I-laser welding ihloselwe kakhulu ukuthuthukisa ukusebenza kahle kwe-welding kanye nekhwalithi yezinto ezincanyana zodonga kanye nezingxenye zokunemba. Namuhla ngeke sikhulume ngezinzuzo ze-laser welding kodwa sigxile endleleni yokusebenzisa amagesi okuvikela ukushisela i-laser ngendlela efanele.

Kungani usebenzise igesi yesihlangu ukushisela i-laser?

Ku-laser welding, igesi yesihlangu izothinta ukwakheka kwe-weld, ikhwalithi ye-weld, ukujula kwe-weld, nobubanzi be-weld. Ezimweni eziningi, ukushaya igesi esizwayo kuzoba nomthelela omuhle ku-weld, kodwa kungase kuphinde kulethe imiphumela emibi.

Uma ufutha igesi yesivikelo ngendlela efanele, izokusiza:

✦Vikela ngempumelelo i-weld pool ukuze unciphise noma ugweme ngisho ne-oxidation

✦Yehlisa ngempumelelo i-splash ekhiqizwa inqubo yokushisela

✦Yehlisa ngempumelelo ama-weld pores

✦Siza i-weld pool isabalale ngokulinganayo uma iqiniswa, ukuze i-weld seam iza nomphetho ohlanzekile nobushelelezi.

✦Umthelela wokuvikela wensimbi yomusi noma ifu le-plasma ku-laser wehliswa ngempumelelo, futhi izinga lokusebenzisa elisebenzayo le-laser liyakhuphuka.

Inqobo nje umavikela uhlobo lwegesi, izinga lokugeleza kwegesi, nokukhetha imodi yokufuthazilungile, ungathola umphumela omuhle we-welding. Kodwa-ke, ukusetshenziswa okungalungile kwegesi yokuvikela nakho kungathinta kabi ukushisela. Ukusebenzisa uhlobo olungalungile lwegesi yesihlangu kungase kuholele ekwakhiweni kwe-weld noma kunciphise izakhiwo zemishini zokushisela. Izinga lokugeleza kwegesi eliphakeme kakhulu noma eliphansi kakhulu lingase liholele ekushiseleni okubi nakakhulu kanye nokuphazamiseka okukhulu kwangaphandle kwensimbi ngaphakathi kwechibi lokushisela, okuholela ekuweni kokushisela noma ukwakheka okungalingani.

Izinhlobo zegesi yesihlangu

Amagesi avikelayo asetshenziswa kakhulu e-laser welding ikakhulukazi i-N2, Ar, kanye ne-He. Izakhiwo zabo zomzimba namakhemikhali zihlukile, ngakho-ke imiphumela yazo kuma-welds nayo ihlukile.

I-nitrogen (N2)

Amandla e-ionization we-N2 aphakathi, aphakeme kunalawo e-Ar, futhi aphansi kunalawo ka-He. Ngaphansi kwemisebe ye-laser, idigri ye-ionization ye-N2 ihlala ku-keel elinganayo, enganciphisa kangcono ukwakheka kwefu le-plasma futhi ikhulise izinga lokusebenzisa elisebenzayo le-laser. I-nitrogen ingasabela nge-aluminium alloy ne-carbon steel ezingeni lokushisa elithile ukuze kukhiqizwe ama-nitride, okuzokwenza ngcono i-weld brittleness futhi kunciphise ukuqina, futhi kube nomthelela omubi kakhulu kuzakhiwo zemishini zamajoyinti wokushisela. Ngakho-ke, akunconywa ukusebenzisa i-nitrogen lapho ushisela i-aluminium alloy ne-carbon steel.

Kodwa-ke, ukusabela kwamakhemikhali phakathi kwe-nitrogen nensimbi engagqwali ekhiqizwe i-nitrogen kungathuthukisa amandla e-weld joint, okuzoba yinzuzo ukuthuthukisa izakhiwo zemishini ye-weld, ngakho ukushisela kwensimbi engagqwali kungasebenzisa i-nitrogen njengegesi evikelayo.

