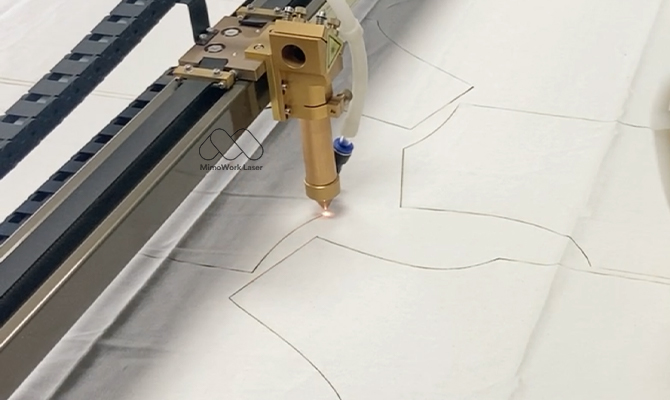

Ama-CO2 Laser cutters ngamatafula okuhambisa ngokuzenzakalelayo alungele kakhulu ukusika izindwangu ngokuqhubekayo. Ngokuqondene,Okuhlanzekile, UKEVLAR, injobe, Indwangu engalukiwe, nokunyeizindwangu zobuchwepheshe zisikwa ngama-lasers kahle nangokufanele. Ukusika kwe-laser okungenamsoco ukwelashwa okugxiliswe kunamandla okushisa, ama-facrators amaningi akhathazeka nge-laser ukusika izindwangu ezimhlophe angahlangana nemiphetho evuthayo onsomi futhi abe nomphumela obalulekile ekucutshungweni okulandelayo. Namuhla, sizokufundisa amaqhinga ambalwa wokuthi ungakugwema kanjani ukushiswa ngokweqile ngendwangu yombala okhanyayo.

Izinkinga ezijwayelekile ezinezindwangu zokusika ze-laser

Uma kukhulunywa ngezindwangu zokusika ama-laser, kukhona umhlaba wonke wendwangu laphaya - ngokwemvelo, zokwenziwa, olekiwe, noma osokiwe. Uhlobo ngalunye luletha ama-quirks alo angathinta isipiliyoni sakho sokusika. Uma usebenza ukotini omhlophe noma izindwangu ezikhanyayo, ungahlangabezana nezinselelo ezithile. Nazi izinkinga ezimbalwa ezijwayelekile ongabhekana nazo:

Qala >> Kuphuzi futhi kuncishisiwe:Ukusika kwe-laser kwesinye isikhathi kungaholela emaphethelweni aphuzi angenangqondo, abonakale ikakhulukazi izindwangu ezimhlophe noma ezikhanyayo.

>> Imigqa yokusika engalingani:Akekho ofuna imiphetho emibi! Uma indwangu yakho inganqunywa ngokulinganayo, ingaphonsa konke ukubukeka kwephrojekthi yakho.

Qala >> Amaphethini wokusika onama-notched:Kwesinye isikhathi, i-laser ingadala ama-notches endwangu yakho, engathinta ama-aesthetics nokusebenza.

Ngokwazi lezi zinkinga, ungalungiselela kangcono futhi uguqule indlela osebenzisa ngayo, uqinisekise inqubo yokunciphisa ama-laser. Ukusika okujabulisayo!

Ungayixazulula kanjani?

Uma ubhekene nezinselelo ngenkathi izindwangu zokusika ze-laser, ungakhathazeki! Nazi ezinye izixazululo eziqondile ukukusiza ukufezekisa ukusikeka okuhlanzekile nemiphumela engcono:

▶ Amandla we-Lungisa nesivinini:Imiphetho evuthayo futhi evuthayo imvamisa ivela kuzilungiselelo zamandla angalungile. Uma amandla akho we-laser ephezulu kakhulu noma ijubane lakho lokusika lihamba kancane, ukushisa kungashisa indwangu. Ukuthola ibhalansi efanelekile phakathi kwamandla nejubane kunganciphisa kakhulu leyo mikhuba e-pesky nsundu.

▶ Thuthukisa ukukhishwa kwentuthu:Uhlelo olunamandla lokuphelelwa amandla lubalulekile. Intuthu iqukethe izinhlayiya ezincane zamakhemikhali ezinganamathela endwangu yakho futhi zibangele ophuzi lapho zivuselela. Qiniseka ukuthi ususa intuthu ngokushesha ukuze ugcine indwangu yakho ihlanzekile futhi igqamile.

▶ Hambisa ukucindezela komoya:Ukushintsha ingcindezi ye-Air Blower yakho kungenza umehluko omkhulu. Ngenkathi kusiza ukuqhuma intuthu, ingcindezi enkulu ingakhipha izindwangu ezibucayi. Thola lelo ndawo emnandi yokusika okusebenzayo ngaphandle kokulimaza impahla yakho.

▶ Bheka itafula lakho lokusebenza:Uma ubona imigqa yokusika engalingani, ingaba ngenxa yetafula elisebenzayo elisebenzayo. Izindwangu ezithambile nezikhanyayo zizwela ikakhulukazi kulokhu. Hlola njalo ithafa lethebula lakho ukuze uqinisekise ukusikeka okungaguquki.

Gcina indawo yokusebenza ihlanzekile:Uma ubona izikhala ekusikekeni kwakho, ukuhlanza ithebula lokusebenza kumele. Ngaphezu kwalokho, cabanga ukwehlisa ukusetha kwamandla okuphansi ukunciphisa amandla okusika emakhoneni, kusiza ukudala imiphetho ehlanzekile.

Ngala mathiphu engqondweni, uzobhekana nezindwangu zokusika ze-laser njenge-pro! I-Happy Crafting!

Sincoma ngobuqotho ukuthi ubheke izeluleko ezengeziwe zochwepheshe ngokusika nokuqopha kwezindwangu kusuka eMimowork Laser ngaphambi kokutshala imali yomshini we-CO2 laser kanye neyethuIzinketho ezikhethekileukucutshungulwa kwezindwangu ngqo kusuka ku-roll.

Yini i-Value engezelwe i-Mimowork CO2 laser Cutter ekucushweni kwezindwangu?

◾ imfucumfucu engaphansi ngenxaIsoftware yokuhlanganisa

◾Amatafula okusebenzaamasayizi ahlukene asiza ukucubungula amafomethi ahlukahlukene wezindwangu

◾IkhameraukukhumbulaNgokusika ama-laser wezindwangu eziphrintiwe

◾ OkuhlukileUkumakwa kwezintoImisebenzi nge-Mark Pen ne-Ink-jet module

◾Uhlelo Lokuhambisangokusika okuzenzakalelayo kwe-laser ngokugcwele kusuka ngqo kusuka ku-roll

◾Auto-federKulula ukondla izinto zokugoqa etafuleni elisebenzayo, bushelelezi ukukhiqizwa kanye nokusindisa izindleko zabasebenzi

◾ Ukusika kwe-laser, okuqoshwe (ukumaka), kanye nokufaka okukodwa kuyabonakala ngenqubo eyodwa ngaphandle kwamathuluzi okushintsha

Funda kabanzi ngendwangu ye-Laser Cutter kanye nomhlahlandlela wokusebenza

Isikhathi sePosi: Sep-07-2022