Umatshini wokusika amagwebu: Kutheni ukhetha iLaser?

Xa kuziwa kumatshini wokusika amagwebu, umatshini wecricut, umsiki wemela, okanye ijethi yamanzi ziinketho zokuqala ezithi gqi engqondweni. Kodwa i-laser foam cutter, itekhnoloji entsha esetyenziselwa ukusika izixhobo zokugquma, ngokuthe ngcembe iba yeyona nto iphambili kwintengiso ngenxa yokuchaneka okuphezulu kunye nezibonelelo zokusika ngesantya esiphezulu. Ukuba ukhangele umatshini wokusika ibhodi ye-foam, i-foam core, i-eva foam, i-foam mat, eli nqaku liya kuba ngumncedi wakho ukuba uvavanye kwaye ukhethe umatshini ofanelekileyo wokusika amagwebu.

Umatshini weCricut

Indlela Yokuqhuba:Oomatshini beCricut zixhobo zokusika idijithali ezisebenzisa ii-blades ukunqumla i-foam esekelwe kwi-designs eyenziwe ngekhompyutha. Zinezinto ezininzi kwaye ziyakwazi ukuphatha iintlobo ezahlukeneyo zamagwebu kunye nobukhulu.

Izinto eziluncedo:Ukusikwa ngokuchanekileyo koyilo oluyinkimbinkimbi, kulula ukuyisebenzisa kunye neetemplates ezenziwe ngaphambili, ezifanelekileyo kwiiprojekthi zokusika amagwebu amancinci.

Imida:Ilinganiselwe kubunzima obuthile bogwebu, inobunzima kwizinto ezishinyeneyo kakhulu okanye ezishinyeneyo zogwebu.

Umsiki wemela

Indlela Yokuqhuba:Abasiki bemela, abakwabizwa ngokuba yincakuba okanye abasiki bentsimbi, basebenzisa incakuba ebukhali ukusika ugwebu olusekwe kwiipateni ezicwangcisiweyo. Banokusika imigca ethe tye, iigophe, kunye nemilo eneenkcukacha.

Izinto eziluncedo:I-Versatile yokusika iintlobo ezahlukeneyo ze-foam kunye nobukhulu, okulungileyo ekudaleni iimilo ezinzima kunye neepateni.

Imida:Kulinganiselwe ukusika kwe-2D, kunokufuna ukupasa okuninzi kwigwebu elishinyeneyo, ukunxitywa kweblade kunokuchaphazela umgangatho wokusika ngokuhamba kwexesha.

Ijethi yamanzi

Indlela Yokuqhuba:Ukusika ijethi yamanzi kusebenzisa umsinga woxinzelelo oluphezulu wamanzi oxutywe namasuntswana abrasive ukusika ugwebu. Yindlela eguquguqukayo enokuthi inqumle izixhobo zogwebu ezishinyeneyo kwaye ivelise imiphetho ecocekileyo.

Izinto eziluncedo:Iyakwazi ukunqumla amagwebu ashinyeneyo naxineneyo, ivelise ukusikwa okucocekileyo nokuchanekileyo, okuguquguqukayo kwiintlobo ezahlukeneyo zamagwebu kunye nobukhulu.

Imida:Ifuna umatshini wokusika ijethi yamanzi kunye nezinto ezixubekileyo, iindleko eziphezulu zokusebenza xa kuthelekiswa nezinye iindlela, zingenakuchaneka njengokusika kwe-laser kuyilo oluntsonkothileyo.

Umsiki weLaser

Indlela Yokuqhuba:Oomatshini bokusika i-Laser basebenzisa i-laser beam egxininisekileyo ukunqumla i-foam ngokufaka umphunga izinto kunye nendlela echazwe kwangaphambili. Banikezela ngokuchaneka okuphezulu kwaye banokudala uyilo oluntsonkothileyo.

Izinto eziluncedo:Ukusika okuchanekileyo kunye neenkcukacha, ezifanelekileyo kwiimilo eziyinkimbinkimbi kunye neenkcukacha ezintle, inkunkuma encinci yezinto eziphathekayo, eziguquguqukayo kwiintlobo ezahlukeneyo ze-foam kunye nobukhulu.

