Iingqwalasela eziphezulu zePlywood yokusika iLaser

IsiKhokelo soMzobo weLaser yoMthi

I-Laser cut plywood inikezela ngokuchaneka okungahambelaniyo kunye nokuguquguquka, iyenza ilungele yonke into ukusuka kubugcisa ukuya kwiiprojekthi ezinkulu. Ukufezekisa imiphetho ecocekileyo kwaye uphephe umonakalo, kubalulekile ukuqonda iisetingi ezichanekileyo, ukulungiswa kwezinto kunye neengcebiso zokulungisa. Esi sikhokelo sabelana ngeengqwalasela eziphambili zokukunceda ufumane iziphumo ezilungileyo xa usebenzisa umatshini wokusika umthi we-laser kwiplywood.

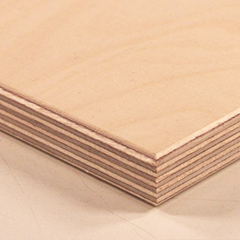

Ukukhetha iPlywood efanelekileyo

Iintlobo zePlywood zokusika iLaser

Ukukhetha i-plywood efanelekileyo kubalulekile ekufezekiseni iziphumo ezicocekileyo nezichanekileyolaser cut plywoodiiprojekthi. Iintlobo ezahlukeneyo zeplywood zibonelela ngeenzuzo ezizodwa, kwaye ukukhetha okulungileyo kuqinisekisa ukusebenza okungcono kunye nokugqiba umgangatho.

I-Laser Sika iPlywood

Birch Plywood

Intle, nkqu neenkozo ezine-voids encinci, igqwesile kwimifanekiso ekroliweyo kunye noyilo oluntsonkothileyo.

IPlywood yePopula

Ikhaphukhaphu, kulula ukuyisika, ilungele iipaneli zokuhombisa kunye noyilo olukhulu.

I-Plywood ejongene neVeneer

Umphezulu we-decorative wood veneer kwiiprojekthi ze-premium, unikezela ngokugqitywa kweenkuni zendalo.

IPlywood ekhethekileyo eNcinci

Amashiti amancinci kakhulu okwenza imodeli, ubugcisa, kunye neeprojekthi ezifuna ukusikwa okubuthathaka.

I-MDF-Core Plywood

Imiphetho yokusika egudileyo kunye noxinaniso olungaguqukiyo, lulungele ukupeyintwa okanye ukugqitywa kwe-laminated.

Yeyiphi iPlywood endinokuthi ndiyikhethe ngokusekwe kwiimfuno zokusika iLaser?

| Ukusetyenziswa kweLaser Cutting | Uhlobo lwePlywood olucetyiswayo | Amanqaku |

|---|---|---|

| Umkrolo oNgcono oluneenkcukacha | Birch | Ukutya okuziinkozo okugudileyo kunye ne-voids encinci kwimiphetho ekrwada |

| Ukusika ngokukhawuleza ngeNgcaciso ePhakathi | Poplar | Ikhaphukhaphu kwaye kulula ukuyisika ukuze usebenze kakuhle |

| Ukusika indawo enkulu | I-MDF-Core | Uxinaniso oluhambelanayo lokusikwa okufanayo |

| Ukugqitywa koMgangatho oPhezulu kuyafuneka | Ubuso-Veneer | Umphezulu wokuhombisa ufuna iisetingi ezichanekileyo |

| Ibhityile, i-Delicate Cuts | Ubukhethekileyo Thin | Incinci kakhulu kwiimodeli ezintsonkothileyo kunye nobugcisa |

IBaltic Birch Plywood

Ukutyeba kwePlywood

Ubunzima beplywood bunokuchaphazela umgangatho we-laser cut cut. Iplywood etyebileyo ifuna amandla aphezulu e-laser ukunqumla, nto leyo enokubangela ukuba iinkuni zitshise okanye zitshise. Kubalulekile ukukhetha amandla e-laser afanelekileyo kunye nesantya sokusika ubukhulu beplywood.

Iingcebiso Zokulungiselela Izinto

Ukusika isantya

Isantya sokusika yindlela ngokukhawuleza i-laser ehamba ngayo kwi-plywood. Izantya eziphakamileyo zokusika zinokunyusa imveliso, kodwa zinokunciphisa umgangatho wokusikwa. Kubalulekile ukulinganisa isantya sokusika kunye nomgangatho ofunekayo wokusika.

Amandla eLaser

Amandla e-laser amisela ukuba i-laser inokunqumla ngokukhawuleza kangakanani kwi-plywood. Amandla e-laser aphezulu anokusika iplywood etyebileyo ngokukhawuleza kunamandla aphantsi, kodwa anokubangela ukuba iinkuni zitshise okanye zitshise. Kubalulekile ukukhetha amandla e-laser afanelekileyo kubunzima beplywood.

