Inqubo ye-laser welding eyisisekelo ihlanganisa ukugxilisa i-laser beam endaweni ehlangene phakathi kwezinto ezimbili kusetshenziswa isistimu yokulethwa kwe-optical. Lapho ugongolo luthinta izinto zokwakha, ludlulisela amandla alo, lushise ngokushesha futhi luncibilikise indawo encane.

Uhlu Lokuqukethwe

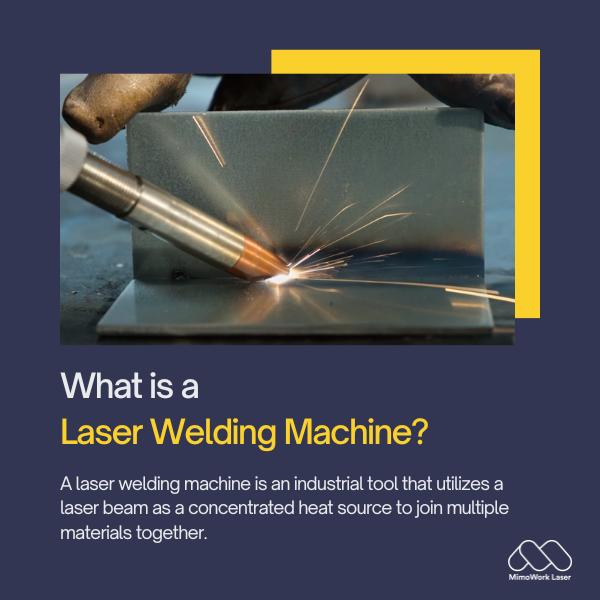

1. Uyini umshini wokushisela i-Laser?

Umshini wokushisela i-laser iyithuluzi lezimboni elisebenzisa i-laser beam njengomthombo wokushisa ogxilile ukuze uhlanganise izinto eziningi ndawonye.

Ezinye izici ezibalulekile zemishini yokushisela i-laser zifaka:

1. Umthombo we-Laser:Iningi lamashisela esimanje lisebenzisa i-solid state laser diode akhiqiza i-laser enamandla amakhulu ku-spectrum ye-infrared. Imithombo ye-laser evamile ihlanganisa i-CO2, i-fiber, nama-laser diode.

2. Amehlo:I-laser beam ihamba ochungechungeni lwezingxenye ze-optical ezifana nezibuko, amalensi, nama-nozzles agxila futhi aqondise i-beam endaweni yokushisela ngokunemba. Izingalo ze-telescoping noma ama-gantries abeka ugongolo.

3. Okuzenzakalelayo:Ama-laser welder amaningi afaka ukulawulwa kwezinombolo zekhompiyutha (CNC) kanye namarobhothi ukuze azenze kube ngokuzenzakalela amaphethini nezinqubo zokushisela. Izindlela ezihlelekayo nezinzwa zempendulo ziqinisekisa ukunemba.

4. Ukuqapha Inqubo:Amakhamera ahlanganisiwe, ama-spectrometer, nezinye izinzwa ziqapha inqubo yokushisela ngesikhathi sangempela. Noma yiziphi izinkinga ezihambisana nokuqondisa kohlaka, ukungena, noma ikhwalithi zingatholwa ngokushesha futhi zixazululwe.

5. I-Safety Interlocks:Izindlu ezivikelayo, iminyango, nezinkinobho ze-e-stop zivikela opharetha ensikeni ye-laser enamandla amakhulu. I-Interlocks ivala i-laser uma izivumelwano zokuphepha zephulwa.

Ngakho-ke, kafushane, umshini wokushisela i-laser iyithuluzi elilawulwa ngekhompuyutha, elinembayo lasezimbonini elisebenzisa ugongolo lwe-laser olugxilile lwezinhlelo zokushisela ezizenzakalelayo, eziphindaphindwayo.

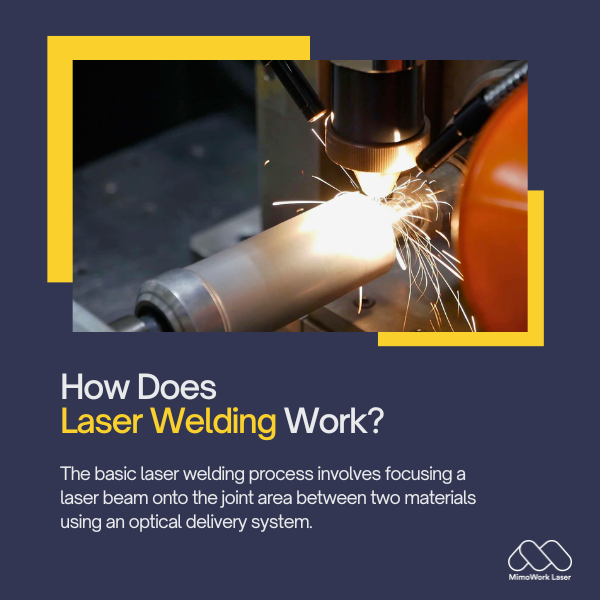

2. Isebenza kanjani i-Laser Welding?

Ezinye izigaba ezibalulekile kunqubo ye-laser welding zifaka:

