Yini i-laser welding? I-Laser Welding ichaze! Konke okudingeka ukwazi nge-laserser welding, kufaka phakathi imigomo ebalulekile namapharamitha aphambili!

Amakhasimende amaningi awaqondi imigomo eyisisekelo yokusebenza komshini we-laser welding, ake ukhethe ukukhetha umshini we-laser welding ofanele, kepha i-mimowork laser ilapha ukukusiza wenze isinqumo esifanele futhi unikeze ukwesekwa okwengeziwe ukukusiza ekuqondeni i-laser welding.

Yini i-laser welding?

I-Laser Welding uhlobo lokuncibilikisa i-welding, isebenzisa ugongolo lwe-laser njengomthombo wokushisa we-welding, umgomo we-welding udlula ngendlela esebenzayo yokuvuselela i-mediation esebenzayo, bese uguqukela kugongolo oluvuselelwayo, lapho ugongolo Futhi ucezu lomsebenzi uthintana, amandla adonswa ucezu lomsebenzi, lapho izinga lokushisa lifinyelela endaweni yokuncibilika yezinto ezibonakalayo zingafakwa.

Ngokusho kwendlela eyinhloko ye-Welding Pool, i-laser welding inezindlela ezimbili eziyisisekelo zokufafaza ukubhutha: ukushisa okushisa nokufuya okujulile (ukhiye we-keyhole) welding. Ukushisa okukhiqizwe ukushisa kwe-sulling kuncibilike ucezu lomsebenzi ngokudluliswa kokushisa, ukuze umhlaba we-welld uncibilike, akukho mfanekiso okufanele wenzeke, okuvame ukusetshenziselwa ukufudumala kwezakhi zejubane eliphansi. I-Fusion Fusion Welding idonsa okuqukethwe futhi kwakha inani elikhulu le-plasma. Ngenxa yokushisa okuphakanyisiwe, kuzoba nezimbobo ezingaphambi kwechibi elibunjiwe. I-Deep Ngentetration Welding iyindlela esetshenziswa kakhulu ye-laserder ye-laselding esetshenziswa kakhulu, ingavimba ucezu lomsebenzi kahle, futhi amandla okufaka akulungile, okuholela ekushiseni okusheshayo kwe-welding.

Inqubo yamapharamitha eLaser Welding

Kunamapharamitha amaningi wenqubo ethinta ikhwalithi ye-laserr welding, efana nobuningi bamandla, i-laser pulse waveform, ukudelela, isivinini se-welding kanye nokukhethwa kwegesi evikela ama-auxilties.

Ubuningi bamandla we-Laser

Ubuningi bamandla bungenye yamapharamitha abaluleke kakhulu ekusebenzeni kwe-laser. Ngokuqina kwamandla aphezulu, ungqimba olungaphezulu lungafudunyezelwa endaweni ebilayo ngaphakathi kwe-microsiscond, okuholela enanini elikhulu le-vaporization. Ngakho-ke, ukuqina kwamandla aphezulu kunenzuzo izinqubo zokususa izinto ezibonakalayo njengokushayela, ukusika kanye nokuqopha. Ngobunzima bamandla ophansi, kuthatha ama-milliseconds ambalwa wokushisa komhlaba ukuze ufinyelele endaweni ebilayo, futhi ngaphambi kokufika komhlaba, okuphansi kufinyelela endaweni yokuncibilika, okulula ukwakha i-weld enhle. Ngakho-ke, ngesimo sokushisa i-Laser Welding, uhla lwamandla kagesi lungu-104-106W / CM2.

I-Laser Pulse Waveform

I-Laser Pulse Waveform akuyona nje iparamitha ebalulekile yokuhlukanisa ukususwa kwezinto ezibonakalayo ekunciphiseni kwezinto ezibonakalayo, kodwa futhi nepharamitha esemqoka ukuthola ivolumu nezindleko zokusebenza kwemishini. Lapho ugongolo oluphezulu lwe-laser ludutshulwe ebusweni bezinto ezibonakalayo, ingaphezulu lezinto ezibonakalayo zizoba nama-60 ~ 90% wamandla we-laser aboniswe futhi acatshangelwe ukulahleka, ikakhulukazi igolide, i-titanium nezinye izinto ezinazo Ukuboniswa okuqinile nokudluliswa okushisayo okusheshayo. Umkhunjuzwa wensimbi uyahlukahluka ngokuhamba kwesikhathi ngesikhathi sokushaya kwe-laser. Lapho izinga lokushisa elingaphezulu lokuqukethwe likhuphuka liye endaweni yokuncibilika, umfutho uncipha ngokushesha, futhi lapho ubuso busesimweni sokuncibilika, isimemezelo sizinza ngenani elithile.

Ububanzi be-Laser Pulse

Ububanzi be-Pulse yipharamitha ebalulekile ye-Pulsed Laser Welding. Ububanzi be-pulse bunqunywa ngokujula kokungena kanye nokushisa indawo ethintekile. Uma ububanzi be-pulse bude, elikhulu, futhi ukujula kokushisa kwakukhona, futhi ukujula kokungena kukhuphuke ngamandla angu-1/2 wobubanzi be-pulse. Kodwa-ke, ukwanda kobubanzi be-puzle kuzonciphisa amandla aphezulu, ngakho-ke ukwanda kobubanzi be-puzle kuvame ukusetshenziselwa ukushisa ukushisa kwe-welding, okuholele ekutheni usayizi we-wald kanye ne-lalding athambile kakhulu. Kodwa-ke, amandla aphansi aphansi aphumela ekufakweni ngokweqile kokushisa, futhi okuqukethwe ngakunye kunobubanzi obufanele obukhulisa ukujula kokungena.

