Laser Welding Jewelry Repair

I-laser welding iyindlela yokuguqula izinto eziguqule imboni yobucwebe.

Uma usebenzisa umshini wokushisela we-laser wobucwebe, abenzi bobucwebe bangakha ukushisela okunembile, kwekhwalithi ephezulu ezinhlobonhlobo zezinsimbi, okuhlanganisa igolide, isiliva, neplatinamu, ngaphandle kokubeka engcupheni ubuqotho noma ukubukeka kobucwebe.

Yini i-Laser Welding Jewelry?

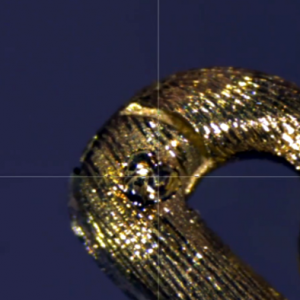

Jewelry Laser Welding

Inzuzo eyinhloko ye-laser welding yobucwebe ukunemba kwayo nokulawula.

I-laser beam ingagxila endaweni encane,

Ivumela ubucwebe ukuthi bashisele izingxenye ezintekenteke

Ngaphandle kokulimaza izinto ezizungezile.

Lokhu kwenza kube usizo ikakhulukazi emisebenzini efana nokusetha amatshe ayigugu,

Ukulungisa ukuqoshwa kwensimbi okuyinkimbinkimbi,

Futhi ukuhlanganisa izingcezu zobucwebe eziyinkimbinkimbi.

Uma kuqhathaniswa Nezindlela Zokushisela Zendabuko:

Ukushisela nge-laser kukhiqiza ukushisa okuncane, kunciphisa ubungozi bokuguga noma ukukhathala kwezinto.

Lokhu kubalulekile uma usebenza ngamatshe azwela ukushisa njengama-emerald nama-opals.

I-laser welding nayo iqeda isidingo sezinto ezengeziwe zokushisela,

Ukwakha isiphetho esihlanzekile, esingenamthungo.

Imishini yokushisela i-laser yobucwebe kulula ukuyisebenzisa futhi ingahlanganiswa nezinqubo zokukhiqiza ezizenzakalelayo,

Ukuthuthukisa ukusebenza kahle nokuvumelana.

Futhi banezindleko zokunakekela eziphansi,

Ukwenza kube utshalomali olusebenzayo lwezindawo zokucobelelana ngolwazi zobucwebe nabakhiqizi.

Uhlobo luni lwe-Welding olusetshenziselwa ubucwebe?

Laser Welding Jewelry Repair

Izinhlobo ezivame kakhulu zokushisela ezisetshenziselwa ubucwebe ziyimicroresistance weldingfuthilaser welding.

I-Laser Welding:

I-laser welding nayo isiye yanda kakhulu embonini yobucwebe.

I-laser welding isebenzisa i-amplified light beam ukuze idale cishe amalunga angabonakali kubucwebe.

Le ndlela yaziwa ngokuguquguquka kwayo, ukwethembeka, kanye nesivinini

I-laser welding ingasetshenziswa ezinhlobonhlobo zezinsimbi eziyigugu,

Kusukela esiliva esicwebezelayo kuya kuplatinamu,

Ngaphandle kokudala ama-brittleness noma ukulimala.

I-Micro-resistance Welding:

I-Microresistance welding iyisinqumo esidumile sezicelo zobucwebe.

Le nqubo ithatha ithuba lokumelana nezinsimbi ezahlukahlukene ukwenza ukuqina,

I-weld enembile ngaphandle kokulimaza izinto ezizungezile.

Ukushisa okulawulwayo nendawo encane yokushisela kwenza i-micro-resistance welding

Ifaneleka kahle izingcezu zobucwebe ezithambile.

Ezinye Izindlela Zokushisela:

I-Brazing WeldingfuthiI-Pulse Arc Weldingngezinye izikhathi zisetshenziselwa ubucwebe,

Kodwa azivamile ukwedlula micro resistance kanye laser welding.

I-Brazing ihlanganisa ukusebenzisa i-filler material ukujoyina izinsimbi,

Ngenkathi i-pulse arc welding isebenzisa i-pulse kagesi ukuhlanganisa izingcezu ndawonye.

Kodwa-ke, lezi zindlela zamasu zingase zinganikezi izinga elifanayo lokunemba nokulawula

Iyadingeka kumiklamo yobucwebe eyinkimbinkimbi.

Ingabe ufuna ukwazi okwengeziwe mayelana Laser Welding Jewelry?

Singasiza!

