Iyini i-Laser Welding?

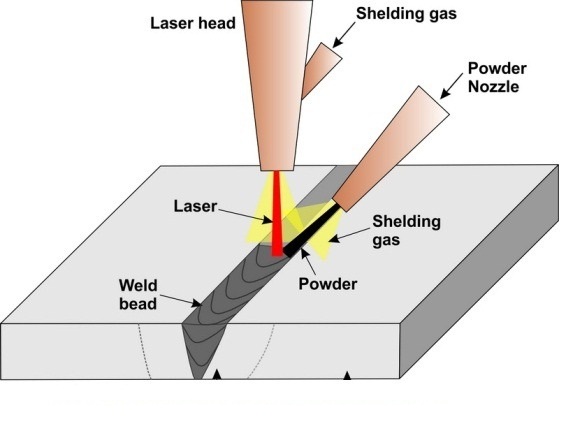

Ukusetshenziswa komshini wokushisela we-laser welding metal workpiece, i-workpiece idonsa i-laser ngokushesha ngemva kokuncibilika kanye nokufakwa kwegesi, insimbi encibilikisiwe ngaphansi kwesenzo sokucindezela umusi ukuze kwakhiwe imbobo encane ukuze ugongolo lwe-laser lukwazi ukudalulwa ngqo phansi embobeni ukuze imbobo iqhubeke nokunwebeka kuze kube yilapho ingcindezi ye-steam ngaphakathi kwembobo kanye nokuqina kwensimbi okuwuketshezi kanye namandla adonsela phansi kufinyelela ibhalansi.

Le modi yokushisela inokujula okukhulu kokungena kanye nesilinganiso esikhulu sobubanzi bobubanzi. Lapho imbobo ilandela ugongolo lwe-laser eduze nendawo yokushisela, insimbi encibilikisiwe ephambi komshini wokushisela we-laser idlula umgodi bese igeleza iye ngemuva, futhi ukushisela kwakheka ngemva kokuqina.

Operation Guide mayelana Laser Welding

▶ Ukulungiselela ngaphambi kokuqala i-laser welder

1. Hlola amandla e-laser kanye nomthombo kagesi womshini wokushisela we-laser

2. Hlola ukuthi i-chiller yamanzi yezimboni engashintshi isebenza ngendlela evamile

3. Hlola ukuthi ithubhu legesi elisizayo ngaphakathi komshini wokushisela livamile

4. Hlola indawo yomshini ngaphandle kothuli, i-spekle, amafutha, njll

▶ Ukuqala umshini wokushisela we-laser

1. Vula ukunikezwa kwamandla bese uvula iswishi yamandla eyinhloko

2. Vula i-cooler yamanzi ehlala njalo yezimboni kanye ne-fiber laser generator

3. Vula i-argon valve bese ulungisa ukugeleza kwegesi ezingeni elifanele lokugeleza

4. Khetha amapharamitha alondolozwe ohlelweni lokusebenza

5. Yenza i-laser welding

▶ Ukucisha umshini wokushisela nge-laser

1. Phuma ohlelweni lokusebenza bese uvala ijeneretha ye-laser

2. Vala okokupholisa amanzi, isikhiphi somusi, nezinye izinto ezisizayo ngokulandelana kwazo

3. Vala umnyango we-valve we-argon cylinder

4. Vala iswishi yamandla eyinhloko

Ukunakwa kwe-Laser Welder

I-Handheld Laser Welding Operation

1. Ngesikhathi sokusebenza komshini wokushisela we-laser, njengesimo esiphuthumayo (ukuvuza kwamanzi, umsindo ongavamile, njll.) kudingeka ucindezele ngokushesha isitobhi esiphuthumayo futhi unqamule ngokushesha ukunikezwa kwamandla.

2. Ukushintsha kwamanzi okujikeleza kwangaphandle kwe-laser welding kufanele kuvulwe ngaphambi kokusebenza.

3. Ngenxa yokuthi isistimu ye-laser ipholiswe ngamanzi futhi amandla kagesi e-laser apholile emoyeni uma uhlelo lokupholisa luhluleka, kwenqatshelwe ngokuphelele ukuqala umsebenzi.

4. Ungaqedisi noma yiziphi izingxenye emshinini, ungashiseli lapho umnyango wokuphepha komshini uvulwa, futhi ungabheki ngqo i-laser noma ubonise i-laser lapho i-laser isebenza ukuze ungalimazi amehlo.

5. Izinto ezivuthayo neziqhumayo akufanele zibekwe endleleni ye-laser noma indawo lapho ugongolo lwe-laser lungakhanyiswa khona, ukuze lungabangeli umlilo nokuqhuma.

6. Ngesikhathi sokusebenza, isifunda sisesimweni se-voltage ephezulu kanye namandla amanje. Akuvunyelwe ukuthinta izingxenye zesifunda emshinini lapho usebenza.

Imibuzo Evame Ukubuzwa

Ukulungiselela kahle kuqinisekisa ukushiselwa kwe-laser okuphephile, okubushelelezi. Nakhu okumele ukuhlole:

Amandla Nokupholisa:Hlola ukunikezwa kwamandla nge-laser, uxhumo lukagesi, kanye nesiqandisi samanzi (okupholile kufanele kugeleze).

Igesi nokugeleza komoya:Hlola i-argon gas tubes ukuze uthole ukuvinjelwa; setha ukugeleza kumazinga anconyiwe.

Ukuhlanzeka komshini:Sula uthuli/uwoyela emshinini—imfucumfucu ibeka engcupheni amaphutha noma ukushisa ngokweqile.

Amasistimu wokupholisa awekho abalulekile ekuphepheni nasekusebenzeni kwe-laser welder.

Ingozi yokushisa ngokweqile:Ama-Lasers akhiqiza ukushisa okukhulu; amasistimu okupholisa (amanzi/igesi) avimbela ukutubeka.

Ukuncika Kwesistimu:Imithombo yamandla e-laser incike ekupholiseni—ukwehluleka kubangela ukuvala shaqa noma ukulimala.

Ukuphepha Kuqala:Ngisho “nezindawo zokushisela ezisheshayo” zidinga ukupholiswa—ukukuziba kugwema iziqinisekiso futhi kubeke engozini izingozi.

I-Argon gas ivikela ukushisela ekungcoleni, iqinisekisa ikhwalithi.

Umphumela Wokuvikela:I-Argon isusa umoya-mpilo, imise ama-welds ekugqwaleni noma ekuthuthukiseni imiphetho enezimbotshana.

Ukuzinza kwe-Arc:Ukugeleza kwegesi kuzinzisa ugongolo lwe-laser, kunciphisa isipatha nokuncibilika okungalingani.

Ukuhambisana Kwezinto:Ibalulekile ezinsimbi (isb., insimbi engagqwali, i-aluminium) ethambekele ekubeni ne-oxidation.

Funda kabanzi mayelana nesakhiwo kanye nomgomo we-laser welder ephathwayo

Isikhathi sokuthumela: Aug-11-2022