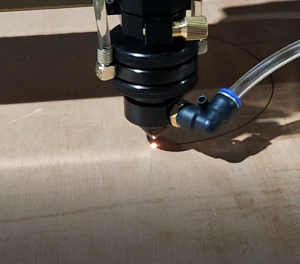

Laser Cutting Die Board Amanyathelo2

Laser Cutting Wood Die Board

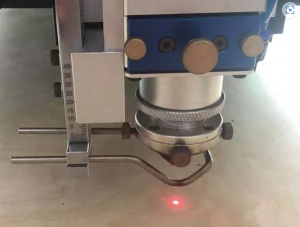

Ilensi yokuJonga

I-lens ekugxilwe kuyo inquma ubukhulu be-laser beam kunye nobunzulu bokusika. Ubungakanani obuncinci bomqadi buvumela ukusikwa okuchanekileyo, ngelixa ubungakanani beam enkulu bunokusika izinto ezityebileyo. Kubalulekile ukukhetha i-lens echanekileyo yokugxila kubukhulu beplywood.

Uncedo lomoya

Uncedo lomoya luvuthela umoya kwi-laser cutting plywood, enceda ukususa inkunkuma kunye nokuthintela ukutshisa okanye ukutshisa. Kubaluleke kakhulu ukusika i-plywood kuba ukhuni lunokuvelisa i-debris eninzi ngexesha lokusika.

Uncedo lomoya

Umkhombandlela wokusika

Isalathiso apho oomatshini bokusika iinkuni ze-laser iplywood inokuchaphazela umgangatho wokusika. Ukugawula iinkozo kunokubangela ukuba iinkuni ziqhekeke okanye zikrazuke, ngelixa ukusika ngeenkozo kunokuvelisa ukusika okucocekileyo. Kubalulekile ukuqwalasela ulwalathiso lwenkozo yokhuni xa uyila ukusika.

ILaser yokusika iinkuni Die Doard 3

Ukujonga ividiyo yeLaser Wood Cutter

Iingqwalasela zoyilo

Xa uyila i-laser cut, kubalulekile ukuqwalasela ubukhulu beplywood, ubuqhetseba boyilo, kunye nohlobo lokudibanisa olusetyenziswayo. Olunye uyilo lunokufuna inkxaso eyongezelelweyo okanye iithebhu ukubamba i-plywood kwindawo ngexesha lokusika, ngelixa abanye banokufuna ingqalelo ekhethekileyo yohlobo lokudibanisa olusetyenzisiweyo.

Imiba eqhelekileyo kunye nokulungisa iingxaki

Ukunciphisa amandla e-laser okanye ukwandisa isantya sokusika; sebenzisa i-masking tape ukukhusela umphezulu.

Ukwandisa amandla e-laser okanye ukunciphisa isantya; qinisekisa ukuba indawo ekugxilwe kuyo isetwe ngokuchanekileyo.

Khetha i-plywood enomxholo ophantsi wokufuma kwaye uyikhusele ngokuqinileyo kwibhedi ye-laser.

Sebenzisa amandla asezantsi ngamapasi amaninzi, okanye uhlengahlengise useto lokusikeka kococeko.

Kwi-laser cut plywood, khetha i-birch, i-basswood, okanye i-maple enomgangatho ogudileyo, iglue-resin ephantsi, kunye ne-voids encinci. Amashiti abhityileyo alungele ukukrolwa, ngelixa amashiti atyebileyo efuna amandla angakumbi.

Ukuququmbela

Ukusika iLaser kwiplywood kunokuvelisa ukusika okuphezulu ngokuchanekileyo kunye nesantya. Nangona kunjalo, kukho izinto ezininzi ezibalulekileyo ekufuneka ziqwalaselwe xa usebenzisa ukusika i-laser kwiplywood, kubandakanya uhlobo lweplywood, ubukhulu bezinto eziphathekayo, isantya sokusika kunye namandla e-laser, i-lens yokugxila, uncedo lomoya, isikhokelo sokusika, kunye nokuqwalaselwa koyilo. Ngokuthathela ingqalelo ezi zinto, unokufezekisa ezona ziphumo zibalaseleyo ngokusika i-laser kwiplywood.

Kucetyiswa umatshini Wood Laser Cutting

| Indawo yokusebenzela (W *L) | 80mm * 80mm (3.15'' * 3.15'') |

| Umthombo weLaser | IFayibha Laser |

| Amandla eLaser | 20W |

| Indawo yokusebenzela (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Umthombo weLaser | CO2 Glass Laser Tube okanye CO2 RF Metal Laser Tube |

| Amandla eLaser | 100W/150W/300W |

| Indawo yokusebenzela (W *L) | 1300mm * 2500mm (51” * 98.4”) |

| Umthombo weLaser | CO2 Glass Laser Tube |

| Amandla eLaser | 150W/300W/450W |

Ngaba uyafuna ukutyala imali kuMatshini weLaser yeWood?

Ixesha lokuposa: Mar-17-2023