Inembile kangakanani i-Jewelry Laser Welder?

Laser Welding Jewelry Repair

Abashiseli belaser bobucwebe baziwa ngokunemba nokunemba okukhethekile.

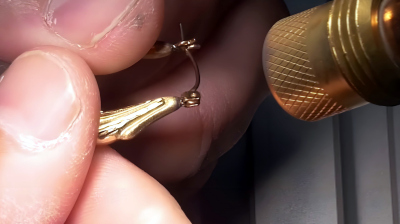

I-laser beam egxilile ivumela abenzi bobucwebe ukuthi benze ukulungisa okuyinkimbinkimbi nokuthambile ngokunemba okuqondile.

Konke mayelana Nokunemba Nokulawula:

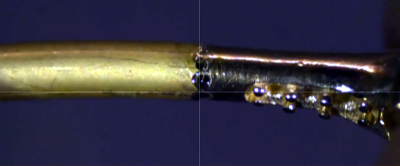

Ukushisa okugxilile kwe-laser kanye nekhono lokulungiswa ukusuka ku-0.2mm ukuya ku-2mm ububanzi

Inikeza ubucwebeukulawula okuphelelelapho i-laser isetshenziswa khona.

Lokhu kuzivumela ukuthi zisebenze eduze kakhulu namatshe angezwani nokushisa

Ngaphandle kokudala umonakalo.

Abenzi bobucwebe manje sebengakwazi ukufeza imisebenzi ababeyiyo

Ngaphambilini kwakungenakwenzeka noma kudla isikhathi esiningi usebenzisa izindlela zendabuko zokunamathisela.

I-Game-Changer yemboni yobucwebe:

Ukunemba kwe-laser welding kuyashintsha umdlalo embonini yobucwebe.

Inika amandla abenzi bobucwebe ukuthi bagcine ubuqotho nokubukeka kwasekuqaleni kwezingcezu zakudala ngesikhathi sokulungiswa,

Ngaphandle kokususa amatshe noma engozini ukulimaza insimbi entekenteke.

I-laser ingakwazi ukuhlanganisa insimbi.

Ngaphandle kokushintsha i-patina noma ukufaka i-oxidating ucezu lwangempela.

Ukufeza Okungenakwenzeka:

Ngemiklamo emisha yobucwebe, ukunemba kwelaser kubaluleke kakhulu.

Amagugu angakwazi ukuhlanganisa izingcezu eziyinkimbinkimbi, ezisebenzisa idayimane ngenkathi egcina imininingwane eyinkimbinkimbi iqinile,

Into engaba nzima kakhulu ngethoshi lendabuko.

I-laser ingasetshenziswa futhi ngokushesha

Futhi lungisa kahle iziphambeko njengezimbobo ze-porosity ngaphandle kokuthinta ingxenye esele.

Ungakwazi yini Laser Weld Gold Jewelry?

Laser Welding Gold Jewelry

Yebo, ungakwazi ngokuphelele laser weld igolide ubucwebe.

I-laser welding iyindlela ephumelela kakhulu futhi enembile

Ukusebenza ngegolide nezinye izinsimbi eziyigugu ekwenzeni nokulungisa ubucwebe.

Izinzuzo Eziyinhloko Zokusebenzisa I-Laser Welding yobucwebe begolide:

Ukuguquguquka- Abashiseli be-laser bangakwazi ukuphatha ama-alloys egolide anhlobonhlobo, kusukela ku-10K kuya ku-24K, kanye nezinye izinsimbi eziyigugu njengeplatinum nesiliva.

Ukulimala Kokushisa Okuncane -I-laser welding ikhiqiza ukushisa okwasendaweni kakhulu, inciphisa "indawo ethinteke ukushisa" futhi inciphise ingozi yokuguquguquka noma ukuguquguquka kwegolide.

Ukunemba -I-laser beam ingaqondiswa ngokunembile ukushisela izindawo ezincane, eziyinkimbinkimbi ngaphandle kokuthinta ingxenye esele yocezu.

Lokhu kwenza i-laser welding ilungele imisebenzi efana nokusetha amatshe ayigugu, ukulungisa ama-prong, nokuhlanganisa imiklamo yobucwebe eyinkimbinkimbi.

Isivinini nokusebenza kahle -Ukushisela nge-laser kuyinqubo esheshayo, evumela abenzi bobucwebe ukuthi baqedele ukulungisa kanye nemisebenzi yokuhlanganisa ngokushesha kunezindlela zendabuko ezifana ne-soldering.

