I-Laser Weld Cleaning

I-Laser Weld Cleaning iyisu elisetshenziselwa ukususa ukungcola, ama-oksidi, nezinye izinto ezingafuneki endaweni yokushisela.Ngaphambi emvakwaInqubo Yokushisela Iphelele. Lokhu Kuhlanzwa kuyisinyathelo Esibalulekile Ezinhlelweni Eziningi Zezimboni Nezokukhiqiza ukuzeQinisekisa Ubuqotho Nokubukekaye-Welded Joint.

I-Laser Cleaning ye-Metal

Ngesikhathi senqubo yokushisela, ukungcola okuhlukahlukene kanye nezinto ezikhiqizwayo zingafakwa endaweni yokushisela, njengei-slag, i-spatter, nokushintsha umbala.

Uma zishiywe zingahlanzekile, lezi zingakwazikunomthelela omubi amandla e-weld, ukumelana nokugqwala, nobuhle bokubukwayo.

Ukuhlanza i-laser weld kusebenzisa i-laser enamandla amakhulu ukuze ukhethe ngokukhetha futhi kususwe lezi zidiphozi ezingaphezulu ezingathandeki.ngaphandle kokulimazainsimbi engaphansi.

Izinzuzo Laser Weld Cleaning

1. Ukunemba- I-laser ingaqondiswa ngokunembile ukuhlanza indawo yokushisela kuphela ngaphandle kokuthikameze izinto ezizungezile.

2. Isivinini- Ukuhlanza i-laser kuyinqubo esheshayo, ezenzakalelayo engahlanza ama-welds ngokushesha kakhulu kunamasu okwenziwa ngesandla.

3. Ukungaguquguquki- Ukuhlanza i-laser kukhiqiza umphumela ofanayo, ophindaphindwayo, oqinisekisa ukuthi wonke ama-welds ahlanzwa ngezinga eliphezulu elifanayo.

4. Azikho Izinto Ezisetshenziswayo- Ukuhlanza i-laser akudingi ama-abrasives noma amakhemikhali, kunciphisa izindleko zokusebenza kanye nemfucuza.

Izicelo: Laser Weld Cleaning

High-Strength Low-Alloy (HSLA) Steel Plates Laser Weld Cleaning

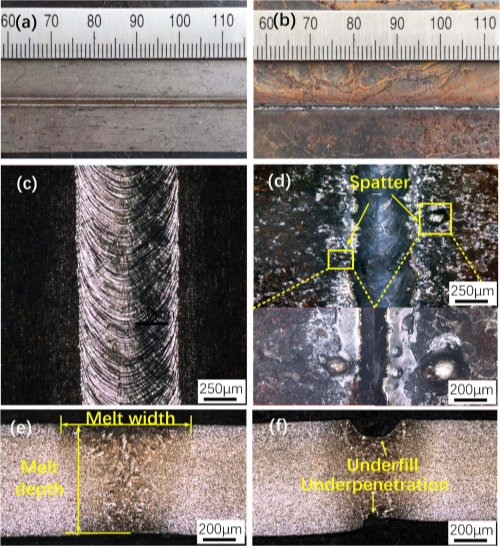

Ukubukeka Kwe-Weld Kokuphathwa Ngokuhlanzwa Kwe-Laser (a, c, e) Nokungalashwa Ukuhlanza I-Laser (b, d, f)

The efanele laser yokuhlanza inqubo nemingcele cansusaukugqwala namafutha avela endaweni yokusebenza.

Ukungena okuphezulukwabonwa ezinhlotsheni ezihlanziwe uma ziqhathaniswa nalezo ezingahlanzwa.

Ukwelashwa kwangaphambili nge-laser kuyasiza ngempumelelogwemaukuvela kwama-pores kanye nemifantu ku-weld kanyekuyathuthukaikhwalithi yokwakha ye-weld.

Ukwelashwa kwangaphambili kwe-Laser Weld Cleaning kunciphisa amaphutha amaningi njengama-pores kanye nemifantu ngaphakathi kwe-weld, ngaleyo ndlela.ngconoizakhiwo eziqinile ze-weld.

Amandla aqinile wesampula enokwelashwa kwangaphambili nge-laser ama-MPa angama-510, okungukuthi30% ngaphezulukunalokho ngaphandle kokuhlanza nge-laser ukwelashwa kwangaphambili.

Ukwelulwa kwejoyinti le-weld elihlanzwe nge-laser ngama-36% okusho ukuthiizikhathi ezingu-3leyo yejoyinti le-weld elingcolile (12%).

Buka Iphepha Locwaningo Loqobo Esangweni Lokucwaninga Lapha.