1. I-Laser Beam Generation:I-solid-state laser diode noma omunye umthombo ukhiqiza i-infrared beam.

2. Ukulethwa kwe-Beam: Izibuko, amalensi, kanye nombhobho kugxilisa ugongolo endaweni eqinile endaweni yokusebenza.

3. Ukushisisa Okubalulekile:I-beam ishisa ngokushesha izinto, ngokuminyana kusondela ku-106 W/cm2.

4. Ukuncibilika nokuhlanganisa:Ichibi elincane elincibilikayo lakha lapho izinto zihlangana khona. Njengoba i-pool iqina, i-weld joint yenziwa.

5. Ukupholisa nokuhlanganisa kabusha: Indawo yokushisela iphola ngezinga eliphezulu ngaphezu kuka-104°C/ngesekhondi, idala i-microstructure eqinile, eqinile.

6. Ukuqhubeka:I-beam ihamba noma izingxenye zibekwe kabusha futhi inqubo iphinda ukuze kuqedelwe i-weld seam. Igesi yokuvikela engangeni nayo ingasetshenziswa.

Ngakho-ke kafushane, i-laser welding isebenzisa i-laser beam egxile kakhulu kanye nokuhamba ngebhayisikili okushisayo okulawulwayo ukuze kukhiqizwe amashisela wendawo athinteke kakhulu ekushiseni okuphezulu.

Sinikeze Ulwazi Oluwusizo Ngemishini Yokushisela I-Laser

Kanye Nezixazululo Ezenziwe Ngokwezifiso Zebhizinisi Lakho

3. Ingabe i-Laser Welding ingcono kune-MIG?

Uma kuqhathaniswa nezinqubo zokushisela ze-metal inert gas (MIG) yendabuko...

I-laser welding inikeza izinzuzo eziningi:

1. Ukunemba: Imishayo ye-laser ingagxilwa endaweni encane engu-0.1-1mm, ivumele ukushisela okunembe kakhulu, okuphindaphindwayo. Lokhu kulungele izingxenye ezincane, ezibekezelela kakhulu.

2. Isivinini:Izilinganiso zokushisela i-laser zishesha kakhulu kune-MIG, ikakhulukazi kumageji amancane. Lokhu kuthuthukisa ukukhiqiza futhi kunciphisa izikhathi zomjikelezo.

3. Ikhwalithi:Umthombo wokushisa ogxilile ukhiqiza ukuhlanekezela okuncane kanye nezindawo ezincane ezithinteke ukushisa. Lokhu kubangela ukushisela okuqinile, kwekhwalithi ephezulu.

4. Okuzenzakalelayo:I-laser welding izenzakalela kalula kusetshenziswa amarobhothi kanye ne-CNC. Lokhu kunika amandla amaphethini ayinkimbinkimbi kanye nokuvumelana okuthuthukisiwe uma kuqhathaniswa ne-MIG yokushisela.

5. Izinto:Ama-Lasers angajoyina inhlanganisela yezinto eziningi, okuhlanganisa izinto eziningi kanye nokushisela kwensimbi okungafani.

Kodwa-ke, i-MIG welding inakhoezinye izinzuzophezu kwe-laser kwezinye izinhlelo zokusebenza:

1. Izindleko:Imishini ye-MIG inezindleko zokutshala eziphansi zokuqala kunezinhlelo ze-laser.

2. Izinto eziwugqinsi:I-MIG ifaneleka kangcono ukushisela izingxenye zensimbi ezijiyile ngaphezu kuka-3mm, lapho ukumuncwa kwe-laser kungaba yinkinga.

3. Ukuvikela igesi:I-MIG isebenzisa isivikelo segesi engasebenzi ukuze ivikele indawo yokushisela, kuyilapho i-laser ivamise ukusebenzisa indlela yohlaka evalekile.

Ngakho-ke, ngamafuphi, i-laser welding ngokuvamile ikhethwaukunemba, i-automation, kanye nekhwalithi yokushisela.

Kodwa i-MIG isalokhu iqhudelana ngokukhiqizwa kweamageji aminyene kubhajethi.

Inqubo efanele incike ekusetshenzisweni kwe-welding ethize kanye nezidingo zengxenye.

4. Ingabe i-Laser Welding Ingcono kune-TIG Welding?

I-Tungsten inert gas (TIG) welding iyinqubo ebhalwe ngesandla, enekhono lobuciko engaveza imiphumela emihle kakhulu ezintweni ezincane.

