I-Laser Welder ephathwa ngesandla

Faka i-Laser Welding Emkhiqizweni Wakho

Ungawakhetha kanjani amandla e-laser afanelekile ensimbi yakho eshiselwe?

Ukuqina kweWeld yohlangothi olulodwa lwamandla ahlukene

| 500W | 1000W | 1500W | 2000W | |

| I-Aluminium | ✘ | 1.2mm | 1.5mm | 2.5mm |

| Insimbi engagqwali | 0.5mm | 1.5mm | 2.0mm | 3.0mm |

| Insimbi Yekhabhoni | 0.5mm | 1.5mm | 2.0mm | 3.0mm |

| Ishidi Elinothayela | 0.8mm | 1.2mm | 1.5mm | 2.5mm |

Kungani i-Laser Welding?

1. Ukusebenza Okuphezulu

▶ 2 - 10 izikhathiukusebenza kahle kokushisela uma kuqhathaniswa nokushisela kwe-arc yendabuko ◀

2. Ikhwalithi Enhle Kakhulu

▶ I-laser welding eqhubekayo ingadalaaqinile & flat welding amalungangaphandle kwe-porosity ◀

3. Izindleko Zokugijima Eziphansi

▶Ukonga izindleko zokusebenza ezingu-80%.kugesi uma kuqhathaniswa ne-arc welding ◀

4. Inkonzo ende yokuphila

▶ Umthombo we-fiber laser ezinzile unobude bempilo ende yesilinganiso seAmahora okusebenza angu-100,000, ukunakekelwa okuncane kuyadingeka ◀

Ukusebenza Okuphezulu & I-Fine Welding Seam

Ukucaciswa - 1500W Handheld Laser Welder

| Imodi yokusebenza | Qhubeka noma ulungise |

| Laser wavelength | 1064NM |

| Ikhwalithi ye-Beam | M2<1.2 |

| Amandla Ajwayelekile | ≤7KW |

| Isistimu yokupholisa | I-Industrial Water Chiller |

| Ubude befayibha | 5M-10MCustomizable |

| Welding ukujiya | Kuncike ezintweni ezibonakalayo |

| Izidingo ze-weld seam | <0.2mm |

| Isivinini sokushisela | 0~120 mm/s |

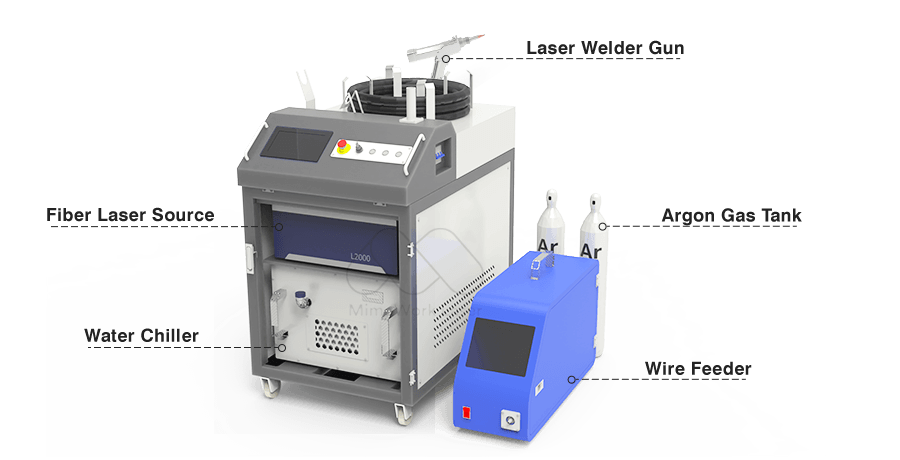

Imininingwane Yesakhiwo - I-Laser Welder

◼ Isakhiwo esikhanyayo nesihlangene, esithatha indawo encane

◼ I-Pulley ifakiwe, kulula ukuhambahamba

◼ 5M/10M intambo yefayibha ende, shisela kalula

▷ Izinyathelo Ezi-3 Eziqediwe

Ukusebenza Okulula - I-Laser Welder

Isinyathelo 1:Vula idivayisi yokuqalisa

Isinyathelo sesi-2:Setha amapharamitha we-laser welding (imodi, amandla, isivinini)

Isinyathelo sesi-3:Thatha isibhamu se-laser welder bese uqala ukushisela nge-laser

Ukuqhathanisa: laser welding VS arc welding

| I-Laser Welding | I-Arc Welding | |

| Ukusetshenziswa kwamandla | Phansi | Phezulu |

| Indawo Ethintekile Ukushisa | Ubuncane | Okukhulu |

| I-Material Deformation | Ngokulula noma akukho deformation | Khubaza kalula |

| Indawo yokushisela | Indawo ye-welding enhle futhi iyalungiseka | Indawo Enkulu |

| Umphumela Welding | Hlanza i-welding edge ngaphandle kokucubungula okwengeziwe okudingekayo | Kudingeka umsebenzi owengeziwe wokupholisha |

| Isikhathi Sokucubungula | Isikhathi esifushane se-welding | Kuthatha isikhathi |

| Ukuphepha Komqhubi | Isibani esikhanyayo esingenabungozi | Ukukhanya okunamandla kwe-ultraviolet ngemisebe |

| Umthelela Wezemvelo | Ihambisana nemvelo | I-ozone ne-nitrogen oxides (ayingozi) |

| Kudingeka Igesi Yokuzivikela | I-Argon | I-Argon |

Kungani ukhethe i-MimoWork

✔Iminyaka engu-20+ yesipiliyoni se-laser

✔Isitifiketi se-CE & FDA

✔100+ ubuchwepheshe be-laser namalungelo obunikazi esoftware

✔Umqondo wesevisi ogxile kumakhasimende

✔Ukuthuthukiswa kwe-laser nocwaningo olusha

Okokufundisa kwevidiyo

Ngokushesha Master Handheld Laser Welding !

Iyini i-Handheld Laser Welder?

Ungayisebenzisa kanjani i-Handheld Laser Welder?

I-Laser Welding Vs TIG Welding: Iyiphi Engcono?

Izinto Ezi-5 Mayelana Ne-Laser Welding (Okuphuthele)

FAQ

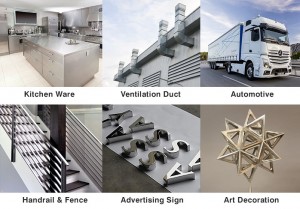

Isebenza kahle nge-aluminium, insimbi engagqwali, i-carbon steel, namashidi angama-galvanized. Ugqinsi olushiselayo luyahlukahluka ngokwempahla namandla we-laser (isb., u-2000W uphatha insimbi engagqwali engu-3mm). Ifanele izinsimbi ezivame kakhulu ekukhiqizeni izimboni.

Ngokushesha kakhulu. Ngezinyathelo ezi-3 ezilula (ukuvula amandla, setha imingcele, qala ukushisela), ngisho nabasebenzisi abasha bangakwazi ukukwenza kahle ngamahora. Akukho ukuqeqeshwa okuyinkimbinkimbi okudingekayo, konga isikhathi kumajika okufunda omqhubi.

Ukunakekelwa okuncane kuyadingeka. Umthombo we-fiber laser unesikhathi sokuphila samahora angu-100,000, futhi isakhiwo esihlangene esinezingxenye ezihlala njalo sinciphisa izidingo zokunakekela, sehlise izindleko zesikhathi eside.