I-Laser Welding Aluminium

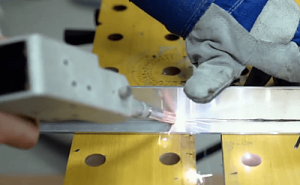

Ukuze i-laser weld aluminium ngokuphepha nangempumelelo, kubalulekile ukulandela izinqubo ezifanele kanye nezinyathelo zokuphepha.

Lokhu kuhlanganisa ukuhlanza ngokuphelele indawo ye-aluminium,

usebenzisa i-laser wavelength efanelekile namandla,

kanye nokuhlinzeka ngegesi evikelayo eyanele.

Ngamasu alungile, i-laser welding ye-aluminium ephathwa ngesandla ingaba yindlela esebenzayo nenenzuzo yokujoyina.

Iyini i-Handheld Laser Welding?

I-Handheld Laser Welding Aluminium

I-laser welding ephathwa ngesandla iyindlela emisha eye yazuza ukudonsa okuphawulekayo ekwenziweni kwensimbi eminyakeni yamuva nje.

Ngokungafani nezindlela ezijwayelekile zokushisela njenge-MIG noma i-TIG,

le nqubo isebenzisa i-laser egxilile ukuze incibilike futhi ihlanganise izingxenye zensimbi ngokunemba okukhethekile.

Izinzuzo eziyinhloko ze-laser welding ephathwayo zifaka isivinini esimangalisayo, ukunemba okuphakeme, kanye nokusebenza okusebenziseka kalula.

Eqinisweni, ukushisela nge-laser kungafinyelela isivinini esifika ngokuphindwe kane kune-MIG yendabuko noma i-TIG yokushisela,

kuyilapho i-laser egxile kakhulu iqinisekisa ukushisela okungaguquki, okusezingeni eliphezulu.

Ngenxa yentuthuko kubuchwepheshe be-fiber laser,

lezi zinhlelo sezingabizi kakhulu futhi zihlala isikhathi eside, okusheshisa ukutholwa kwazo okusabalele emkhakheni wokusebenza kwensimbi.

Ingabe i-Aluminium Ingenziwa I-Laser Welded?

I-Laser Welding Aluminium ene-Aluminium Laser Welder

Yebo, i-aluminium ingashiselwa ngempumelelo nge-laser, okuhlanganisa nezinhlelo zokushisela ze-laser eziphathwayo.

Ukushisela nge-laser kunikeza izinzuzo ezimbalwa zokushisela i-aluminium uma kuqhathaniswa nezinye izindlela zokushisela.

Izinzuzo Laser Welding Aluminium

Amalunga Okushisela Amancane Nezindawo Ezincane Ezithintwa Ukushisa :

Lokhu kunciphisa kakhulu ukuhlanekezela okushisayo ngenkathi kugcinwa ukuqina kwesakhiwo sezingxenye ze-aluminium.

Ukulawula Okunembile:

Ukushisela nge-laser kunikeza amandla akhethekile okuzenzakalela, okuvumela ukunemba okuhlelekayo kweyunifomu, ama-welds ekhwalithi ye-premium.

Amandla Wokushisela Izigaba Ze-Aluminium Encane:

Ukushisela nge-laser kungajoyina ngempumelelo i-aluminium ibe mncane njengo-0.5 mm ngaphandle kokushiswa kwezinto.

Izinselelo Eziyingqayizivele ze-Laser Welding Aluminium

High Reflectivity

Indawo ecwebezelayo ye-aluminium ibangela ukulahleka kwamandla okukhulu kwe-laser, okwenza kube nezinselele zokuhlanganisa okusebenzayo kwe-beam-material. Izindlela zokucubungula ezithuthukile zibalulekile ukuze kuthuthukiswe ukumuncwa kwamandla e-laser.

Ukuthambekela kwe-Porosity kanye nokuqhekeka Okushisayo

Ukususwa kokushisa okusheshayo kwe-aluminium kanye nezici zechibi elincibilikisiwe eliwuketshezi ngokuvamile kubangela ukungapheleli kokushisela okufana nezimbotshana zegesi nemifantu eshisayo. Ukulawulwa okunembile kwezinqubo eziguquguqukayo kanye nokuvikelwa kwegesi engasebenzi kubalulekile ngakho-ke.

I-Laser Welding Aluminium Ingaba Yinselele

Singakunikeza Izilungiselelo Ezilungile kuwe

Indlela Ye-Laser Weld Aluminium Ngokuphephile?