Imida:Ukusetwa kokuqala kunye nokulinganisa okufunekayo, iindleko zokuqala eziphezulu xa kuthelekiswa nezinye iindlela, izilumkiso zokhuseleko ezifunekayo ngenxa yokusetyenziswa kwelaser.

Ukuthelekisa: yeyiphi engcono ukusika igwebu?

Thetha ngeUkuchaneka:

Imishini yokusika i-Laser inikezela ngokuchaneka okuphezulu kunye neenkcukacha zoyilo oluntsonkothileyo, kulandelwa ukusika kwejethi yamanzi, ngelixa oomatshini beCricut kunye nabasiki bengcingo abashushu bafanelekile ukusika okulula.

Thetha ngeUkuguquguquka:

Oomatshini bokusika i-Laser, ukusika ijethi yamanzi, kunye nabasiki bengcingo abashushu baguquguquka ngakumbi ekuphatheni iintlobo ezahlukeneyo zamagwebu kunye nobukhulu xa kuthelekiswa noomatshini beCricut.

Thetha ngeUkuntsokotha:

Imishini yeCricut ilula ukuyisebenzisa kunye neetemplates ezenziwe ngaphambili, ngelixa i-wire cutters eshushu ifanelekile ukubunjwa okusisiseko, ukusika i-laser, kunye nokusika ijethi yamanzi kwimilo enzima kunye nokuyila.

Thetha ngeIxabiso:

Oomatshini beCricut ngokuqhelekileyo bafikeleleka ngakumbi, ngelixa oomatshini bokusika i-laser kunye nokusika ijethi yamanzi bafuna utyalo-mali oluphezulu kunye nokugcinwa rhoqo.

Thetha ngeUkhuseleko:

Imishini yokusika i-Laser, ukusika i-jet yamanzi, kunye ne-hot cutters ifuna ukhuseleko ngenxa yokushisa, amanzi aphezulu, okanye ukusetyenziswa kwe-laser, ngelixa ii-Cricut machines zikhuselekile ngokubanzi ukuba zisebenze.

Isishwankathelo, ukuba unesicwangciso sexesha elide sokuvelisa amagwebu, kwaye ungathanda iimveliso zesiko kunye neempawu, ukufumana ixabiso elongezelelweyo ukusuka apho, i-laser foam cutter iya kuba lukhetho lwakho olufanelekileyo. Umsiki we-laser we-foam ubonelela ngemveliso echanekileyo ephezulu ngelixa uphucula ukusebenza kakuhle kokusika. Kukho inzuzo ephezulu kwaye engaguqukiyo kwi-foam yokusika i-laser nokuba ufuna ukutyala imali kumatshini kwinqanaba lokuqala. Ukuqhubekeka okuzenzekelayo kunenzuzo yokwandisa isikali semveliso. Kwelinye, ukuba uneemfuno zesiko kunye nokuguquguquka kokulungiswa, umsiki we-laser we-foam ufanelekile kuyo.

▽

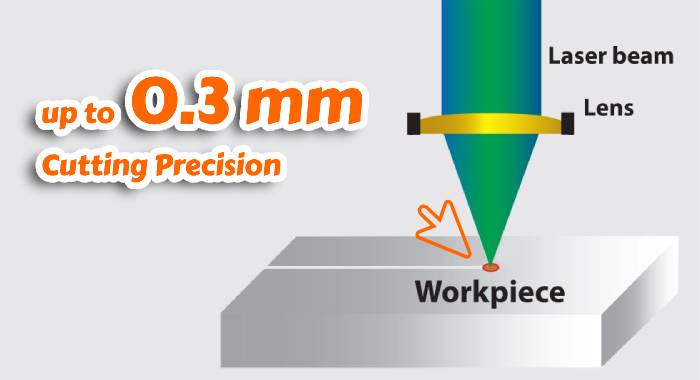

✦ High Cutting Precision

Ngombulelo kwinkqubo yokulawula idijithali kunye ne-laser beam emihle, i-foam laser cutters inikeza ukuchaneka okuphezulu kunye nokuchaneka ekusikeni izixhobo ze-foam. Umqa we-laser ogxininisiweyo unokudala uyilo oluntsonkothileyo, imiphetho ebukhali, kunye neenkcukacha ezintle ngokuchaneka okukhethekileyo. Inkqubo ye-CNC iqinisekisa ukuthembeka kokucubungula ngaphandle kwempazamo ngesandla.