I-Argon (Ar)

Amandla we-ionization we-Argon aphansi kakhulu, futhi i-ionization degree yayo izoba phezulu ngaphansi kwesenzo se-laser. Khona-ke, i-Argon, njengegesi evikelayo, ayikwazi ukulawula ngokuphumelelayo ukwakheka kwamafu e-plasma, okuzonciphisa izinga lokusebenzisa okusebenzayo kwe-laser welding. Umbuzo ophakamayo: ingabe i-argon iyikhandidethi elibi lokusebenzisa i-welding njengegesi evikelayo? Impendulo ithi Cha. Ukuba igesi engasebenzi, i-Argon ilukhuni ukusabela ngeningi lezinsimbi, futhi i-Ar ishibhile ukuyisebenzisa. Ngaphezu kwalokho, ukuminyana kwe-Ar kukhulu, kuzoba kuhle ukucwila ebusweni bechibi elincibilikisiwe le-weld futhi kungavikela kangcono i-weld pool, ngakho-ke i-Argon ingasetshenziswa njengegesi evamile yokuvikela.

I-Helium (Yena)

Ngokungafani ne-Argon, i-Helium inamandla amakhulu e-ionization angakwazi ukulawula ukwakheka kwamafu e-plasma kalula. Ngesikhathi esifanayo, i-Helium ayiphenduli nanoma yiziphi izinsimbi. Kuyisinqumo esihle ngempela se-laser welding. Inkinga nje ukuthi i-Helium ibiza kakhulu. Kubakhiqizi abahlinzeka ngemikhiqizo yensimbi yokukhiqiza ngobuningi, i-helium izokwengeza inani elikhulu ezindlekweni zokukhiqiza. Ngakho i-helium ngokuvamile isetshenziswa ocwaningweni lwesayensi noma emikhiqizweni enenani eliphakeme kakhulu elingeziwe.

Indlela yokuphefumula igesi yesihlangu?

Okokuqala, kufanele kucace ukuthi lokho okubizwa ngokuthi "i-oxidation" ye-weld yigama elivamile kuphela, elibhekisela ekuphenduleni kwamakhemikhali phakathi kwe-weld kanye nezingxenye eziyingozi emoyeni, okuholela ekuwohlokeni kwe-weld. Ngokuvamile, insimbi yokushisela isabela nomoya-mpilo, i-nitrogen, ne-hydrogen emoyeni ezingeni lokushisa elithile.

Ukuvimbela i-weld ekubeni "i-oxidized" kudinga ukunciphisa noma ukugwema ukuthintana phakathi kwezingxenye ezinjalo eziyingozi kanye nensimbi yokushisela ngaphansi kwezinga lokushisa eliphezulu, elingekho kuphela ensimbi yechibi elincibilikisiwe kodwa sonke isikhathi kusukela esikhathini lapho insimbi yokushisela incibilika kuze kube yilapho insimbi ye-pool encibilikisiwe iqina futhi izinga lokushisa layo lipholisa phansi lifinyelele ezingeni elithile lokushisa.

Izindlela ezimbili eziyinhloko zokufutha igesi yesihlangu

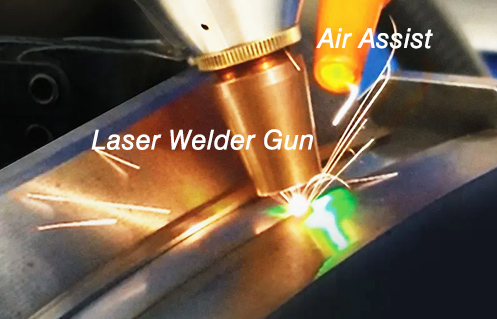

▶Enye ifutha igesi yesihlangu ku-eksisi eseceleni, njengoba kuboniswe kuMfanekiso 1.

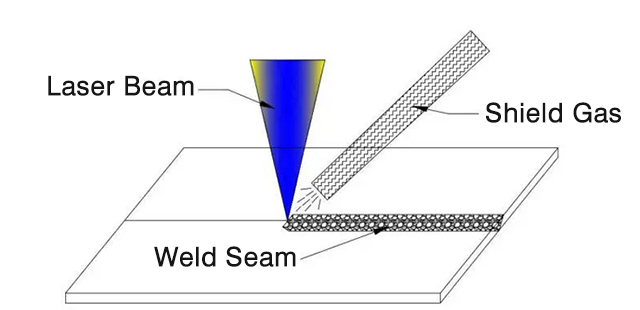

▶Enye indlela yokuvuthela i-coaxial, njengoba kuboniswe kuMfanekiso 2.