Laser Welding Highly Reflective Aluminium

I-laser welding aluminium iveza izinselelo ezimbalwa eziyingqayizivele okufanele zibhekwe ukuze kuqinisekiswe ukushisela okuphephile nokuphumelelayo.

Ngokombono wezinto ezibonakalayo,

I-aluminium conductivity ephezulu ye-thermal,

Iphuzu elincibilikayo eliphansi,

Ukuthambekela kokwenza izendlalelo ze-oxide

Konke kungaba nomthelela ebunzimeni bokushisela.

Indlela Yokunqoba Lezi Zinselele? (Okwe-Aluminium Laser Weld)

Phatha Okokufaka Ukushisa:

Ukushisa okuphezulu kwe-aluminium kusho ukuthi ukushisa kungasakazeka ngokushesha kuyo yonke indawo yokusebenza, okuholela ekuncibilikeni okukhulu noma ekuwohlokeni.

Sebenzisa umshini wokushisela we-laser onamandla anele ukuze ungene kokubalulekile, kodwa lawula ngokucophelela okokufaka kokushisa ngokulungisa amapharamitha afana nesivinini sokushisela namandla e-laser.

Susa Izendlalelo ze-Oxide

Isendlalelo se-oxide esakheka phezu kwe-aluminium sinephuzu lokuncibilika eliphakeme kakhulu kunesisekelo sensimbi, esingaholela ku-porosity nokunye ukukhubazeka.

Hlanza ngokuphelele indawo ngaphambi kokushisela, kungaba ngomshini noma ngamakhemikhali, ukuze uqinisekise ikhwalithi enhle yokushisela.

Vimbela Ukungcoliswa kwe-Hydrocarbon

Noma yimaphi ama-lubricant noma ukungcola endaweni ye-aluminium nakho kungabangela izinkinga ngesikhathi sokushisela.

Qinisekisa ukuthi i-workpiece ihlanzekile ngokuphelele futhi yomile ngaphambi kokuqala inqubo yokushisela.

Ukucatshangelwa Okukhethekile Kokuphepha (Kwe-Laser Welding Aluminium)

Ukuphepha kwe-Laser

Ukubonakala okuphezulu kwe-aluminium kusho ukuthi i-laser beam ingagxuma izungeze indawo yokusebenza, okwandisa ingozi yokuchayeka kweso nesikhumba.

Qinisekisa ukuthi kunezimiso ezifanele zokuphepha nge-laser, okuhlanganisa ukusetshenziswa kwezingubo zamehlo ezivikelayo nezivikelayo.

Ukukhishwa Kwentuthu

I-aluminiyamu yokushisela ingakhiqiza intuthu eyingozi, okuhlanganisa naleyo evela ku-vaporization yezinto eziyingxubevange njenge-magnesium ne-zinc.

Imishini efanele yokukhipha umoya kanye nokukhipha intuthu ibalulekile ukuze kuvikelwe isishiseli nendawo ezungezile.

Ukuvimbela Umlilo

Okokufaka kokushisa okuphezulu nensimbi encibilikisiwe ehambisana ne-laser welding aluminium kungadala ingozi yomlilo.

Thatha izinyathelo zokuphepha ukuze uvimbele ukuvutha kwezinto eziseduze ezivuthayo futhi ube nezinto ezifanele zokucisha umlilo esandleni.

Laser Welding Aluminium Izilungiselelo

I-Handheld Laser Welding Aluminium Frame

Uma kukhulunywa nge-laser welding aluminium, izilungiselelo ezifanele zingenza umehluko.

Izilungiselelo Ezijwayelekile Ze-Laser Welding Aluminium (Okokubhekisela Kuphela)

Laser Amandla

Ukubonakala okuphezulu kwe-aluminium kusho ukuthi amandla e-laser aphezulu ayadingeka ngokujwayelekile, ukusuka ku-1.5 kW ukuya ku-3 kW noma ngaphezulu, kuye ngogqinsi lwempahla.

I-Focal Point

Ukugxilisa i-laser beam ngaphansi kancane kobuso be-aluminium (cishe u-0.5 mm) kungasiza ukuthuthukisa ukungena nokunciphisa ukubonakala.

I-Shielding Gas

I-Argon iyigesi yokuvikela evame ukusetshenziswa kakhulu ye-laser welding aluminium, njengoba isiza ukuvimbela i-oxidation kanye ne-porosity ekushiseleni.