✦ IiMathiriyeli eziBanzi eziNgcono

Abasiki be-laser be-foam banezinto ezininzi kwaye banokuphatha uluhlu olubanzi lweentlobo zamagwebu, ukuxinana, kunye nobukhulu. Bangakwazi ukunqumla amaphepha amagwebu, iibhloko, kunye nezakhiwo ze-3D ze-foam ngokulula. Ngaphandle kwezixhobo zogwebu, i-laser cutter inokuphatha ezinye izinto ezinje ngeziva, ufele kunye nelaphu. Oko kuya kubonelela ngokulula kakhulu ukuba ufuna ukwandisa ishishini lakho.

Iintlobo zegwebu

Uyakwazi ukusika i-laser

• I-Polyurethane Foam (PU):Olu lukhetho oluqhelekileyo lokusika i-laser ngenxa yokuguquguquka kwayo kunye nokusetyenziswa kwizicelo ezinje ngokupakishwa, i-cushioning, kunye ne-upholstery.

• I-Polystyrene Foam (PS):I-polystyrene eyandisiweyo kunye ne-extruded foams ifanelekile ukusika i-laser. Zisetyenziselwa ukugquma, ukwenza imodeli, kunye nokwenza ubugcisa.

• Polyethylene Foam (PE):Eli gwebu lisetyenziselwa ukupakisha, ukuthambisa, kunye nezixhobo zokuncedisa.

• Igwebu lePolypropylene (PP):Ihlala isetyenziswa kushishino lweemoto kwingxolo kunye nolawulo lokungcangcazela.

• I-Ethylene-Vinyl Acetate (EVA) Ugwebu:Igwebu le-EVA lisetyenziswa kakhulu ukwenza ubugcisa, ukupakisha, kunye nezihlangu, kwaye iyahambelana nokusika kwelaser kunye nokukrolwa.

• Ugwebu lwePolyvinyl Chloride (PVC):Igwebu lePVC lisetyenziselwa imiqondiso, imiboniso, kunye nokwenza imodeli kwaye inokusikwa ngelaser.

Ukutyeba kwegwebu

Uyakwazi ukusika i-laser

* Ngomqadi welaser onamandla kunye nocolekileyo, umsiki welaser ogwebu unokusika amagwebu angqindilili ukuya kuthi ga kwi-30mm.

✦ Imiphetho ecocekileyo netywiniweyo

Umphetho ococekileyo kunye ogudileyo wokusika yeyona nto ibalulekileyo abavelisi bahlala beyikhathalele. Ngenxa yamandla obushushu, ugwebu lunokutywinwa kwangexesha emphethweni, oluqinisekisa ukuba umphetho ulungile ngelixa ugcina i-scrip ukubhabha ekubhabheni kuyo yonke indawo. Igwebu lokusika iLaser livelisa imiphetho ecocekileyo netywiniweyo ngaphandle kokuqhekeka okanye ukunyibilika, okukhokelela ekusikeni okujongeka njengengcali. Oku kuphelisa imfuno yeenkqubo zokugqiba ezongezelelweyo kwaye iqinisekisa imveliso yokugqibela esemgangathweni. Oku kubalulekile kwezinye izicelo ezinemigangatho ephezulu ekusikeni ngokuchanekileyo, njengezixhobo zonyango, iinxalenye zefektri, iigaskets, kunye nezixhobo zokukhusela.