I-Commercial Aluminium Alloy 5A06 I-Laser Weld Cleaning

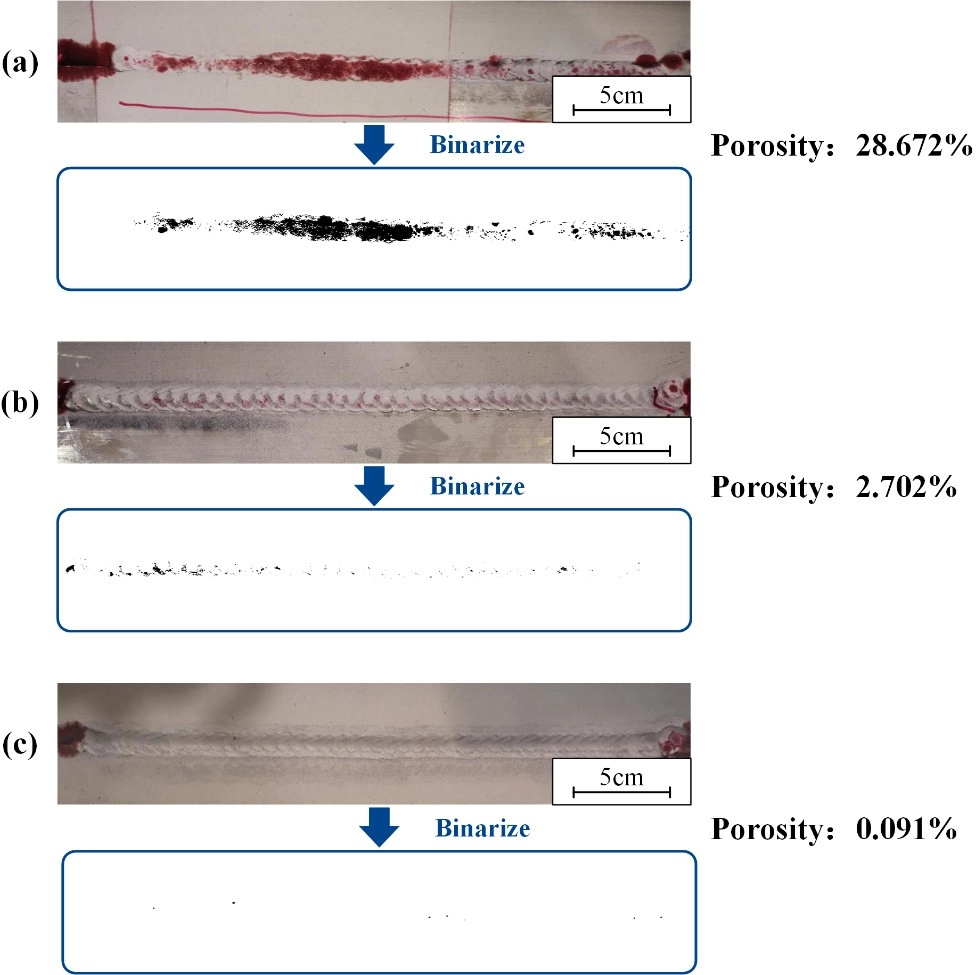

Umphumela Wokuhlolwa Kwe-Permeation kanye Ne-Porosity Esampula: (a) Uwoyela; (b) Amanzi; (c)Ukuhlanza iLaser.

Ugqinsi longqimba lwe-Aluminium alloy 5A06 oxide luyi-1–2 lm, futhi ukuhlanzwa nge-laser kubonisaumphumela othembisayoekukhishweni kwe-oxide ye-TIG welding.

I-porosity yatholakalaendaweni yokuhlanganisa ye-TIG weldsngemva kwenhlabathi evamile, kanye nokufakwa okune-morphology ebukhali kwahlolwa futhi.

Ngemuva kokuhlanza i-laser,kwakungekho porosity eyayikhonaendaweni ye-fusion.

Ngaphezu kwalokho, okuqukethwe kwe-oxygenkwehle kakhulu, evumelana nemiphumela yangaphambilini.

Ngaphezu kwalokho, ungqimba oluncane lokuncibilika okushisayo lwenzeka ngesikhathi sokuhlanza i-laser, okuholele ekuthenii-microstructure ecwengekileendaweni ye-fusion.

Buka Iphepha Locwaningo Loqobo Esangweni Lokucwaninga Lapha.

Noma Bheka lesi sihloko Esishicilelwe kuso:I-Aluminium Yokuhlanza I-Laser (Indlela Abacwaningi Abayenze Ngayo)

Uyafuna ukwazi mayelana nokuhlanza i-Laser Weld?

