelding beLaser ngesandla

Umatshini wokuwelda we-laser we-Handheld ufumene ukuthandwa kakhulu kumashishini ahlukeneyo ngenxa yokuchaneka kunye nokusebenza kakuhle.

Nangona kunjalo, njengayo nayiphi na enye indlela ye-welding, ayikhuselekanga kwimingeni kunye nemiba enokuthi ivele ngexesha lenkqubo ye-welding.

Oku kubanzilaser welding ingxakiijolise ekulungiseni iingxaki eziqhelekileyo ezidibene noomatshini bokuwelda bezandla belaser, iingxaki ezinxulumene ne-welding, kunye nemiba emalunga nomgangatho we-welds.

Qalisa kwangaphambili Iimpazamo koomatshini bokuwelda beLaser kunye nezisombululo

1. Izixhobo azinakuQala (Amandla)

Isisombululo: Jonga ukuba iswitshi yentambo yombane iyasebenza na.

2. Izibane azinakuKhanyiswa

Isisombululo: Khangela ibhodi yangaphambili yomlilo kunye okanye ngaphandle kwe-voltage ye-220V, khangela ibhodi yokukhanya; 3Ifuse, isibane sexenon.

3. Isibane Sikhanyisiwe, Akukho Laser

Isisombululo: Qaphela i-handheld laser welding machine inxalenye yesiboniso ngaphandle kokukhanya iyinto eqhelekileyo. Okokuqala, khangela inxalenye ye-CNC yeqhosha le-laser ivaliwe, ukuba ivaliwe, emva koko uvule iqhosha le-laser. Ukuba iqhosha lelaser liqhelekile, vula isibonisi solawulo lwamanani ukubona ukuba isicwangciso sokukhanya okuqhubekayo, ukuba akunjalo, tshintshela ekukhanyeni okuqhubekayo.

Imiba ye-Welding yeSigaba se-Laser Welder & Fixes

Umthungo weWeld Mnyama

Igesi yokukhusela ayivulwanga, nje ukuba igesi ye-nitrogen ivuliwe, ingasombululwa.

Ulwalathiso lokuhamba komoya lwegesi ekhuselayo luphosakele, ulwalathiso lokuhamba komoya lwegesi ekhuselayo kufuneka lwenziwe ngokuchasene nolwakhiwo lwentshukumo yomsebenzi.

Ukunqongophala kokungena kwi-Welding

Ukungabikho kwamandla e-laser kunokuphucula ububanzi be-pulse kunye nangoku.

I-lens yokugxila ayilona inani elichanekileyo, ukulungelelanisa inani eligxininisiweyo kufuphi nendawo yokugxila.

Ukuncipha kweBeam yeLaser

Ukuba amanzi okupholisa angcolisekile okanye akatshintshwanga ixesha elide, anokusombululwa ngokutshintsha amanzi okupholisa kunye nokucoca ityhubhu yeglasi ye-UV kunye nesibane se-xenon.

I-lens egxininisekileyo okanye i-resonant cavity diaphragm ye-laser yonakaliswe okanye ingcolile, kufuneka ithathelwe indawo okanye icocwe ngexesha.

Hambisa i-laser kwindlela ephambili ye-optical, lungisa umboniso opheleleyo kunye ne-semi-reflection diaphragm kwindlela ephambili ye-optical, khangela kwaye ujikeleze indawo ngephepha lomfanekiso.

I-laser ayiphumi kwi-nozzle yobhedu ngaphantsi kwentloko yokugxila. Lungisa i-45-degree reflective diaphragm ukwenzela ukuba i-laser iphume kumbindi we-nozzle yegesi.

Laser Welding Quality Troubleshooting

1.Spatter

Emva kokuba i-laser welding igqityiwe, iinqununu ezininzi zetsimbi zivela phezu kwezinto okanye umsebenzi womsebenzi, unamathele kumphezulu wezinto okanye umsebenzi.

Isizathu sokutshiza: umphezulu wezinto ezicwangcisiweyo okanye umsebenzi awuhlambulukanga, kukho ioli okanye ukungcola, kunokubangelwa ukuguquguquka komgangatho we-galvanized.

1) Nikela ingqalelo ekucoceni izinto okanye isiqwenga somsebenzi phambi kwe-laser welding;

2) I-Spatter inxulumene ngokuthe ngqo nobuninzi bamandla. Ukunciphisa ngokufanelekileyo amandla e-welding kunokunciphisa i-spatter.

