• Ukulawulwa kwekhwalithi eLaser Welding?

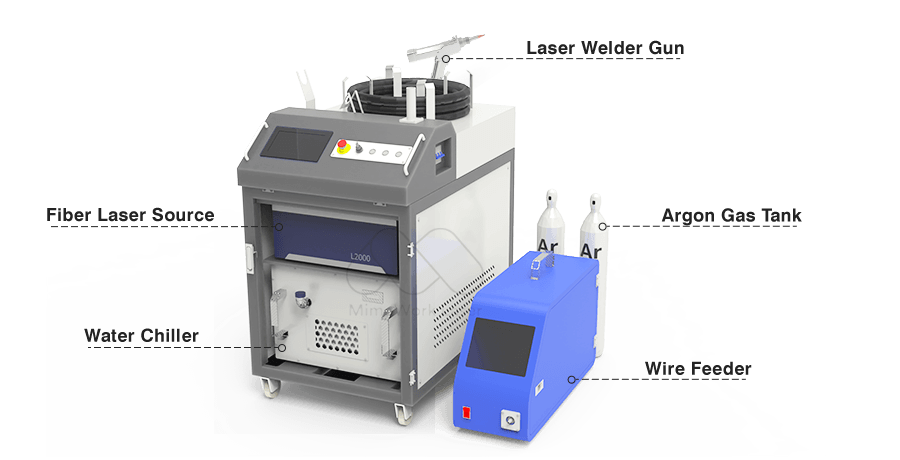

Ngokusebenza kahle okuphezulu, ukunemba okuphezulu, umphumela omkhulu we-welding, ukuhlanganiswa okuzenzakalelayo okuzenzakalelayo, nezinye izinzuzo, i-laser welding isetshenziswa kabanzi ezimbonini zezimboni ze-welding kanye nokukhiqiza, kubandakanya nezempi, kwezokwelapha, i-aerospace, 3c Izingxenye ezizenzakalelayo, i-mechanical sheet insimbi, amandla amasha, i-hardware yokuhlanza, kanye nezinye izimboni.

Kodwa-ke, noma iyiphi indlela ye-welding uma ingenawo umgomo wayo nobuchwepheshe, izokhiqiza iziphambeko ezithile noma imikhiqizo ethile enephutha, i-laser welding ayifani.

• Yini okufanele ngiyenze ukuxazulula lezo ziphutha?

Ukuqonda kahle kuphela kwalezi zinkinga, nokufunda ukuthi ungazigwema kanjani lezi zinkinga, ukudlala kangcono inani le-laser welding, ukucubungula ukubukeka okuhle, nemikhiqizo yekhwalithi enhle.

Onjiniyela ngokusebenzisa ukuqongelela okuhlangenwe nakho kwesikhathi eside, bafingqe ukuthi kube neziphambeko ezivamile ze-welding zesisombululo, ngokubhekiswa kozakwabo embonini!

Yiziphi izinkinga ezinhlanu ezijwayelekile zokuphilisa?

>> imifantu

Qala >> Peres in Weld

>> Splash

Qala >> Undercut

>> Ukuwa kwechibi elibiwe

Uma ungathanda ukwazi kabanzi nge-Handheld Laser Welders, ungabheka ikhasi lethu ukuthola eminye imininingwanengokusebenzisa isixhumanisi phansi ngezansi!

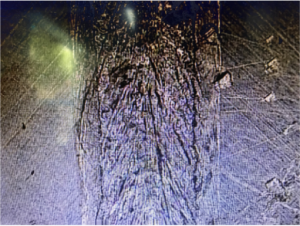

◼ Imifantu lapho i-laser welding

Imifantu ekhiqizwa e-laser eqhubekayo i-welding iqhubeka nokuqhekeka okushisa, njengokuqhekeka kwe-crystallization, njll.

Isizathu esiyinhloko ukuthi iWeld ikhiqiza amandla amakhulu okuthi acwebile ngaphambi kokuqina okuphelele.

Usebenzisa i-wire feeder ukugcwalisa izintambo noma ukucindezela ucezu lwensimbi kunganciphisa noma ukuqeda imifantu ekhonjiswe ngesikhathi se-laser welding.