Lokhu kungakhuphula ukukhiqiza endaweni yokusebenzela yobucwebe.

Ungakwazi yini i-Laser Weld Silver Jewelry?

Laser Welding Gold Jewelry

Yebo, ungakwazi ukushisela isiliva nge-laser ekwenzeni ubucwebe.

Isiliva sidinga izilungiselelo zamandla e-laser aphezulu uma kuqhathaniswa nezinye izinsimbi njengegolide noma iplatinamu.

I-laser welder idinga ukuthi ikwazi okungenani ama-kilowathi angu-6 wamandla aphezulu we-pulse ukushisela isiliva ngempumelelo.

Inqubo yokushisela isiliva ngokuvamile ithatha isikhathi eside kunezinye izinsimbi eziyigugu.

Lokhu kungenxa ye-silver's surface tension.

Ukusebenzisa igesi ye-inert njenge-argon noma i-nitrogen ngesikhathi senqubo yokushisela i-laser

Ingasiza ukuthuthukisa ikhwalithi yokushisela futhi yehlise ukungcola.

Igesi ye-inert idala "ifu" elivikelayo elizungeze indawo yokushisela.

Iqala "Ngezansi", Iphethe ngokuthi "Better":

Lapho isiliva welding laser, kungcono ukusebenzisa intambo yokugcwalisa okuqukethwe kwesiliva ephansi kancane,

Njengocingo "lwesiliva weld hard", esikhundleni sesiliva esicwengekile esingu-925.

Okuqukethwe kwesiliva okuphansi kuvumela ucingo ukuthi lugeleze kangcono kuzilungiselelo zamandla aphansi,

Ukunciphisa ingozi yokugoba noma ukuqhekeka.

Kubalulekile ukuqala ngezilungiselelo zamandla aphansi futhi usebenze kancane kancane lapho isiliva le-laser welding.

Lokhu kusiza ukuthola izinga lokushisa elilungile locezu ngalunye futhi kudala amashisela aqinile, angaguquki.

Ubucwebe be-Laser Welder

Igqama ngosayizi wawo womshini ohlangene nokusebenza kalula ekulungiseni ubucwebe kanye nokukhiqiza imihlobiso.

Ukuze uthole amaphethini amahle kanye nemininingwane yezinhlanga kubucwebe. Ungakwazi ukubhekana nalokhu nge-laser welder encane ngemva kokuzijwayeza kancane.

I-Compact DesignUkufinyeleleka.

I-Electronic Filter Protectionokwezokuphepha kwamehlo.

InengqondoI-Digital Control System.

IsekelaUkupholisa Umoya noma Amanzi.

Ingabe i-Laser Welding Jewelry Repair ingcono kuneSoldering?

Uma kuziwa ekulungiseni ubucwebe, ubucwebe banezinketho ezimbili eziyinhloko:

I-Laser WeldingfuthiIthoshi Soldering.

Zombili lezi zindlela zinezinzuzo nezinkinga zazo,

Futhi ukukhetha ekugcineni kuncike ezidingweni ezithile zesiqephu sobucwebe.

Nge-Laser Welding:

Ukushiswa kwe-laser kuvame ukucatshangelwaindlela ephakeme yokulungisa ubucwebe.

Ngokungafani ne-soldering yendabuko, ukushiswa kwe-laser kuvumela ubucwebe ukuthi bulungise ubucwebe ngokuphumelelayo nangempumelelo

Ngaphandle kokukhipha amatshe azwela ukushisa

Futhi ngaphandle kokusebenzisa i-flux noma i-lead solder.

Inqubo yokushisela i-laser ihlanzeke kakhulu, ayinakho ukushintsha kombala,

Futhi kudinga isikhathi esincane ukulungisa kabusha ucezu.

Amandla Okushisela Angcono Nokuguquguquka:

I-laser welding nayo idala isibopho esinamandla kune-soldering.

I-laser weld enhle inamandla ngokuphindwe kathathu kune-virgin metal,

Noma izikhathi ezingu-260 ezinamandla kunejoyinti le-solder.

Lokhu kwenza ukulungiswa kwe-laser-welded kuhlale isikhathi eside futhi mancane amathuba okuthi kuhluleke ngokuhamba kwesikhathi.

Enye inzuzo ye-laser welding ukuthi ingasetshenziswa ezinhlobonhlobo zezinto zokwakha,

Kubandakanya ubucwebe obugcwele igolide nobucwebe begolide,

Okungase kube nzima ukukulungisa usebenzisa izindlela zendabuko zokuhlanganisa.