2. Iintanda

Ukuba isantya sokupholisa se-workpiece sikhawuleza kakhulu, ubushushu bamanzi okupholisa kufuneka bulungelelaniswe kwindawo yokunyusa ubushushu bamanzi.

Xa i-gap efanelekileyo ye-workpiece inkulu kakhulu okanye kukho i-burr, ukuchaneka kwe-machining ye-workpiece kufuneka kuphuculwe.

Umsebenzi awukacocwa. Kule meko, i-workpiece kufuneka ihlambuluke kwakhona.

Isantya sokuhamba kwegesi ekhuselayo sikhulu kakhulu, esingasombululwa ngokunciphisa izinga lokuhamba kwegesi ekhuselayo.

3. Imbombo kwiWeld Surface

Izizathu zokuveliswa kwe-porosity:

1) I-laser welding pool etyhidiweyo inzulu kwaye imxinwa, kwaye izinga lokupholisa likhawuleza kakhulu. Irhasi eveliswa kwidama elinyibilikisiweyo ishiywe lixesha kakhulu ukuba ingaphuphuma, nto leyo inokukhokelela ngokulula ekuyilweni kwe-porosity.

2) Umphezulu we-weld awucocwanga, okanye umphunga we-zinc wephepha le-galvanized.

Coca umphezulu we-workpiece kunye nomphezulu we-weld phambi kwe-welding ukuphucula i-volatilization ye-zinc xa ishushu.

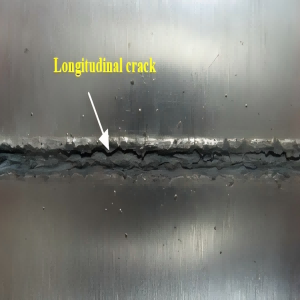

4. Ukuphambuka kweWelding

Intsimbi ye-weld ayiyi kuqinisa embindini wesakhiwo esidibeneyo.

Isizathu sokuphambuka: Ukumiswa okungachanekanga ngexesha le-welding, okanye ixesha lokuzalisa ngokungafanelekanga kunye nokulungelelanisa ucingo.

Isisombululo: Lungisa indawo ye-welding, okanye ixesha lokuzalisa kunye nendawo yocingo, kunye nendawo yesibane, ucingo kunye ne-weld.

5. Surface Slag Entrapment, Ebonakala ikakhulu phakathi kweeLayers

Ukubanjwa kwe-slag ebusweni kubangela:

1) Xa i-welding ye-multi-layer multi-pass welding, i-coating phakathi kwe-layer ayicocekanga; okanye umphezulu we-weld wangaphambili awusicaba okanye umphezulu we-weld awuhlangabezani neemfuno.

2) Ubuchule bokusebenza kwe-welding engafanelekanga, njengamandla okufaka i-welding ephantsi, isantya se-welding sikhawuleza kakhulu.

Isisombululo: Khetha isantya esifanelekileyo se-welding yangoku kunye nesantya se-welding, kwaye i-interlayer coating kufuneka icocwe xa i-multi-layer multi-pass welding. Gaya kwaye ususe i-weld nge-slag phezu komhlaba, kwaye wenze i-weld xa kuyimfuneko.

Ezinye izixhobo - Iingxaki zeLaser Welder eziqhelekileyo kunye nezisombululo

1. Ukungaphumeleli kwesiXhobo soKhuseleko loKhuseleko

Izixhobo zokukhusela ukhuseleko lomatshini we-laser welding, ezifana nomnyango wegumbi lokuwelda, inzwa yokuhamba kwegesi, kunye nenzwa yobushushu, zibalulekile ekusebenzeni kwayo ngokufanelekileyo. Ukungaphumeleli kwezi zixhobo akunakuphazamisa kuphela ukusebenza okuqhelekileyo kwesixhobo kodwa kubangela ingozi yokulimala kumqhubi.

Xa kukho ukungasebenzi kakuhle kunye nezixhobo zokukhusela ukhuseleko, kuyimfuneko ukumisa ukusebenza ngokukhawuleza kwaye uqhagamshelane neengcali zokulungiswa kunye nokutshintshwa.