I-Beam Diameter

Ukuthuthukisa ububanzi be-laser beam, ngokuvamile obuphakathi kuka-0.2 no-0.5 mm, kungabhalansisa ukungena nokokufaka kokushisa kogqinsi oluthile.

Isivinini sokushisela

Isivinini sokushisela kufanele silinganiswe ukuze kuvinjwe kokubili ukuntuleka kokungena (okushesha kakhulu) kanye nokokufaka ukushisa okukhulu (kuhamba kancane kakhulu).

Izivinini ezinconyiwe ngokuvamile zisukela kumayintshi angu-20 kuye kwangu-60 ngomzuzu.

Izicelo ze-Laser Welding Aluminium

I-Laser Welding Aluminium ene-Handheld Laser Welder

Ukushisela nge-laser sekuyindlela edumile yokujoyina izingxenye ze-aluminium kuzo zonke izimboni ezihlukahlukene ngenxa yezinzuzo zayo eziyingqayizivele.

Imboni Yezimoto

Ama-laser we-aluminium asetshenziswa kakhulu embonini yezimoto ukujoyina amaphaneli e-aluminium, iminyango, nezinye izingxenye zesakhiwo.

Lokhu kusiza ukwehlisa isisindo semoto, kuthuthukise ukusebenza kahle kukaphethiloli, futhi kuthuthukise amandla awo wonke kanye nokuqina komzimba wemoto.

Imboni ye-Aerospace

Emkhakheni we-aerospace, i-laser welding isetshenziswa ukuze kuhlanganiswe izindwani zenjini, ama-turbine discs, izindonga zekhabhinethi, nezicabha ezenziwe ngama-alloys e-aluminium.

Ukulawula okunembile kanye nendawo encane ethinteke ekushiseni ye-laser welding iqinisekisa ubuqotho besakhiwo nokuqina kwalezi zingxenye zezindiza ezibalulekile.

Ezogesi Nokuxhumana

I-laser welding isetshenziselwa ukushisela izingxenye ze-aluminium kumishini kagesi, njengamabhodi wesifunda, izinzwa, nezibonisi.

Ukunemba okuphezulu kanye ne-automation ye-laser welding yenza ukuxhumana okuthembekile nokungashintshi, okubalulekile ekusebenzeni nasekuzinzeni kwemikhiqizo ye-elekthronikhi.

Amadivayisi Ezokwelapha

I-Aluminium laser welding isetshenziswa ekwenziweni kwemishini yezokwelapha, okuhlanganisa amathuluzi okuhlinza, izinaliti, ama-stents, nezinto zikagesi zamazinyo.

Imvelo eyinyumba nengenamonakalo ye-laser welding ibalulekile ekuqinisekiseni ukuphepha kanye nenhlanzeko yale mikhiqizo yezokwelapha.

Ukucutshungulwa Kwesikhunta

I-laser welding isetshenziswa embonini yokucubungula isikhunta ukulungisa nokuguqula isikhunta se-aluminium,

Okufana nokunyathela isikhunta, isikhunta somjovo, nokubunjwa kokubumba.

Ukwengeza okunembile kanye namakhono okulungisa ngokushesha we-laser welding

Siza ukunweba ubude bempilo nokusebenza kwalawa mathuluzi okukhiqiza abalulekile.

Ngokubukeka komshini ohlangene futhi omncane, umshini we-laser welder ophathwayo ufakwe isibhamu selaser esiphathwayo esinyakazayo, esingasindi futhi esilungele izinhlelo zokushisela ezinamalaza amaningi kunoma yimaphi ama-engeli nezindawo.

Amandla e-Laser:1000W - 1500W

Usayizi Wephakheji (mm):500*980*720

Indlela Yokupholisa:Ukupholisa Amanzi

Izindleko Ezisebenzayo & Iyaphatheka

Umshini wokushisela i-laser we-fiber engu-3000W ufaka amandla amakhulu okukhiphayo, okuwenza ukwazi ukushisela amapuleti ensimbi ashubile ngesivinini esisheshayo.

Ifakwe i-chiller yamanzi enamandla amakhulu ukupholisa ngokushesha izinga lokushisa le-laser welder, i-fiber laser welder enamandla amakhulu ingasebenza kahle futhi ikhiqize ikhwalithi yokushisela ehlala njalo yekhwalithi ephezulu.

High Power OutputNgesilungiselelo Sezimboni

Ukusebenza OkuphakemeOkwezinto eziwugqinsi

I-Industrial Water UkupholisaUkuze Kusebenze Okuvelele