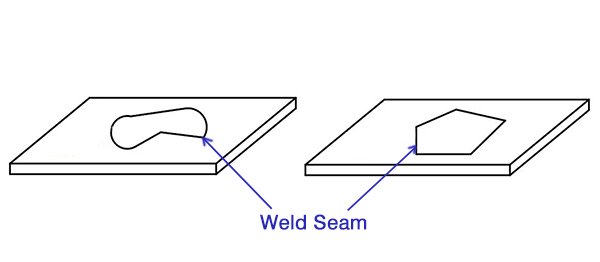

Umfanekiso 1.

Umfanekiso 2.

Ukukhethwa okuqondile kwezindlela ezimbili zokuphefumula kuwukucatshangelwa okuphelele kwezici eziningi. Ngokuvamile, kunconywa ukuthatha indlela yegesi evikelayo ehlangothini.

Ezinye izibonelo ze-laser welding

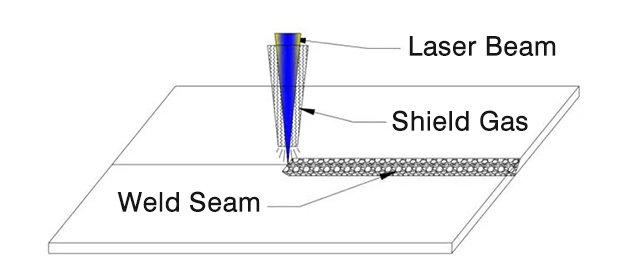

1. Ukushisela ubuhlalu/umugqa oqondile

Njengoba kukhonjisiwe kuMfanekiso 3, ukwakheka kokushisela komkhiqizo kuqondile, futhi ifomu elihlanganyelwe lingaba ilunga lezinqe, ilunga lethanga, ilunga lekhona elingalungile, noma ijoyinti lokushisela eligqagqene. Ngalolu hlobo lomkhiqizo, kungcono ukusebenzisa igesi evikelayo ephephetha i-axis eseceleni njengoba kukhonjisiwe kuMfanekiso 1.

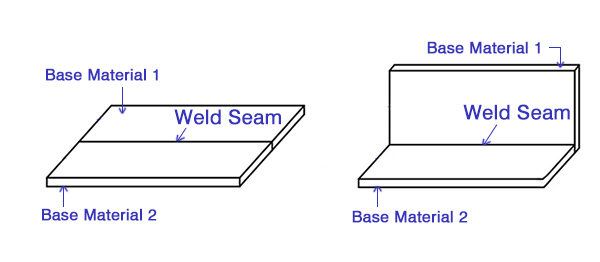

2. Vala isibalo noma indawo yokushisela

Njengoba kuboniswe ku-Figure 4, ukuma kwe-weld yomkhiqizo kuyiphethini evaliwe njenge-circumference yendiza, indiza ye-multilateral shape, indiza ye-multi-segment linear shape, njll. Ifomu elihlangene lingaba i-butt joint, i-lap joint, i-welding egqagqene, njll. Kungcono ukwamukela indlela ye-coaxial protective gas njengoba kuboniswe kuMfanekiso 2 walolu hlobo lomkhiqizo.

Ukukhethwa kwegesi yokuzivikela kuthinta ngokuqondile izinga lokushisela, ukusebenza kahle, kanye nezindleko zokukhiqiza, kodwa ngenxa yokwehlukahlukana kwezinto zokushisela, enkambweni yangempela yokushisela, ukukhethwa kwegesi yokushisela kuyinkimbinkimbi futhi kudinga ukucatshangelwa okubanzi kwezinto zokushisela, indlela yokushisela, isikhundla sokushisela, kanye nezidingo zomphumela wokushisela. Ngokusebenzisa izivivinyo zokushisela, ungakhetha igesi yokushisela efanelekile ukuze uthole imiphumela engcono.

Unentshisekelo yokushisela i-laser futhi uzimisele ukufunda indlela yokukhetha igesi yesihlangu

Izixhumanisi Ezihlobene:

Isikhathi sokuthumela: Oct-10-2022