Kiss cuttingiyindlela yokusika esetshenziswa ezimbonini ezahlukahlukene, njengokuphrinta nokukhiqiza.

Kubandakanya ukusika ungqimba olungaphezulu lwempahla, ngokuvamile ungqimba olungaphezulu oluncane, ngaphandle kokusika izinto ezisekelayo.

Igama elithi "kiss" ekusikeni ngokuqabula libhekisela eqinisweni lokuthi i-blade yokusika noma ithuluzi lithintana kancane nempahla, efana nokuyinika "ukuqabula."

Le nqubo ivamise ukusetshenziselwa ukwenza izitika, amalebula, ama-decal, noma amaphethini ayinkimbinkimbi lapho ungqimba olungaphezulu ludinga ukusikwa ngenkathi ishiya isekela linjalo.

Ukusika i-Kiss kuyindlela eqondile eqinisekisa ukuthi impahla isikwa ngokuhlanzekile ngaphandle kokulimaza i-substrate engaphansi.

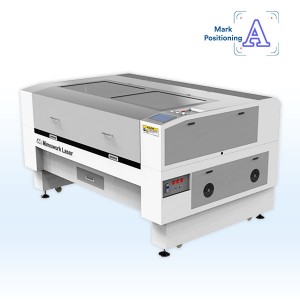

Ukusika i-laser kiss kuyindlela enembile futhi eguquguqukayo yokusika esebenzisa i-laser ukusika ungqimba olungaphezulu lwento ngaphandle kokusika izinto ezisekelayo.

Kungukuhluka kokusikwa kokuqabula, okubandakanya ukusika ngaphandle kokungena ku-substrate.

Ekusikeni kokuqabula nge-laser, i-laser beam egxilile isetshenziselwa ukwenza ukusikeka okunembe kakhulu, futhi ivamise ukusetshenziselwa ukusika izinto ezinamathelayo ezifana nezitikha, amalebula, namadekali.

Ukuqina kwe-laser kulawulwa ukuze kuqinisekiswe ukuthi inqamula isendlalelo esingaphezulu ngenkathi ishiya isekela lingathintwa.

Le ndlela ivame ukusetshenziswa ezimbonini lapho imiklamo eyinkimbinkimbi noma eyenziwe ngokwezifiso idinga ukusikwa ngokunemba okuphezulu.

I-Laser Kiss Cutting: Okubalulekile & Okubalulekile

1. Imboni yokupakisha:

Ukusika-ukuqabula nge-laser kubalulekile embonini yokupakisha ekudaleni amalebula angokwezifiso, izitika, namadeli.

Inqubo yokusika enembile iqinisekisa ukuthi amalebula anamathela ngokuphelele kumaphakheji, athuthukisa ukwethulwa komkhiqizo kanye nokuhlonza umkhiqizo.

2. Amadivayisi Ezokwelapha:

Imishini yezokwelapha idinga izingxenye eziyinkimbinkimbi ezinokubekezelela okunembile.

I-laser kiss-cut ibalulekile ekukhiqizeni izingxenye ezifana nokubopha amanxeba, izinto zokunamathisela zezokwelapha, namathuluzi okuxilonga.

3. Izimpawu Nokuphrinta:

Embonini yezimpawu nokuphrinta, ukusika nge-laser kusetshenziselwa ukwakha imiklamo eyinkimbinkimbi yezimpawu, amabhanela, nezinto zokukhangisa.

4. Indwangu Nemfashini:

Okwe-elekthronikhi, i-laser kiss-cut iqinisekisa ukwenziwa okunembile kwezinto ezifana namateyipu anamathelayo, izivikeli zesikrini, nezinto zokugqumisa.

5. Imboni Yezogesi:

Imishini yezokwelapha idinga izingxenye eziyinkimbinkimbi ezinokubekezelela okunembile.

I-laser kiss-cut ibalulekile ekukhiqizeni izingxenye ezifana nokubopha amanxeba, izinto zokunamathisela zezokwelapha, namathuluzi okuxilonga.

6. Ukwenza ngokwezifiso kanye nokwenza kube ngokwakho:

Ikhono lokwenza ngokwezifiso imikhiqizo kanye nokwenza ngezifiso imikhiqizo nge-laser kiss-cutting inikeza umkhawulo wokuncintisana ezimbonini ezihlukahlukene, okuvumela amabhizinisi ukuthi ahlangabezane nezintandokazi zomuntu ngamunye futhi akhe imiklamo eyingqayizivele.

Ngamafuphi:

I-laser kiss-cut iyindlela eguquguqukayo nenembayo enomthelela ofinyelela kude ezimbonini eziningi.

Ikhono layo lokusingatha izinto eziningi ezihlukahlukene, kusukela emikhiqizweni enamathelayo kuya kwezindwangu kanye nezingxenye ze-elekthronikhi, lenza kube inqubo ebalulekile emabhizinisini agxile ekuletheni izixazululo ezisezingeni eliphezulu, ezenziwe ngezifiso, nezisimeme.

Izinzuzo Eziningi: I-CO2 Laser Kiss Cutting

1. Ukusika Ngokunemba kanye Nenqubo Yokungaxhunywana Naye

Amasistimu we-laser we-CO2 anikeza ukunemba okuphezulu nokunemba, okuvumela ukusika okuyinkimbinkimbi nokunemininingwane yezinto ezahlukahlukene.

Lokhu kuzenza zilungele izinhlelo zokusebenza ezidinga ukubekezelelana okuqondile kanye nemininingwane emihle.

Indlela yokusika engathinteki iqeda ubungozi bokulimala ezintweni ezibucayi noma ezibucayi.

