Esona siKhokelo seLazi yokuSika isihluzi selaphu:

Iintlobo, iiNzuzo, kunye nezicelo

Intshayelelo:

Izinto eziphambili ekufuneka uzazi ngaphambi kokungena

Amalaphu esihluzi adlala indima ebalulekileyo kuluhlu olubanzi lwemizi-mveliso, ukusuka kuhluzo lwamanzi kunye nomoya ukuya kumayeza kunye nokwenza ukutya. Njengoko amashishini efuna ukuphucula ukusebenza kakuhle, ukuchaneka, kunye nokwenza ngokwezifiso kwimveliso yelaphu lokucoca, ilaphu lokusika i-laser liye lavela njengesisombululo esithandwayo. Ngokungafaniyo neendlela zokusika zesiNtu, ilaphu lokusikwa kwelaphu le-laser libonelela ngenqanaba eliphezulu lokuchaneka, isantya, kunye nenkunkuma yempahla encinci, iyenza ibe lolona khetho lufanelekileyo lokusika amalaphu okucoca enziwe ngezinto ezahlukeneyo ezifanaipolyester, inayiloni, kwayeamalaphu angalukwanga.

Kweli nqaku, siza kujonga ngakumbi kwiindidi ezahlukeneyo zelaphu lokucoca kunye nendlela ilaphu lokusika isihluzo esisebenza ngayo kwiimathiriyeli ezahlukeneyo. Uya kubona ukuba kutheni kuye kwaba njaloukuya kwisisombululo sokuvelisa umgangatho ophezulu, iimveliso zokuhluza ezilungiselelweyo. Siza kwabelana ngezimvo ezisuka kuvavanyo lwethu lwamva nje ngemathiriyeli efana negwebu kunye nepolyester, sikunika imizekelo yehlabathi yokwenyani yendlela ilaphu lokusika isihluzi selaphu linokunyusa ukusebenza kakuhle kunye nokungaguquguquki kwimveliso.

Ulisika njani ilaphu lesihluzi seLaser | Laser Cutting Machine for Filtration Industry

Yiza kwividiyo ukuze ujonge inkqubo yokusikwa kwelaphu lelaphu lokucoca. Imfuno ephezulu yokusika ukuchaneka idume umatshini wokusika we-laser kwishishini lokuhluza.

Iintloko ezimbini ze-laser ziphucula ngakumbi imveliso, zonyusa isantya sokusika ngelixa uqinisekisa umgangatho.

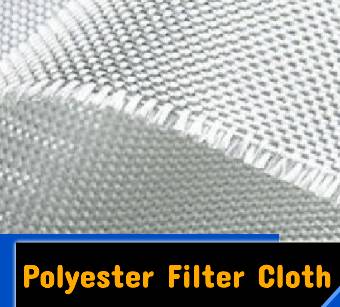

1. Ilaphu lesihluzi sePolyester:

• Ukusetyenziswa:Ilaphu le-polyester lokucoca sesinye sezona zixhobo zixhaphakileyo ekuhluzweni ngenxa yokuqina, ukumelana neekhemikhali, kunye nokukwazi ukumelana nobushushu obuphezulu.

•Usetyenziso:Ihlala isetyenziswa kwiinkqubo zokucoca umoya, ukucocwa kwamanzi, kunye neenkqubo zokuhluza kwimizi-mveliso.

•Iingenelo zokusika iLaser:I-polyester iyahambelana kakhuluilaphu lokucoca i-laserkuba ivelisa imiphetho ecocekileyo, nechanekileyo. I-laser iphinda itywine imiphetho, ithintele ukonakala kunye nokwandisa amandla elaphu ngokubanzi.

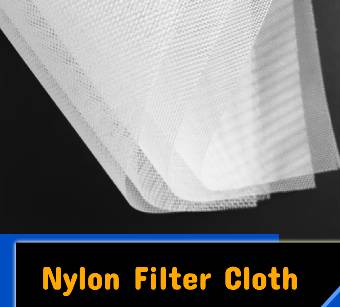

2. Ilaphu lesiSihluzo seNayiloni:

• Ukusetyenziswa:Eyaziwa ngokuba bhetyebhetye kunye nokuqina, ilaphu lesihluzo senayiloni lifanelekile ekufuneni izicelo zokuhluza, njengakwimizi-mveliso yeekhemikhali okanye kwicandelo lokutya nesiselo.

