I-Laser Welding Machine Welding Parameters Incazelo Eningiliziwe

I-laser welding iyindlela enembile nephumelelayo yokuhlanganisa izinto, ikakhulukazi izinsimbi.

Ukuqonda imingcele yokushisela kubalulekile ukuze uthole imiphumela emihle.

Lesi sihloko siveza izimiso ezibalulekile namapharamitha anomthelela ekusebenzeni kwe-laser welding, okuhlanganisa ukushuba kwezinto, ububanzi bezintambo, izilungiselelo zamandla, nokunye.

Izimiso Eziyinhloko Laser Welding

1. Ukuqina Kwezinto kanye Nobubanzi Bentambo:

o Uma ushisela izinto eziwugqinsi, kubalulekile ukusebenzisa ucingo olushubile kanye nesilungiselelo samandla aphezulu.

Ngokuphambene nalokho, ezintweni ezincanyana, i-welding wire kakhudlwana namandla aphansi afanelekile.

o Isibonelo, uma ubukhulu bezinto ezibonakalayo bukhula, ububanzi bezintambo kufanele futhi bukhule ngokulinganayo, futhi amandla kufanele alungiswe ukuze abe phezulu kuyilapho kunciphisa isivinini sokuphakela kwentambo.

Lokhu kuqinisekisa ukuthi amandla anele angena ezintweni ze-weld eqinile.

2. Izilungiselelo zamandla kanye nokubukeka kwe-Weld:

o Ukusetha amandla kuthonya ngokuqondile ukubukeka kwe-weld.

Amandla aphansi avamise ukukhiqiza indawo yokushisela emhlophe, kuyilapho amandla aphakeme ephumela ekuthungeni okumnyama, okunemibala eyengeziwe.

Njengoba amandla akhula, i-weld ingase futhi iguquke isuke ekubukekeni okunemibala eminingi iye kumbala omnyama kakhulu, okubonisa ukuthi i-weld yakha ohlangothini olulodwa.

o Lesi sici sibalulekile ekuhloleni ikhwalithi ye-weld nokuqinisekisa ukuthi ihlangabezana namazinga afunekayo.

3. Ukukhetha Ububanzi Bentambo:

o Ukukhetha i-diameter yocingo efanelekile kubalulekile.

Ububanzi bentambo yokushisela akumele budlule ukujiya kwempahla, futhi kufanele bucheme ekubeni bukhulu kunento eyisisekelo.

Lokhu kukhetha kuba nomthelela kakhulu ekugcwaleni kobuhlalu be-weld.

o Intambo ewugqinsi ingaba nomthelela ekushiseleleni okuqinile, kuyilapho ucingo oluncane kakhulu lungabangela ukuhlangana okunganele kanye nelunga elibuthakathaka.

4. I-Welding Wire Diameter kanye nobubanzi bokuskena:

o Ububanzi bentambo yokushisela buphinde buthinte ububanzi bokuskena be-laser beam.

Intambo ecinene izodinga ububanzi bokuskena obuncane, obungaba wusizo ekusetshenzisweni kokushisela okunembayo lapho kudingeka khona imininingwane emihle.

o Lobu budlelwane buvumela ukulawula okungcono kokufaka ukushisa futhi kuqinisekisa ukuthi i-weld igxile endaweni oyifunayo, ukunciphisa umonakalo ongaba khona ezintweni ezizungezile.

Ufuna Ukwazi Imininingwane Engeziwe

Mayelana ne-Laser Welding?

Izinto Zangaphandle Ezithinta Amapharamitha Welding

Kubalulekile ukuqaphela ukuthi izici ezihlukahlukene zangaphandle, ezifana nokuvikela igesi nezimo zemvelo, zingathinta kakhulu inqubo yokushisela.

Ngakho-ke, kuhle ukulungisa imingcele ye-welding ngokusekelwe ezimweni zesikhathi sangempela.

