Isebenza Kanjani I-CO2 Laser: Incazelo Efingqiwe

I-CO2 laser isebenza ngokusebenzisa amandla okukhanya ukusika noma ukuqopha izinto ngokunemba. Nakhu ukuhlukaniswa okwenziwe lula:

Inqubo iqala ngokukhiqizwa kwe-laser enamandla amakhulu. Kulaser CO2, lo msebe ukhiqizwa igesi ye-carbon dioxide ethokozisayo enamandla kagesi.

I-laser beam ibe iqondiswa ngochungechunge lwezibuko ezikhulisayo futhi zigxile ekukhanyeni okugxilile, okunamandla aphezulu.

I-laser beam egxilile iqondiswe endaweni ebonakalayo, lapho ihlangana khona nama-athomu noma ama-molecule. Lokhu kusebenzisana kubangela ukuthi okokusebenza kushise ngokushesha.

Ukuze usike, ukushisa okunamandla okukhiqizwa i-laser kuyancibilika, kushise, noma kuhwamulise into, kwakheka ukusika okunembayo endleleni ehleliwe.

Ukuze uqoshwe, i-laser isusa izendlalelo zezinto, idale umklamo obonakalayo noma iphethini.

Okwenza amalaser e-CO2 ahluke yikhono lawo lokuletha le nqubo ngokunemba okukhethekile nangesivinini, okuwenza abe yigugu ezilungiselelweni zezimboni zokusika izinto ezihlukahlukene noma ukwengeza imininingwane eyinkimbinkimbi ngokuqoshwa.

Empeleni, i-CO2 laser cutter ihlanganisa amandla okukhanya ukuze iqophe izinto ngokunemba okumangalisayo, inikeze isisombululo esisheshayo nesinembayo sokusika izimboni nokuqopha izinhlelo zokusebenza.

Isebenza Kanjani I-CO2 Laser?

Isifinyezo esifushane sale vidiyo

Abasiki be-laser yimishini esebenzisa isibani esinamandla sokukhanya kwe-laser ukusika izinto ezahlukahlukene. I-laser beam ikhiqizwa into ethokozisayo, efana negesi noma ikristalu, ekhiqiza ukukhanya okugxilile. Khona-ke iqondiswa ngochungechunge lwezibuko namalensi ukuze igxile endaweni eqondile futhi eqinile.

I-laser egxilile ingahwamuka noma incibilikise into ehlangana nayo, ivumele ukusikeka okunembile nokuhlanzekile. Abasiki be-laser bavame ukusetshenziswa ezimbonini ezinjengokukhiqiza, ubunjiniyela, kanye nobuciko bokusika izinto ezifana nokhuni, insimbi, ipulasitiki, nendwangu. Banikeza izinzuzo ezifana nokunemba okuphezulu, isivinini, ukuguquguquka, kanye nekhono lokudala imiklamo eyinkimbinkimbi.