Kodwa-ke, i-laser welding inezinzuzo ezithile kune-TIG:

1. Isivinini:I-Laser welding ishesha kakhulu kune-TIG yezinhlelo zokusebenza zokukhiqiza ngenxa yokunemba kwayo okuzenzakalelayo. Lokhu kuthuthukisa ukusebenza.

2. Ukunemba:I-laser beam egxilile ivumela ukunemba kokubeka endaweni phakathi kwekhulu lemilimitha. Lokhu akukwazi ukufaniswa isandla somuntu esine-TIG.

3. Ukulawula:Izinqubo eziguquguqukayo ezifana nokufaka ukushisa kanye nejometri ye-weld kulawulwa ngokuqinile nge-laser, okuqinisekisa inqwaba yemiphumela engashintshi phezu kwenqwaba.

4. Izinto:I-TIG ingcono kakhulu ezintweni ezisetshenziswayo ezithambile, kuyilapho ukushiswa kwe-laser kuvula inhlanganisela ebanzi yezinto eziningi.

5. Okuzenzakalelayo: Amasistimu we-laser yerobhothi anika amandla ukushisela okuzenzakalelayo ngaphandle kokukhathala, kuyilapho i-TIG ngokuvamile idinga ukunakwa okugcwele komsebenzisi kanye nobuchwepheshe.

Kodwa-ke, i-TIG welding igcina inzuzoumsebenzi wokunemba wegeji elincane noma i-alloy weldinglapho okokufaka ukushisa kufanele kulungiswe ngokucophelela. Kulezi zinhlelo zokusebenza ukuthinta kukachwepheshe onekhono kubalulekile.

5. Kuyini Ububi of Laser Welding?

Njenganoma iyiphi inqubo yezimboni, ukushiswa kwe-laser kunokuthile okungenzeka kube phansi okufanele kucatshangelwe:

1. Izindleko: Yize zithengeka kakhulu, amasistimu e-laser anamandla amakhulu adinga ukutshalwa kwezimali okukhulu uma kuqhathaniswa nezinye izindlela zokushisela.

2. Izinto ezisetshenziswayo:Imibhobho yegesi kanye nemishini yokubona izinto iyancipha ngokuhamba kwesikhathi futhi kufanele ishintshwe, kwenezele ezindlekweni zobunikazi.

3. Ukuphepha:Izimiso eziyisisekelo eziqinile kanye nezindlu zokuphepha ezivaliwe ziyadingeka ukuze kuvinjelwe ukuchayeka ensikeni ye-laser enamandla kakhulu.

4. Ukuqeqeshwa:Ama-operators adinga ukuqeqeshwa ukuze asebenze ngokuphepha futhi agcine ngendlela efanele imishini yokushisela i-laser.

5. Umugqa wokubuka:I-laser beam ihamba ngemigqa eqondile, ngakho-ke amajiyometri ayinkimbinkimbi angase adinge imishayo eminingi noma ukubekwa kabusha kocezu lomsebenzi.

6. Ukumuncwa:Izinto ezithile ezifana nensimbi ewugqinsi noma i-aluminium kungase kube nzima ukushisela uma zingamunca kahle ubude begagasi be-laser obukhethekile.

Ngokuqaphela okufanele, ukuqeqeshwa, kanye nokwenza kahle kwenqubo, nokho, i-laser welding iletha ukukhiqiza, ukunemba, kanye nezinzuzo zekhwalithi ezinhlelweni eziningi zezimboni.

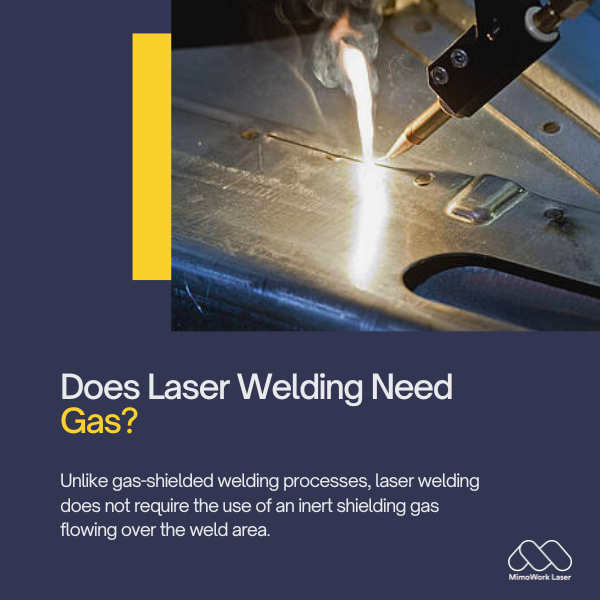

6. Ingabe i-Laser Welding Idinga Igesi?

Ngokungafani nezinqubo zokushisela ezivikelwe ngegesi, i-laser welding ayidingi ukusetshenziswa kwegesi evikelayo engenzi lutho egeleza phezu kwendawo yokushisela. Lokhu kungenxa yokuthi:

1. I-laser beam egxilile ihamba emoyeni ukuze yakhe iphuli yokushisela encane, enamandla amakhulu encibilika futhi ihlanganise izinto.