2. I-Wire Feeder Jamming

Ukuba kukho i-jam feeder jam kule meko, into yokuqala ekufuneka siyenzile kukukhangela ukuba umlomo wompu uvalekile, inyathelo lesibini kukukhangela ukuba i-wire feeder ivalekile kwaye kukho ukujikeleza kwediski yesilika kuqhelekileyo.

Shwankathela

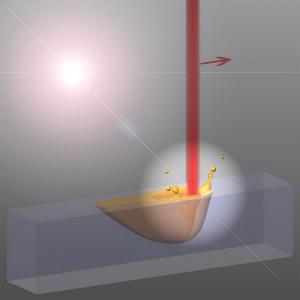

Ngokuchaneka okungahambelaniyo, isantya kunye nokuguquguquka, i-laser welding yitekhnoloji exabisekileyo kumashishini afana neemoto, i-aerospace kunye ne-elektroniki.

Nangona kunjalo, iziphene ezahlukeneyo zinokuthi zenzeke ngexesha lenkqubo ye-welding, kubandakanywa i-porosity, i-crack, i-splashing, i-bead engaqhelekanga, ukutshiswa, ukuguqulwa, kunye ne-oxidation.

Isiphako ngasinye sinesizathu esithile, njengeSettings laser engafanelekanga, ukungcola kwezinto eziphathekayo, iigesi ezingonelanga zokukhusela, okanye amajoyina angahambi kakuhle.

Ngokuqonda ezi ziphene kunye nezizathu zabo ezisisiseko, abavelisi banokusebenzisa izisombululo ezijoliswe kuzo, ezifana nokuphucula iiparamitha ze-laser, ukuqinisekisa ukudibanisa ngokufanelekileyo, ukusebenzisa iigesi ezikhuselekileyo ezisemgangathweni, kunye nokusebenzisa unyango lwangaphambili kunye ne-post-weld.

Uqeqesho olululo lwabaqhubi, ukugcinwa kwezixhobo zemihla ngemihla kunye nokubekwa kweliso kwinkqubo yexesha lokwenyani kuphucuka ngakumbi umgangatho we-welding kunye nokunciphisa iziphene.

Ngendlela ebanzi yokuthintela isiphene kunye nokuphuculwa kwenkqubo, i-laser welding ihlala ihambisa iiwelds ezinamandla, ezithembekileyo nezikumgangatho ophezulu ezihlangabezana nemigangatho engqongqo yoshishino.

Andazi ukuba loluphi uhlobo umatshini welding laser ukuba ukhethe?

Kufuneka uyazi: Ungawukhetha njani umatshini welaser ophathwa ngesandla

Umthamo oPhezulu kunye nokuWattage kwizicelo ezahlukeneyo zeWelding

Umatshini wokuwelda we-laser we-2000W ubonakaliswe ngobungakanani bomatshini omncinci kodwa umgangatho we-welding omenyezelayo.

Umthombo we-fiber laser ozinzileyo kunye nentambo yefayibha edibeneyo inika ukuhanjiswa kwe-laser beam ekhuselekileyo kwaye ezinzileyo.

Ngamandla aphezulu, i-laser welding keyhole igqibelele kwaye yenza ukuba i-welding joint firmer iqine nakwintsimbi eshinyeneyo.

Ukuphatheka ngokuguquguquka

Ngokubonakala komatshini odibeneyo kunye nomncinci, umatshini we-laser welder ophathwayo uxhotyiswe ngompu we-laser welder oshukumayo olula kwaye ulungele ukusetyenziswa kwe-laser welding kwi-angle kunye nomphezulu.

Ukuzikhethela iintlobo ezahlukeneyo zemilomo ye-laser welder kunye neenkqubo zokutyisa ucingo oluzenzekelayo zenza umsebenzi we-laser welding lula kwaye inobubele kubaqalayo.

Isantya esiphezulu se-laser welding yonyusa kakhulu ukusebenza kwakho kwemveliso kunye nemveliso ngelixa uvumela isiphumo esihle kakhulu selaser.

Izinto ekufuneka Uyazi malunga: Handheld Laser Welding

Ukuba uyonwabele le vidiyo, kutheni ungacingiubhalisela kwisiteshi sethu seYouTube?

Yonke into eThengiweyo kufuneka yaziswe kakuhle

Singakwazi ukuNceda ngolwazi oluneenkcukacha kunye noBonwano!

Ixesha lokuposa: Jan-16-2025