Isebenza Kanjani I-CO2 Laser: Incazelo Eningiliziwe

1. Isizukulwane se-Laser Beam

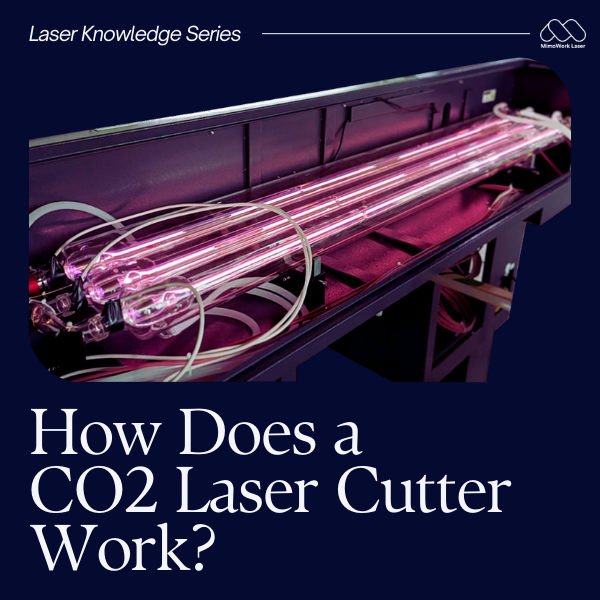

Enhliziyweni yawo wonke umsiki we-laser we-CO2 kuneshubhu le-laser, eligcina inqubo ekhiqiza i-laser enamandla amakhulu. Ngaphakathi kwegumbi legesi elivaliwe leshubhu, ingxube ye-carbon dioxide, i-nitrogen ne-helium gases inikezwa amandla ngokuphuma kukagesi. Uma le ngxube yegesi ijabule ngale ndlela, ifinyelela esimweni samandla aphezulu.

Njengoba ama-molecule egesi ajabulile ephumula abuyele ezingeni eliphansi lamandla, akhulula ama-photon okukhanya kwe-infrared anobude obukhethekile begagasi. Lokhu kusakazwa kwemisebe ye-infrared ehambisanayo yikho okwenza ugongolo lwe-laser olukwazi ukusika nokuqopha izinto ezihlukahlukene ngokunembile. Ilensi yokugxilisa ibe isilolonga ukuphuma kwe-laser enkulu ibe indawo yokusika ewumngcingo ngokunemba okudingekayo emsebenzini oyinkimbinkimbi.

2. Ukukhulisa i-Laser Beam

I-CO2 Laser Cutter Izohlala Isikhathi Esingakanani?

Ngemuva kokukhiqizwa kokuqala kwama-infrared photon ngaphakathi kweshubhu le-laser, ugongolo lube seludlulela kunqubo yokukhulisa amandla ukuze lukhulise amandla awo kumazinga okusika awusizo. Lokhu kwenzeka njengoba ugongolo ludlula izikhathi eziningi phakathi kwezibuko ezikhanya kakhulu ezifakwe ekugcineni kwegumbi legesi. Ngokuhamba ngakunye nokubuya, ama-molecule egesi amaningi ajabulile azofaka isandla ensimini ngokukhipha ama-photon avumelanisiwe. Lokhu kubangela ukukhanya kwe-laser ukuthi kukhule ngamandla, okuholela ekukhiqizweni okukhulu ngokuphindwe ngezigidi kunokokuqala okukhuthaziwe.

Uma isikhuliswe ngokwanele ngemva kokuboniswa kwesibuko okuningi, i-infrared beam egxilile iphuma eshubhu isilungele ukusika noma ukuqopha izinto ezihlukahlukene. Inqubo yokukhulisa i-amplification ibalulekile ekuqiniseni i-beam kusukela ekukhishweni kwezinga eliphansi kuya emandleni aphezulu adingekayo ekufakeni izicelo zokwenziwa kwezimboni.

3. Isibuko System

Indlela Yokuhlanza Futhi Ufake I-Laser Focus Lens

Ngemuva kokukhulisa ngaphakathi kweshubhu le-laser, i-infrared beam eqinile kufanele iqondiswe ngokucophelela futhi ilawulwe ukuze ifeze injongo yayo. Yilapho uhlelo lwesibuko lufeza indima ebalulekile. Ngaphakathi kwe-laser cutter, uchungechunge lwezibuko eziqondaniswe ngokunemba zisebenza ukudlulisa i-amplified laser beam endleleni yokubona. Lezi zibuko zenzelwe ukugcina ukuhambisana ngokuqinisekisa ukuthi wonke amagagasi asesigabeni, ngaleyo ndlela alondoloze ukungqubuzana nokugxila kwe-beam njengoba ihamba.

Kungakhathaliseki ukuthi iqondisa i-beam ezintweni ezihlosiwe noma ukuyibuyisela emuva kushubhu elizwakalayo ukuze ikhulise ngokwengeziwe, isistimu yesibuko idlala indima ebalulekile ekuletheni ukukhanya kwe-laser lapho idinga ukuya khona. Indawo yayo ebushelelezi kanye nokuma kwayo okuqondile okuhlobene nezinye izibuko yikho okuvumela ugongolo lwe-laser ukuthi lusetshenziswe futhi lulolongelwe imisebenzi yokusika.