•Usetyenziso:Ngokuqhelekileyo isetyenziselwa ukuhluzwa kweekhemikhali, unyango lwamanzi, kunye nokucoca ukutya.

•Iingenelo zokusika iLaser:Amandla enayiloni kunye nokumelana nokunxiba kuyenza ibe ngumgqatswa ogqwesileyoilaphu lokucoca i-laser. I-laser iqinisekisa imiphetho egudileyo, etywiniweyo egcina ukuqina kwesixhobo kunye neempawu zokuhluza.

3. Ilaphu lesiSihluzo sePolypropylene:

• Ukusetyenziswa:Ipolypropylene yaziwa ngokugqwesa kwayo ukumelana neekhemikhali, iyenza ilungele ukuhluza iikhemikhali ezinobundlobongela okanye izinto ezinobushushu obuphezulu.

•Usetyenziso:Isetyenziselwa ukuhluza amayeza, ukuhluzwa kwamashishini, kunye nokucoca ulwelo.

•Iingenelo zokusika iLaser: Ilaphu lokucoca i-lasernjengepolypropylene ivumela ukusikwa okuchanekileyo kunye noyilo oluntsonkothileyo ngaphandle kokonakalisa izinto. Imiphetho etywiniweyo ibonelela ngokuthembeka kwesakhiwo esingcono, okwenza ukuba ifaneleke kwizicelo ezibalulekileyo.

4. Ilaphu leSihluzo esingalukwanga:

• Ukusetyenziswa:Ilaphu lesihluzo esingalukwanga likhaphukhaphu, liyabhetyebhetye kwaye liyabiza. Isetyenziswa kwizicelo apho ukusetyenziswa lula kunye noxinzelelo oluphantsi kubalulekile.

•Usetyenziso:Isetyenziswa kwiimoto, emoyeni, nakuhluzo lothuli, kunye nakwiimveliso zokucoca ezilahlwayo.

•Iingenelo zokusika iLaser:Amalaphu angalukwanga angabalaser cutngokukhawuleza nangempumelelo.Ilaphu lokucoca i-laseriguquguquka kakhulu kwiimfuno ezahlukeneyo zokuhluza, ivumela ukugqobhoza okuhle kunye nokusikeka kwendawo enkulu.

Ilaphu lokusika i-laser lisebenzisa umqadi welaser ogxininisiweyo, onamandla aphezulu anyibilikayo okanye enze umphunga welaphu kanye kwindawo yoqhagamshelwano. Ukukhokelwa yi-CNC (i-Computer Numerical Control system), i-laser ihamba ngokuchaneka okumangalisayo, okwenza kube lula ukusika okanye ukukrola iintlobo ezahlukeneyo zelaphu lokucoca ngokuchaneka okubalaseleyo.

Ewe, ayizizo zonke izinto zelaphu zokucoca ezifanayo. Ngamnye ufuna iisetingi ezilungelelanisiweyo ukufezekisa iziphumo ezilungileyo zokusika. Masicazulule indlela elisebenza ngayo ilaphu lokusika i-laser kwezinye zezinto ezisetyenziswa kakhulu.

I-Laser Cut Polyester:

Ilaphu le-polyester lokucoca liqinile kwaye liyaxhathisa ukolula, nto leyo ngamanye amaxesha inokwenza kube nzima ukusika ngezixhobo zemveli. Ukusika kweLaser kubonelela ngenzuzo ecacileyo apha, njengoko ihambisa imiphetho egudileyo, etywiniweyo ethintela ukonakala ngelixa igcina amandla elaphu. Oku kuchaneka kubaluleke ngakumbi kumashishini afana nokucocwa kwamanzi okanye ukulungiswa kokutya, apho ukusebenza kokucoca okungaguqukiyo kuyadingeka.