✦ Ukusebenza okuphezulu

I-Laser yokusika i-foam yinkqubo ekhawulezayo nesebenzayo. I-laser beam inqumla kwizinto ze-foam ngokukhawuleza kwaye ngokuchanekileyo, ivumela ukuveliswa ngokukhawuleza kunye namaxesha okuguqula. IMimoWork iyile iinketho ezahlukeneyo zoomatshini belaser kwaye inolungelelwaniso olwahlukileyo onokuthi uluphucule, njengeentloko ezimbini zelaser, iintloko ezine zelaser, kunye ne-servo motor. Unokukhetha ulungelelwaniso olufanelekileyo lwelaser kunye neenketho zokwandisa ngakumbi ukusebenza kwakho kwemveliso. Nawuphi na umbuzo onokuthi uqhagamshelane nengcali yethu ye-laser ngexesha lakho lasimahla. Ngaphandle koko, ukusika i-laser ye-foam kulula ukuyisebenzisa, ngakumbi kumntu oqalayo, kufuna iindleko ezincinci zokufunda. Siza kunika izisombululo ezifanelekileyo zomatshini we-laser kunye nokufakela okuhambelanayo kunye nenkxaso yesikhokelo.>> Thetha nathi

✦ Inkunkuma yezinto eziphathekayo

Ngoncedo oluphambiliisoftware yokusika i-laser (MIMOCut), yonke inkqubo ye-foam yokusika i-laser iya kufumana ilungiselelo lokusika ngokufanelekileyo. Abasiki be-laser be-foam banciphisa inkunkuma yezinto eziphathekayo ngokulungisa indlela yokusika kunye nokunciphisa ukususwa kwezinto ezingaphezulu. Oku kusebenza kakuhle kunceda ukugcina iindleko kunye nezibonelelo, ukwenza i-laser cutting foam ibe yindlela ezinzileyo. Ukuba unemfuno yokuzalela, ikhonaisoftware yokuzenzela indlwaneungakhetha, ukunceda ukwenza lula inkqubo yokuzalela, uphucula ukusebenza kakuhle kwakho.

✦ Iimilo ezintsonkothileyo kunye noYilo

Abasiki be-laser be-foam banokwenza iimilo ezintsonkothileyo, iipateni ezintsonkothileyo, kunye noyilo oluneenkcukacha oluya kuba nzima okanye olungenzekiyo ukufezekiswa ngeendlela zokusika zesintu. Esi sikhundla sivula amathuba amatsha kwiiprojekthi zoyilo kunye nezicelo.

✦ Ukusika okungaQhagamshelwanga

I-Laser yokusika i-foam yinkqubo engeyiyo yoqhagamshelwano, oku kuthetha ukuba umqadi we-laser awuchukumisi ngokwasemzimbeni umphezulu we-foam. Oku kunciphisa umngcipheko wokuguqulwa kwezinto kunye nokuqinisekisa umgangatho wokusika ohambelanayo.

✦ Ukwenza ngokwezifiso kunye noKwakho

Abasiki be-laser be-foam bavumela ukwenza ngokwezifiso kunye nokwenziwa komntu kwiimveliso zogwebu. Bangakwazi ukusika iimilo zesiko, iilogo, isicatshulwa, kunye nemizobo, zizenze zilungele ukuphawulwa, imiqondiso, ukupakishwa, kunye nezinto zokuthengisa.

Umsiki weLaser we-Foam odumileyo

Xa uthathe isigqibo sokutyala imali kumatshini wokusika i-laser kwimveliso yakho ye-foam, kuya kufuneka uqwalasele iintlobo zemathiriyeli ye-foam, ubungakanani, ubukhulu kunye nokunye ukufumana i-laser cutter ye-foam enolungelelwaniso olufanelekileyo. I-laser cutter ene-flatbed ye-foam ine-1300mm * 900mm indawo yokusebenza, yi-entry-level laser cutter. Kwiimveliso ze-foam eziqhelekileyo ezifana neebhokisi zezixhobo, imihombiso, kunye nobugcisa, i-Flatbed Laser Cutter 130 lolona khetho ludumileyo lokusika amagwebu kunye nokukrola. Ubungakanani kunye namandla ayanelisa uninzi lweemfuno, kwaye ixabiso liyafikeleleka. Dlula kuyilo, inkqubo yekhamera ephuculweyo, itafile yokusebenza ngokuzikhethela, kunye nohlengahlengiso olongezelelweyo lomatshini onokuthi ukhethe.