Imifantu eLaser Welding

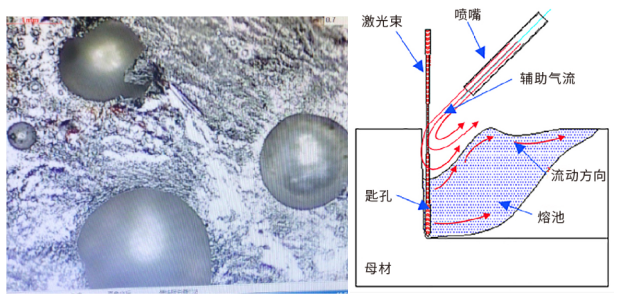

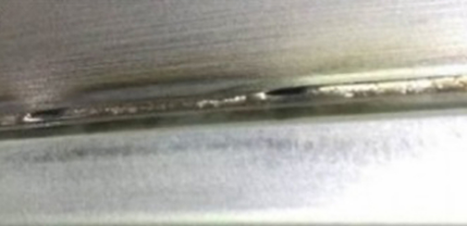

◼ pores inwer

Ama-pores eWeld

Imvamisa, ichibi le-laser welding lijulile futhi lincane, futhi izinsimbi zivame ukwenza ukushisa kahle futhi ngokushesha okukhulu. Igesi ekhiqizwa echibini elicwengekileyo lingenaso isikhathi esanele sokuphunyuka ngaphambi kokuba insimbi ye-welding ipholile. Icala elinjalo kulula ukuholela ekwakhekeni kwama-pores.

Kepha futhi ngoba indawo yokushisa ye-laser welding incane, insimbi ingaphola kakhulu ngokushesha, futhi i-porosuti evelelayo eboniswe eLaser Welding ngokuvamile inzima kune-Fusion Welding.

Ukuhlanza indawo yokusebenza ngaphambi kokufudumeza kunganciphisa ukuthambekela kwama-pores, futhi ukuqondiswa kokushaya kuzothinta futhi ukwakheka kwama-pores.

◼ Splash

◼ Ukuwa kwechibi elibunjiwe

I-Splash ekhiqizwa nguLaser Welding ithinta kakhulu ikhwalithi ye-Weld Surce futhi ingangcolisa futhi ilimaze ilensi.

I-spatter ihlobene ngokuqondile nokuqina kwamandla futhi ingancishiswa ukunciphisa amandla kahle ama-welding.

Uma ukungena ukungena kunganele, ijubane le-welding lingancishiswa.

Splash e-laser welding

Uma ijubane le-welding lihamba kancane, ichibi elibunjiwe likhulu futhi libanzi, inani lensimbi elibunjiwe liyanda, futhi ukungezwani okungaphezulu kunzima ukugcina insimbi eqinile, isikhungo seWeld sizocwila, sakha ukuwa kanye nemigodi.

Ngalesi sikhathi, kuyadingeka ukunciphisa amandla okuqina kwamandla ngokufanele ukugwema ukuwa kwechibi elibunjiweyo.

Ukuwa kwechibi elibunjiwe

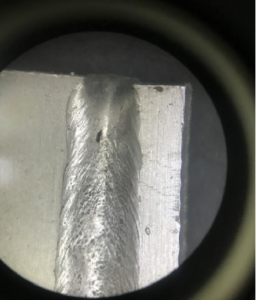

◼ Undercut eLaser Welding

Uma unqamula i-wetal mailpiece ngokushesha okukhulu, insimbi ewuketshezi ngemuva komgodi ikhomba enkabeni yeWeld ayinaso isikhathi sokwabiwa kabusha.

Ukuqina ezinhlangothini zombili zeWeld kuzokwakha ukuluma. Lapho igebe phakathi kwezingcezu ezimbili zomsebenzi likhulu kakhulu, ngeke kube nensimbi ebilisiwe ebilisiwe ukuze i-caulking, lapho kuzokwenzeka khona i-welding onqenqemeni lokuluma.

Esigabeni esiphelayo se-laser welding, uma amandla ehla ngokushesha kakhulu, umgodi kulula ukuwa futhi uholele ekulimaleni okufanayo kwe-welding. Amandla okulinganisa okungcono nendawo yokuhamba ngezilungiselelo ze-laser welding zingaxazulula isizukulwane sokuluma onqenqemeni.

Undercut e-laser welding

I-Handheld Laser Welders ongayikhetha

Ufuna ukwazi kabanzi nge-laser welding?

Noma yikuphi ukuxubeka kanye nemibuzo yomshini we-waser welding we-handheld?

Isikhathi sePosi: Jan-30-2023