Ukususwa kwe-Laser oxide

Ama-oksidi ayinhlanganisela evamile evela ezinqubweni ze-oxidation ezithinta izinto ezihlukahlukene.

Ukuqonda ukuthi kwenzeka kanjani i-oxidation kusiza ekulawuleni imiphumela yayo.

Ikakhulukazi ezimbonini lapho ubuqotho bezinto ezibonakalayo bubalulekile.

Ukuhlanza i-laser kuvela njengesixazululo esisebenza kahle kakhulu sokususa lezi zendlalelo ze-oxide ezingafuneki.

Ukuqinisekisa ukuthi izinto ezisetshenziswayo zibuyiselwa esimweni sazo sangempela ngaphandle kokulimala.

Iyini i-Oxide & Oxidation?

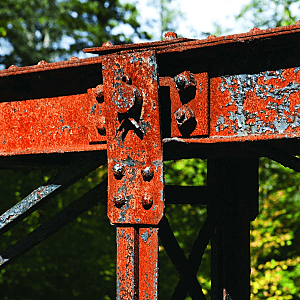

I-Oxidation Itholakala Kumathrekhi Wesitimela

Ama-oxides ayinhlanganisela yamakhemikhali ahlanganisa umoya-mpilo nenye into.

Angakwazi ukwakha ezintweni ezihlukahlukene, okuhlanganisa izinsimbi, izitsha zobumba, ngisho nezingezona izinsimbi.

Izibonelo Ezivamile zihlanganisa:

Ukugqwala:

I-iron oxide (Fe₂O₃), eyakheka ku-iron nensimbi lapho isabela kumswakama nomoya-mpilo.

I-Aluminium oxide:

Isendlalelo esivikelayo esakha ku-aluminium, esivimbela ukugqwala okuqhubekayo.

I-Copper oxide:

I-patina eluhlaza (Cu₂(OH)₂CO₃) ekhula endaweni yethusi ngokuhamba kwesikhathi.

Izinsimbi:

Izinsimbi ezifana ne-iron, ithusi, ne-aluminium zikhishwa kalula emoyeni lapho zichayeka emoyeni.

Lokhu kungenza buthaka ubuqotho besakhiwo sensimbi.

I-Ceramics:

I-oxidation ingase futhi ithinte izitsha zobumba, ikakhulukazi lezo ezenziwe ngama-oxide ensimbi.

Ukushintsha izakhiwo nokubukeka kwabo.

I-Non-Metals:

Ezinye izinto ezingezona izinsimbi, njengekhabhoni, zingase zikhiphe i-carbon dioxide (CO₂) uma zishisiwe.

Kungani I-Oxidation Kufanele Ihlanzwe?

I-Oxidation Etholakala Ezakhiweni Zebhuloho Ingahlanzwa I-Laser

I-oxidation ingathinta kakhulu izinto ezahlukahlukene kuzilungiselelo zezimboni.

Okuholela ezinhlobonhlobo zezinkinga ezingaba nomthelela ekusebenzeni kahle, ukuphepha, kanye nezindleko.

Nazi izizathu ezimbalwa zokuthi kungani kubalulekile ukubhekana ne-oxidation:

Ubuqotho Besakhiwo Sezinsimbi:Ubuhle kanye Nekhwalithi Yokusebenza

I-oxidation, ikakhulukazi ezinsimbi njengensimbi nensimbi, iholela ekugqwaleni.

Okungenza buthaka izingxenye zesakhiwo.

Amabhuloho:

Ukugqwala kungonakalisa ukuphepha kwamabhuloho, kudinge ukulungiswa okubizayo noma ukushintshwa.

Imishini:

Izingxenye ezigqwalile emishinini zingehluleka, okuholela esimeni esibizayo kanye nezingozi ezingaba khona zokuphepha.

Uwoyela Negesi:

I-oxidation emapayipini ingaholela ekuvuzeni noma ekuqhumeni, okuholela ezingozini zemvelo kanye nokulahlekelwa kwezimali.

KwandiswaIzindleko Zokulungisa &YehlisiweUkusebenza

Uma i-oxidation ingabhekwana nayo, ingaholela ekwenyukeni kwezindleko zokulungisa nokulungisa.

Nakuba futhi ivimbela ukusebenza kwezinhlelo ezihlukahlukene

Ukulungisa Kaningi:

Ukulungisa njalo noma ukufaka esikhundleni sezingxenye ezine-oxidized kungakhinyabeza isabelomali.

Izishintshi Zokushisa:

I-oxidation ingehlisa ukusebenza kahle kwezishintshi zokushisa, okuholela ezindlekweni eziphezulu zamandla.

Izisetshenziswa Zokukhiqiza:

Indawo ene-oxidized ingaphazamisa izinqubo zokukhiqiza, ibangele amaphutha kanye nemfucuza.

I-Oxidation Ingaholela Ezinkingeni Ezinkulu

Xazulula futhi Uvikele Ikusasa Ngomshini Wokususa I-Laser Oxide

Isicelo: Ukususwa kwe-Laser oxide

Isidingo Sokususwa Kwe-Oxide Cishe Yonke Indawo

Ukususwa kwe-laser oxide kuyindlela ethuthukisiwe esetshenziselwa ukuqeda ngempumelelo i-oxidation ezintweni ezahlukahlukene, ikakhulukazi izinsimbi.