Singasiza!

Yini Engingayisebenzisa Ukuhlanza Ama-welds Ami?

Ukuhlanza Welds NikezaAmabhondi AqinilefuthiUkuvimbela Ukugqwala

Nazi ezinyeIzindlela ZendabukoOkokuhlanza ama-Welds:

Incazelo:Sebenzisa ibhulashi locingo noma isondo ukuze ususe i-slag, i-spatter, nama-oxides.

Okuhle:Akubizi futhi kusebenza ngempumelelo ekuhlanzeni indawo.

Ububi:Kungase kusebenze kanzima futhi kungase kungafinyeleli ezindaweni eziqinile.

Incazelo:Sebenzisa i-grinder ukushelela ama-welds futhi ususe ukungapheleli.

Okuhle:Isebenza kahle ekuhlanzeni okukhulu nokubunjwa.

Ububi:Ingashintsha iphrofayili yokushisela futhi ingase yethule ukushisa.

Incazelo:Sebenzisa izixazululo ezine-asidi noma izincibilikisi ukuze uncibilikise ukungcola.

Okuhle:Isebenza kahle ezinsalela eziqinile futhi ingasetshenziswa ezinhlelweni ezahlukahlukene.

Ububi:Idinga izinyathelo zokuphepha nokulahlwa okufanele.

Incazelo:Propel impahla ehubhukayo ngesivinini esikhulu ukuze ususe ukungcola.

Okuhle:Kuyashesha futhi kusebenza kahle ezindaweni ezinkulu.

Ububi:Kungabangela ukuguguleka komhlaba uma kungalawuleki.

Incazelo:Sebenzisa amagagasi omsindo wemvamisa ephezulu kusixazululo sokuhlanza ukuze ususe udoti.

Okuhle:Ifinyelela izimo eziyinkimbinkimbi futhi isusa ukungcola kahle.

Ububi:Izinto zokusebenza zingabiza futhi usayizi wokuhlanza unganqunyelwa.

NgobaUkukhishwa kwe-Laser & Ukulungiswa kwe-Laser Surface:

Ukukhishwa kwe-Laser

Incazelo:Sebenzisa imishayo ye-laser enamandla amakhulu ukuhwamisa ukungcola ngaphandle kokuthikameze izinto eziyisisekelo.

Okuhle:Inembile, ihambisana nemvelo, futhi iyasebenza ezinhlelweni ezibucayi.

Ububi:Izisetshenziswa zingabiza, futhi zidinga ukusebenza okunekhono.

Ukulungiswa kwe-Laser Surface

Incazelo:Sebenzisa ama-laser ukulungisa izindawo ngokukhipha ama-oxide nokungcola ngaphambi kokushisela.

Okuhle:Ithuthukisa ikhwalithi yokushisela futhi yehlise amaphutha.

Ububi:Izisetshenziswa nazo zingabiza, futhi zidinga ukusebenza okunekhono.

Indlela yokuhlanza i-Laser Metal?

I-Laser Cleaning iyindlela ephumelelayo yokususa izinto ezingcolisayo

Gqoka i-PPE efanele, okuhlanganisa izibuko zokuphepha, amagilavu, nezingubo zokuzivikela.

Vikela ucezu lwensimbi endaweni ezinzile ukuze uvimbele ukunyakaza ngesikhathi sokuhlanza. Lungisa ikhanda le-laser libe ibanga elinconyiwe ukusuka phezulu, ngokuvamile phakathi10-30 mm.

Qhubeka uqaphe inqubo yokuhlanza. Bheka izinguquko endaweni, njengokususwa kokungcola noma yimuphi umonakalo ensimbi.

Ngemva kokuhlanza, hlola indawo yokushisela ukuze uthole ukuhlanzeka kanye nanoma yikuphi ukungcola okusele. Kuye ngesicelo, cabangaukusebenzisa i-coating yokuzivikelaukuvimbela ukugqwala kwesikhathi esizayo.

Iliphi ithuluzi elingcono kakhulu lokuhlanza ama-welds?

Ukuhlanza I-Laser Kugqama Njengelinye Lamathuluzi Angcono Kakhulu Akhona

Kunoma ngubani obambe iqhaza ekwenziweni kwensimbi noma ekunakekeleni, ukuhlanzwa kwe-laser kuyintoithuluzi eliyigugu lokuhlanza ama-welds.

Ukunemba kwayo, ukusebenza kahle, kanye nezinzuzo zemvelo kuyenza ibe yisinqumo esifaneleukuzuza imiphumela yezinga eliphezulungenkathi kunciphisa ubungozi kanye nesikhathi sokuphumula.