4. Ilensi yokugxila

Thola Ubude be-Laser Focal Ngaphansi Kwamaminithi angu-2

Ingxenye yokugcina ebalulekile endleleni yokubona ye-laser cutter ilensi yokugxilisa ingqondo. Le lensi eklanywe ngokukhethekile iqondisa ngokunembile isigxobo se-laser esithuthukisiwe esihambe ngohlelo lwesibuko sangaphakathi. Yenziwe ngezinto eziyisipesheli njenge-germanium, ilensi iyakwazi ukuhlanganisa amaza e-infrared ishiya ishubhu elikhalayo elinephuzu elincane kakhulu. Lokhu kugxila okuqinile kwenza i-beam ifinyelele amandla okushisa ebanga lokushisela adingekayo ezinqubweni ezihlukahlukene zokwenziwa.

Noma ngabe ukushaya amaphuzu, ukuqopha, noma ukusika ezintweni eziminyene, ikhono lokugxilisa amandla e-laser ngokunemba kwesikali se-micron yikhona okuletha ukusebenza okuguquguqukayo. Ngakho-ke ilensi yokugxila idlala indima ebalulekile yokuhumusha amandla amakhulu omthombo we-laser ibe ithuluzi lokusika lezimboni elisebenzisekayo. Idizayini yayo nekhwalithi ephezulu ibalulekile ekuphumeni okunembile nokuthembekile.

5-1. Ukusebenzisana Kwezinto: Ukusika kwe-Laser

I-Laser Cut 20mm Eminyene ye-Acrylic

Ngezinhlelo zokusebenza zokusika, i-laser beam egxile ngokuqinile iqondiswe ezintweni eziqondiwe, ngokuvamile amashidi ensimbi. Imisebe ye-infrared enamandla imuncwa insimbi, ibangele ukushisa ngokushesha phezulu. Njengoba ingaphezulu lifinyelela emazingeni okushisa adlula indawo yokubilisa yensimbi, indawo encane yokusebenzisana iyahwamuka ngokushesha, isuse izinto ezigxilile. Ngokudabula i-laser ngamaphethini ngokulawula ikhompuyutha, umumo ophelele uyasikwa kancane kancane ukusuka kumashidi. Ukusika okunembayo kuvumela izingxenye eziyinkimbinkimbi ukuthi zenzelwe izimboni ezinjengezezimoto, i-aerospace kanye nezokukhiqiza.

5-2. Ukusebenzisana Kwezinto: I-Laser Engraving

Isifundo se-LightBurn sokuqoshwa kwesithombe

Lapho wenza imisebenzi yokuqopha, umqophi we-laser ubeka indawo okugxilwe kuyo ezintweni, ngokuvamile ukhuni, ipulasitiki noma i-acrylic. Esikhundleni sokusika ngokugcwele, amandla amancane asetshenziselwa ukuguqula izingqimba ezingaphezulu ngokushisa. Imisebe ye-infrared inyusa amazinga okushisa angaphansi kwendawo yokuhwamuka kodwa aphezulu ngokwanele ukuze ashise noma akhiphe umbala. Ngokuguqula ngokuphindaphindiwe i-laser ibe yivula noma uyivale ngenkathi i-rastering ngamaphethini, izithombe ezingaphezulu ezilawulwayo ezifana namalogo noma imiklamo zishiswa zibe okokusebenza. Ukuqoshwa okuhlukahlukene kuvumela ukumaka nokuhlobisa unomphela ezinhlobonhlobo zezinto.

6. Ukulawula Ikhompyutha

Ukwenza imisebenzi ye-laser enembayo, umsiki uncike kulawulo lwezinombolo lwekhompyutha (CNC). Ikhompuyutha esebenza kahle kakhulu elayishwe isofthiwe ye-CAD/CAM ivumela abasebenzisi ukuthi badizayine izifanekiso eziyinkimbinkimbi, izinhlelo, nokugeleza komsebenzi wokukhiqiza wokucubungula nge-laser. Ngethoshi le-acetylene elixhunyiwe, ama-galvanometers, kanye nokuhlanganiswa kwamalensi okugxilile - ikhompuyutha ingaxhumanisa ukunyakaza kwe-laser beam kuzo zonke izinto zokusebenza ngokunemba kwe-micrometer.

