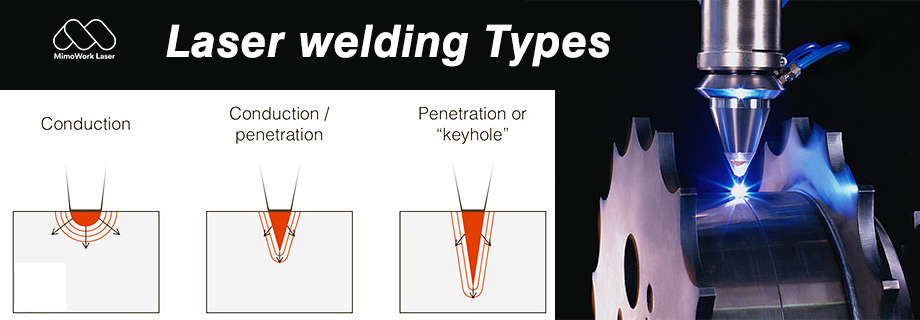

Ukushiswa kwe-laser kungenziwa ngokuqhubekayo noma nge-pulsed laser generator. Umgomo we-laser welding ungahlukaniswa ube yi-welding conduction welding kanye ne-laser deep fusion welding. Ubuningi bamandla obungaphansi kuka-104 ~ 105 W/cm2 wukushisela ukushisa, ngalesi sikhathi, ukujula kokuncibilika, nesivinini sokushisela kuhamba kancane; Lapho ukuminyana kwamandla kungaphezu kuka-105 ~ 107 W/cm2, indawo yensimbi igoqeka ibe "izimbobo zokhiye" ngaphansi kwesenzo sokushisa, yakha i-fusion welding ejulile, enezici zejubane lokushisela elisheshayo kanye nesilinganiso esikhulu sobubanzi bobubanzi.

Namuhla, sizofaka ikakhulukazi ulwazi lwezinto ezinkulu ezithinta ikhwalithi ye-laser deep fusion welding

1. Amandla eLaser

Ku-laser deep fusion welding, amandla e-laser alawula kokubili ukujula kokungena kanye nesivinini sokushisela. Ukujula kwe-weld kuhlobene ngokuqondile nokuminyana kwamandla e-beam futhi kuwumsebenzi wamandla ebhili yesigameko kanye nendawo yokugxila ye-beam. Ngokuvamile, ngomugqa othile we-laser wobubanzi, ukujula kokungena kuyanda ngokwanda kwamandla e-beam.

2. I-Focal Spot

Usayizi wendawo ye-Beam ungenye yezinto eziguquguqukayo ezibaluleke kakhulu ku-laser welding ngoba inquma ukuminyana kwamandla. Kodwa ukukukala kuyinselele kuma-lasers anamandla amakhulu, nakuba kunamasu amaningi okulinganisa angaqondile atholakalayo.

Usayizi wendawo yomkhawulo wokuhluka wokugxilwa kwe-beam angabalwa ngokuya ngethiyori ye-diffraction, kodwa usayizi wangempela wendawo mkhulu kunevelu ebaliwe ngenxa yokuba khona kokubonakala kokugxila okungalungile. Indlela yokulinganisa elula yindlela yephrofayela ye-iso-temperature, ekala ububanzi bendawo okugxilwe kuyo kanye nokubhobozwa ngemva kokushiswa kwephepha eliwugqinsi futhi lingene ngepuleti le-polypropylene. Le ndlela ngomkhuba wokulinganisa, ibamba usayizi wamandla we-laser nesikhathi sesenzo se-beam.

