1. Isivinini sokusika

Amakhasimende amaningi ekubonisaneni komshini wokusika we-laser azobuza ukuthi umshini we-laser ungasika ngokushesha kangakanani. Ngempela, umshini wokusika we-laser uyimishini esebenza kahle kakhulu, futhi isivinini sokusika ngokwemvelo sigxile ekukhathazekeni kwamakhasimende. Kodwa isivinini sokusika esisheshayo asichazi ikhwalithi yokusika i-laser.

Ngokushesha kakhulu tyena ukusika isivinini

a. Ayikwazi ukunqamula okokusebenza

b. Indawo yokusika iveza okusanhlamvu okuyi-oblique, kanti ingxenye engezansi ye-workpiece ikhiqiza amabala ancibilikayo

c. Unqenqema lokusika

Yehlisa kakhulu isivinini sokusika

a. Isimo sokuncibilika ngendawo yokusika emaholoholo

b. Igebe elibanzi lokusika kanye nekhona elicijile liyancibilika libe amakhona ayindilinga

Ukwenza umshini wokusika we-laser udlale kangcono umsebenzi wawo wokusika, ungamane ubuze ukuthi umshini we-laser ungasika kanjani, impendulo ngokuvamile ayinembile. Ngokuphambene nalokho, hlinzeka i-MimoWork ngokucaciswa kwempahla yakho, futhi sizokunikeza impendulo enomthwalo wemfanelo kakhudlwana.

2. Iphuzu lokugxila

Ngenxa yokuthi ukuminyana kwamandla e-laser kunethonya elikhulu esivinini sokusika, ukukhethwa kobude bokugxila kwelensi kuyiphuzu elibalulekile. Usayizi wendawo ye-laser ngemva kokugxila kwe-laser ulingana nobude bokugxila belensi. Ngemuva kokuthi i-laser beam igxilwe ilensi enobude obufushane bokugxila, usayizi wendawo ye-laser mncane kakhulu futhi ukuminyana kwamandla endaweni okugxilwe kuyo kuphezulu kakhulu, okuzuzisayo ekusikeni kwezinto ezibonakalayo. Kodwa okubi kwayo ukuthi ngokujula kokugxila okufushane, isibonelelo esincane kuphela sokulungiswa kobukhulu bento. Ngokuvamile, ilensi yokugxilisa ingqondo enobude obufushane bokugxila ifaneleka kakhulu ezintweni ezizacile zokusika ngesivinini esikhulu. Futhi ilensi yokugxilisa ingqondo enobude obude bokugxila inokujula okugxilile okubanzi, inqobo nje uma inamandla okwanele, ifaneleka kakhulu ukusika izinto zokusebenza eziwugqinsi njengegwebu, i-acrylic, nokhuni.

Ngemva kokunquma ukuthi iyiphi ilensi yobude bokugxila okufanele isetshenziswe, indawo ehlobene yendawo okugxilwe kuyo endaweni yokusebenza ibaluleke kakhulu ukuze kuqinisekiswe ikhwalithi yokusika. Ngenxa yobuningi bamandla obuphezulu endaweni okugxilwe kuyo, ezimweni eziningi, indawo okugxilwe kuyo ingaphansi noma kancane ngaphansi kwendawo yokusebenza lapho usikwa. Kuyo yonke inqubo yokusika, kuyisimo esibalulekile sokuqinisekisa ukuthi isikhundla esihlobene sokugxila kanye ne-workpiece sihlala njalo ukuze sithole izinga lokusika elizinzile.

3. Isistimu Yokuvuthela Umoya & Negesi Eyisixwayiso

Ngokuvamile, i-laser cutting material idinga ukusetshenziswa kwegesi elisizayo, ikakhulukazi elihlobene nohlobo nokucindezela kwegesi elisizayo. Ngokuvamile, igesi elisizayo likhishwa nge-coaxially nge-laser beam ukuze kuvikelwe ilensi ekungcoleni futhi kuphephethe i-slag phansi kwendawo yokusika. Ngezinto ezingezona ezensimbi kanye nezinye izinto zensimbi, umoya ocindezelweyo noma igesi ye-inert isetshenziselwa ukususa izinto ezincibilikisiwe nezihwamukile, kuyilapho kuvimbela ukusha okukhulu endaweni yokusika.

Ngaphansi kwesisekelo sokuqinisekisa igesi elisizayo, ukucindezela kwegesi kuyisici esibaluleke kakhulu. Uma usika izinto ezincane ngesivinini esikhulu, ingcindezi yegesi ephezulu iyadingeka ukuvimbela i-slag ukuthi inganamatheli ngemuva kokusikwa (i-slag eshisayo izolimaza umkhawulo osikiwe lapho ishaya umsebenzi). Lapho ubukhulu bezinto ezibonakalayo bukhula noma ijubane lokusika lihamba kancane, ukucindezela kwegesi kufanele kuncishiswe ngokufanelekile.