Uma ubheke ukuthuthukisa izinqubo zakho zokuhlanza, cabanga ukutshala imali kubuchwepheshe bokuhlanza i-laser.

Uwenza kanjani ama-Welds abukeke Ahlanzekile?

Ukuhlanza I-Laser Kusiza Ukuzuza Ukushisela Okuhlanzekile Nokubukeka Kwezobuchwepheshe

Ukulungiswa kwe-Surface

Ukuhlanza kokuqala:Ngaphambi kokushisela, qiniseka ukuthi isisekelo sensimbi ayinakho ukungcola njengokugqwala, uwoyela, nokungcola. Lesi sinyathelookubalulekile ekufezeni i-weld ehlanzekile.

Ukuhlanza i-Laser:Sebenzisa uhlelo lokuhlanza nge-laser ukuze ususe ngempumelelo noma yikuphi ukungcola okungaphezulu. Indlela ehlosiwe iqinisekisa ukuthi ukungcola kuphela okususwayongaphandle kokulimaza insimbi.

Ukuhlanza kwangemva kokushisela

Ukuhlanza kwangemva kokushisela:Ngemva kokushisela, hlanza ngokushesha indawo yokushisela ngelaser ukuze ususe i-slag, i-spatter, ne-oxidation engaphazamisa ukubukeka kwe-weld.

Ukuvumelana:Inqubo yokuhlanza i-laser inikeza imiphumela efanayo, iqinisekisa ukuthi wonke ama-welds anokugcina okuhambisanayo, okuhlanzekile.

Imibukiso Yevidiyo: Ukuhlanza I-Laser Kwensimbi

Iyini i-Laser Cleaning futhi isebenza kanjani?

Enye yezinzuzo ezinkulu zokuhlanza i-laser ukuthi kunjaloinqubo eyomile.

Okusho ukuthi asikho isidingo sokukhuculula imfucumfucu ngemuva.

Mane uqondise i-laser beam endaweni ofuna ukuyihlanzangaphandle kokuthinta izinto eziyisisekelo.

Izihlanzi ze-laser nazokuhlangene futhi kuyaphatheka, ukuvumelaukuze kuhlanzwe kahle endaweni.

Idinga ngokujwayelekileizinto zokuzivikela eziyisisekelo kuphela, njengezibuko zokuphepha nezinsimbi zokuphefumula.

I-Laser Ablation Ingcono Ekuhlanzeni Ukugqwala

Ukuqhunyiswa kwesihlabathi kungadalauthuli oluningi futhi kudinga ukuhlanzwa okukhulu.

Dry ice yokuhlanza kuyintoebiza kakhulu futhi ayifaneleki kangako imisebenzi emikhulu.

Ukuhlanza amakhemikhali kungasezibandakanya izinto eziyingozi kanye nezindaba zokulahlwa.

Ngokungqubuzanayo,ukuhlanza i-laser kuvela njengendlela evelele.

Iguquguquka ngendlela emangalisayo, iphatha uhla lokungcola ngokunemba

Inqubo iyona eyongayo ngokuhamba kwesikhathi ngenxanoukusetshenziswa kwezinto ezibonakalayo kanye nezidingo zokunakekelwa okuphansi.

I-Handheld Laser Cleaning Machine: I-Laser Weld Cleaning

I-Pulsed Laser Cleaner(100W, 200W, 300W, 400W)

Ama-pulsed fiber laser cleaner afaneleka kakhulu ukuhlanzwaobucayi,ebucayi, nomasengozini yokushisaizindawo ezingaphezulu, lapho imvelo enembile nelawulwayo ye-laser pulsed ibalulekile ekuhlanzeni okuphumelelayo nokungenamonakalo.

Amandla e-Laser:100-500W

I-Pulse Length Modulation:10-350ns

Ubude bekhebula le-Fiber:3-10m

Ubude begagasi:1064nm

Umthombo we-Laser:I-Pulsed Fiber Laser

Umshini Wokususa Ukugqwala kwe-Laser(Pre & Post Laser Weld Cleaning)

I-laser weld yokuhlanza isetshenziswa kabanzi ezimbonini ezifanai-aerospace,ezezimoto,ukwakhiwa kwemikhumbi, futhiukukhiqiza izinto zikagesilaphoizinga eliphezulu, ama-welds angenasicizibalulekile ekuphepheni, ekusebenzeni nasekubukekeni.

Amandla e-Laser:100-3000W

I-Adjustable Laser Pulse Frequency:Kufika ku-1000KHz

Ubude bekhebula le-Fiber:3-20m

Ubude begagasi:1064nm, 1070nm

UkusekelaOkuhlukahlukeneIzilimi