Ukuthi ulandela izindlela zevekhtha ezidizayinelwe umsebenzisi zokusika noma ukurasha izithombe ze-bitmap ukuze ziqoshwe, impendulo yendawo yesikhathi sangempela iqinisekisa ukuthi i-laser isebenzisana nezinto njengoba kucaciswe ngokwedijithali. Ukulawula ikhompuyutha kwenza amaphethini ayinkimbinkimbi ngeke akwazi ukuziphindaphinda mathupha. Yandisa kakhulu ukusebenza kwe-laser kanye nokuguquguquka kwezinhlelo zokusebenza zokukhiqiza ezincane ezidinga ukwenziwa kokubekezela okuphezulu.

I-Cutting Edge: Yini Engenziwa I-CO2 Laser Cutter?

Esimeni esiguqukayo njalo sokukhiqiza nobungcweti besimanje, i-CO2 laser cutter ivela njengethuluzi eliguquguqukayo nelibaluleke kakhulu. Ukunemba kwayo, isivinini, kanye nokuvumelana nezimo kuye kwashintsha indlela izinto ezibunjwa ngayo neziklanywe ngayo. Omunye wemibuzo ebalulekile abathanda, abadali, kanye nezingcweti zemboni abavame ukuzindla ngayo uthi: Yini ngempela isinqamu se-laser ye-CO2 esingasikwa?

Kulokhu kuhlola, siqaqa izinto ezihlukile ezivumela ukunemba kwelaser, siphushe imingcele yalokho okungenzeka endaweni yokusika nokuqopha. Hlanganyela nathi njengoba sizulazula kunxanxathela yezinto ezikhothamela amandla e-CO2 laser cutter, ukusuka kuma-substrates avamile ukuya kwezinye izinketho ezingavamile, ukuveza amakhono aphambili achaza lobu buchwepheshe obuguqulayo.

>> Bheka Uhlu Oluphelele Lwezinto Zokusebenza

Nazi Izibonelo Ezithile:

(Chofoza izihlokwana ukuze uthole ulwazi olwengeziwe)

Njenge-classic ehlala njalo, i-denim ayikwazi ukubhekwa njengomkhuba, ayisoze yangena futhi iphuma emfashini. Izakhi ze-denim bezilokhu ziyindikimba yokuklama yakudala yemboni yezingubo, ethandwa kakhulu ngabaklami, izingubo ze-denim yizona kuphela isigaba sezingubo ezithandwayo ngaphezu kwe-suit. Ukugqoka i-jeans, ukuklebhula, ukuguga, ukufa, ukubhoboza kanye nezinye izinhlobo zokuhlobisa ziyizimpawu zokunyakaza kwe-punk, ne-hippie. Ngezincazelo ezihlukile zamasiko, idenim kancane kancane yaduma phakathi nekhulu leminyaka futhi kancane kancane yathuthuka yaba isiko lomhlaba wonke.

I-Galvo Laser Engraver Eshesha Kakhulu Ye-Laser Engraving Heat Transfer Vinyl izokutholela igxathu elikhulu ekukhiqizeni! Ukusika i-vinyl nge-laser engraver kuwumkhuba wokwenza izesekeli zezingubo, namalogo ezingubo zemidlalo. Ijubane eliphezulu, ukunemba okuphelele kokusika, nokuhambisana kwezinto ezihlukahlukene, ikusiza ngefilimu yokudlulisa ukushisa okusika nge-laser, amadeli anqunyiwe we-laser, izinto zokusika ze-laser, ifilimu yokusika ye-laser, noma okunye. Ukuze uthole umphumela omuhle we-vinyl wokusika, umshini wokuqopha we-CO2 galvo laser uwumdlalo ongcono kakhulu! Ngokungakholakali yonke i-laser cutting htv ithathe imizuzwana engu-45 kuphela ngomshini wokumaka we-galvo laser. Sibuyekeze umshini futhi sagxuma ngokusika nokuqopha ukusebenza.

