Yini i-laser welding? I-Laser Welding vs arc welding? Ungakwazi yini i-laser weld aluminium (nensimbi engenacala)? Ngabe ufuna i-Laser Welder ethengiswayo evumelana nawe? Le ndatshana izokutshela ukuthi kungani i-Handheld Laser Welder ingcono ngezicelo ezahlukahlukene kanye nebhonasi yalo eyengeziwe yebhizinisi lakho, ngohlu olunemininingwane ye-rundown ukukusiza ekuthatheni izinqumo.

Kusha emhlabeni we-laser imishini noma umsebenzisi onamava wemishini ye-laser, enokungabaza ngokuthenga kwakho okulandelayo noma ukuthuthukiswa? Kuyakhathazeka ngoba i-Mimowr Laser yathola umhlane wakho, ngeminyaka engama-20 + yesipiliyoni se-laser, silapha ngemibuzo yakho futhi silungele imibuzo yakho.

Yini i-laser welding?

I-fiber Laser Welder iphatha ngesandla esikushoyo ngendlela ye-fusion welding. Ngokushisa okuhlanganisiwe nokukhulu okuvela ku-laser beam, insimbi eyingxenye iyancibilikisa noma i-vaporised, ukuhlangana nezinye izinto ngemuva kokupholisa insimbi nokuqina ukuze kwakhiwe i-welding ehlanganisiwe.

Uthi bewazi?

I-handheld laser welder ingcono kune-arc welder yendabuko futhi nakhu.

Uma kuqhathaniswa ne-arc welder yendabuko, i-laser welder ihlinzeka:

•Shonisaukusetshenziswa kwamandla

•Okuncane nje okufaneleIndawo ethintekile

•Kancane noma chaUkuguqulwa Kwezinto Ezibonakalayo

•Kuguqulwe futhi kulungileIndawo ye-Welding

•Hlanzaumphetho we-welding ngeakusekho okunyeIyacubungula Kudingeka

•-ZamasifushaneIsikhathi se-Welding -2 kuya ku-10izikhathi ngokushesha okukhulu

• I-EMITS REARCIAnce Light ngeakukho ukulimala

• imveloubungane

Izici ezibalulekile zomshini we-waser welder wesandla:

Isiphephe

Amagesi asetshenziswa kakhulu wokuvikela we-laser welding ikakhulukazi uN2, AR, futhi yena. Izakhiwo zazo ezingokomzimba nezamakhemikhali zihlukile, ngakho-ke imiphumela yazo kuma-welds nayo ihlukile.

Ukutholakala

Uhlelo lwe-welding oluphathwa ngesandla luhlome nge-compact laser welder, ukuhlinzeka lula nokuguquguquka ngaphandle kokuyekethisa, i-weld ingenziwa kalula futhi ukusebenza kwe-welding kuphezulu komugqa.

Kuqiza kahle

Ngokwezivivinyo ezenziwa ngabasebenza emasimini, inani le-Welding WELDIT ye-Waser Welding eyodwa lilingana nezindleko ezimbili zomshini womshini we-welding wendabuko.

Ukuvumelatgakata

I-Laser Welding Handheld ilula ukusebenza, ingalingenisa ishidi lensimbi elingagqwali, ishidi lensimbi, ishidi elenziwe ngezinsimbi nezinye izinto zensimbi.

Ukuqhubekela phambili

Ukuzalwa kwe-Handheld Laser Welder kungukuvuselelwa okukhulu kwezobuchwepheshe, futhi kungukuqala okunonya kwezixazululo ze-laserver yendabuko ye-laserder efana ne-Argon arc

Izinto ezisetshenziselwa ukusetshenziselwa i-laser welding - izici namathiphu:

Lolu uhlu lwezinto zokwakha ezisetshenziselwa ukufudumala i-laser, kwezinye izici ezijwayelekile nezimpawu zezinto zokwakha ngokuningiliziwe kanye namathiphu akho okuthola imiphumela engcono yokufudumeza.

Insimbi engagqwali

I-coefficion ethe xaxa yensimbi engenasici iphakeme ngakho-ke i-stain-steel-nsimbi yomsebenzi kulula ukuyifaka ngokweqile lapho i-welding ngezixazululo ze-welding yendabuko, indawo ethintekile yokushisa iyizinkinga ezimbi kakhulu. Kodwa-ke, ngokusebenzisa umshini we-welding we-waser we-waser welding uxazulula izinkinga eziningi ngangokunokwenzeka kwinqubo yonke ye-welding ekhiqizwayo iphansi, kuhlanganiswe neqiniso lokuthi insimbi engenasici inokuvuselelwa okuphansi okushisayo, ukumuncwa kwamandla okuphezulu nokuncipha kanye nokusebenza kahle kokuncibilika. I-Weld eyakhiwe kahle, ebushelelezi ingatholakala ngemuva kokufudumala kalula.