Ukucaciswa komatshini

| Indawo yokusebenzela (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isoftware | Isoftware engasebenziyo |

| Amandla eLaser | 100W/150W/300W |

| Umthombo weLaser | CO2 Glass Laser Tube okanye CO2 RF Metal Laser Tube |

| Inkqubo yoLawulo loomatshini | Inyathelo Motor Belt Control |

| Itheyibhile yokuSebenza | Itheyibhile eSebenzayo yoBusi okanye iThayibhile yokuSebenza yeKnife Strip |

| Isantya esiphezulu | 1-400mm/s |

| Isantya sokukhawulezisa | 1000~4000mm/s2 |

Iinketho: Phucula iMveliso yeFoam

Ugxininiso oluzenzekelayo

Ungadinga ukuseta umgama othile wogxininiso kwisoftware xa izinto zokusika zingekho tyaba okanye ezinobunzima obahlukeneyo. Emva koko intloko ye-laser iya kunyuka kwaye ihle ngokuzenzekelayo, igcina umgama wokugqalisela ofanelekileyo ukuya kumphezulu wezinto.

I-Servo Motor

I-servomotor yi-servomechanism evaliweyo esebenzisa ingxelo yendawo ukulawula ukuhamba kwayo kunye nendawo yokugqibela.

Ibhola Screw

Ngokuchaseneyo nezikrufu eziqhelekileyo zokukhokela, izikrufu zebhola zithande ukuba nkulu, ngenxa yesidingo sokuba nesixhobo sokujikeleza kwakhona iibhola. I-screw yebhola iqinisekisa isantya esiphezulu kunye nokuchaneka okuphezulu kwe-laser cut.

Usetyenziso olubanzi

Funda ngakumbi malunga neFoam Laser Cutter

Ukuba uneepatters ezinkulu zokusika okanye i-foam roll, umatshini wokusika we-foam laser 160 ulungele wena. I-Flatbed Laser Cutter 160 ngumatshini wefomati enkulu. Nge-auto feeder kunye netheyibhile yokuhambisa, unokufezekisa izixhobo zokucwangcisa ngokuzenzekelayo. I-1600mm *1000mm yendawo yokusebenza ifanelekile kuninzi lwe-yoga mat, i-marine mat, i-cushion yokuhlala, i-gasket ye-industrial kunye nokunye. Iintloko ze-laser ezininzi zikhethwa ukunyusa imveliso. Uyilo oluvaliweyo oluvela kumatshini wokusika i-laser luqinisekisa ukhuseleko lokusetyenziswa kwe-laser. Iqhosha lokumisa likaxakeka, ukukhanya komqondiso kaxakeka, kunye nawo onke amacandelo ombane afakwe ngokungqongqo ngokwemigangatho yeCE.

Ukucaciswa komatshini

| Indawo yokusebenzela (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Isoftware | Isoftware engasebenziyo |

| Amandla eLaser | 100W/150W/300W |

| Umthombo weLaser | CO2 Glass Laser Tube okanye CO2 RF Metal Laser Tube |

| Inkqubo yoLawulo loomatshini | Ukuhanjiswa kwebhanti kunye neNyathelo yeMotor Drive |

| Itheyibhile yokuSebenza | ITheyibhile eSebenzayo yoBusi / Itafile eSebenzayo yeKnife Strip. |

| Isantya esiphezulu | 1-400mm/s |

| Isantya sokukhawulezisa | 1000~4000mm/s2 |

Iinketho: Phucula iMveliso yeFoam

Iintloko zeLaser ezimbini

Ngeyona ndlela ilula kunye neyoqoqosho yokukhawulezisa ukusebenza kwakho kwemveliso kukunyusa iintloko ezininzi ze-laser kwi-gantry efanayo kwaye usike ipateni efanayo ngaxeshanye. Oku akuthathi sithuba esongezelelweyo okanye umsebenzi.