3. Igesi Evikelayo

Inqubo yokushisela nge-laser ivame ukusebenzisa amagesi avikelayo (i-helium, i-argon, i-nitrogen) ukuze kuvikelwe ichibi elincibilikisiwe, kuvinjwe i-workpiece kusuka ku-oxidation kwinqubo yokushisela. Isizathu sesibili sokusebenzisa igesi evikelayo ukuvikela ilensi egxilile ekungcolisweni umhwamuko wensimbi kanye nokufafazwa ngamaconsi awuketshezi. Ikakhulukazi ku-high-power laser welding, i-ejecta iba namandla kakhulu, kuyadingeka ukuvikela ilensi. Umphumela wesithathu wegesi evikelayo ukuthi iphumelela kakhulu ekuhlakazeni isivikelo se-plasma esikhiqizwa yi-high-power laser welding. Umhwamuko wensimbi udonsa umsebe we-laser bese u-ionze ube yifu le-plasma. Igesi evikelayo ezungeze umhwamuko wensimbi ibuye ibe ion ngenxa yokushisa. Uma kune-plasma eningi kakhulu, i-laser beam ngandlela-thile idliwa yi-plasma. Njengamandla esibili, i-plasma ikhona endaweni yokusebenza, okwenza ukujula kwe-weld kungashoni futhi indawo ye-weld pool ibe banzi.

Indlela yokukhetha igesi yokuvikela efanele?

4. Izinga lokumuncwa

Ukumuncwa kwe-laser kwento kuncike kwezinye izici ezibalulekile zezinto ezibonakalayo, njengezinga lokumunca, ukubukeka kwe-reflection, ukuqhutshwa kwe-thermal, izinga lokushisa elincibilikayo, nezinga lokushisa lokuhwamuka. Kuzo zonke izici, okubaluleke kakhulu izinga lokumunca.

Izinto ezimbili ezithinta izinga lokumuncwa kwento eyisigxobo se-laser. Eyokuqala yi-coefficient yokumelana yezinto. Kutholakala ukuthi izinga lokumunca lezinto ezibonakalayo lilingana nempande yesikwele ye-coefficient yokumelana, futhi i-coefficient yokumelana iyahlukahluka ngokushisa. Okwesibili, isimo esingaphezulu (noma sokuqeda) sezinto ezibonakalayo sinethonya elibalulekile ekufakweni kwe-beam, okunomthelela obalulekile kumphumela wokushisela.

5. Welding Speed

Isivinini se-welding sinethonya elikhulu ekujuleni kokungena. Ukwenyusa isivinini kuzokwenza ukujula kokungena kungabi ncane kakhulu, kodwa kuphansi kakhulu kuzoholela ekuncibilikeni ngokweqile kwezinto kanye ne-workpiece welding ngokusebenzisa. Ngakho-ke, kukhona ijubane elifanele lejubane lokushisela lempahla ethile enamandla athile e-laser nogqinsi oluthile, futhi ukujula kokungena okuphezulu kungatholwa ngenani elihambisanayo lesivinini.

6. Ubude bokugxila beLensi yokugxila

Ilensi yokugxila ivamise ukufakwa ekhanda lesibhamu esishiselayo, ngokuvamile, ubude bendawo obungu-63~254mm (ububanzi obungu-2.5 "~10") bukhethwa. Ubukhulu bendawo okugxilwe kuyo bulingana nobude bokugxila, uma ubude bendawo bufushane, ibala liba lincane. Kodwa-ke, ubude bobude obugxilile buphinde buthinte ukujula kokugxila, okungukuthi, ukujula kokugxila kukhula ngokuhambisana nobude bokugxila, ngakho ubude bokugxila obufushane bungathuthukisa ukuminyana kwamandla, kodwa ngenxa yokuthi ukujula kokugxila kuncane, ibanga eliphakathi kwelensi nendawo yokusebenza kufanele ligcinwe ngokunembile, futhi ukujula kokungena akukukhulu. Ngenxa yethonya lama-splashes kanye nemodi ye-laser ngesikhathi sokushisela, ukujula okugxilile okufushane okusetshenziswe ekushiseleni kwangempela ngokuvamile kungu-126mm (ububanzi obungu-5 "). Ilensi enobude obugxilwe obungu-254mm (ububanzi obungu-10 ") ingakhethwa uma umthungo mkhulu noma i-weld idinga ukunyuswa ngokwandisa usayizi wendawo. Kulokhu, amandla aphezulu okukhipha i-laser (ukuminyana kwamandla) ayadingeka ukuze kuzuzwe umphumela womgodi wokungena ojulile.

Imibuzo eyengeziwe mayelana nentengo yomshini we-laser welding kanye nokucushwa

Isikhathi sokuthumela: Sep-27-2022