2. Umoya ozungezile awuyona i-ionized njenge-gas plasma arc futhi awuphazamisi uhlaka noma ukwakheka kwe-weld.

3. I-weld iqina ngokushesha kakhulu ekushiseni okugxilile kangangokuthi yakheka ngaphambi kokuba ama-oxide akheke phezulu.

Kodwa-ke, izinhlelo ezithile ezikhethekile zokushisela i-laser zingase zizuze ngokusebenzisa igesi yokusiza:

1. Ngezinsimbi ezisebenzayo njenge-aluminium, igesi ivikela i-hot weld pool emoyeni osemoyeni.

2. Emisebenzini ye-laser enamandla amakhulu, igesi iqinisa i-plasma plume eyakhayo phakathi nokushisela okujulile.

3. Amajethi egesi asusa intuthu nemfucumfucu ukuze kudluliselwe kangcono izingongolo ezindaweni ezingcolile noma ezipendiwe.

Ngakho-ke kafushane, nakuba kungadingeki ngempela, igesi ye-inert ingase inikeze izinzuzo zezicelo ezithile eziyinselele zokushisela noma izinto zokwakha. Kodwa inqubo ngokuvamile ingenza kahle ngaphandle kwayo.

▶ Yiziphi Izinto Okungenziwa Laser Welded?

Cishe zonke izinsimbi kungenziwa laser ashiselwe kuhlanganiseinsimbi, i-aluminium, i-titanium, ama-nickel alloys, nokunye.

Ngisho nezinhlanganisela zensimbi ezingafani zingenzeka. Isihluthulelo yibokufanele imunce kahle ubude begagasi be-laser.

▶ Ungashisela Izinto Eziwugqinsi Kangakanani?

Amashidi azacile njenge0.1mm futhi ugqinsi njengoba 25mmngokuvamile ingashiswa nge-laser, kuye ngohlelo oluthile namandla e-laser.

Izingxenye eziwugqinsi zingase zidinge i-welding ye-multi-pass noma i-optics ekhethekile.

▶ Ingabe I-Laser Welding Ifanele Ukukhiqizwa Kwevolumu Ephezulu?

Nakanjani. Amaseli we-robotic laser welding avame ukusetshenziswa ezindaweni zokukhiqiza ezinesivinini esikhulu, ezizenzakalelayo ezinhlelweni ezinjengokukhiqiza izimoto.

Amazinga okusebenzisa amamitha ambalwa ngomzuzu ayafinyeleleka.

▶ Yiziphi izimboni ezisebenzisa i-Laser Welding?

Izicelo ezijwayelekile ze-laser welding zingatholakala kuezezimoto, zikagesi, izisetshenziswa zezokwelapha, i-aerospace, ithuluzi/ukufa, kanye nokukhiqizwa kwengxenye encane enembayo.

Ubuchwepheshe bunjalongokuqhubekayo ukunwetshwa emikhakheni emisha.

▶ Ngikhetha kanjani isistimu yokushisela i-laser?

Izinto okufanele zicatshangelwe zifaka izinto zokusebenza, usayizi/ubukhulu, izidingo zokuphuma, isabelomali, kanye nekhwalithi yokushisela edingekayo.

Abahlinzeki abahloniphekile bangasiza ukucacisa uhlobo lwe-laser olulungile, amandla, okokubona, kanye ne-automation yohlelo lwakho lokusebenza oluthile.

▶ Yiziphi Izinhlobo Zokushisela Ezingenziwa?

Izindlela ezijwayelekile zokushisela i-laser zihlanganisa izinqe, i-lap, i-fillet, ukubhoboza, nama-cladding welds.

Ezinye izindlela ezintsha ezifana nokukhiqiza izithasiselo ze-laser nazo ziyavela ukuze zilungiswe kanye nezinhlelo zokusebenza ze-prototyping.

▶ Ingabe I-Laser Welding Iwufanele Umsebenzi Wokulungisa?

Yebo, i-laser welding ifaneleka kahle ukulungisa izinto ezinenani eliphezulu.

Okokufaka kokushisa okugxilile kunciphisa umonakalo owengeziwe ezintweni eziyisisekelo ngesikhathi sokulungiswa.

Ufuna Ukuqalisa Ngomshini Welder We-Laser?

Kungani ungasicabangeli?

Isikhathi sokuthumela: Feb-12-2024