Lokhu kubaluleke kakhulu lapho usikwa izinto ezifana namafilimu anamathelayo, izindwangu, noma amagwebu.

2. I-Minimal Material Waste & Versatility

I-focus laser beam inciphisa udoti wezinto ezibonakalayo ngoba isika ngokunemba okukhulu.

Lokhu kubalulekile ezimbonini ezifuna ukunciphisa izindleko zokukhiqiza futhi zandise ukusetshenziswa kwezinto ezibonakalayo.

Amalaser e-CO2 angasika izinhlobonhlobo zezinto zokwakha, kusukela kokunamathelayo kuye kwezindwangu, amagwebu, namapulasitiki.

Lokhu kuguquguquka kubenza bafanelekele izinhlelo zokusebenza ezahlukahlukene kuzo zonke izimboni.

3. Isivinini Esiphezulu & Imiphetho Ehlanzekile

Amalaser e-CO2 angasebenza ngesivinini esikhulu, abe nomthelela ekwandeni kokukhiqiza.

Ijubane labo lizuzisa kakhulu ekugijimeni kokukhiqiza kwevolumu ephezulu.

Ukushisa okukhiqizwa i-laser ngesikhathi sokusika kuvala imiphetho yezinto, kuvimbela ukubola noma ukuqaqa.

Lokhu kunenzuzo ikakhulukazi lapho usebenza ngezindwangu nezindwangu.

4. Izindleko zamathuluzi ezehlisiwe kanye nokuthayipha okusheshayo

Ngokungafani nezindlela ezivamile zokusika noma zokusika imishini, ukusika kwe-laser ye-CO2 kuqeda isidingo samathuluzi abizayo noma isikhunta, ukonga ezindlekweni zokusetha kanye nezikhathi zokuhola.

Ukusika kwe-laser ye-CO2 kuyisinqumo esihle kakhulu se-prototyping esheshayo, okuvumela ukulungiswa okusheshayo nezinguquko zedizayini ngaphandle kwesidingo sokuguqulwa kwamathuluzi.

5. Ukwenza ngokwezifiso & Ukusebenza Okuthuthukisiwe

Ukuvumelana nezimo kwama-laser e-CO2 kwenza kube lula ukushintsha phakathi kwamaphethini okusika ahlukene, okwenza kube lula ukwamukela imiklamo eyenziwe ngokwezifiso kanye nezidingo ezihlukahlukene zokukhiqiza.

Izici ze-automation ezifana ne-auto-feeders kanye nokulungiselelwa kwamakhanda amaningi kuqhubekela phambili nokuthuthukisa ukusebenza kahle kuzilungiselelo zokukhiqiza ngobuningi.

6. Ukwehliswa Kwesondlo Nokuqina

Amasistimu we-laser we-CO2 aziwa ngokuqina kwawo kanye nezidingo zokulondolozwa okuphansi, okuholela ekwehliseni isikhathi sokuphumula nezindleko zokusebenza.

I-CO2 laser cutters ifaneleka kokubili ukusebenza kwezinga elincane kanye nezicelo zezimboni ezinkulu, ihlinzeka ngokulinganisa ukuze ihambisane nezidingo zokukhiqiza.

Izinto Ezifanele I-Laser Kiss Cutting

Amateyipu namafilimu azinamathiselayo

Amashidi okunamathela anamaceleni amabili

Izinamathiselo ezizwela ukucindezela (PSA)

Amafilimu okuzivikela nama-foil

Izindwangu zokugqoka

Izinto ze-Upholstery

Isikhumba

Izindwangu zokwenziwa

Ikhanvasi

Ikhadibhodi

Ibhodi lamaphepha

Amakhadi okubingelela

Amalebula amaphepha nezitikha

Izinto ze-Foam

Irabha yesipontshi

I-Neoprene

Irabha ye-Silicone

Izinto ze-gasket (iphepha, irabha, ukhokho)

Seal materials

Izinto zokuvikela ukushisa

Amashidi epulasitiki azacile

Ama-Polyesters

I-polypropylene

I-polyethylene

Ifilimu ye-polyester

Mylar

Izinsimbi zensimbi (i-aluminium, ithusi)

Kapton ifilimu

Vinyl amashidi

Amafilimu e-vinyl

Izinto ezifakwe nge-vinyl

Izinto ezihlanganisiwe ezinezingqimba zokunamathela

Ama-laminates anezingqimba eziningi

Izinto ezinendawo eqoshiwe, njengephepha eliqoshiwe noma amapulasitiki aqoshiwe

Amafilimu okuvikela asetshenziswa ezimbonini ezahlukahlukene

Izingxenye ezinamathelayo zama-elekthronikhi

Amafilimu okuvikela ezikrini nezibonisi

Amateyipu ezokwelapha

Izingubo zokugqoka amanxeba

Izingxenye zokunamathisela zemishini yezokwelapha

Amalebula azwela ingcindezi

Amalebula okuhlobisa nama-decal

Izindwangu ezingalukiwe

I-Laser Engraving Heat Transfer Vinyl

> Yiluphi ulwazi okufanele ulunikeze?

> Imininingwane yethu yokuxhumana

Imibuzo Evamile Mayelana Ne-Laser Kiss Cutting

▶ Ingabe i-CO2 laser kiss cut ifaneleka ukwenza i-prototyping nokugijima kokukhiqiza okufushane?

▶ Ingabe kukhona ukucatshangelwa kokuphepha lapho usebenzisa imishini yokusika i-CO2 laser kiss?

▶ Yiziphi izinzuzo zokusika i-CO2 laser kiss ngaphezu kwezinye izindlela zokusika?

Ungalungiseleli Noma Yini Engaphansi Kokukhethekile

Invest in the Best

Isikhathi sokuthumela: Nov-07-2023