ILaser Sika amalaphu angalukwanga:

Amalaphu angalukwanga alula kwaye anobuthathaka, nto leyo ewenza abe ngumdlalo ogqwesileyo wokusika i-laser. Ngale teknoloji, izinto eziphathekayo zinokucutshungulwa ngokukhawuleza ngaphandle kokuphazamisa isakhiwo sayo, okukhokelela ekucoceni okucocekileyo, okuchanekileyo okubalulekileyo ekubunjweni kweefilitha. Le ndlela ibaluleke kakhulu xa usebenza ngamalaphu angabonakaliyo kwi-filtration yonyango okanye yemoto, apho ukuchaneka kunye nokuhambelana ngundoqo.

I-Laser Sika Inayiloni:

Amalaphu eNyiloni ayaziwa ngokuguquguquka kwawo kunye nokuqina, kodwa anokuba nzima ukujongana neendlela zokusika ngoomatshini. Ukusetyenzwa kweLaser kusombulula lo mngeni ngokuvelisa amanxeba abukhali, amanxeba achanekileyo ngaphandle kokuphazamisa. Isiphumo zizihluzo ezibambe imilo yazo kwaye zinikeze ukusebenza okuthembekileyo, okubalulekileyo kwiimeko ezibango ezinje ngekhemikhali okanye usetyenziso lwamayeza.

I-Laser Cut Foam:

Igwebu yimathiriyeli ethambileyo nenemingxuma enokukrazuka okanye igqwetheke ngokulula xa isikwe ngeencakuba. Itekhnoloji yeLaser inikezela ngesisombululo esicocekileyo nesithembekileyo, njengoko inqumla i-foam ngaphandle kokutyumza iiseli okanye ukuphazamisa isakhiwo sayo. Oku kuqinisekisa ukuba izihluzi ezenziwe kwi-foam zigcina i-porosity yazo kunye nokusebenza, zibenza zibe luncedo ngakumbi kwizicelo ezifana nokucocwa komoya kunye nokugquma kwe-acoustic.

Kutheni ukhetha ukusika iLaser kwilaphu lokucoca?

Ilaphu lokucoca i-laseribonelela ngeenzuzo ezininzi kwiindlela zokusika zesiNtu, ngakumbi kwimathiriyeli yelaphu lokucoca. Nazi ezinye zeenzuzo eziphambili:

1. Ukuchaneka kunye noMphetho ococekileyo

Ilaphu lokucoca i-laseriqinisekisa ukusikwa okuchanekileyo kunye nemiphetho ecocekileyo, evaliweyo, ebalulekileyo ekugcineni ingqibelelo yesakhiwo selaphu lokucoca. Oku kubaluleke kakhulu kwiinkqubo zokucoca apho izinto eziphathekayo kufuneka zigcine amandla azo okucoca ngokufanelekileyo.

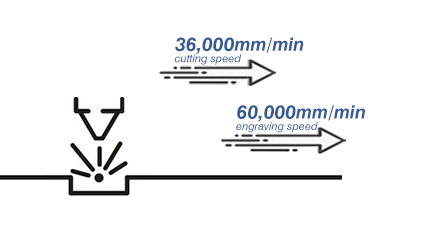

2. Isantya esikhawulezayo kunye nokusebenza kakuhle

Ilaphu lokucoca i-laserikhawuleza kwaye isebenza ngakumbi kuneendlela zoomatshini okanye zokusika, ngakumbi kuyilo oluntsonkothileyo okanye oluqhelekileyo. Iinkqubo yokusika ilaphu laseriyakwazi ukuzenzekelayo, ukunciphisa imfuno yokungenelela ngesandla kunye nokukhawulezisa amaxesha okuvelisa.

3. Inkunkuma yezinto eziphathekayo

Iindlela zokusika zemveli zihlala zenza inkunkuma yezinto ezigqithisileyo, ngakumbi xa usikwa iimilo ezinzima.Ilaphu lokucoca i-laserinika ukuchaneka okuphezulu kunye nokuchithwa kwezinto ezincinci, okwenza kube yindlela ebiza kakhulu kwimveliso encinci kunye nenkulu.