• I-Shielding Gas: Uhlobo nezinga lokugeleza kwegesi evikelayo kungathinta ikhwalithi nokubukeka kwe-weld.

Ukumbozwa kahle kwegesi kungavimbela i-oxidation futhi kuthuthukise ukuphela okuphelele.

• Izimo Zemvelo: Izinto ezifana nezinga lokushisa, umswakama, nokugeleza komoya kungaba nomthelela ekusebenzeni komshini wokushisela we-laser kanye nezakhiwo ze-weld.

Noma yiluphi olunye ulwazi mayelana ne-Laser Welder?

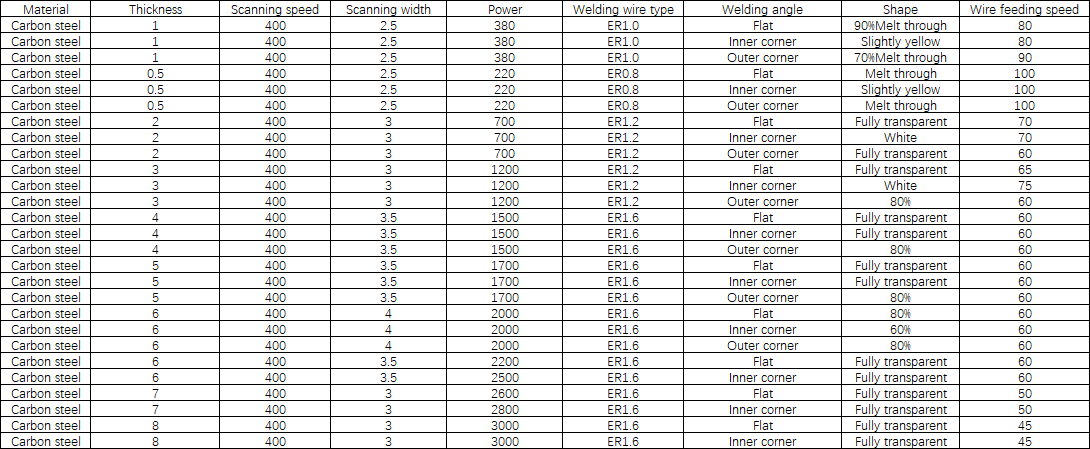

I-Laser Welding Carbon Steel

Qaphela: Ngenxa yethonya le-zinc layer yeshidi likathayela, amandla eshidi elinothayela angehliswa ngendlela efanele.

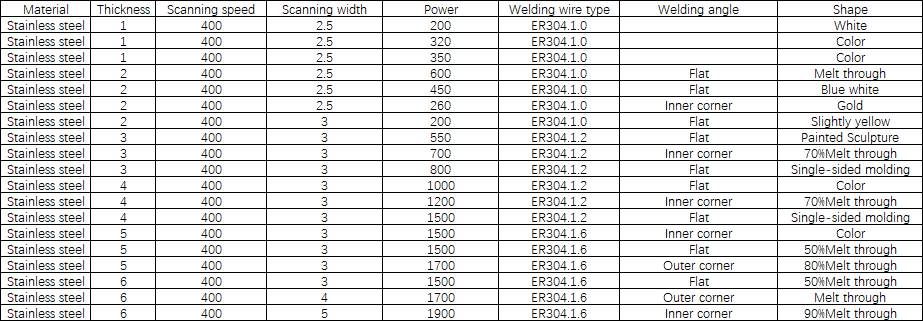

I-Handheld Laser Welding Stainless Steel

Amanothi:3000W insimbi engagqwali amandla reference carbon steel

Angazi Ukuthi Ungakhetha Kanjani Umshini We-Laser?

Singasiza!

Kusukela kumavidiyo abandakanyayo kuya ezindabeni ezifundisayo

Indlela Yokusebenzisa I-Handheld Laser Welder | Isifundo sokuqala

Isikhathi sokuthumela: Jan-06-2025