Ubungako be-defacus

I-Laser Welding ivame ukudinga inani elithile lokudilizwa, ngoba ubuningi bamandla balesi sikhungo seSpoke e-laser Focus buphezulu kakhulu, okulula ukuhwamuka nokuvezwa kwezimbobo ezigodini. Ukusatshalaliswa kobuningi bamandla kufana ngendiza ngayinye kude nokugxila kwe-laser.

Kunezindlela ezimbili ze-defacus:

I-defocus enhle nengemuhle. Uma indiza egxilwe kuyo itholakala ngaphezulu komsebenzi, kuyi-defocus enhle; Ngaphandle kwalokho, kuyi-defocus engemihle. Ngokusho kwe-geometric Optics theory, lapho ibanga phakathi kwezindiza ezihlekisayo nezingalungile zokukhubazeka kanye nendiza ye-welding lilingana, ubuningi bamandla endizeni ehambisanayo buyehlukene. Endabeni ye-defocus engemihle, ukungena okukhulu kwemali kungatholakala, okuhlobene nenqubo yokwakheka yechibi elibunjiweyo.

Ijubane le-Welding

Ijubane le-Welding linquma ikhwalithi ye-welding ebusweni, ukujula ukungena, ukushisa indawo ethintekile nokunye. Ijubane le-welding lizothinta ukufakwa kokushisa ngesikhathi ngasinye seyunithi. Uma ijubane le-welding lihamba kancane, ukufakwa kokushisa kuphezulu kakhulu, okuphumela ekushisweni kwendawo. Uma ijubane le-welding lishesha kakhulu, ukufakwa kokushisa kuncane kakhulu, kuphumela ekusetshenzisweni kwe-workpiece kweldering ngokwengxenye nangaphandle. Ukunciphisa ijubane le-welding kuvame ukusetshenziselwa ukuthuthukisa ukungena.

Igesi yokuvikela enesizayo

Igesi yokuvikelwa yokuvikelwa kwe-AUxiliary iyinqubo ebalulekile e-High Power Laser Welding. Ngakolunye uhlangothi, ukuvikela izinto zensimbi kusuka ekuphathweni nasekungcoliseni isibuko esigxile kakhulu; Ngakolunye uhlangothi, ukuvikela i-plasma ekhiqizwe kwinqubo ye-welding kusuka ekugxileni kakhulu futhi ivikele i-laser ukuthi ifinyelele phezulu kwezinto ezibonakalayo. Ngenqubo ye-laser welding, i-helium, i-argen, i-nitrogen namanye amagesi kwesinye isikhathi bavame ukusetshenziselwa ukuvikela ichibi elibunjiweyo, ukuze bavimbele i-oxidation kwi-axidation ebunjiniyela be-welding. Izici ezifana nohlobo lwegesi evikelayo, usayizi wokugeleza komoya kanye ne-angle evuthayo kunomthelela omkhulu emiphumeleni ye-welding, futhi izindlela ezihlukile zokushaya zizoba nomthelela othile kwikhwalithi ye-welding.

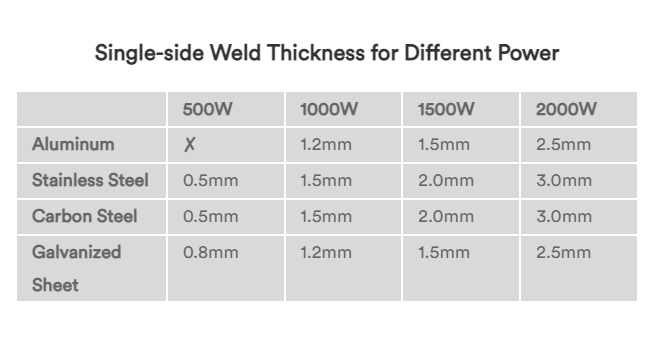

I-waser ye-waser ye-Handheld yethu enconyiwe:

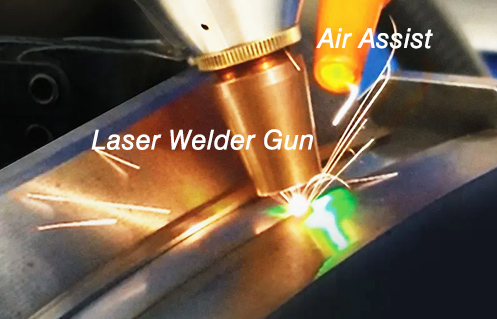

I-Laser Welder - Indawo Yokusebenza

◾ Uhla lokushisa lwemvelo yokusebenza: 15 ~ 35 ℃

◾ Uhla lomswakama lwendawo yokusebenza yendawo yokusebenza: <70% akukho ukuguqulwa

◾ Ukupholisa: I-Water chiller iyadingeka ngenxa yomsebenzi wokususa ukushisa kwezinto zokuhlambalaza ama-laser, uqinisekise ukuthi i-laser welder isebenza kahle.

(Ukusetshenziswa okuningiliziwe kanye nokuqondisa mayelana ne-Water Chiller, ungabheka:Izindlela zokufakazela iqhwa zohlelo lweCo2 Laser)

Wanna wazi kabanzi nge-laser welders?

Isikhathi sePosi: Dec-22-2022