Xa uzama ukusika uninzi loyilo olwahlukeneyo kwaye ufuna ukugcina imathiriyeli ukuya kwelona qondo likhulu, iNesting Softwareiya kuba lukhetho oluhle kuwe.

IAuto Feederidityaniswe neTheyibhile yeConveyor sisisombululo esifanelekileyo sochungechunge kunye nemveliso yobuninzi. Ihambisa izinto eziguquguqukayo (indwangu eninzi yexesha) ukusuka kumqulu ukuya kwinkqubo yokusika kwi-laser system.

Usetyenziso olubanzi

Qala iMveliso yakho yogwebu ngeFlatbed Laser Cutter 160!

• Ngaba unokusika igwebu ngesixhobo sokusika i-laser?

Ewe, igwebu linokusikwa ngelaser cutter. I-Laser yokusika igwebu yinkqubo eqhelekileyo kunye nesebenzayo ebonelela ngeenzuzo ezininzi, kubandakanya ukuchaneka, ukuguquguquka, kunye nokusebenza kakuhle. Umqadi we-laser ogxininisiweyo uyatshintsha okanye unyibilike izinto zogwebu ngendlela emiselweyo, okukhokelela ekusikekeni okucocekileyo kunye nokuchanekileyo ngemiphetho etywiniweyo.

• Ngaba ungayisika i-eva igwebu ngelaser?

Ewe, i-EVA (i-ethylene-vinyl acetate) i-foam inokunqunyulwa nge-laser ngokufanelekileyo. Igwebu le-EVA sisixhobo esisebenza ngeendlela ezininzi esisetyenziswa rhoqo kumashishini ahlukeneyo afana nezihlangu, ukupakishwa, ubugcisa, kunye ne-cosplay. I-Laser yokusika igwebu le-EVA ibonelela ngeengenelo ezininzi, kubandakanya ukusikwa okuchanekileyo, imiphetho ecocekileyo, kunye nokukwazi ukwenza uyilo oluntsonkothileyo kunye neemilo. Umqadi welaser ogxininisiweyo unyusa umphunga wemathiriyeli yogwebu ecaleni kwendlela emiselweyo, okukhokelela ekusikeni okuchanekileyo kunye neenkcukacha ngaphandle kokuqhekeka okanye ukunyibilika.

• Indlela yokusika igwebu ngelaser?

1. Lungiselela iLaser Cutting Machine:

Qinisekisa ukuba umatshini wokusika we-laser umiselwe ngokufanelekileyo kwaye ulungelelaniswe ukusika i-foam. Jonga ugxininiso lwe-laser beam kwaye uyilungelelanise ukuba kuyimfuneko ekusebenzeni ngokufanelekileyo kokusika.

2. Khetha iiSetingi eziLungileyo:

Khetha amandla afanelekileyo e-laser, isantya sokusika, kunye noseto lokuphindaphinda ngokusekwe kuhlobo kunye nobukhulu bezinto zogwebu ozisikayo. Jonga kwimanyuwali yomatshini okanye udibane nomvelisi ngesetingi ezicetyiswayo.

3. Lungiselela imathiriyeli yegwebu:

Beka izinto ze-foam kwibhedi yokusika i-laser kwaye uyikhusele kwindawo usebenzisa i-clamps okanye itafile ye-vacuum ukukhusela ukunyakaza ngexesha lokusika.

4. Qala inkqubo yokusika iLaser:

Layisha ifayile yokusika kwi-software yomshini wokusika i-laser kwaye ubeke i-laser beam kwindawo yokuqala kwindlela yokusika.

Qalisa inkqubo yokusika, kwaye i-laser beam iya kulandela indlela echazwe kwangaphambili, ukusika kwizinto eziphathekayo ze-foam endleleni.

Fumana iiNzuzo kunye neeNzuzo kwi-Foam Laser Cutter, Thetha nathi ukuze ufunde ngakumbi

Nayiphi na imibuzo malunga neLaser Cutting Foam?

Ixesha lokuposa: May-09-2024