Kungakhathaliseki ukuthi ufuna isevisi yokusika i-laser yegwebu noma ucabanga ukutshala imali kusisiki se-laser eyigwebu, kubalulekile ukwazi okwengeziwe ngobuchwepheshe belaser ye-CO2. Ukusetshenziswa kwezimboni kwegwebu kubuyekezwa njalo. Imakethe yegwebu yanamuhla yakhiwe ngezinto eziningi ezahlukahlukene ezisetshenziswa ezinhlobonhlobo zezicelo. Ukusika igwebu elinomthamo omkhulu, imboni iya ngokuya ithola ukuthi i-laser cutter ifaneleka kakhulu ukusika nokuqopha amagwebu enziwe nge-polyester (PES), i-polyethylene (PE), noma i-polyurethane (PUR). Kwezinye izinhlelo zokusebenza, ama-laser anganikeza enye indlela emangazayo ezindleleni zokucubungula zendabuko. Ngaphezu kwalokho, igwebu elinqunyiwe le-laser libuye lisetshenziswe ezinhlelweni zobuciko, njengezikhumbuzo noma ozimele bezithombe.

Ungakwazi yini ukusika i-plywood nge-laser? Yebo yebo. I-plywood ifaneleka kakhulu ukusika nokuqopha ngomshini wokusika we-laser we-plywood. Ikakhulukazi ngokwemininingwane ye-filigree, ukucutshungulwa kwe-laser okungaxhunywanga kuyisici sayo. Amapaneli e-Plywood kufanele alungiswe etafuleni lokusika futhi asikho isidingo sokuhlanza udoti nothuli endaweni yokusebenza ngemva kokusika. Phakathi kwazo zonke izinto zokhuni, i-plywood iyindlela ekahle yokukhetha ngoba inezimfanelo eziqinile kodwa ezingasindi futhi iyindlela ethengekayo kumakhasimende kunezingodo eziqinile. Ngamandla e-laser amancane adingekayo, ingasikwa njengogqinsi olufanayo lokhuni oluqinile.

Isebenza Kanjani I-CO2 Laser Cutter: Ekuphetheni

Kafushane, amasistimu okusika i-CO2 laser asebenzisa ubunjiniyela obunembayo nezindlela zokulawula ukuze asebenzise amandla amakhulu esibani se-infrared laser ekwenzeni izimboni. Emgogodleni, ingxube yegesi inikwa amandla ngaphakathi kweshubhu elizwakalayo, ikhiqize ukusakazwa kwama-photon akhuliswa ngokuboniswa kwezibuko ezingenakubalwa. Ilensi yokugxilisa ingqondo ibe ishaneli le nsimbi eqinile ibe iphoyinti elincane kakhulu elikwazi ukuxhumana nezinto ezisezingeni lamangqamuzana. Kuhlanganiswe nokunyakaza okuqondiswe ngekhompuyutha ngama-galvanometers, amalogo, umumo, ngisho nezingxenye zonke zingaqoshwa, ziqoshwe noma zisikwe ezimpahleni zeshidi ngokunemba kwesikali se-micron. Ukuqondanisa kahle kanye nokulinganiswa kwezingxenye ezifana nezibuko, amashubhu kanye ne-optics kuqinisekisa ukusebenza kwe-laser okuphelele. Sekukonke, impumelelo yezobuchwepheshe engena ekulawuleni i-laser enamandla amakhulu yenza amasistimu e-CO2 asebenze njengamathuluzi ezimboni asebenza ngezindlela ezihlukahlukene ngokuphawulekayo kuzo zonke izimboni eziningi zokukhiqiza.

Ungalungiseleli Noma Yini Engaphansi Kokukhethekile

Invest in the Best

Isikhathi sokuthumela: Nov-21-2023