4. Ukwenza ngokwezifiso kunye nokuguquguquka

Ilaphu lokucoca i-laserivumela ukwenziwa ngokugqibeleleyo kwamalaphu okucoca. Nokuba ufuna imibhobho encinci, iimilo ezithile, okanye uyilo oluneenkcukacha,ilaphu lokucoca i-laseringakwazi ukulungiselela iimfuno zakho ngokulula, ikunika ukuguquguquka ukuvelisa uluhlu olubanzi lweemveliso zelaphu lokucoca.

5. Akukho siXhobo seSixhobo

Ngokungafaniyo nokusika okanye ukusika oomatshini,ilaphu lokucoca i-laserayibandakanyi ukudibana ngokwasemzimbeni kunye nesixhobo, okuthetha ukuba akukho kunxitywa kweencakuba okanye izixhobo. Oku kunciphisa iindleko zokugcina kunye nexesha lokunciphisa, okwenza kube yisisombululo esithembekileyo sexesha elide.

• Indawo yokusebenzela (W *L): 1000mm * 600mm

• Amandla eLaser: 60W/80W/100W

• Indawo yokusebenzela (W *L): 1300mm * 900mm

• Amandla eLaser: 100W/150W/300W

• Indawo yokusebenzela (W *L): 1800mm * 1000mm

• Amandla eLaser: 100W/150W/300W

Ukuququmbela

Ilaphu lokucoca i-laserIbonakalise ukuba yeyona ndlela ibalaseleyo yokusika amalaphu okucoca, ibonelela ngezinto ezininzi eziluncedo njengokuchaneka, isantya, kunye nenkcitho encinci. Nokuba usikwa ipolyester, ugwebu, inayiloni, okanye amalaphu angalukwanga, ilaphu lokusikwa kwelaphu lokucoca liqinisekisa iziphumo ezikumgangatho ophezulu ezinemiphetho etywiniweyo kunye noyilo olulungiselelweyo. Uluhlu lweMimoWork Laser yenkqubo yokusika ilaphu yelaphu yokucoca ibonelela ngesisombululo esigqibeleleyo kumashishini abo bonke ubungakanani obujonge ukukhulisa inkqubo yabo yokuvelisa ilaphu.

Qhagamshelana nathi namhlanje ukuze ufunde ngakumbi malunga nendlela yethuIlaphu lokuhluza oomatshini bokusika i-laserinokuphucula imisebenzi yakho yokusika ilaphu kunye nokuphucula umgangatho weemveliso zakho.

Xa kuziwa ekukhetheni iumatshini wokusika ilaphu laser, qwalasela oku kulandelayo:

Iintlobo zoomatshini:

I-CO2 laser cutters iyacetyiswa ngokubanzi ukusika ilaphu lokucoca kuba i-laser inokusika iimilo ezahlukeneyo kunye nobukhulu. Kuya kufuneka ukhethe ubungakanani obufanelekileyo bomatshini we-laser kunye namandla ngokweentlobo zezinto zakho kunye neempawu. Qhagamshelana nengcali yelaser ukuze ufumane iingcebiso zobuchwephesha belaser.

Uvavanyo Lokuqala:

Ngaphambi kokuba utyale imali kumatshini wokusika i-laser, eyona ndlela ilungileyo kukwenza uvavanyo lwezinto eziphathekayo usebenzisa i-laser. Ungasebenzisa isilaphu selaphu lokucoca kwaye uzame amandla ahlukeneyo e-laser kunye nezantya ukujonga umphumo wokusika.

Naziphi na iiNgcebiso malunga neLaser Cutting Filter Lath, Wamkelekile ekuxoxeni nathi!

Nayiphi na imibuzo malunga noMatshini wokusika iLaser weFafa yelaphu?

Igqityelwe ukuvuselelwa: ngoSeptemba 9, 2025

Ixesha lokuposa: Nov-14-2024