4. Izinga lokuzindla

Ubude begagasi belaser ye-CO2 bungu-10.6 μm obulungele ukumunca izinto ezingezona ezensimbi. Kodwa i-CO2 laser ayifanele ukusika insimbi, ikakhulukazi izinto zensimbi ezinezimo eziphakeme ezifana negolide, isiliva, ithusi ne-aluminium yensimbi, njll.

Izinga lokumuncwa kwento egxotsheni lidlala indima ebalulekile esigabeni sokuqala sokushisa, kodwa uma imbobo yokusika yakhiwe ngaphakathi kwendawo yokusebenza, umthelela womzimba omnyama wembobo wenza izinga lokumuncwa kwento ebholeni lisondele ku-100%.

Isimo esingaphezulu sezinto ezibonakalayo sithinta ngokuqondile ukumuncwa kwe-beam, ikakhulukazi ubulukhuni obungaphezulu, futhi ungqimba lwe-oxide olungaphezulu luzodala izinguquko ezisobala kuzinga lokumuncwa kwendawo. Emsebenzini wokusika i-laser, kwesinye isikhathi ukusebenza kokusika kwento kungathuthukiswa ngomthelela wesimo sezinto ezibonakalayo esilinganisweni sokumuncwa kwensimbi.

5. I-Laser Head Nozzle

Uma i-nozzle ikhethwe ngendlela engafanele noma ingagcinwa kahle, kulula ukubangela ukungcola noma ukulimala, noma ngenxa yokujikeleza okubi komlomo we-nozzle noma ukuvaleka kwendawo okubangelwa ukushaywa kwensimbi eshisayo, imisinga e-eddy izokwakhiwa ku-nozzle, okuholela ekusebenzeni okubi kakhulu kokusika. Ngezinye izikhathi, umlomo we-nozzle awuhambisani ne-beam egxiliwe, okwenza i-beam ukuze uphuce umphetho we-nozzle, okuzophinde kuthinte ikhwalithi yokusika onqenqemeni, ukwandise ububanzi be-slit futhi wenze usayizi wokusika uhlukanise.

Ngama-nozzles, izindaba ezimbili kufanele zinakwe ngokukhethekile

a. Umthelela wobubanzi be-nozzle.

b. Umthelela webanga phakathi kombhobho nendawo yokusebenza.

6. Indlela Yokubona

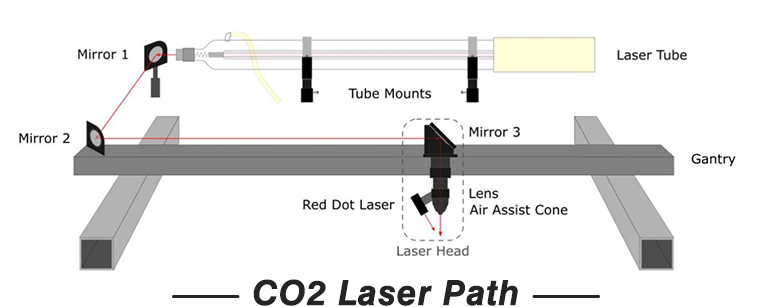

I-beam yasekuqaleni ekhishwa yi-laser idluliselwa (kuhlanganise nokubonisa nokudluliswa) ngohlelo lwendlela yangaphandle, futhi ikhanyise ngokunembile ingaphezulu le-workpiece elinamandla amakhulu kakhulu.

Izakhi ze-optical zesistimu ye-optical path yangaphandle kufanele zihlolwe njalo futhi zilungiswe ngesikhathi ukuze kuqinisekiswe ukuthi lapho isibani sokusika sisebenza ngaphezu kwendawo yokusebenza, i-beam yokukhanya idluliselwa ngendlela efanele enkabeni ye-lens futhi igxile endaweni encane ukusika i-workpiece ngekhwalithi ephezulu. Uma isikhundla sanoma iyiphi i-optical element sishintsha noma singcolile, ikhwalithi yokusika izothinteka, futhi ngisho nokusika ngeke kwenziwe.

I-lens yangaphandle ye-optical path ingcoliswa ukungcola emoyeni futhi iboshwe yizinhlayiya ezishaywayo endaweni yokusika, noma i-lens ayipholile ngokwanele, okuzokwenza ukuthi i-lens ishise futhi ithinte ukudluliswa kwamandla e-beam. Idala ukungqubuzana kwendlela yokubona ukuthi ikhukhuleke futhi iholele emiphumeleni emibi. I-lens overheating izophinde ikhiqize ukuhlanekezela okugxile futhi ifake ngisho ne-lens engozini.

Funda kabanzi mayelana nezinhlobo ze-co2 laser cutter nezintengo

Isikhathi sokuthumela: Sep-20-2022