Insimbi yekhabhoni

I-Handheld Laser Welder ingasetshenziswa ngqo ngensimbi ejwayelekile yekhabhoni, umphumela uqhathaniswa ne-Insimbi Laser Welding, ngenkathi indawo ethinta ukushisa yensimbi ekhanwini incane kakhulu, kepha ngesikhathi sokushisa se-welding, izinga lokushisa eliyinsalela liphezulu, ngakho-ke Kuyasadingeka ukuthi kufezeke ucezu lomsebenzi ngaphambi kokufudumeza okuhambisana nokulondolozwa kokushisa ngemuva kokuqeda ukuqeda ingcindezi ukugwema ukuqhekeka.

I-Aluminium ne-Aluminium Alloys

I-Aluminium ne-Aluminium Alloy yizinto ezibonakalayo ezibonakalayo, futhi kungenzeka kube nezinkinga ze-porolity endaweni ye-welding noma impande yengcezu yomsebenzi. Uma kuqhathaniswa nezinto zokwenziwa zensimbi ezedlule, i-aluminium ne-aluminium alloy zizoba nezidingo eziphakeme zokuhlelwa kwamapharamitha kwemishini, kepha inqobo nje uma amapharamitha akhethiwe we-welding efanelekile, ungathola i-weld nge-mehendi yensimbi elilinganayo.

Ama-alloys we-Copper neCopper

Imvamisa, lapho usebenzisa isixazululo se-welding yendabuko, izinto zethusi zizoshukunyiswa kwinqubo ye-welding ukusiza ukuthukuthela ngenxa yokuvuselelwa okuphezulu okukhona, okukhona ngokungafanele kungahle kuholele ekuhlolweni okungaphelele, okungekho emthethweni kanye neminye imiphumela engafuneki ngesikhathi sokufudumala. Ngokuphambene nalokho, i-Laser Welder ephethwe ngesandla ingasetshenziselwa ngqo i-Welding Copper kanye ne-Alloys yethusi ngaphandle kwezinkinga ngenxa yamakhono okuqashwa kwamandla okwedlulele kanye nejubane le-welding elisheshayo le-laserder ye-laserder.

Ukufa kwensimbi

Umshini we-welding we-laser we-laser we-laser ungasetshenziselwa izinhlobonhlobo ezahlukahlukene zensimbi efa, futhi umphumela we-welding uhlala ehlangana.

I-waser ye-waser ye-Handheld yethu enconyiwe:

I-Laser Welder - Indawo Yokusebenza

◾ Uhla lokushisa lwemvelo yokusebenza: 15 ~ 35 ℃

◾ Uhla lomswakama lwendawo yokusebenza yendawo yokusebenza: <70% akukho ukuguqulwa

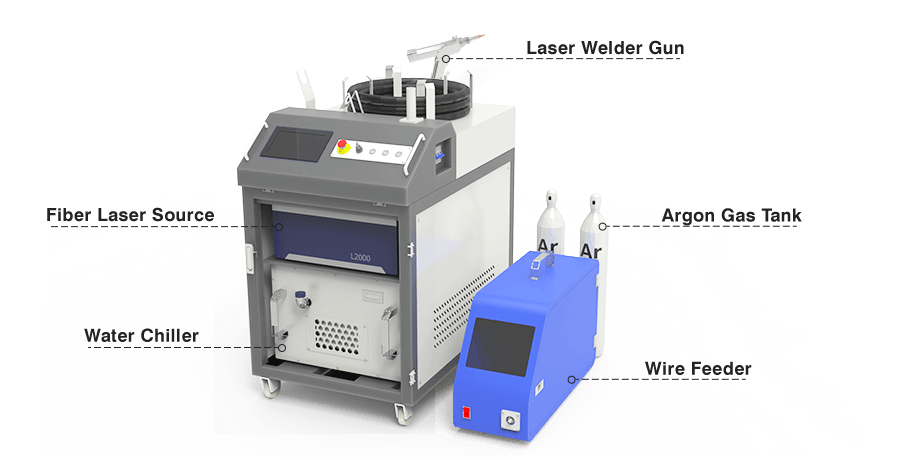

◾ Ukupholisa: I-Water chiller iyadingeka ngenxa yomsebenzi wokususa ukushisa kwezinto zokuhlambalaza ama-laser, uqinisekise ukuthi i-laser welder isebenza kahle.

(Ukusetshenziswa okuningiliziwe kanye nokuqondisa mayelana ne-Water Chiller, ungabheka:Izindlela zokufakazela iqhwa zohlelo lweCo2 Laser)

Wanna wazi kabanzi nge-laser welders?

Isikhathi Sokuposa: Dec-09-2022