Le ndlela ithola ukuduma ezinhlelweni eziningi zezimboni ngenxa yokunemba kwayo, ukusebenza kahle kwayo, kanye ne-eco-friendly.

Nakhu ukuhlolisisa izinhlelo ezithile zokususwa kwe-laser oxide.

I-Aluminium ngokwemvelo yakha isendlalelo se-oxide esivikelayo lapho sichayeke emoyeni.

Kodwa-ke le oxide ngezinye izikhathi ingaphazamisa ukuqhubeka nokusebenza noma ukubopha.

Ezimbonini ezifana ne-aerospace nezimoto.

Ukususa lesi sendlalelo se-oxide kubalulekile ekuzuzeni ukushisela okuqinile nokuqinisekisa ukunamathela okunamathelayo okufanele.

Ukuhlanza i-laser kuvumela ukususwa okuhlosiwe kwe-oxide ngaphandle kokulimaza i-aluminium engaphansi.

Ukuqinisekisa ukuthi izindawo ezingaphezulu zihlanzekile futhi zilungele ukwelashwa okwengeziwe.

Ukususwa kwe-Stainless Steel oxide

Insimbi engagqwali ivame ukusetshenziswa ezindaweni ezithandwa yi-oxidation, okuholela ekwakhekeni kokugqwala noma isikali.

Ezimbonini zokucubungula ukudla, ezemithi, nezimboni zamakhemikhali.

Ukugcina izindawo zensimbi engagqwali zihlanzekile kubalulekile ukuze kube nenhlanzeko nokuphepha.

Ukususwa kwe-laser oxide kuhlanza kahle izindawo zensimbi engagqwali, kubuyisele ukubukeka kwazo futhi kuvimbele ukugqwala.

Okubuye kuthuthukise isikhathi eside semishini.

Ekushiseleni, ukuba khona kwama-oxide ezindaweni zensimbi kungaholela eqophelweni eliphansi lokuhlangana kanye nokushisela okubuthakathaka.

Ngaphambi kokushisela, kubalulekile ukususa noma iyiphi i-oxidation noma ukungcola endaweni yensimbi ukuze uqinisekise isibopho esiqinile.

Ukuhlanza i-laser kunikeza indlela esheshayo nenembayo yokulungisa izindawo.

Okuholela ekushiseleni okuqinile, okuthembeke kakhulu kanye nokunciphisa amathuba okuba namaphutha.

Ukulungiswa Kwendawo Yokumboza Nokubopha

Ukulungiswa kwendawo efanele kubalulekile ngaphambi kokufaka izinto zokumboza noma amapende ukuze kuqinisekiswe ukunamathela nokuqina.

Ezimbonini zezimoto nezokukhiqiza.

Indawo engaphezulu kufanele ingabi nama-oxides kanye nokungcola ukuze kuzuzwe ukusebenza kahle kokunamathela.

Ukususwa kwe-laser oxide kuhlanza ngokuphelele izindawo.

Ukukhuthaza ukunamathela okungcono kwama-coatings kanye nokuthuthukisa ukuphela okuphelele nokuhlala isikhathi eside komkhiqizo.

Ukususwa kwe-laser oxide kuyahlukahluka futhi kungasetshenziswa kwezinye izilungiselelo ezahlukahlukene:

Izingxenye Zezimoto Zokuhlanza I-Laser:Izingxenye zokuhlanza njengezingxenye zenjini ngaphambi kokuhlanganisa ukuvimbela ukugqwala.

I-elekthronikhi: Ukulungiselela izindawo zensimbi zokunamathisela noma zokunamathisela ukuze kuthuthukiswe ukuhamba nokuthembeka.

Izisetshenziswa zezimboni zokuhlanza i-laser:Ukugcinwa njalo kwemishini ukususa i-oxidation nokwandisa impilo yesevisi.

Umshini Wokususa I-Laser oxide

Ukususwa kwe-laser oxide kuyindlela ephumelela kakhulu yokubhekana ne-oxidation ezintweni ezifana ne-aluminium nensimbi engagqwali kuzo zonke izinhlelo zokusebenza, okuhlanganisa ukushisela, ukulungiswa kwendawo, kanye nokubopha.

Ukunemba kwayo, ukusebenza kahle, kanye nemvelo eco-friendly ikwenza kube ukukhetha okuhle ezimbonini ezifuna ukugcina amazinga aphezulu ekhwalithi nokusebenza.

Amandla e-Laser:100W - 500W

I-Pulse Frequency Range:20 - 2000 kHz

I-Pulse Length Modulation:10 - 350 ns

I-oxidation ingaholela ezinkingeni ezinkulu ezinhlelweni ezahlukahlukene zezimboni, ezithinta ukuphepha, izindleko, nokusebenza kahle.

Ngokubhekana ne-oxidation ngokuqhubekayo, ikakhulukazi ngezixazululo ezithuthukisiwe ezifana nokuhlanza i-laser, amabhizinisi angavikela impahla yawo, athuthukise ukusebenza, futhi alondoloze umkhawulo wokuncintisana.

Amandla e-Laser:1000W - 3000W

I-Laser Wavelength:1070nm

Ukupholisa:Ukupholisa Amanzi